Process of preparing FER zeolite inside surfactant system

A surfactant and zeolite technology, which is applied in the direction of crystalline aluminosilicate zeolite, iron conglomerate crystalline aluminum silicate zeolite, etc., can solve the problem of high surfactant price, shorten the reaction time and change the grain shape , the effect of improving the crystallinity of the product

Inactive Publication Date: 2005-04-27

FUDAN UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Kulkarni and collaborators ([1] Ahedi, R.K.; Kotasthane, A.N.; Rao, B.S.; Manna, A.; Kulkarni, B.D.J. Colloid Interf. Sci. 2001, 236(1), 47; [2] Khomane, R.B.; Kulkarni, B.D.; Ahedi, R.K.J.Colloid Interf.Sci.2001, 236(2), 208) synthesized FER zeolite with higher crystallinity in pyrrolidine / ionic surfactant and pyrrolidine / nonionic surfactant systems respectively, But the price of the surfactant it chooses is relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0025] Example 11, the FER zeolite synthesized in Example 1 was measured by low-temperature nitrogen adsorption method, and its Langmuir specific surface area was 418.2m 2 / g, the micropore volume is 0.13cm 3 / g.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention is preparation process of FER zeolite inside mixed reactant colloid system containing surfactant. FER zeolite is obtained through hydrothermal reaction inside the reactant system comprising alkali metal source, oxide source of trivalent element, oxide source of four-valent element, water, structural guide agent and small amount of surfactant. The present invention adopts non-ionic surfactant glycerin or OP emulsifier. The small amount of surfactant added into the reactant system can inhibit the creation of hetero crystal phase, raise the crystallization degree of the synthetic product, alter the appearance of crystal grain, reduce the consumption of template agent, shorten reaction time, lower reaction temperature and make the reactant system suitable for industrial production of FER zeolite.

Description

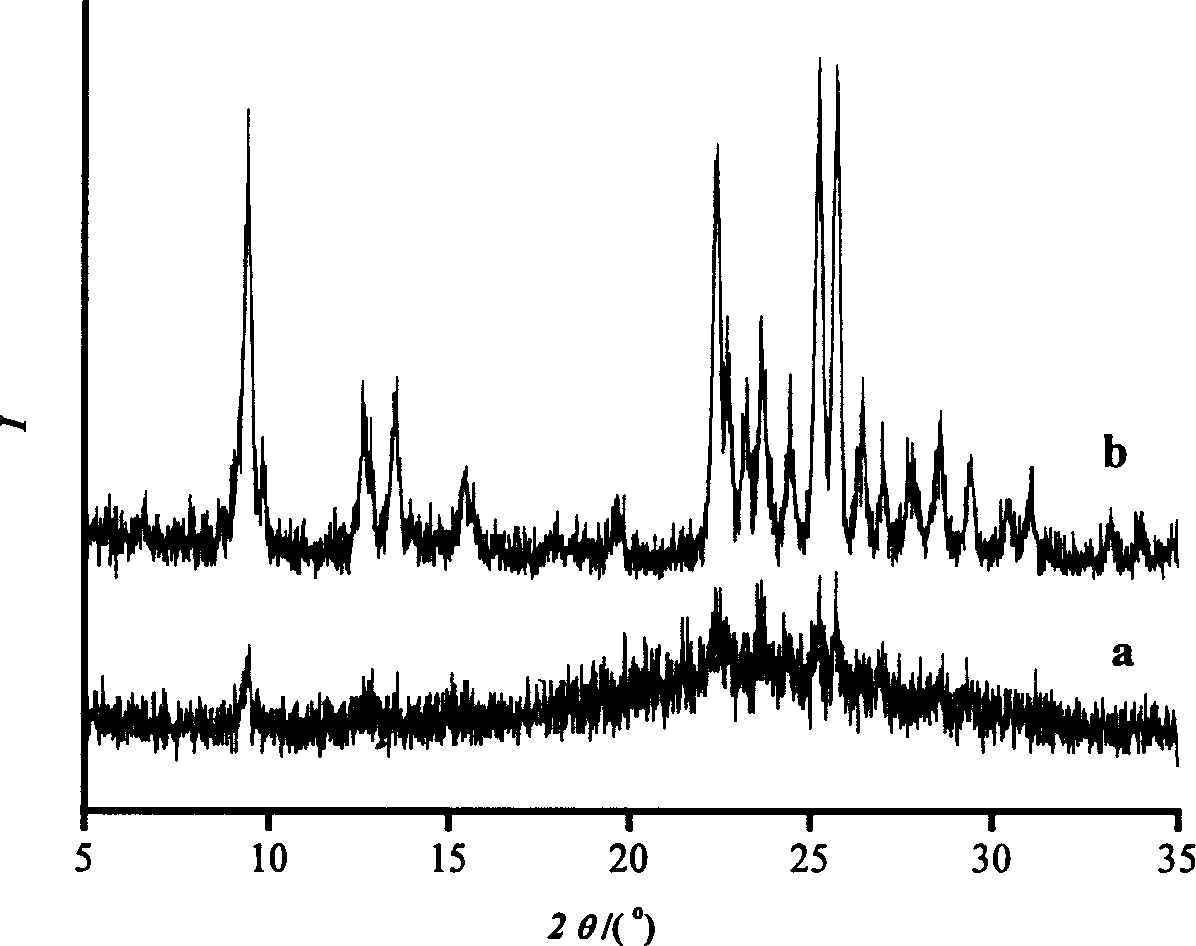

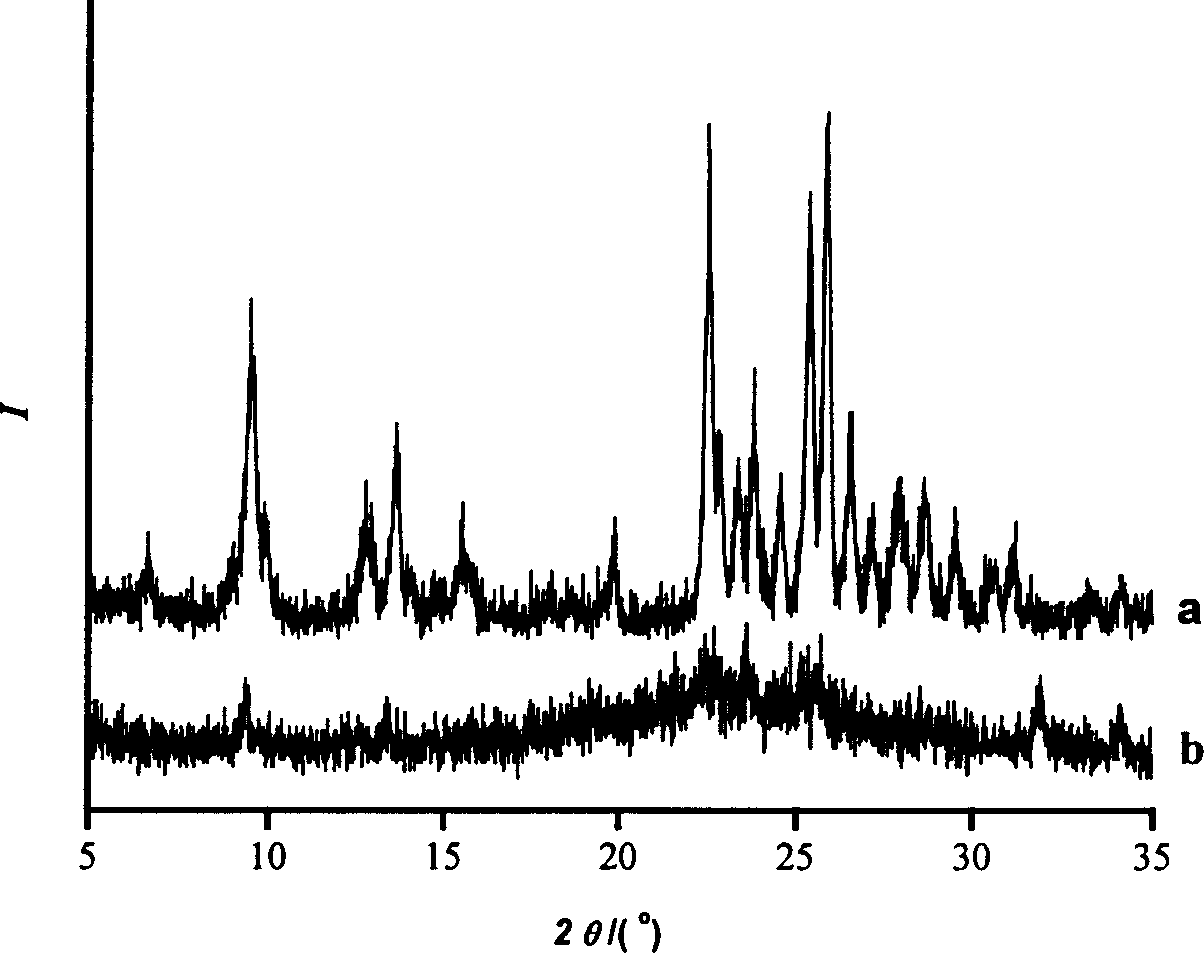

technical field [0001] The invention belongs to the technical field of material synthesis, and in particular relates to a method for preparing FER zeolite in a colloidal system of a reaction mixture containing nonionic surfactant glycerin or OP emulsifier. Background technique [0002] Zeolite molecular sieve is a kind of inorganic aluminosilicate crystal. Its skeleton contains regular and orderly arranged pores or cages of molecular size (pore size 0.30-1.50nm), which has the functions of shape-selective catalysis, ion exchange and molecular sieving. It is widely used in crude oil processing and refining, petroleum catalytic cracking and petrochemical industries. [0003] FER (ZSM-35, ferrierite) is a zeolite with a mesopore structure, which contains ten-membered ring channels (0.42×0.54nm, along the [001] direction) and crossed eight-membered ring channels (0.35×0.48nm, along the [001] direction). [010] direction), the six-membered ring channel parallel to the ten-membere...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B39/44

Inventor 程晓维龙英才

Owner FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com