Metal modification ZSM-5 molecular sieve based catalyst and preparation method and application

A ZSM-5, metal modification technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large acidity drop of molecular sieves, blockage of molecular sieve channels, high reaction temperature, etc., and achieve the modification effect Good, reduce energy consumption, improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

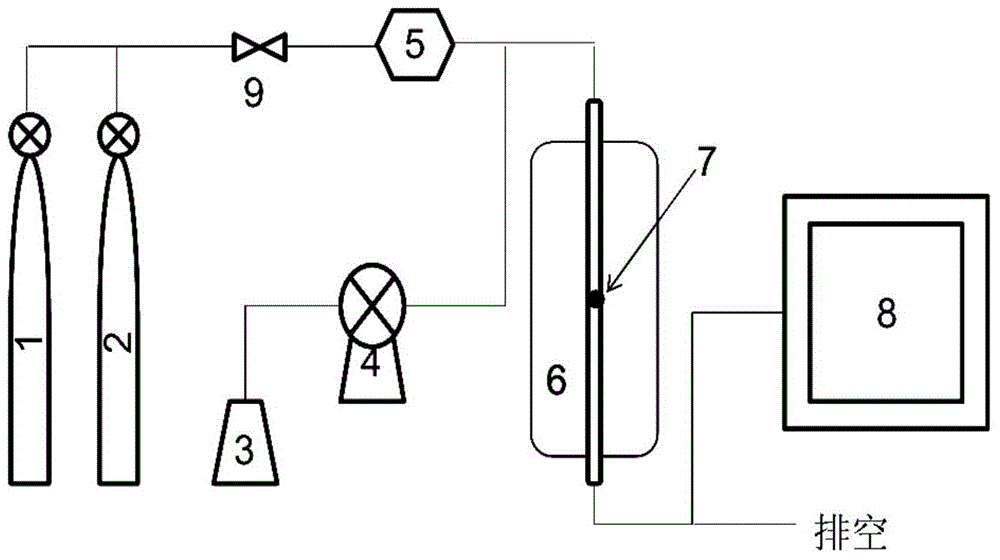

Method used

Image

Examples

Embodiment 1

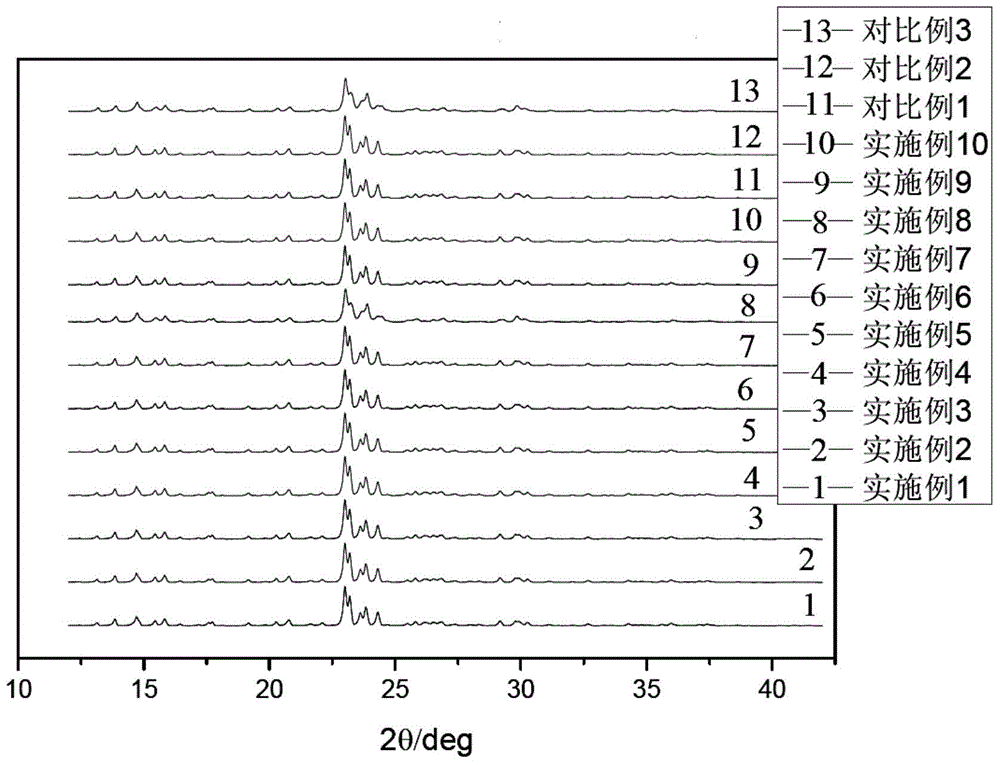

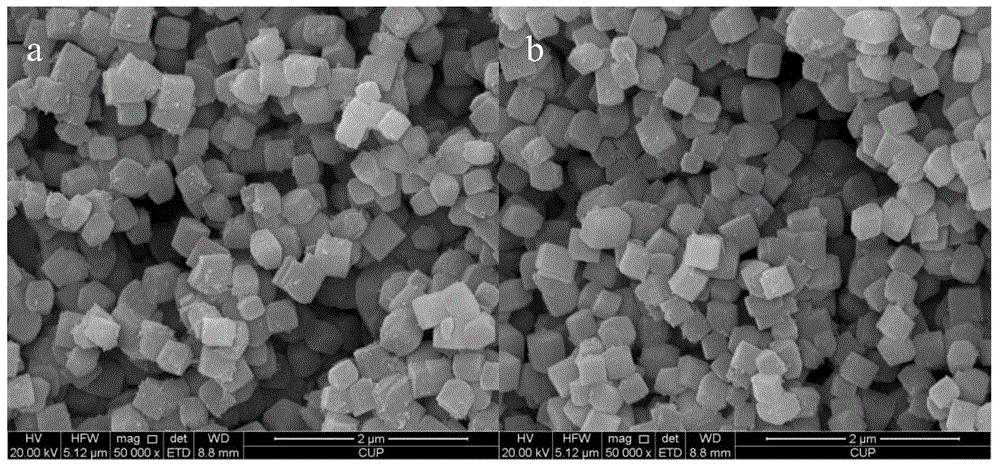

[0052] Dissolve 30g of lanthanum nitrate into 400ml of water to prepare a solution, slowly add the solution dropwise to 200g of HZSM-5 with a silicon-aluminum ratio of 28, stir thoroughly for 2 hours, transfer the solid-liquid mixture to a high-temperature reaction kettle, and heat it at 140°C After reacting for 12 hours, the reaction kettle was taken out, cooled to room temperature in the air, the lid of the reaction kettle was opened, and dried at 100°C for 10 hours to obtain catalyst powder. The catalyst was pressed into tablets at 20 MPa, and 40-80 mesh particles were sieved to obtain a catalyst for evaluation. The XRD pattern of the product is as follows figure 2 As shown, the electron microscope photos of the product are as follows image 3 shown.

Embodiment 2

[0054] Dissolve 30g of cerium chloride into 400ml of water and oxalic acid mixture (water: oxalic acid = 4:1) to prepare a solution, slowly add this solution dropwise to 200g of HZSM-5 with a silicon-aluminum ratio of 38, fully After stirring for 2 hours, the solid-liquid mixture was transferred to a high-temperature reactor, and reacted at 140°C for 14 hours, then the reactor was taken out, cooled to room temperature in air, the lid of the reactor was opened, and dried at 100°C for 10 hours to obtain catalyst powder. The catalyst was pressed into tablets at 20 MPa, and 40-80 mesh particles were sieved to obtain a catalyst for evaluation.

Embodiment 3

[0056] Dissolve 25g of cerium nitrate into 400ml of water and citric acid mixture (water: citric acid mass ratio is 10:1) to prepare a solution, slowly add the solution dropwise to 200g of HZSM-5 with a silicon-aluminum ratio of 180, and stir thoroughly After 2 hours, the solid-liquid mixture was transferred to a high-temperature reactor, reacted at 180°C for 12 hours, and then the reactor was taken out, cooled to room temperature in air, the lid of the reactor was opened, and dried at 100°C for 10 hours to obtain catalyst powder. The catalyst was pressed into tablets at 20 MPa, and 40-80 mesh particles were sieved to obtain a catalyst for evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com