Preparation method and application of hierarchical pore SSZ-13 molecular sieve and method for preparing olefin from methanol

A technology of methanol to olefins and molecular sieves, which is applied in the direction of molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and base exchange compounds, etc. It can solve the difficult control of molecular sieve desilication and dealumination processes, high synthesis cost of hierarchical porous materials, and expensive templates problems such as solvents, to achieve the effects of easy industrial application, high selectivity, and reduced over-etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

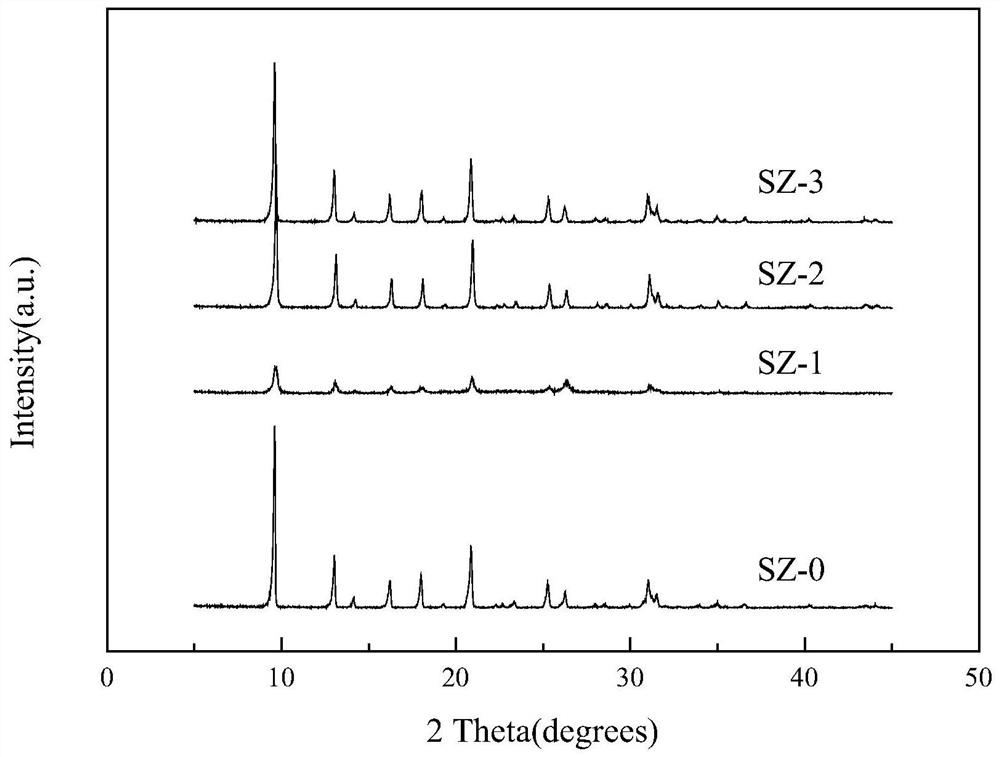

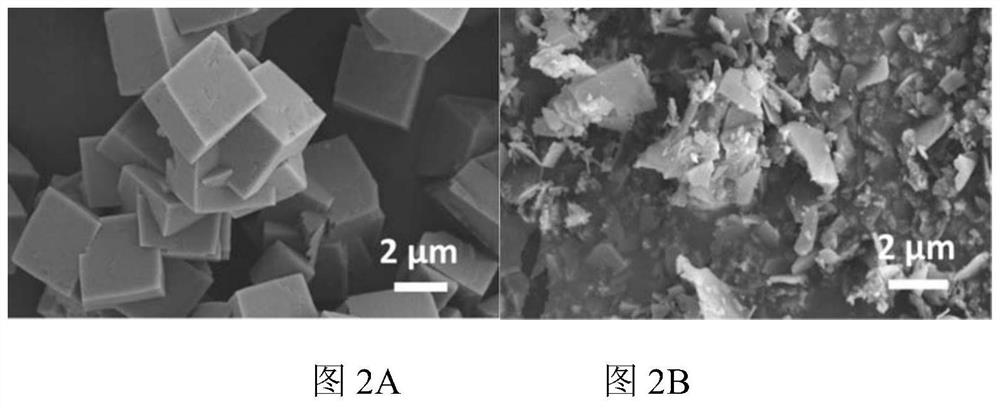

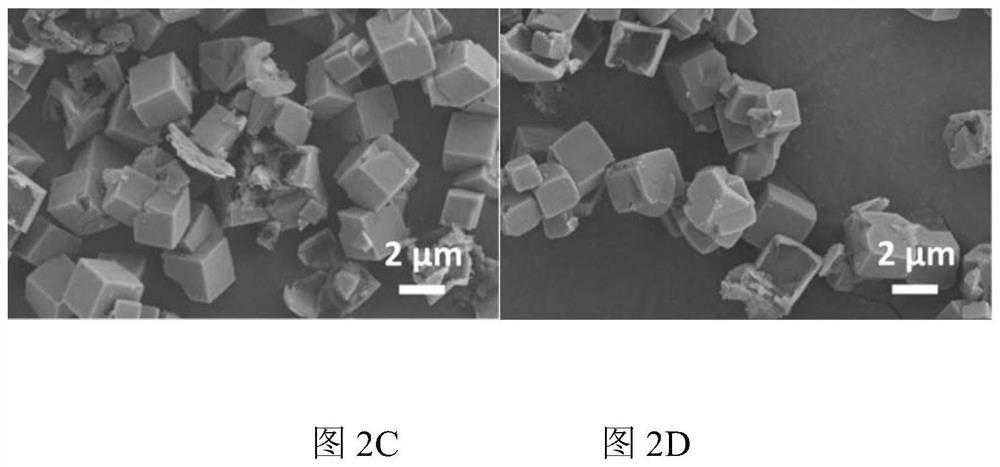

[0047] Weigh 8.4g to remove the hydrogen-type microporous SSZ-13 molecular sieve of the organic template (SiO in the molecular sieve gel 2 / Al 2 o 3 molar ratio 80) was added to 336ml of copper nitrate solution with a concentration of 0.1mol / L, and stirred in a water bath at 70°C for 2h to obtain Cu 2+ protected by SSZ-13 molecular sieves. The molecular sieve solid product after framework protection was centrifuged and added to 336ml of 0.2mol / L sodium hydroxide aqueous solution, and stirred in a water bath at 70°C for 2h. After alkali treatment, the solid product was centrifuged and added to 168 ml of aqueous hydrogen chloride solution with a hydrogen ion concentration of 0.3 mol / L, and stirred at room temperature for 2 hours. After the acid treatment, the solid product was centrifuged and washed, then added to 336ml of ammonium chloride solution with a concentration of 1mol / L, and exchanged ammonium ions in a water bath at 70°C for 2 hours, and exchanged 3 times. The sol...

Embodiment 2

[0050] Weigh 7.2g to remove the hydrogen-type microporous SSZ-13 molecular sieve of the organic template (SiO in the molecular sieve gel 2 / Al 2 o 3 molar ratio 80) was added to 288ml of zinc nitrate solution with a concentration of 0.1ml / L, and stirred in a water bath at 70°C for 2h to obtain Zn 2+ protected by SSZ-13 molecular sieves. The molecular sieve solid product after framework protection was centrifuged and added to 288ml of 0.2mol / L sodium hydroxide aqueous solution, and stirred in a water bath at 70°C for 2h. After alkali treatment, the solid product was centrifuged and added to 144 ml of aqueous hydrogen chloride solution with a hydrogen ion concentration of 0.3 mol / L, and stirred at room temperature for 2 hours. After the acid treatment, the solid product was centrifuged and washed, then added to 288ml of ammonium chloride solution with a concentration of 1mol / L, and exchanged ammonium ions in a water bath at 70°C for 2 hours, and exchanged 3 times. The solid ...

Embodiment 3

[0053] Evaluation of Catalytic Performance of Sample Molecular Sieve MTO Reaction Application.

[0054] The MTO reaction performance of the microporous SSZ-13 molecular sieve (SZ-0) before treatment, the molecular sieve catalyst obtained in Comparative Example 1 and Examples 1 and 2 was investigated by using a fixed bed micro-reactor device. The evaluation method is as follows: use a mold to press the hydrogen-type molecular sieve sample into tablets, crush it and pass it through a 60-80 mesh sieve, collect 1 g of the sieved molecular sieve sample and put it into a fixed-bed reactor, and fill the upper and lower ends of the molecular sieve with quartz sand. Before the reaction, the catalyst needs to be pretreated, and the flow rate is 60ml / min nitrogen carrier gas, the reactor is raised from normal temperature to 500°C for 1h and kept for 0.5h, then lowered to the reaction temperature of 350°C, and the reaction material methanol is introduced , its mass concentration is 60%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com