Preparation method and application of SAPO-34 molecular sieves with flaky morphology

A technology of SAPO-34 and molecular sieve, which is applied in the field of molecular sieves, can solve problems such as the complexity of the synthesis process, and achieve the effects of low cost, high and low carbon olefin selectivity, and reduced raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

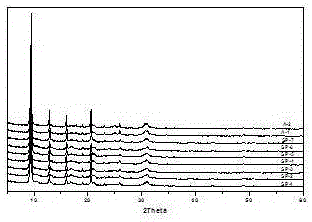

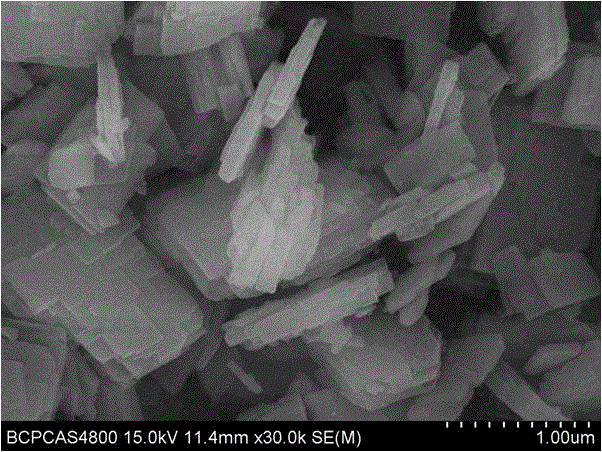

[0037] Add water, pseudoboehmite, phosphoric acid, tetraethylammonium hydroxide, triethylamine and silica sol to the beaker in turn at room temperature, mix and stir for 3 hours, and adjust the pH of the mixture to 6.5-7 to obtain SAPO -34 molecular sieve initial gel mixture; the molar ratio of the components in this mixture is: 0.5SiO 2 : 1.3P 2 o 5 : 1.0Al 2 o 3 : 0.5TEAOH : 4.0TEA:30H 2 O: After the stirring, put the initial gel mixture into a stainless steel reaction kettle, put the reaction kettle in an oven, raise the temperature to 200°C, and crystallize at a constant temperature for 30 hours. After the crystallization is complete, take out the reactor and cool it rapidly; the solid product is separated by centrifugation, washed with deionized water until neutral, and dried to obtain the original powder of SAPO-34 molecular sieve; the original powder is calcined at 550°C for 6 hours to obtain a white tablet Shaped SAPO-34 molecular sieve (referred to as SP-1). ...

Embodiment 2

[0039] Add phosphoric acid, water, aluminum isopropoxide and activated kaolin to the beaker in turn at room temperature, mix and stir for 1 hour, then add tetraethylammonium hydroxide and diethylamine in turn, mix and stir for 0.5 hours, and adjust the mixing The pH value of the liquid is located at 5.5-6, and the initial gel mixture of SAPO-34 molecular sieve is obtained; the molar ratio of each component in the mixture is: 0.1SiO 2 : 2.0P2 o 5 : 1.0Al 2 o 3 : 2.0TEAOH : 0.05DEA : 100H 2 O: After the stirring, put the initial gel mixture into a stainless steel reaction kettle, put the reaction kettle in an oven, raise the temperature to 170°C, and crystallize at a constant temperature for 60 hours. After the crystallization is complete, take out the reaction kettle and quench it; the solid product is separated by centrifugation, washed with deionized water until neutral, and dried to obtain the original powder of SAPO-34 molecular sieve; the original powder is calcined a...

Embodiment 3

[0041] Add water, ammonium hydrogen phosphate, aluminum sol, sodium silicate, tetraethylammonium chloride and triethylamine to the beaker in turn at room temperature, mix and stir for 10 hours, and adjust the pH of the mixture to 7.5-8 to obtain SAPO -34 molecular sieve initial gel mixture; the molar ratio of each component in the mixture is: 1.2SiO 2 : 1.0P 2 o 5 : 1.0Al 2 o 3 : 0.05TEAC : 10TEA : 20H 2 O: After the stirring, put the initial gel mixture into a stainless steel reaction kettle, put the reaction kettle in an oven, raise the temperature to 220°C, and crystallize at constant temperature for 10 hours. After the crystallization is completed, take out the reaction kettle and quench it; the solid product is separated by centrifugation, washed with deionized water until neutral, and dried to obtain the raw powder of SAPO-34 molecular sieve; the raw powder is calcined at 500°C for 10 hours to obtain a white tablet Shaped SAPO-34 molecular sieve (referred to as S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com