Core-shell microsphere catalyst

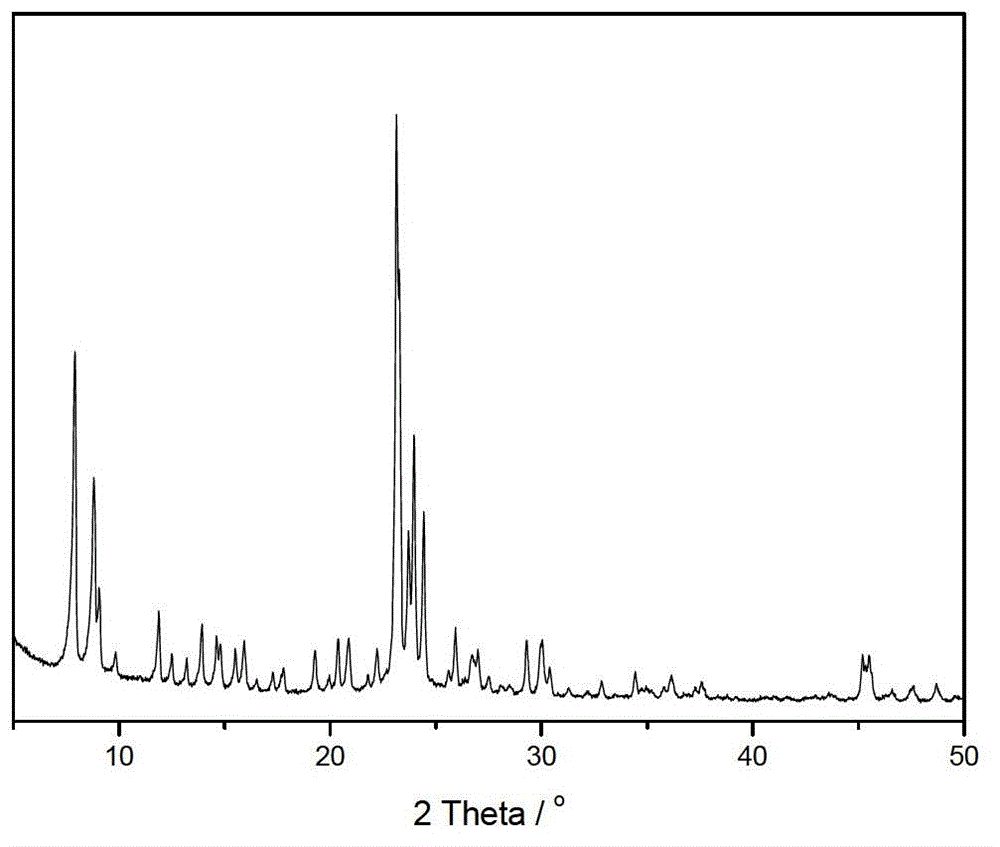

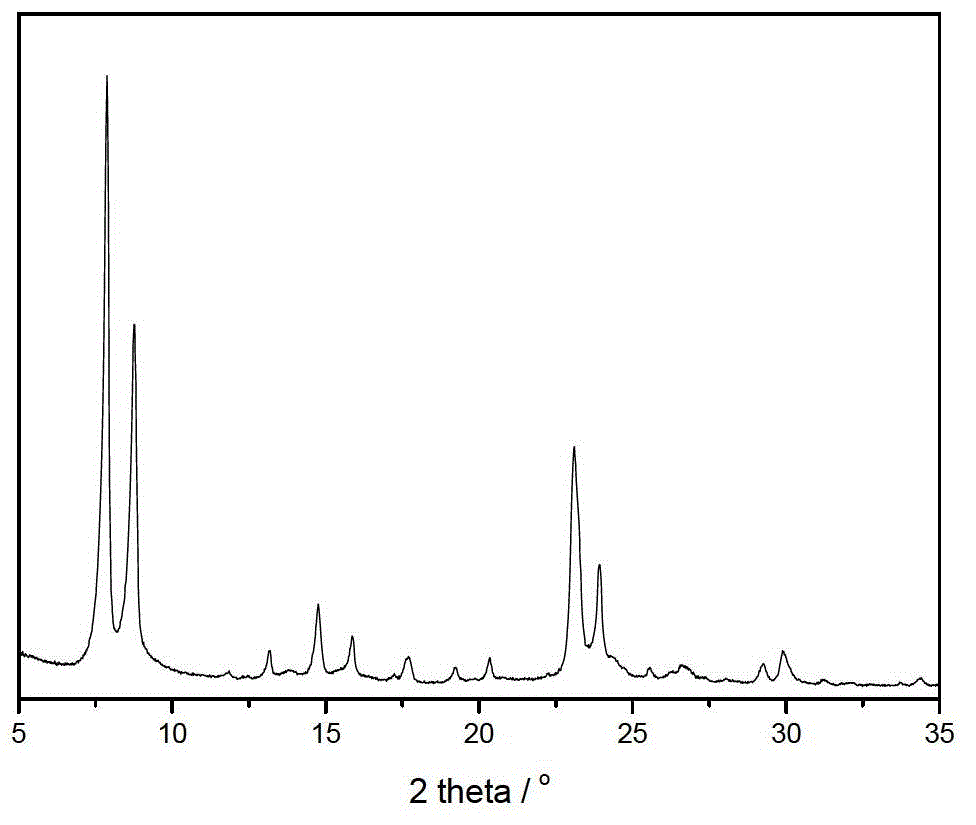

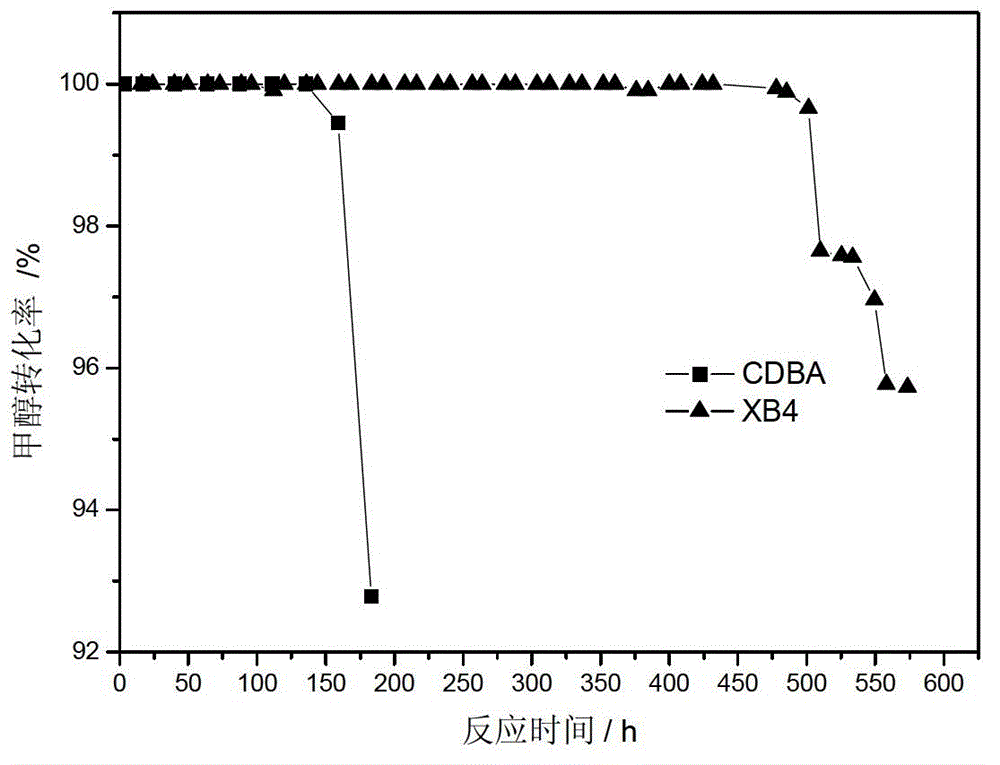

A catalyst, core-shell type technology, applied in the field of small ball catalysts, can solve problems such as easy coking, low P/E ratio, small pore size of molecular sieve catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 7.8 kg dry rubber powder (containing 74% by weight Al 2 o 3 , produced by Sinopec Catalyst Changling Branch, the same below) was dissolved in 1694 kg of tetrapropyl ammonium hydroxide aqueous solution (containing 20% by weight of tetrapropyl ammonium hydroxide), and then 577 kg of solid silica gel (Qingdao Ocean Chemical Co., Ltd. Company production, the same below), stirring and mixing for 2 hours. The molar composition of the resulting reaction mixture is: TPAOH / SiO 2 =0.2, SiO 2 / Al 2 o 3 =140,H 2 O / SiO 2 =9.5. The reaction mixture was charged into a stainless steel crystallization kettle, and crystallized at 130°C for 90 hours under continuous stirring and autogenous pressure. Then the crystallized product was filtered, washed, and dried at 120°C for 16 hours to obtain the molecular sieve raw powder product A1.

[0053] Put the above-mentioned dried raw powder A1 in a muffle furnace and calcined at 550° C. for 6 hours to obtain calcined molecular sieve po...

Embodiment 2

[0058] Put 4.5 kg of dry rubber powder and 1271 kg of tetrapropyl ammonium hydroxide aqueous solution (containing 20% by weight tetrapropyl ammonium hydroxide, produced by Sinopec Catalyst Jianchang Branch) into a stainless steel crystallization kettle for dissolution, and then add 260 kg Deionized water and 577 kg of solid silica gel were stirred and mixed for 2 hours. The molar composition of the resulting reaction mixture is: TPAOH / SiO 2 =0.15, SiO 2 / Al 2 o 3 =180,H 2 O / SiO 2 =9. The reaction mixture was crystallized at 140°C for 75 hours under continuous stirring and autogenous pressure. Then the crystallized product was filtered, washed, and dried at 120°C for 16 hours to obtain the molecular sieve powder product B1.

[0059] Put the above dried raw powder B1 in a muffle furnace and calcined at 550°C for 4 hours to obtain calcined molecular sieve powder B2.

[0060] Take 200 kg of the above-mentioned roasted molecular sieve powder B2 on a dry basis and add it t...

Embodiment 3

[0064] Add 0.8 kg of aluminum hydroxide to 330 kg of tetrapropylammonium hydroxide aqueous solution to dissolve, then add 150 g of deionized water and 150 kg of white carbon black (manufactured by Guangdong Haihua Chemical Co., Ltd.), and stir and mix for 2 hours. The molar composition of the resulting reaction mixture is: TPAOH / SiO2 =0.17, SiO 2 / Al 2 o 3 =300,H 2 O / SiO 2 =12. The reaction mixture was charged into a stainless steel crystallization kettle, and crystallized at 120°C for 100 hours under continuous stirring and autogenous pressure. Then the crystallized product was filtered, washed, and dried at 120°C for 16 hours to obtain the molecular sieve powder product C1.

[0065] Put the above dried raw powder C1 in a muffle furnace and calcined at 600°C for 2 hours to obtain calcined molecular sieve powder C2.

[0066] Take 100 kg of the above-mentioned roasted molecular sieve powder C2 on a dry basis and add it to 1000 kg of deionized water for stirring and beatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com