Method for quickly synthesizing SAPO(silicoaluminophosphate)-34 molecular sieve and catalyst prepared from molecular sieve

A SAPO-34, molecular sieve technology, applied in the direction of molecular sieve catalyst, molecular sieve and alkali exchange phosphate, physical/chemical process catalyst, etc., can solve the problems of unable to obtain crystal products, low synthesis yield, long crystallization time, etc. Excellent catalytic performance, less dosage and longer reaction life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

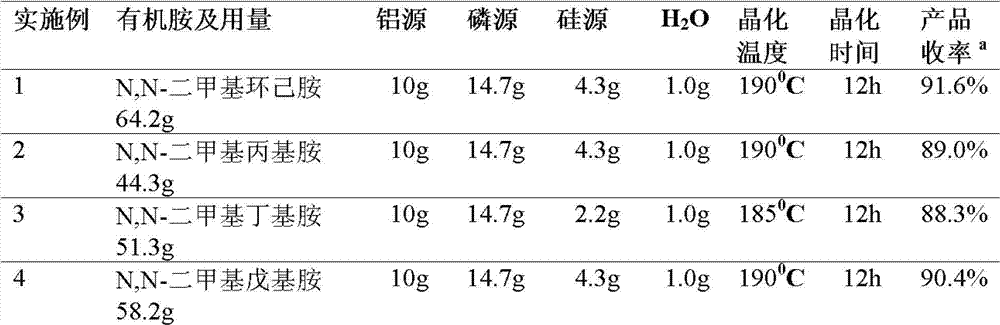

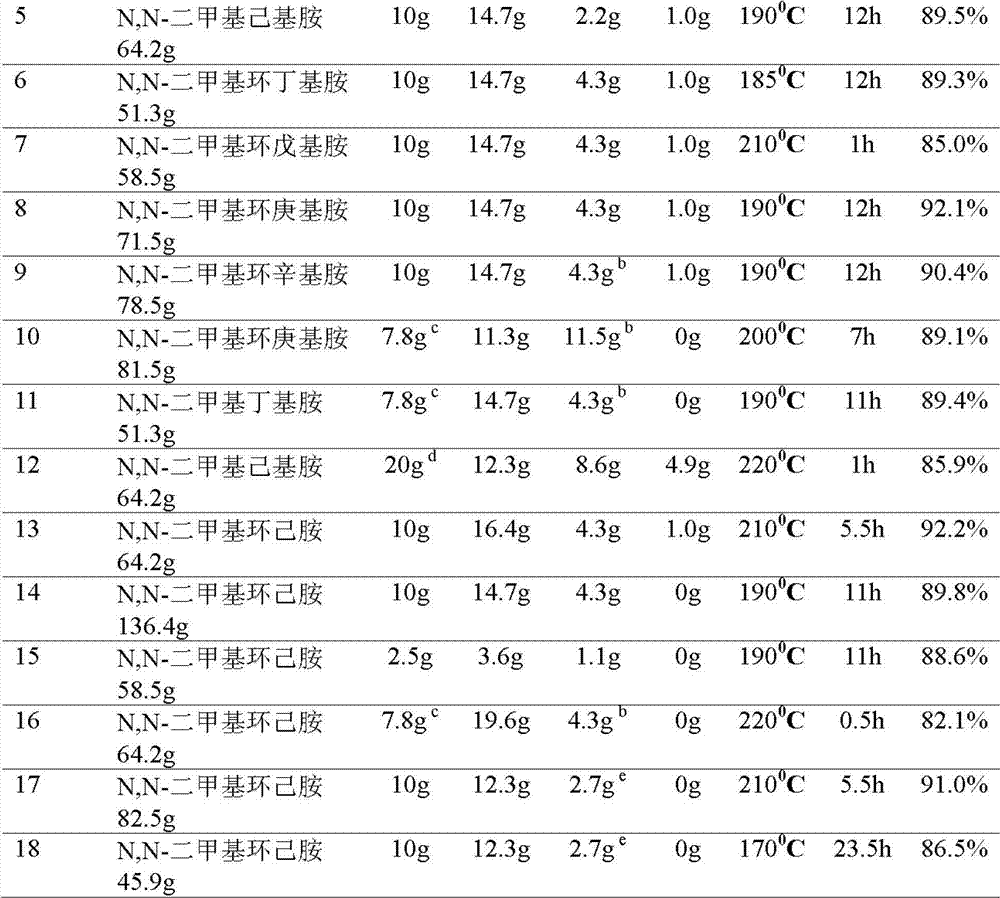

Embodiment 1-18

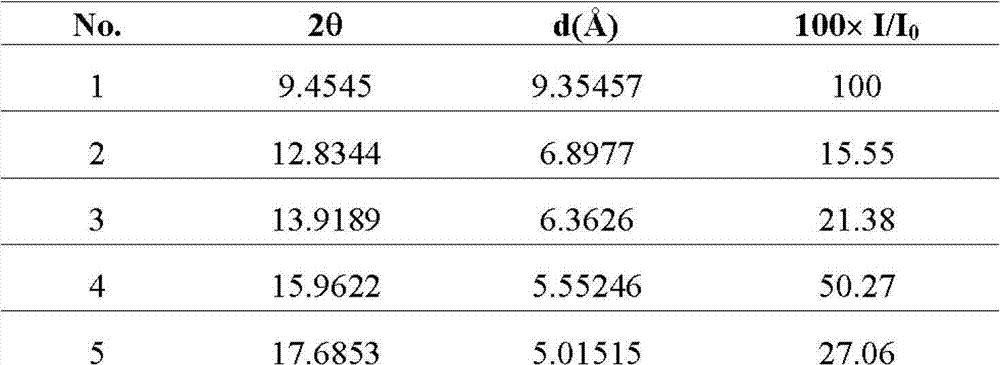

[0035] See Table 1 for specific batching dosage and crystallization conditions. The specific batching process is as follows. Mix and stir the aluminum source and the organic amine, and record it as mixture A. Mix silicon source, phosphorus source and deionized water and stir for 30 minutes, then add the mixture to A, stir vigorously for 30 minutes in a closed state to make it evenly mixed, then transfer the gel to a stainless steel reaction kettle, heat up to a certain temperature and dynamically Crystallize for a certain period of time. After the crystallization, the solid product was centrifuged, washed, and dried in air at 100°C to obtain the original powder. The sample was analyzed by XRD, and the result showed that the synthesized product was SAPO-34 molecular sieve. The XRD data of the product of Example 1 is shown in Table 2. The XRD results of Examples 2-18 are close to those of Example 1, that is, the peak positions are the same, and the relative peak intensity of e...

Embodiment 19

[0044] The batching process, batching dosage and crystallization conditions are the same as in Example 1, only the organic amine is changed to 35g N, N-dimethylcyclohexylamine and 28g N, N-dimethyl n-butylamine. After crystallization, the solid product was centrifuged, washed, and dried in air at 100°C to obtain 20.2g of raw powder (15% weight loss on calcination at 600°C), and the solid yield was 92%. The sample was analyzed by XRD, and the XRD result was close to that of Example 1, that is, the peak position was the same, and the relative peak intensity of each peak fluctuated within ±10%, indicating that the synthesized product was SAPO-34 molecular sieve.

Embodiment 20

[0046] The batching process, batching dosage and crystallization conditions are the same as in Example 1, only the organic amine is changed to 30g N, N-dimethylcyclohexylamine and 30g N,N-dimethylcyclohexylamine. After the crystallization, the solid product was centrifuged, washed, and dried in air at 100°C to obtain 19.5g of raw powder (14.5% weight loss on calcination at 600°C), and the solid yield was 89.5%. The sample was analyzed by XRD, and the XRD result was close to the sample in Example 1, that is, the peak position was the same, and the relative peak intensity of each peak fluctuated in the range of ±10%, indicating that the synthesized product was SAPO-34 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com