Propeller power device and ship

A power device and propeller technology, which is applied in the direction of rotating propellers, ship propulsion, ship parts, etc., can solve the problems of high energy consumption, slow ship speed, poor seakeeping performance, etc., achieve high driving speed, optimize seakeeping performance, and reduce wave making The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

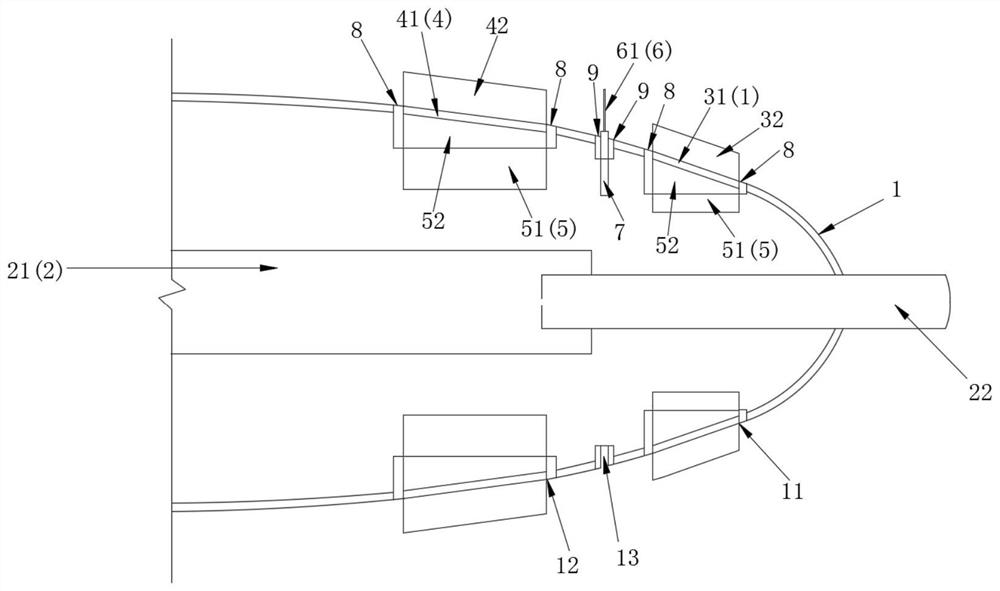

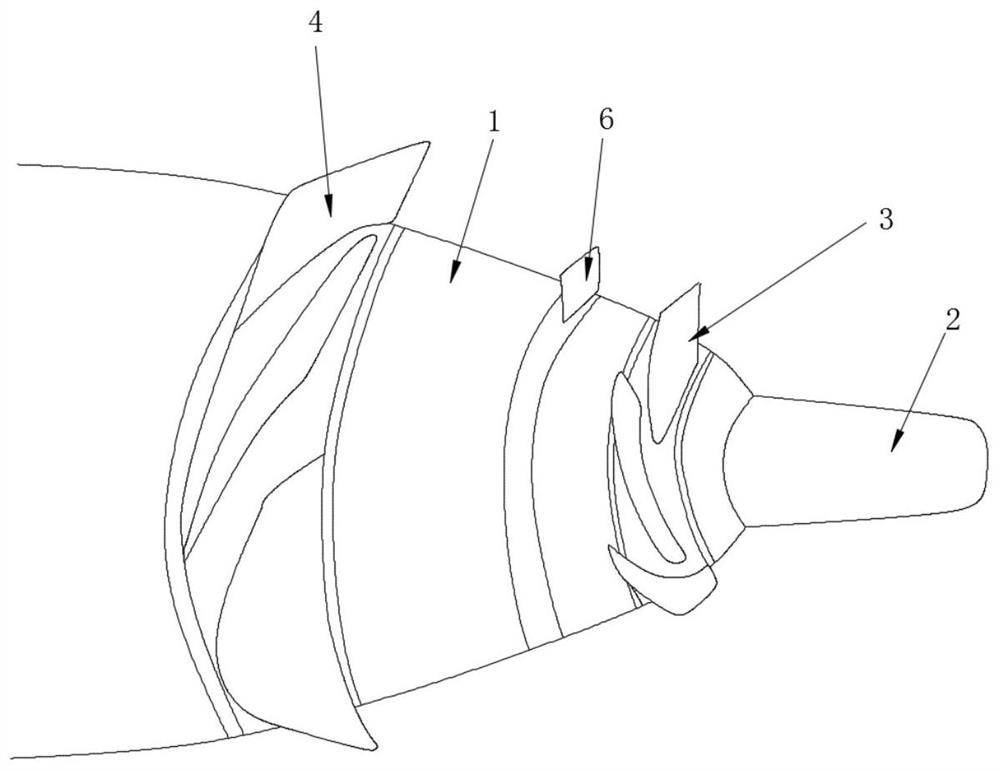

[0035] refer to figure 1 and image 3 , this embodiment mentions a propeller power device, including a casing 1, a front end protection structure 2, a first propeller assembly 3, a second propeller assembly 4 and a first drive structure 5, the casing 1 is connected to the bow, preferably arranged at The bow of the general rear drive type displacement ship or the parts below the waterline of the front bow of the catamaran, multihull, small waterplane area catamaran and other ships, and the rear drive device form a double drive with front and rear drive Force structure, shell 1 is streamlined design and its front end cross-sectional area is smaller than rear end cross-sectional area;

[0036] The front-end protection structure 2 passes through the front end of the casing 1 and is located outside the casing 1. The front-end protection structure 2 can absorb most of the energy generated by the impact of the front end of the propeller power unit, thereby weakening the impact force...

Embodiment 2

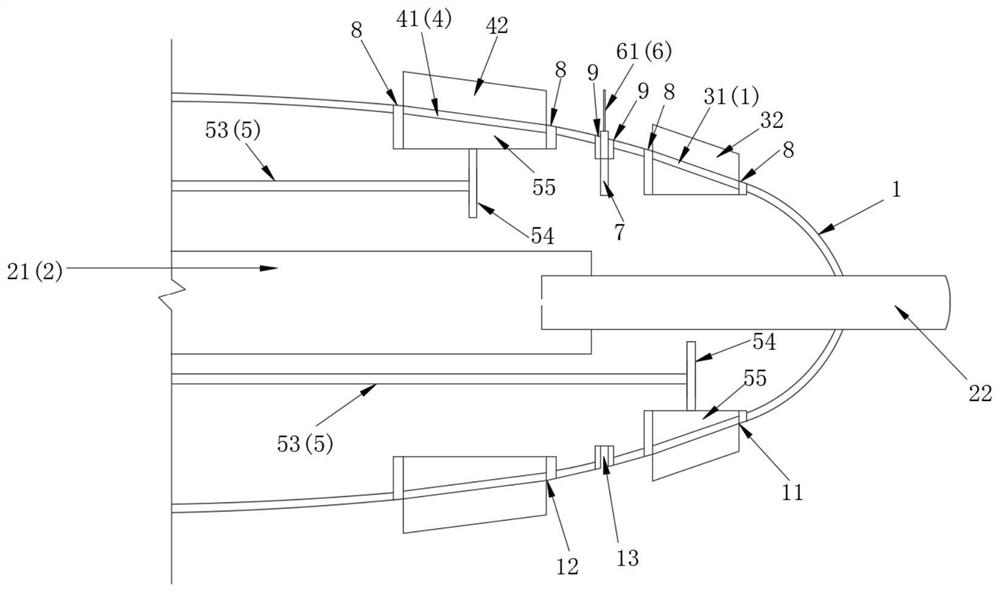

[0047] refer to figure 2 and image 3 , this embodiment mentions a propeller power device, including a casing 1, a front end protection structure 2, a first propeller assembly 3, a second propeller assembly 4 and a first drive structure 5, the casing 1 is connected to the bow, preferably arranged at The bow of the general rear drive type displacement ship or the parts below the waterline of the front bow of the catamaran, multihull, small waterplane area catamaran and other ships, and the rear drive device form a double drive with front and rear drive Force structure, shell 1 is streamlined design and its front end cross-sectional area is smaller than rear end cross-sectional area;

[0048] The front-end protection structure 2 passes through the front end of the casing 1 and is located outside the casing 1. The front-end protection structure 2 can absorb most of the energy generated by the impact of the front end of the propeller power unit, thereby weakening the impact forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com