Shark fin bow structure and bulbous bow ship form thereof

A shark fin and bulbous bow technology is applied in the field of shark fin ship bow structure and its bulbous bow shape, which can solve the problems of increasing the contact area between the ship and the water, disturbance of the flow field, and increasing the viscous resistance of the ship. The effect of breaking wave resistance, reducing wave resistance increase, and reducing additional resistance value-added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

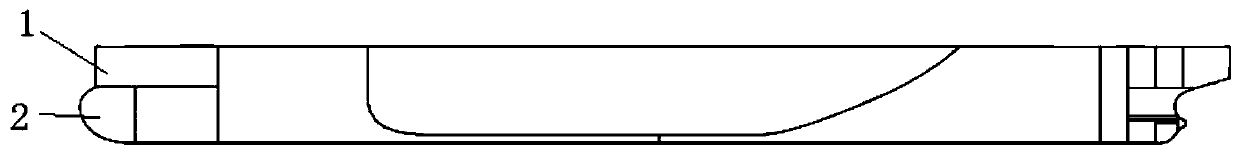

[0018] The invention provides a shark fin bow structure, such as figure 1 As shown, this structure includes an upper part 1 and a lower part, and the lower part is a bulbous nose 2; the front end of the upper part is perpendicular to the sea level, extends upwards to the surface of the bow of the hull, connects downwards to the bulbous nose 2, and connects to the light of the hull backward. Shun connection.

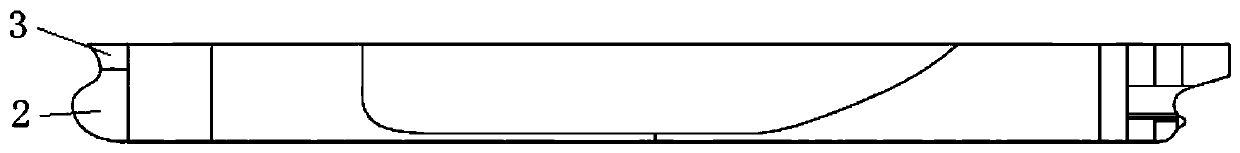

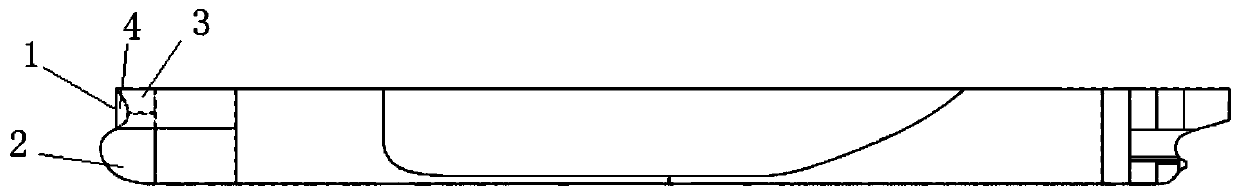

[0019] figure 2 It is a side view of the ship type in the prior art, and there is a depression between the upper part 3 and the bulbous nose 2 of the ship type in the prior art; as image 3 Shown, improve on prior art ship type, install the upper part 1 of the present invention additionally as appendage structure; As Figure 4 Shown, the left half is the front view of prior art ship type A, and half part is the front view of ship type B of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com