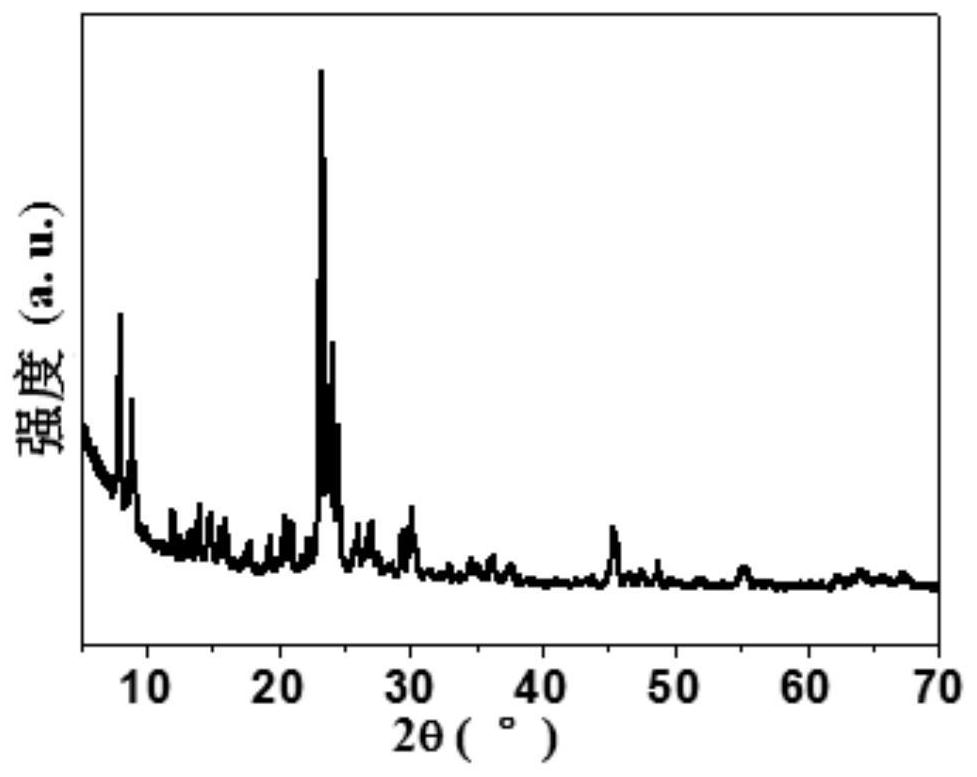

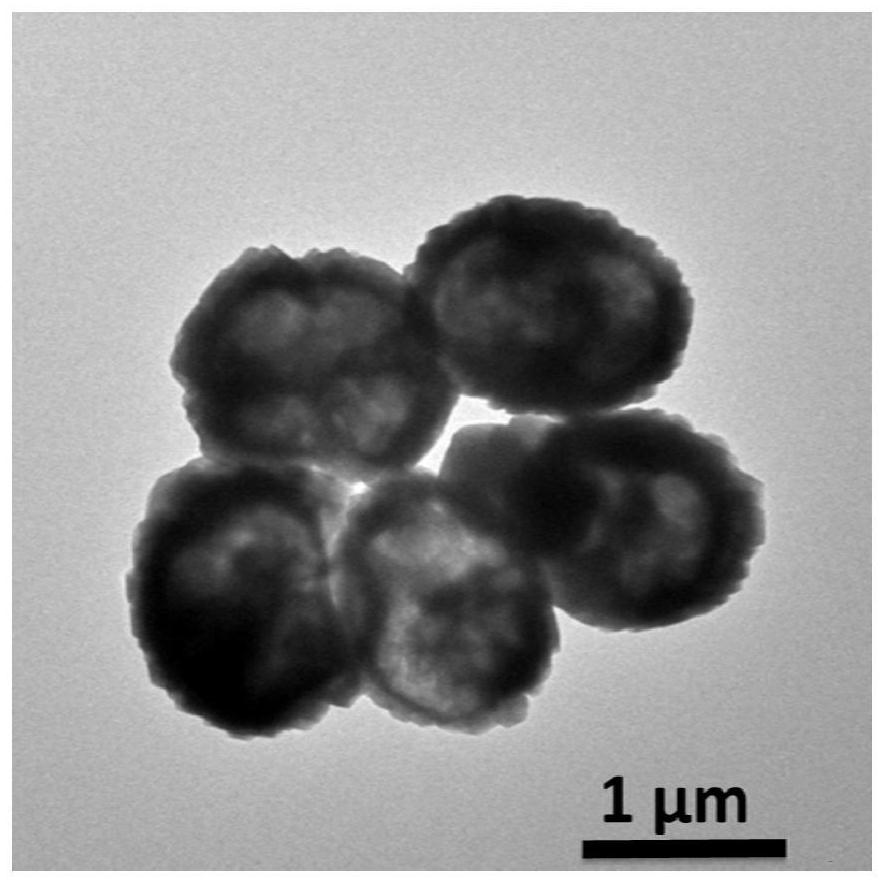

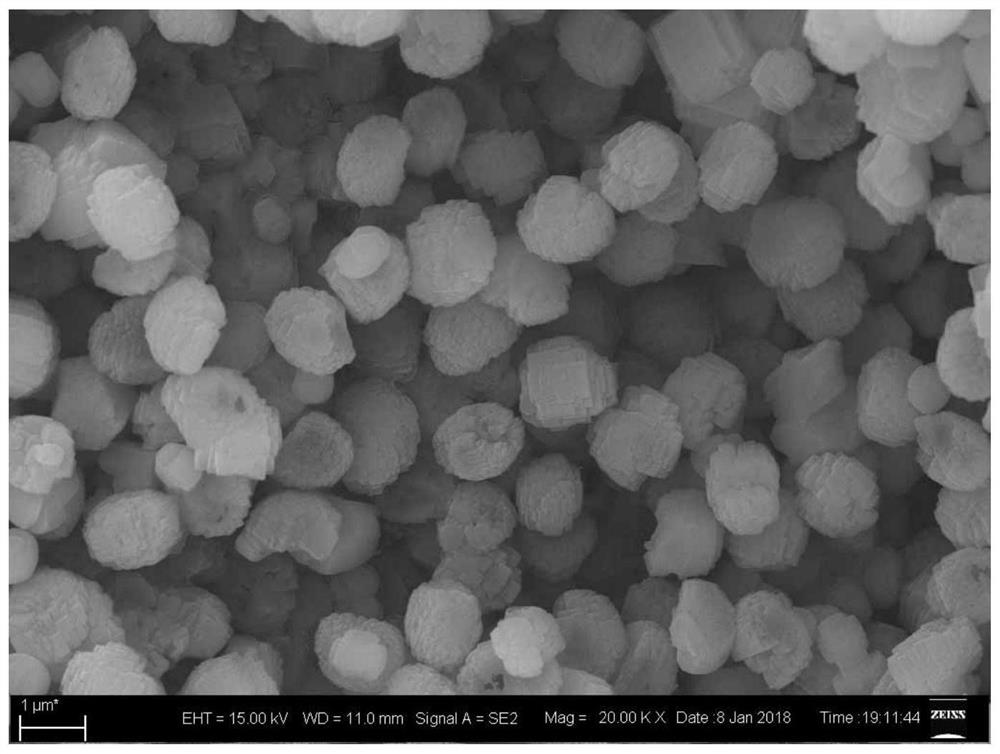

A kind of preparation method of hollow multi-stage pore zsm-5 molecular sieve

A ZSM-5, multi-level pore technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of poor molecular sieve dispersion and single pore size, and achieve high dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: the preparation method of the hollow multi-stage porous ZSM-5 molecular sieve of the present embodiment is carried out according to the following steps:

[0026] 1. Weigh silicon source, aluminum source, inorganic base, organic template, water and surfactant; wherein the molar ratio of silicon source, aluminum source, inorganic base, organic template to water is 1: (0.03~0.05): (0.2~0.5): (0.01~1): (30~50); the amount of surfactant added is (0.7~3)×10 of the molar amount of the organic template -3 times; wherein the surfactant is polyvinylpyrrolidone (PVP) or ethylenediaminetetraacetic acid disodium salt (EDTA-disodium);

[0027] 2. Mix surfactant, water, inorganic base and aluminum source evenly to obtain solution A;

[0028] 3. Add silicon source dropwise to solution A. After the dropwise addition, stir for 4-5 hours at a temperature of 70-90°C to obtain solution B;

[0029] 4. Add the organic template agent dropwise to the solution B. After...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is different from Embodiment 1 in that the inorganic base described in step 1 is sodium hydroxide, ammonia water or potassium hydroxide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum source described in step 1 is one or a combination of aluminum nitrate, sodium metaaluminate and aluminum sulfate. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com