Multi-layer line board structure and manufacturing method thereof

A technology of multi-layer circuit and production method, applied in the direction of multi-layer circuit manufacturing, circuit substrate material, printed circuit manufacturing, etc., can solve the problems of poor circuit, excessive etching, interlayer dislocation, etc., to reduce excessive etching and improve uniformity , The effect of reducing the copper thickness range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and specific embodiments:

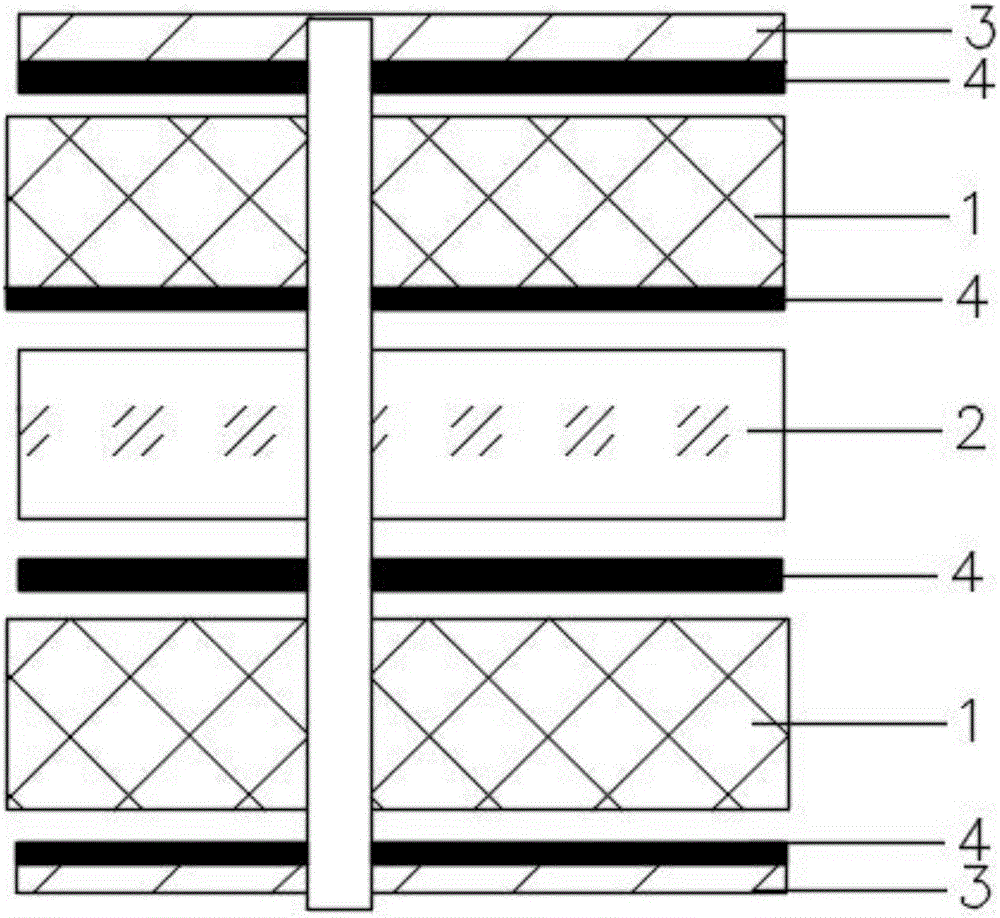

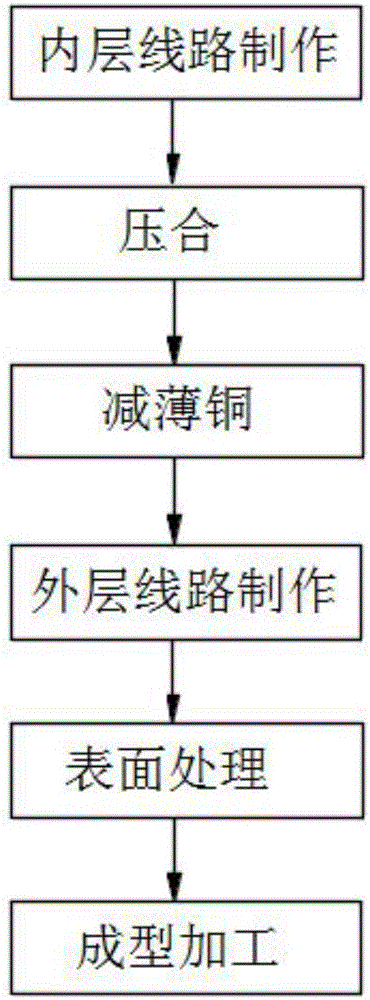

[0026] Such as figure 1 As shown, the multilayer circuit board structure of the present invention includes a plurality of inner layer substrates 1 stacked in sequence, an optical core plate 2 is arranged between adjacent inner layer substrates 1, and the upper and last layers of the first inner layer substrate 1 An outer layer of copper foil 3 is provided under an inner layer substrate 1, and a prepreg 4 is provided between the inner layer substrate 1 and the adjacent optical core board 2 or outer layer copper foil 3. The thickness of the optical core plate 2 is preferably 0.6-0.8 mm, and the thickness of the inner substrate 1 is preferably 0.1 mm. The optical core board 1 is used to replace 5 prepregs of the original technology, and the heating rate of the pressing is controlled to prevent problems such as sliding plate and interlayer dislocation during press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com