An electrolysis preparation device for ozone

A preparation device and ozone technology, applied in the electrolysis process, electrolysis components, electrode shapes/types, etc., can solve the problems of reducing the amount of ozone dissolved in ozone water, increasing costs, and increasing the water level of the cathode water tank, so as to avoid the increase of hydrogen concentration. , Improve the safety of use and avoid the effect of material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

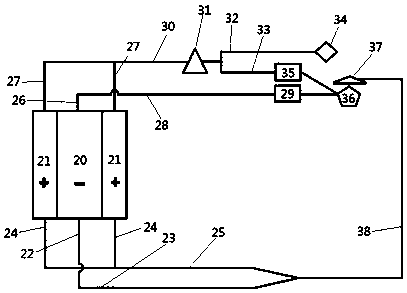

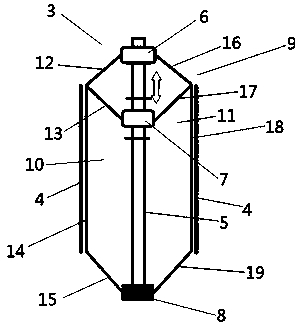

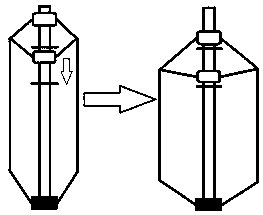

[0033] Attached below Figure 1-3 The technical solutions of the present invention are further described through specific implementation methods.

[0034] An ozone electrolysis preparation device, comprising an electrolysis water tank 1, an electrolysis generator device 2 and an electrolysis generator adjustment device 3, the electrolysis generator device 2 includes an electrolysis electrode assembly 4 and a corresponding power supply, and the electrolysis electrode assembly 4 includes an anode Catalyst membrane plate, cathode catalyst membrane plate and PEM membrane, the anode catalyst membrane plate, cathode catalyst membrane plate and PEM membrane in the electrolysis electrode assembly 4 all adopt elastic deformable material; Electrolysis generator adjustment device 3 comprises vertical shaft 5, adjustment The slider 6, the supporting slider 7 and the fixed block 8; the adjusting slider 6 and the supporting slider 7 are movably sleeved on the vertical shaft 5, and can move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com