Normal butane method-based maleic anhydride production line

A technology of n-butane method maleic anhydride and production line, which is applied in the field of butane method maleic anhydride process production line, can solve the problems of production safety impact, environmental pollution, small heat exchange area, etc. The effect of a large thermal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

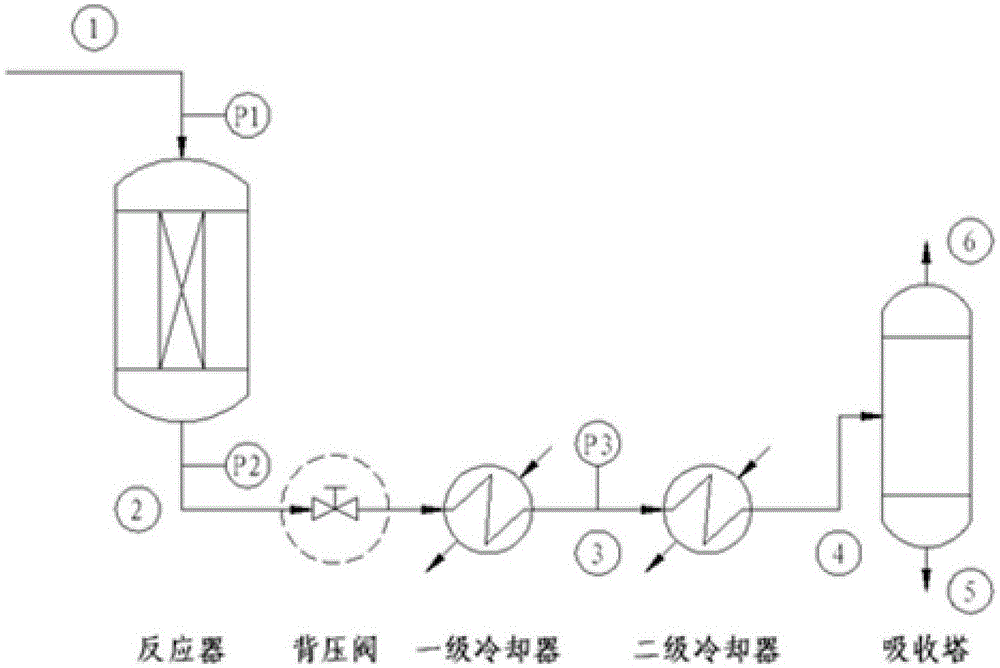

[0017] Such as figure 1 As shown, a normal butane process maleic anhydride process production line includes a reactor, a primary cooler, a secondary cooler, and an absorption tower connected in sequence through a pipeline, and is characterized in that: between the reactor and the cooler is provided Back pressure valve.

[0018] The beneficial effects of this embodiment are: the pressure inside and outside the reactor system is isolated through the back pressure valve to ensure the required reaction pressure of the reactor; the pressure level of subsequent equipment is greatly reduced, the safety risk is reduced, and the equipment is reduced. Maintenance costs.

Embodiment 2

[0020] On the basis of implementation 1, the finned tube heat exchanger is adopted as the cooler.

[0021] The beneficial effect of this embodiment is that a finned tube heat exchanger is used to replace the traditional tube-and-tube heat exchanger. The finned tube heat exchanger has a small volume, light weight of equipment, large heat exchange area and low overall cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com