Synthesis method of SAPO-34 molecular sieve with surface defects

A molecular sieve and defect technology, which is applied in the synthesis field of SAPO-34 molecular sieve with cubic shape, can solve the problems of high cost, not very excellent, and difficult to operate, and achieve excellent catalytic performance, long light olefin selectivity, and long reaction life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a SAPO-34 molecular sieve with excellent catalytic performance. The synthesis of the SAPO-34 molecular sieve provided by the present embodiment comprises the following steps:

[0049] 1) Prepare the reaction system

[0050] 42.75g of pseudo-boehmite was added into 300g of deionized water, stirred and dispersed in a water bath at 30°C. Then slowly add 65.56g of phosphoric acid therein, and stir for 30min to form a gel. Then add 33.24g of silica sol and stir for 1h. Finally add 85.89g mixed template agent (the mixed template agent used is the mixture of triethylamine and tetraethylammonium hydroxide, wherein, the molar ratio of triethylamine and tetraethylammonium hydroxide is 50:1), stir for 1.5h , to get the reaction system.

[0051] 2) Put the above reaction system into a pressure-resistant reactor for dynamic hydrothermal crystallization

[0052] When performing dynamic hydrothermal crystallization, the temperature of dynamic hydrothermal...

Embodiment 2

[0055] This embodiment provides a SAPO-34 molecular sieve with excellent catalytic performance. The synthesis of the SAPO-34 molecular sieve provided by the present embodiment comprises the following steps:

[0056] 1) Prepare the reaction system

[0057] The preparation of the reaction system in this example is the same as in Example 1, that is, the raw materials and feeding ratios used in this example are the same as those in Example 1.

[0058] 2) Put the above reaction system into a pressure-resistant reactor for dynamic hydrothermal crystallization

[0059] When performing dynamic hydrothermal crystallization, the temperature of dynamic hydrothermal crystallization is 180°C, and the crystallization time is 6h.

[0060] 3) After the crystallization is completed, the SAPO-34 molecular sieve is obtained after washing, drying and roasting.

Embodiment 3

[0062] This embodiment provides a SAPO-34 molecular sieve with excellent catalytic performance. The synthesis of the SAPO-34 molecular sieve provided by the present embodiment comprises the following steps:

[0063] 1) Prepare the reaction system

[0064] The preparation of the reaction system in this example is the same as in Example 1.

[0065] 2) Put the above reaction system into a pressure-resistant reactor for dynamic hydrothermal crystallization

[0066] When performing dynamic hydrothermal crystallization, the temperature of dynamic hydrothermal crystallization is 185°C, and the crystallization time is 3h.

[0067] 3) After the crystallization is completed, the SAPO-34 molecular sieve is obtained after washing, drying and roasting.

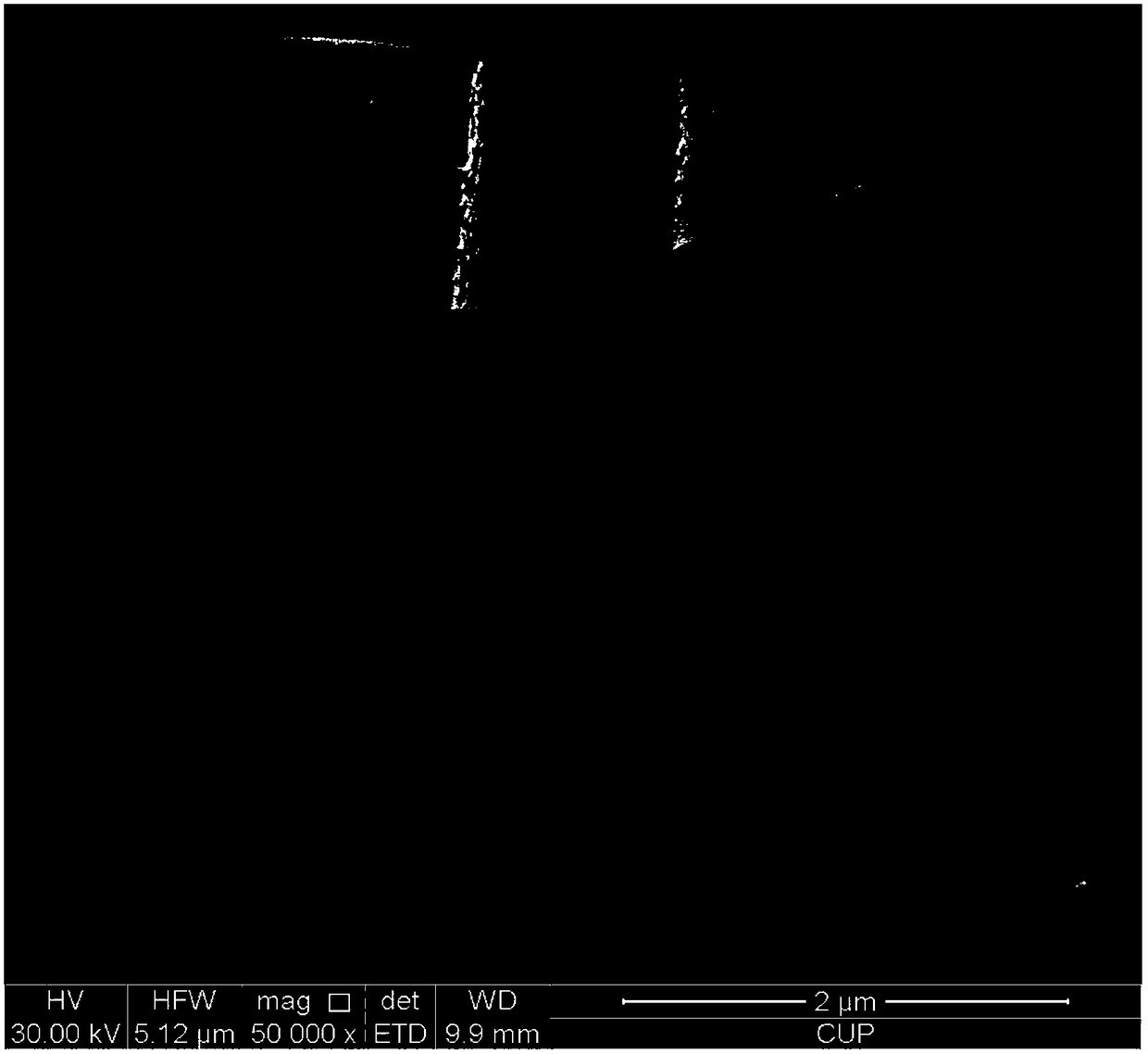

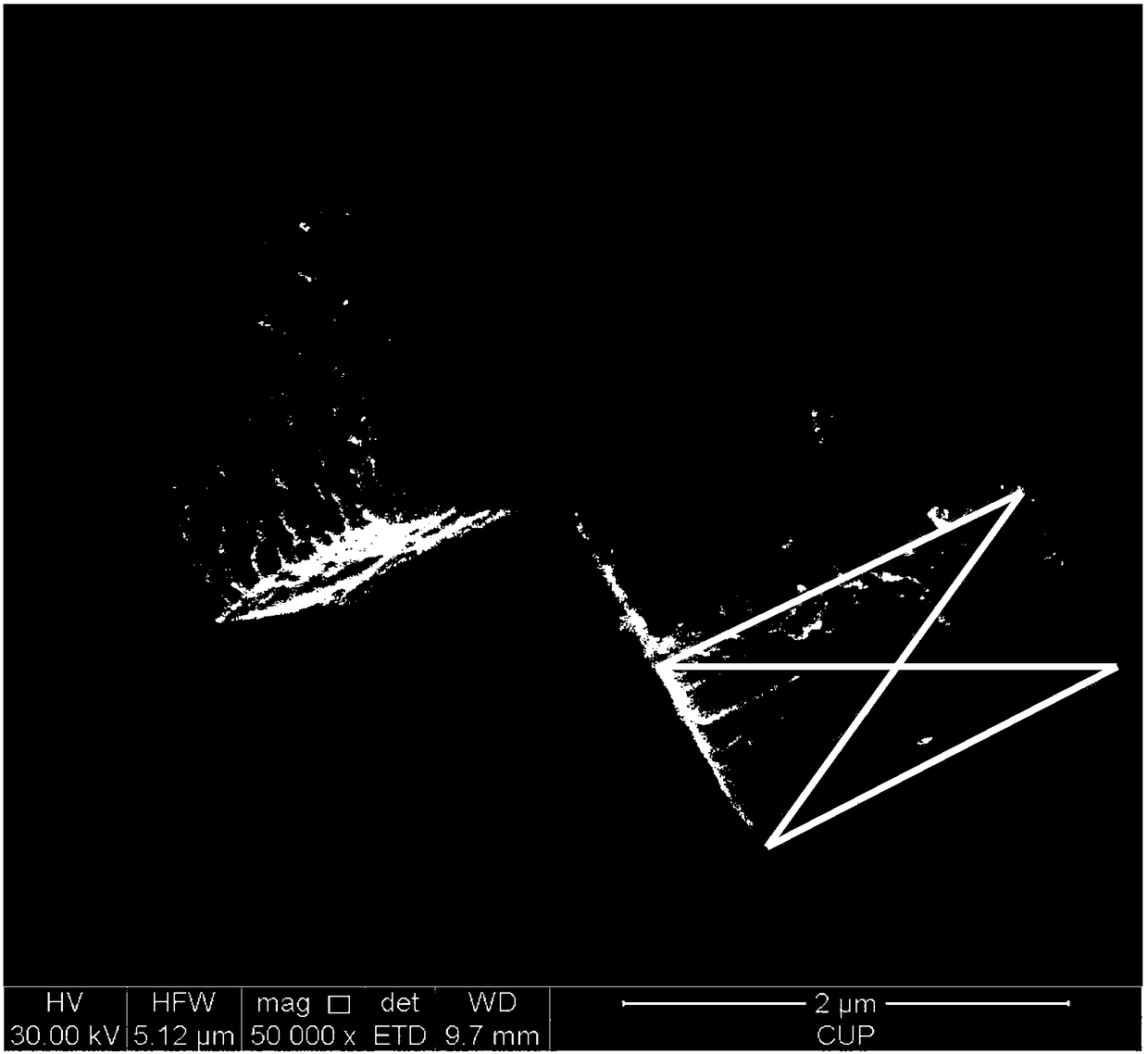

[0068] The test result of the SAPO-34 molecular sieve that embodiment 1-3 provides is as table 1 and table 2, Figure 2 to Figure 4 shown. As can be seen from Examples 1-3, the technical scheme provided by the present invention can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com