Symbiotic composite molecular sieve catalyst applied to MTO reaction, and preparation method thereof

A composite molecular sieve and molecular sieve technology, applied in the direction of molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve problems such as catalyst deactivation, achieve high catalytic activity, good stability, and improve selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Take 1000g SAPO-34 (composition ratio 0.25SiO 2 ·Al 2 o 3 0.89P 2 o 5 1.07H 2 O) Molecular sieve, 110.87g HY(nSiO 2 / nAl 2 o 3 =5.2, dry basis 78wt%) molecular sieve, 108.40g water glass (Na 2 O: 7.48wt%, SiO 2 : 24.61wt%), 572.52g silica gel solution (Na 2 O: 0.23wt%, SiO 2 : 29.49wt%) and deionized water to prepare a slurry with a solid content of 35%, spray drying (inlet temperature 140°C, outlet temperature 80°C) to form microspheres with an average particle size of 60-80μm, and roast at 700°C 4 hours to obtain pretreated microspheres.

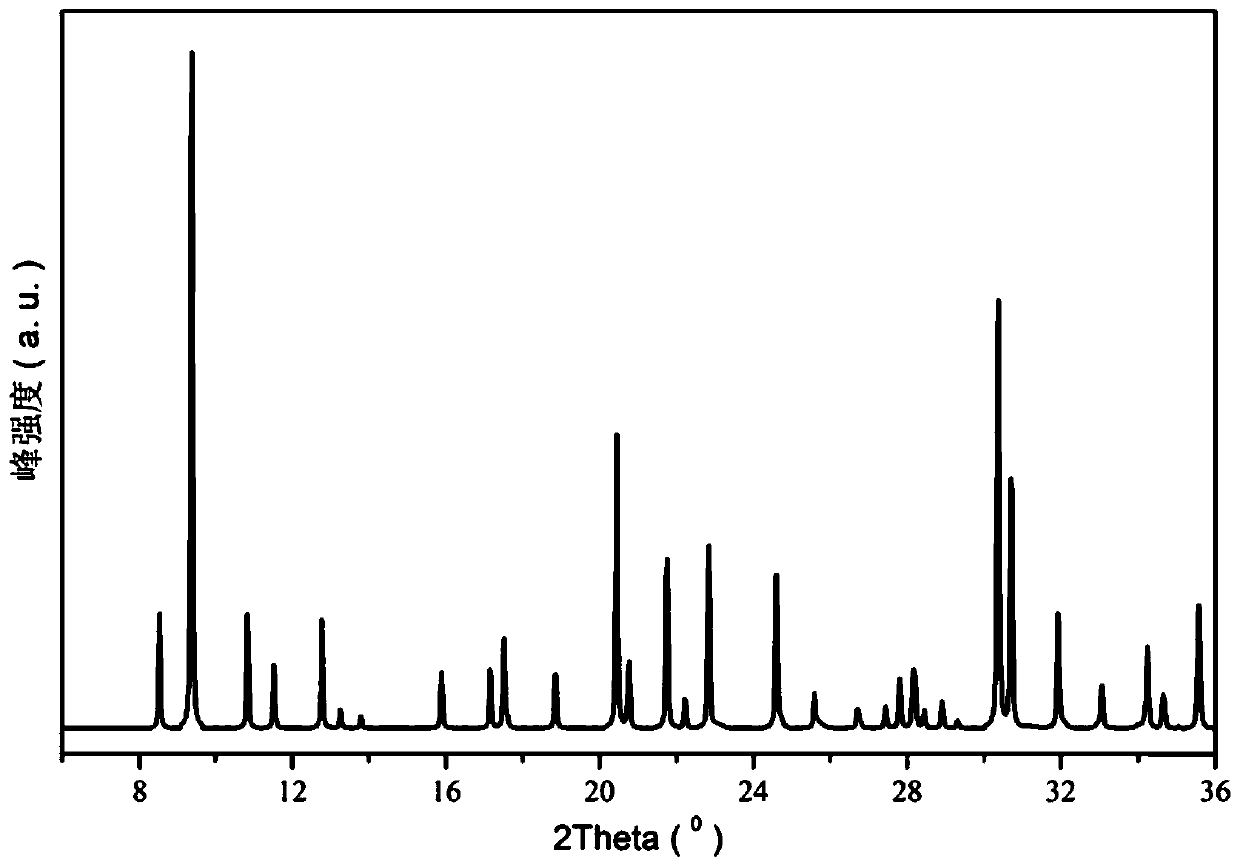

[0029](2) Mix the pretreated microspheres with 16.24g of NaOH, 357.60g of diethyldimethylammonium hydroxide (referred to as OSDA, concentration 20wt%) and 2813.54g of deionized water. After subtracting the weight of SAPO-34, the proportion in the remaining mixture sol is nNa 2 O:nSiO 2 :nAl 2 o 3 :nOSDA:nH 2 The molar ratio of O=0.09:1:0.05:0.15:50. Put the above mixed sol into a crystallization synthesis kettl...

Embodiment 2

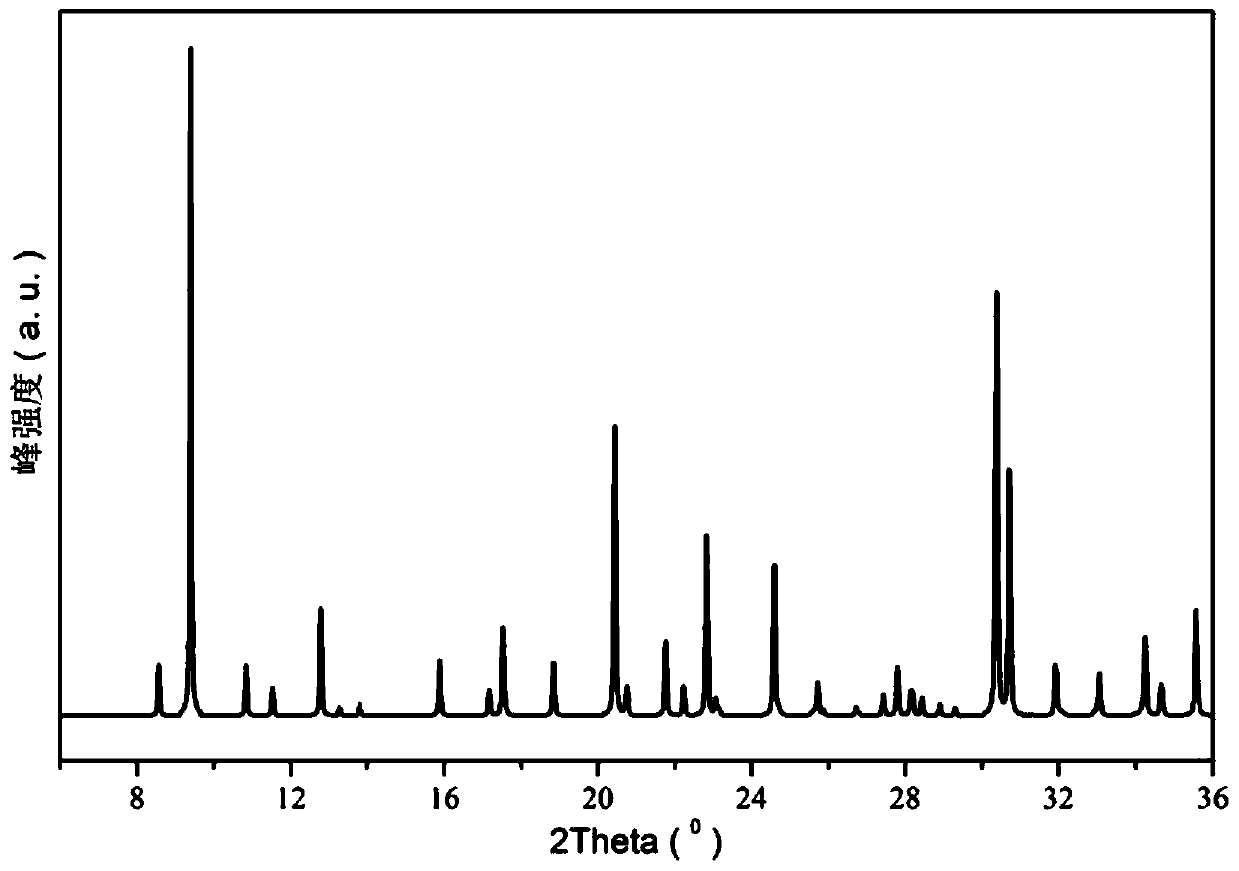

[0032] The processing method of synthesizing SAPO-34 / RUB-50 symbiotic composite molecular sieve is similar to embodiment 1, and difference is: the slurry concentration that carries out spray drying is 25%, and using template agent is diethyldimethylammonium chloride solution ( Template agent solution concentration 20.0wt%), the obtained SAPO-34 / RUB-50 symbiotic composite molecular sieve microspheres and 1.0mol / L nickel nitrate aqueous solution were ion-exchanged according to the mass ratio of 1:10. figure 2 The XRD diffraction pattern shown in proves that the material is SAPO-34 / RUB-50 intergrowth composite molecular sieve, which is denoted as SARU-2.

Embodiment 3

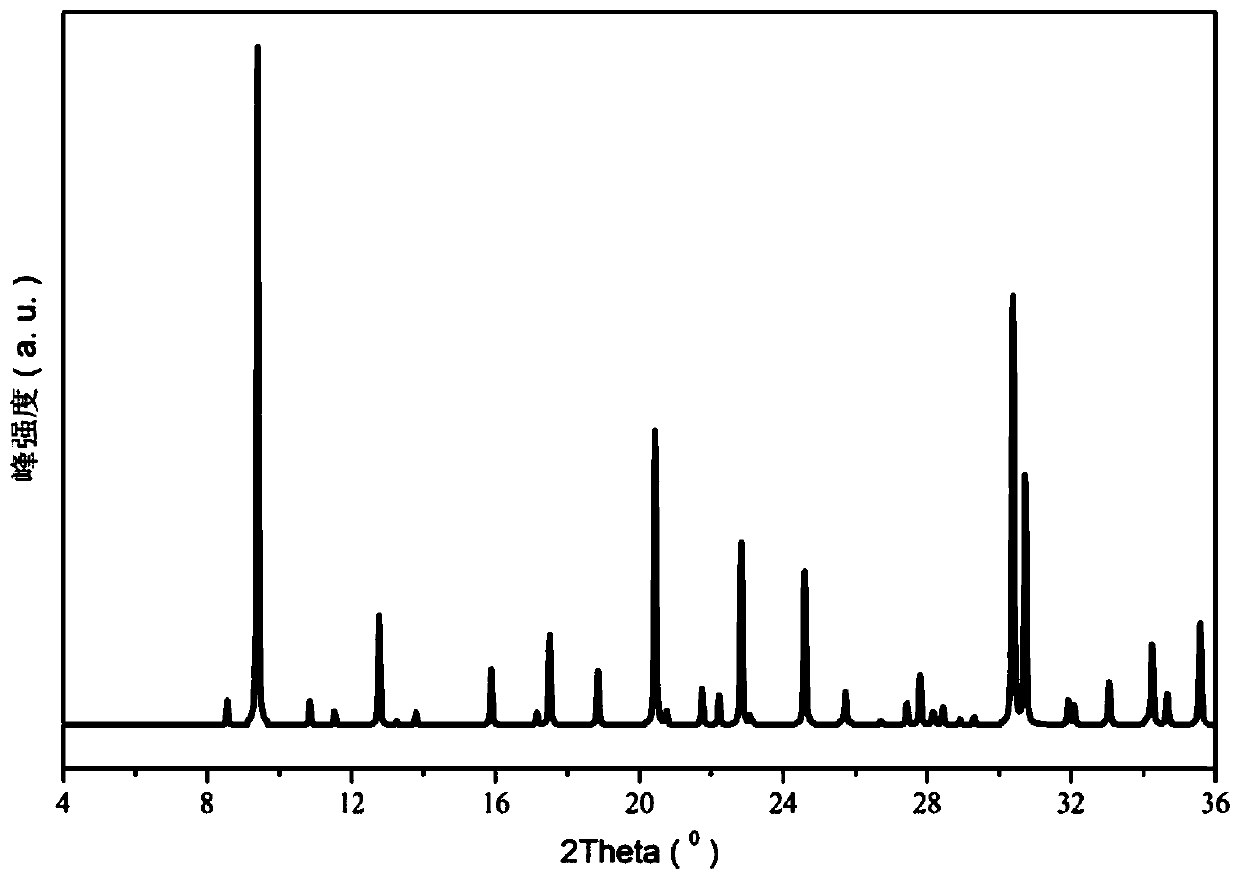

[0034] The processing method of synthesizing SAPO-34 / RUB-50 symbiotic composite molecular sieve is similar to embodiment 1, and difference is: the slurry concentration that carries out spray drying is 45%, and using template agent is N-methylquinuclidinium (template agent Concentration 20.0wt%), crystallization synthesis conditions are stirring at 80rpm speed, crystallization at 180°C for 96 hours. The obtained SAPO-34 / RUB-50 symbiotic composite molecular sieve microspheres were ion-exchanged with a 1.0 mol / L aqueous solution of lanthanum nitrate at a mass ratio of 1:10. The addition amount of various raw materials synthesized by crystallization is shown in Table 1, image 3 The XRD diffraction pattern shown in proves that the material is a SAPO-34 / RUB-50 intergrowth composite molecular sieve, which is denoted as SARU-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com