Patents

Literature

100results about How to "Effective compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

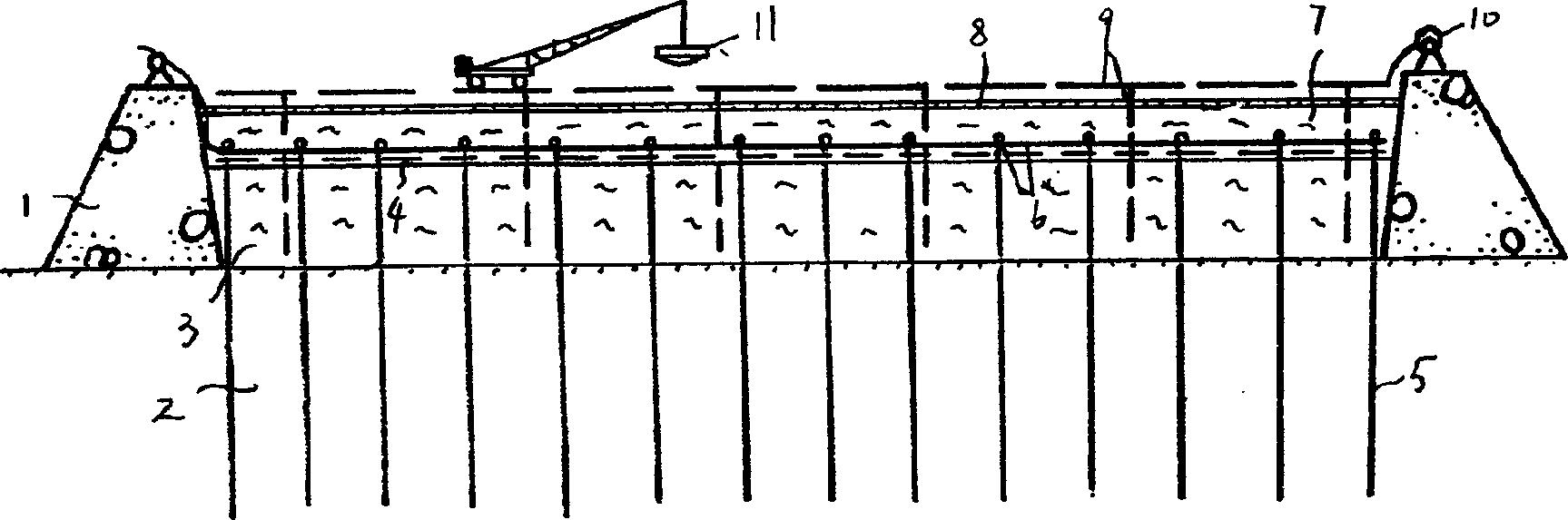

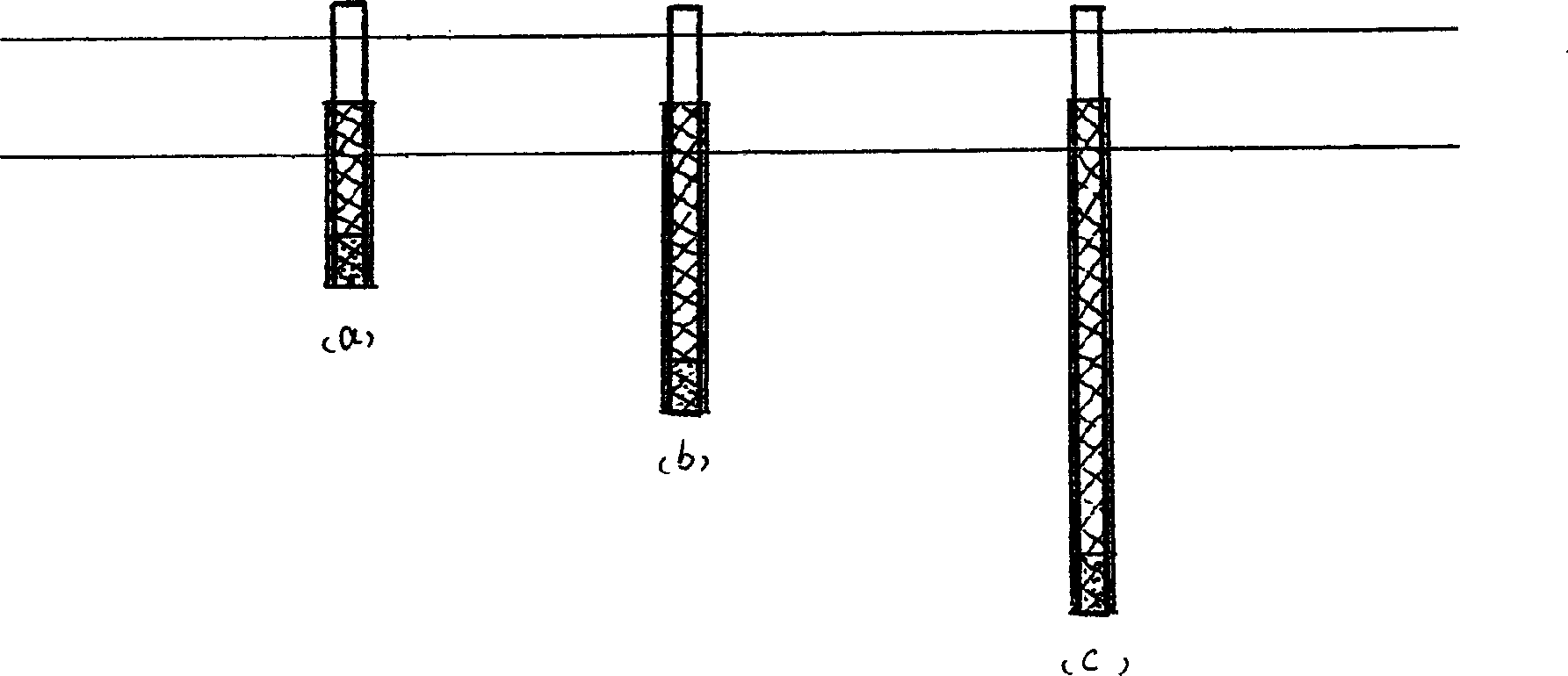

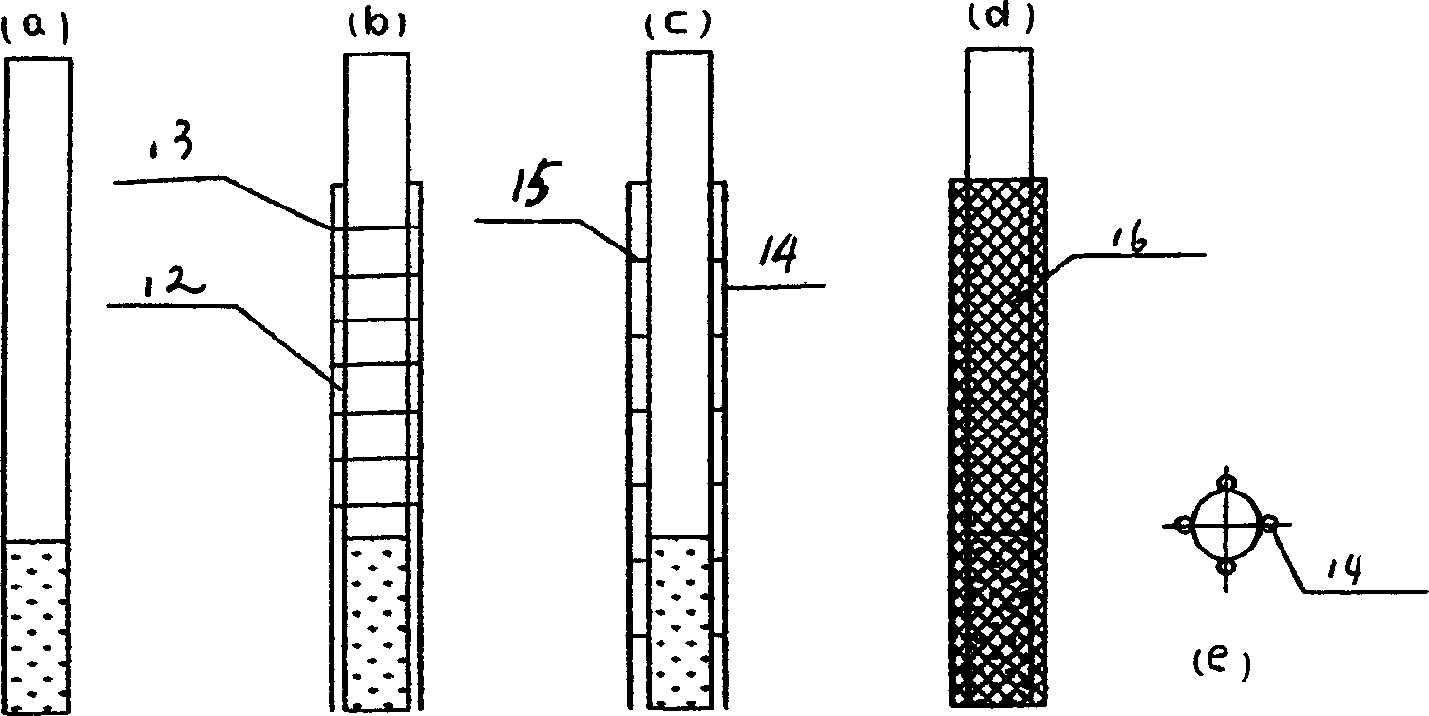

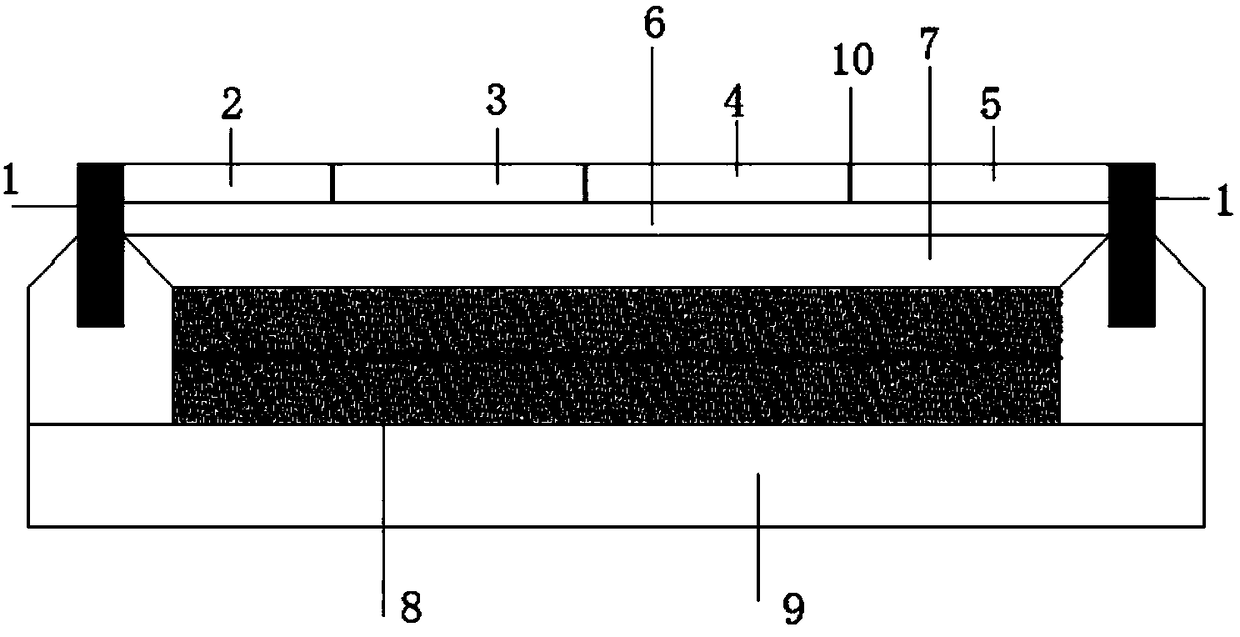

Combined method for fastening soft soil ground by dual vacuum prepressing and dynamic extruding method

InactiveCN1818227AEffective secondary reinforcementImprove consolidation indexSoil preservationFilling materialsReduction procedure

A method for reinforcement of yielding soil of large area or hollow land includes the following procedures in order: 1. low position vacuum pre-press procedure as building cofferdam, filling in sludge to certain height, paving cloth and bamboo fence on the top, vertically inserting in water emission plastic boards, laying horizontal vacuum pipe net, installing vacuum pre-press system and sealing with mud layer of 0.8-1.5 m thick then vacuum bumping for pre-press; 2. high vacuum rate well point water reduction procedure as applying a high vacuum rate well point water reduction system on the mud sealing layer, removing well point pipe after the first round of water reduction; 3. low power strong tamping procedure as paving a layer of filling material on the mud sealing layer then tamping. Roller compact the surface after 2-3 rounds of procedure 2 and 3.

Owner:张志铁 +1

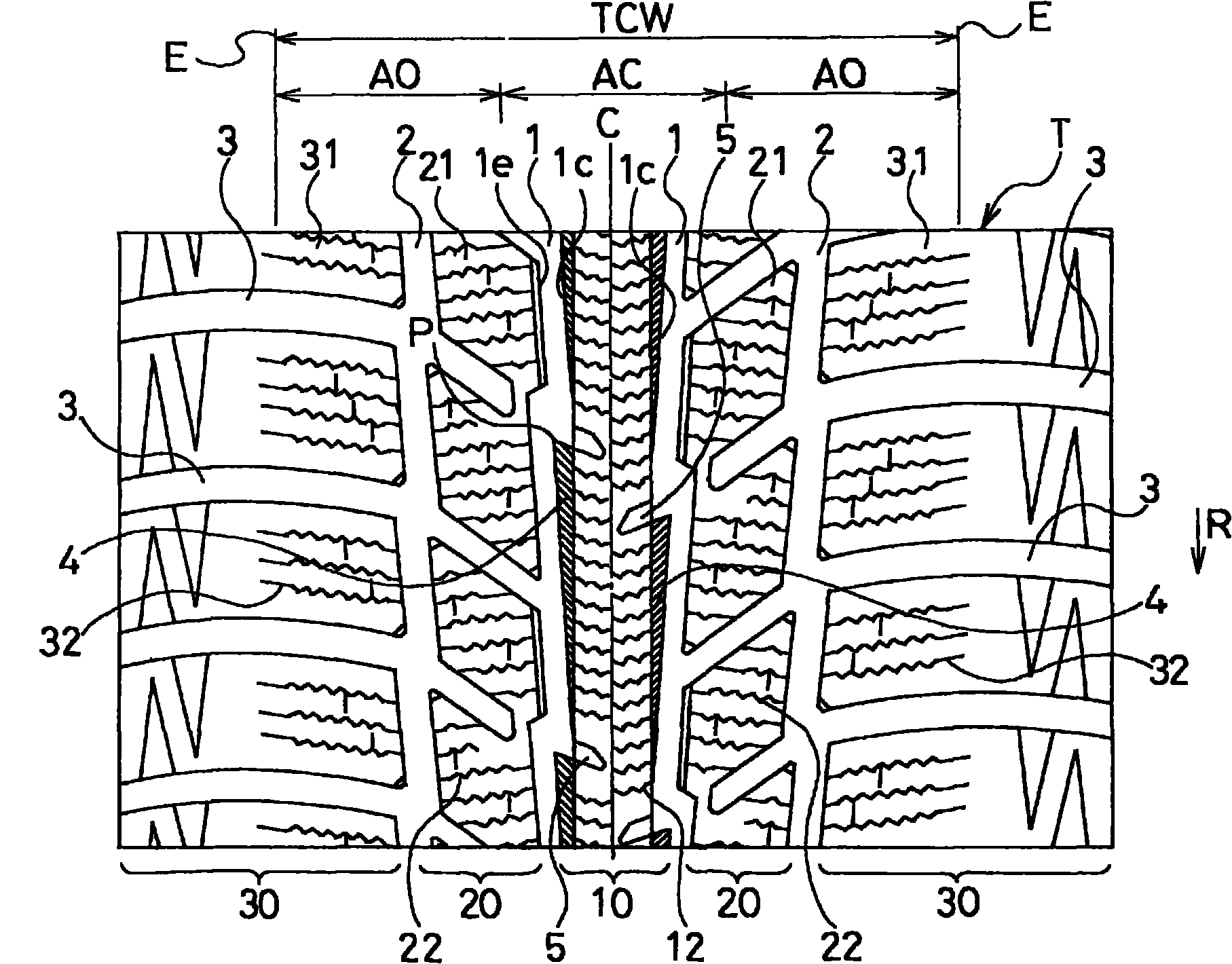

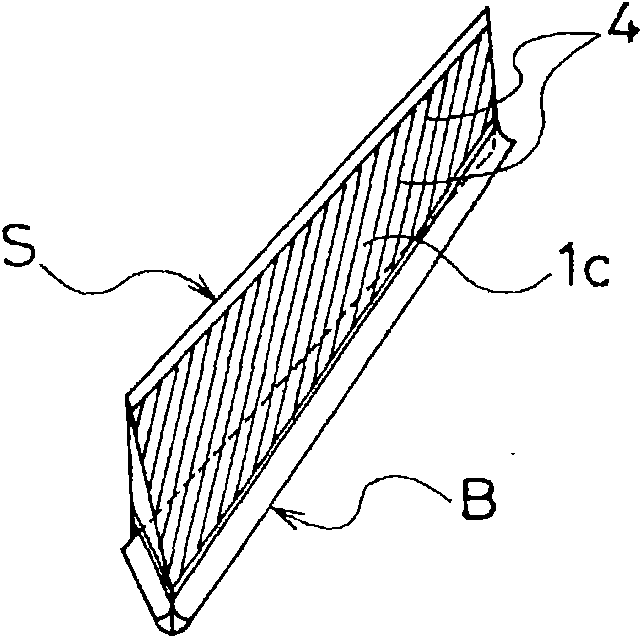

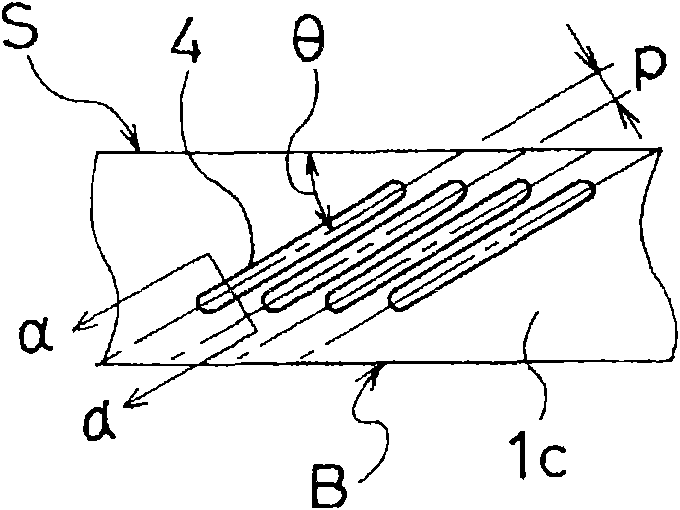

Pneumatic tire

ActiveCN101804773AHigh shear forceWithout sacrificing drivabilityTyre tread bands/patternsRoad surfaceGradual increase

Provided is a pneumatic tire having snow performances which are capable of being enhanced without sacrificing its running performance on dry road surfaces. A pneumatic tire of the invention includes two first main grooves, a plurality lateral grooves and a plurality of sipes in a tread part. In the pneumatic tire, a groove wall surface, of each first main groove, closer to a tire equatorial line is formed so as to cyclically repeat, in the tire circumferential direction, a change in an inclination angle of the groove wall surface to a direction normal to a tread, the change being a gradual increase from a minimum value of 0 DEG to 15 DEG to a maximum value of 15 DEG to 45 DEG. In places where the inclination angel of the groove wall surface, of the first main groove, closer to the tire equatorial line, is at its maximum, no lateral grooves communicate with the first main groove, and in the places, the other groove wall surface, of the first main groove, closer to a corresponding contact end extends uninterruptedly.

Owner:THE YOKOHAMA RUBBER CO LTD

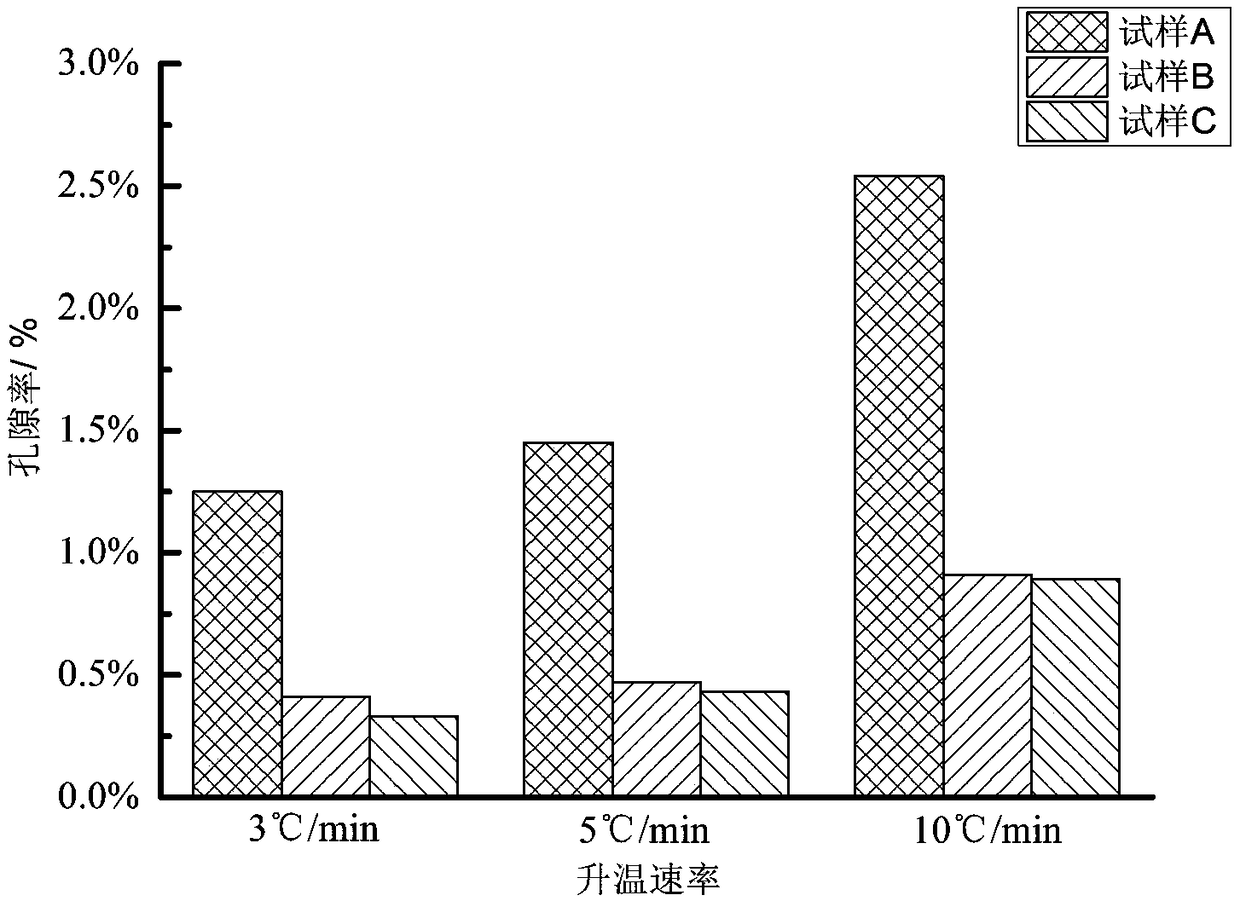

Preparation method for ternary positive electrode active material and battery

The invention provides a preparation method for a ternary positive electrode active material. The preparation method comprises the following steps: S1, mixing a lithium source, a nickel source, a cobalt source and a manganese source to obtain a mixture; S2, drying the mixture and pre-burning the mixture in an oxidizing atmosphere at a temperature of 200 to 800 DEG C so as to obtain a precursor; S3, mixing the precursor with a bonding agent and then carrying out isostatic pressing so as to obtain a compacted material, wherein isostatic pressing pressure is 10 to 50 MPa; and S4, sintering the compacted material in an oxidizing atmosphere at a temperature of 800 to 1200 DEG C and carrying out crushing and screening so as to obtain the ternary positive electrode active material. Meanwhile, the invention further discloses a battery prepared from the ternary positive electrode active material prepared by using the preparation method. With the preparation method for the ternary positive electrode active material, compaction density of the ternary positive electrode active material can be greatly improved; and the method is simple and easily practicable.

Owner:GUIZHOU ANDA TECH ENERGY CO LTD

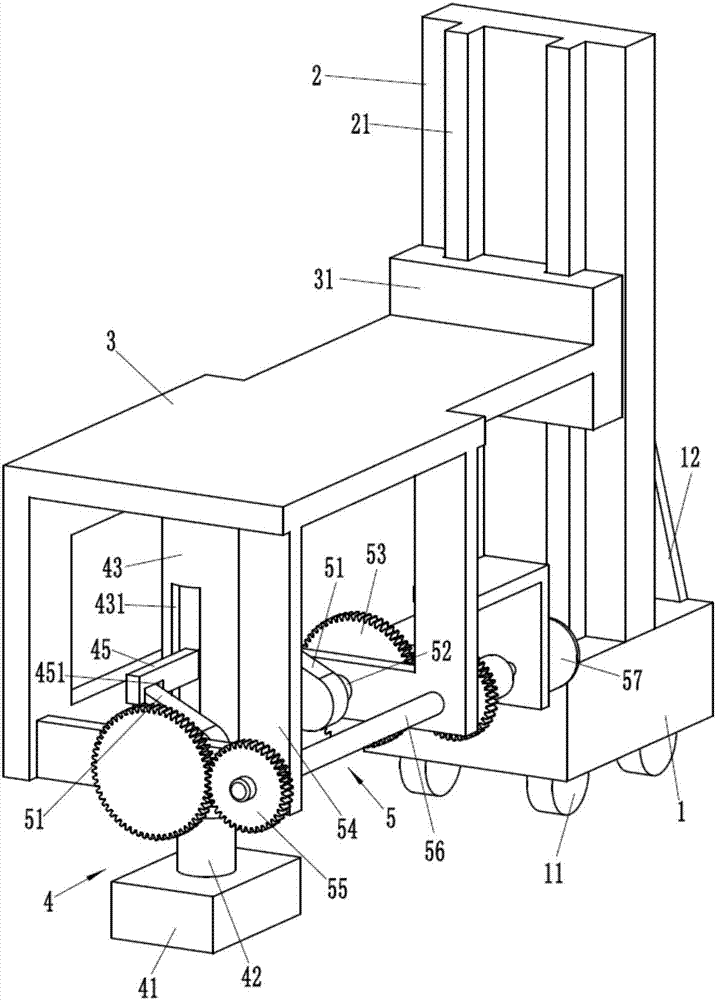

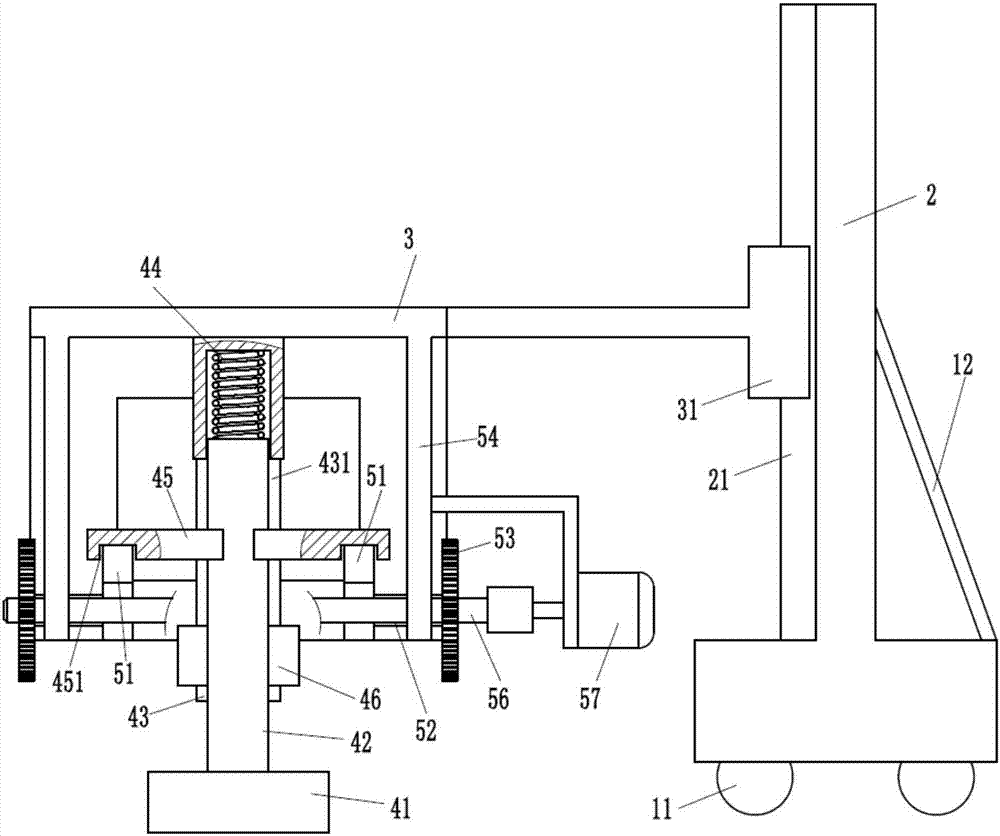

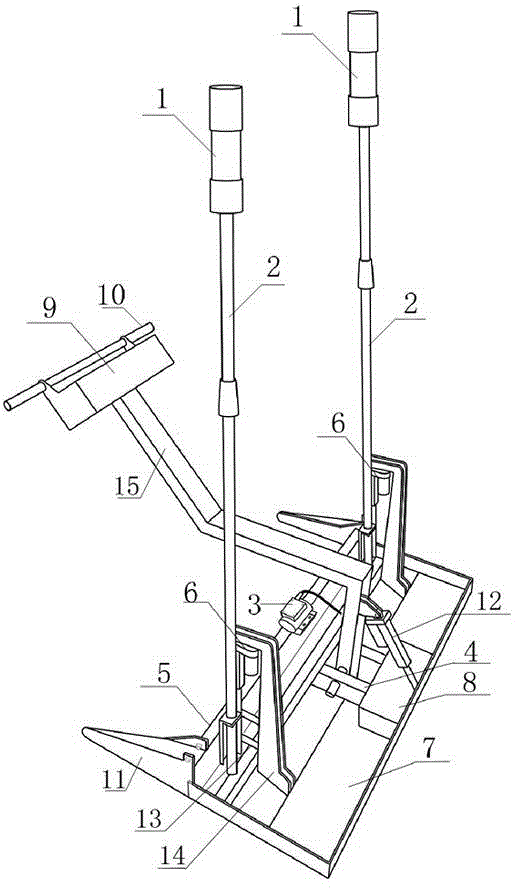

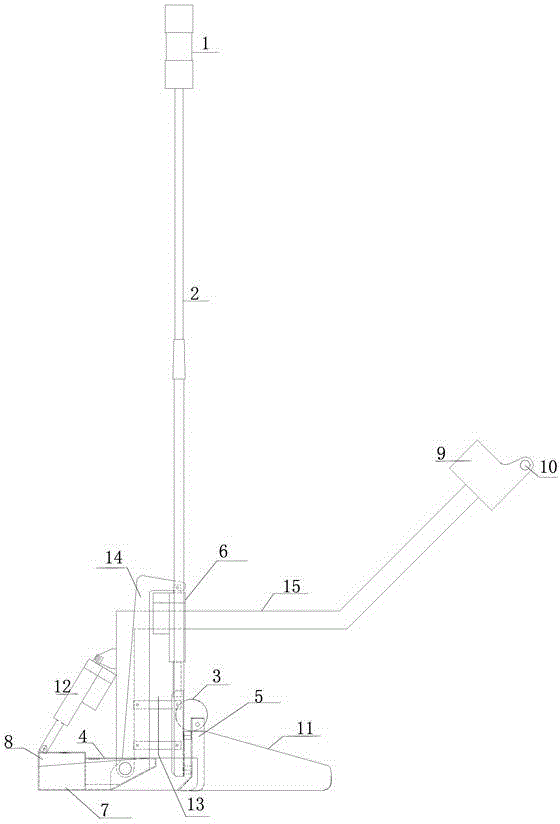

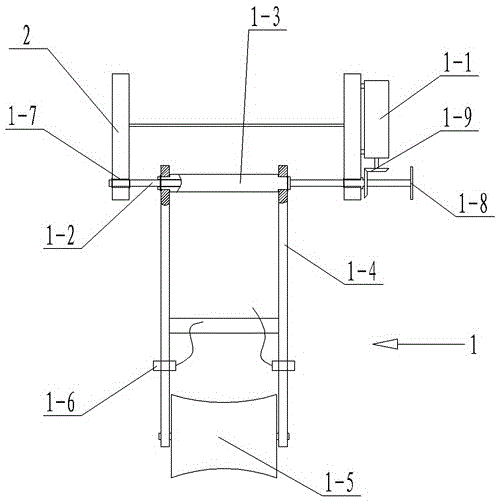

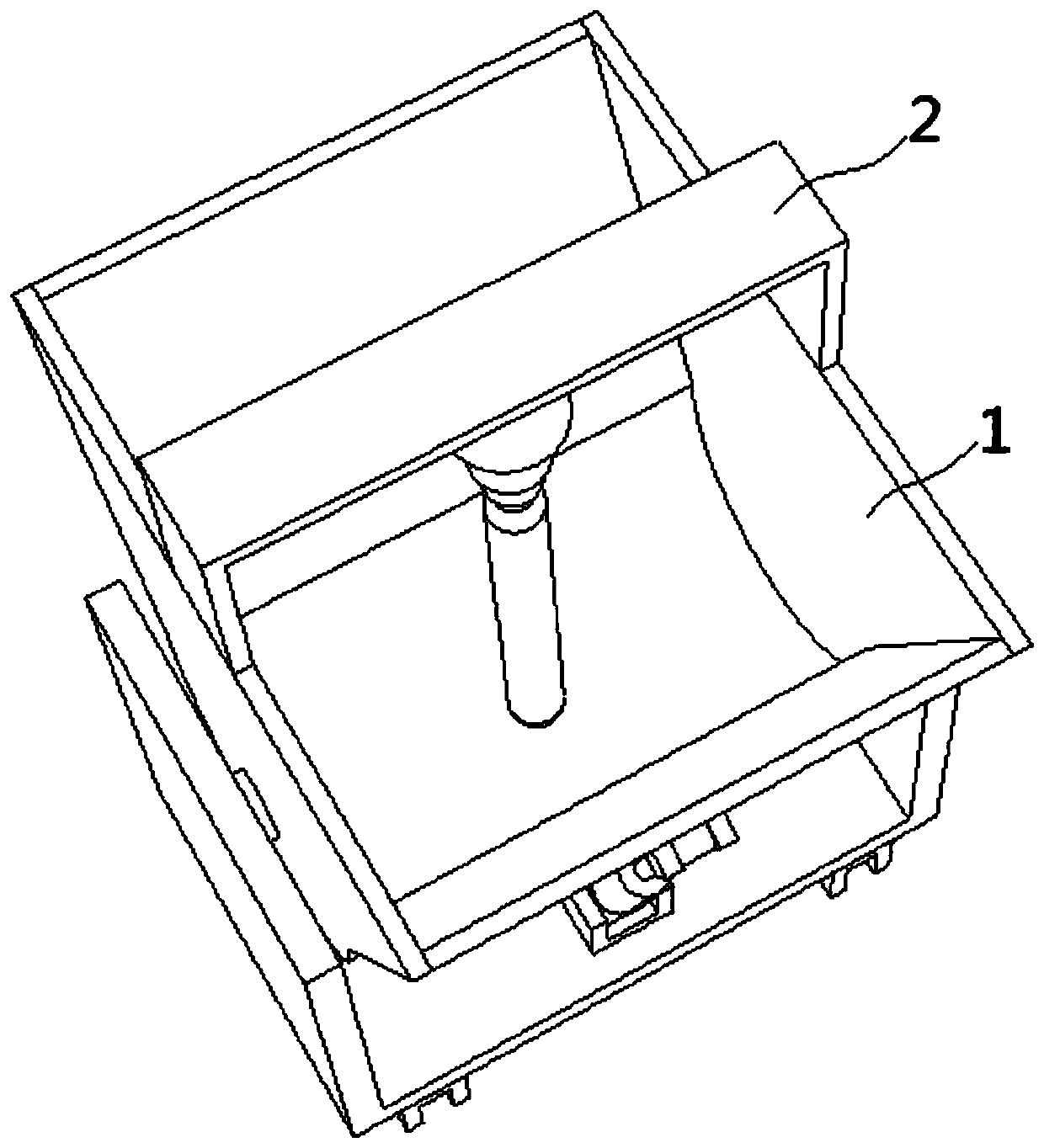

Tamping machine for civil engineering

The invention discloses a tamping machine for civil engineering. The tamping machine for civil engineering comprises a supporting seat, wherein the supporting seat is fixedly connected with a supporting plate in the vertical direction; the supporting plate is slidably connected with a right-angled carrying plate through a vertical slide track; and a tamping part is arranged on the right-angled carrying plate. By the tamping machine, the ground can be effectively tamped and flattened. The tamping machine for civil engineering has the advantages of stable and reliable structure and convenience in use.

Owner:HUZHOU ZHONGCHEN CONSTR

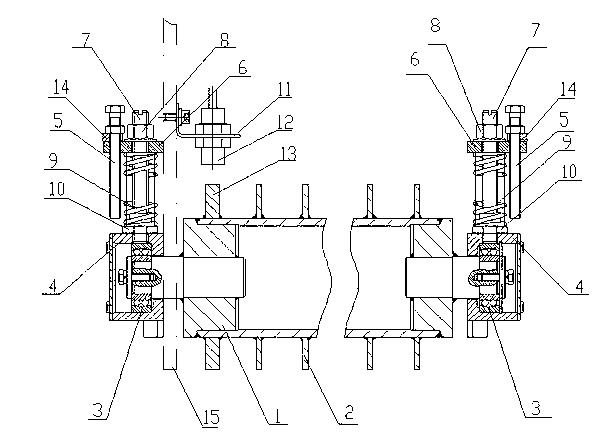

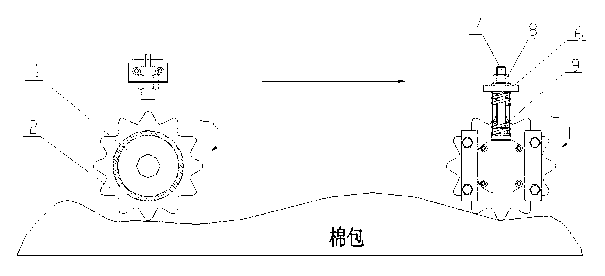

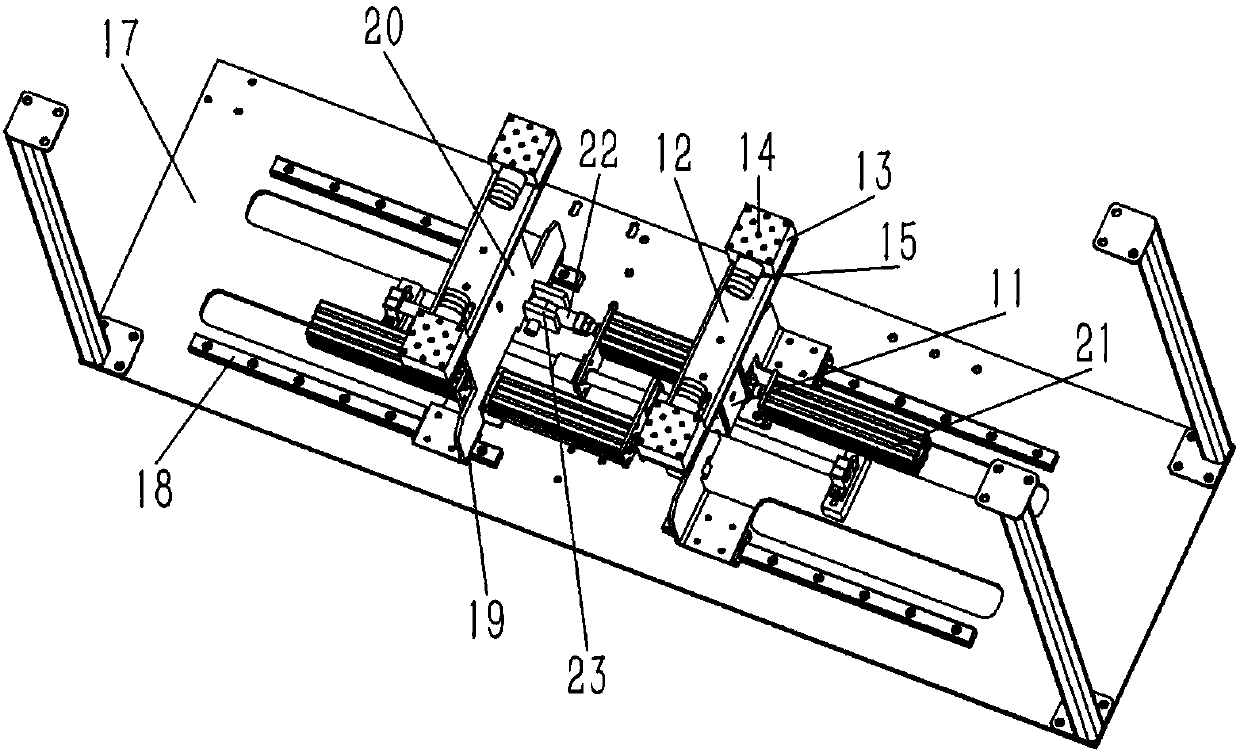

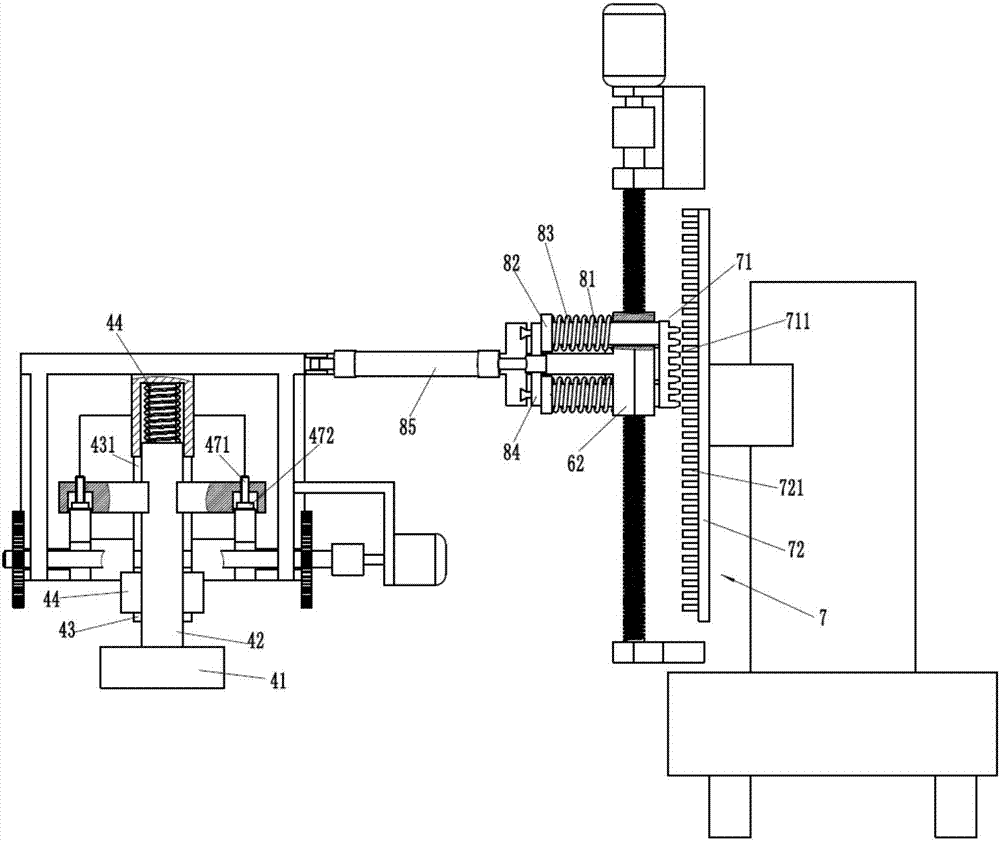

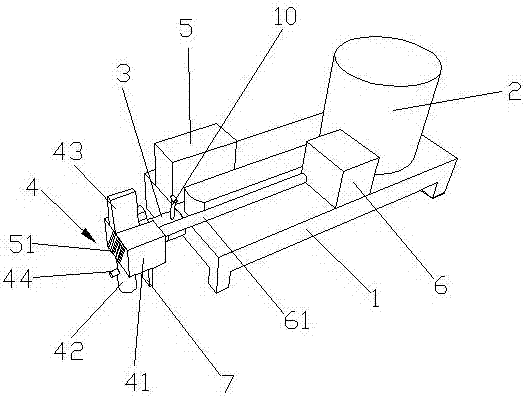

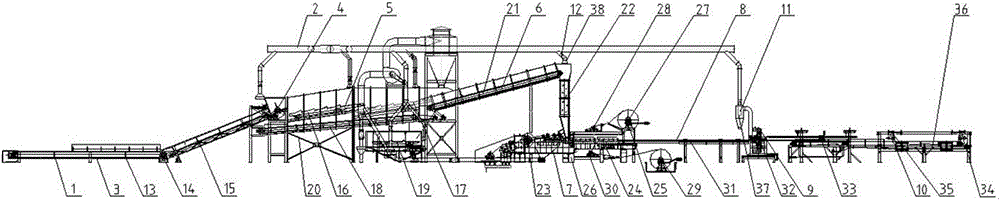

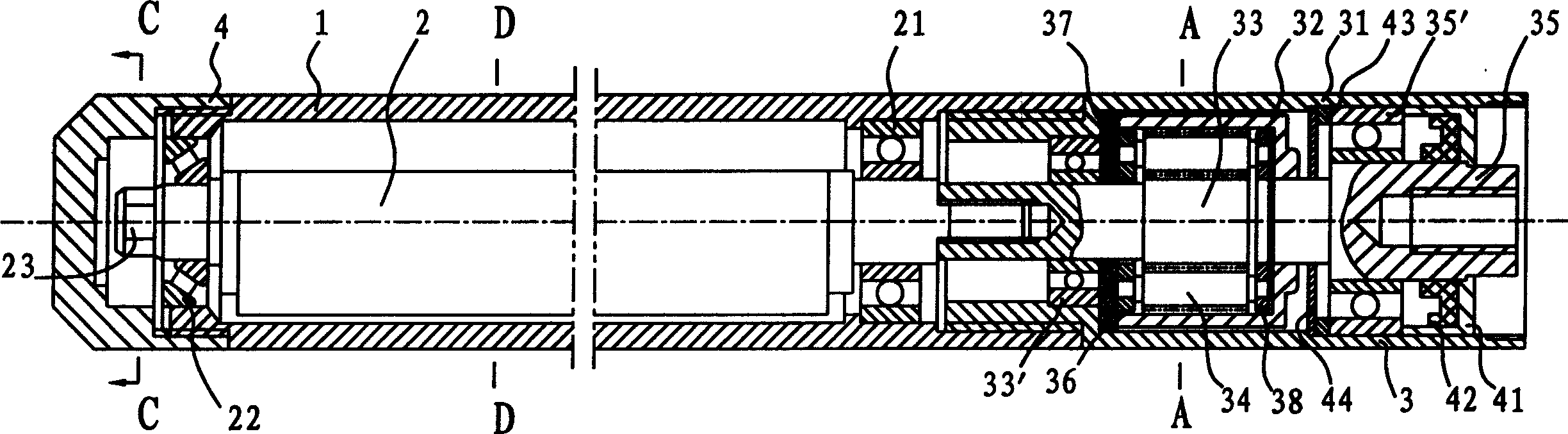

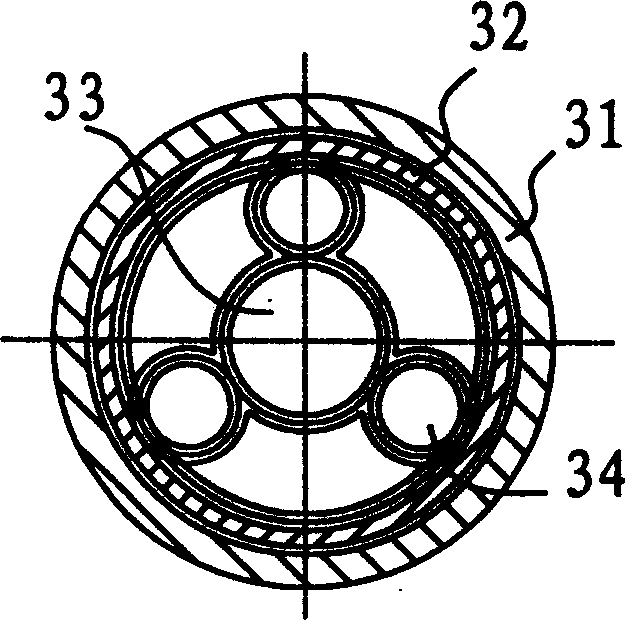

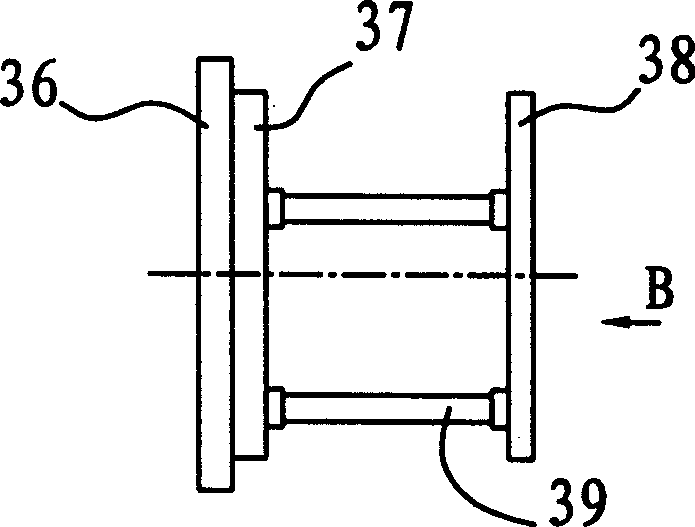

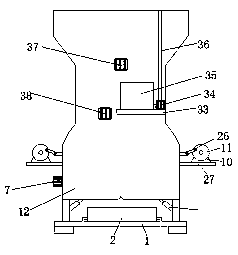

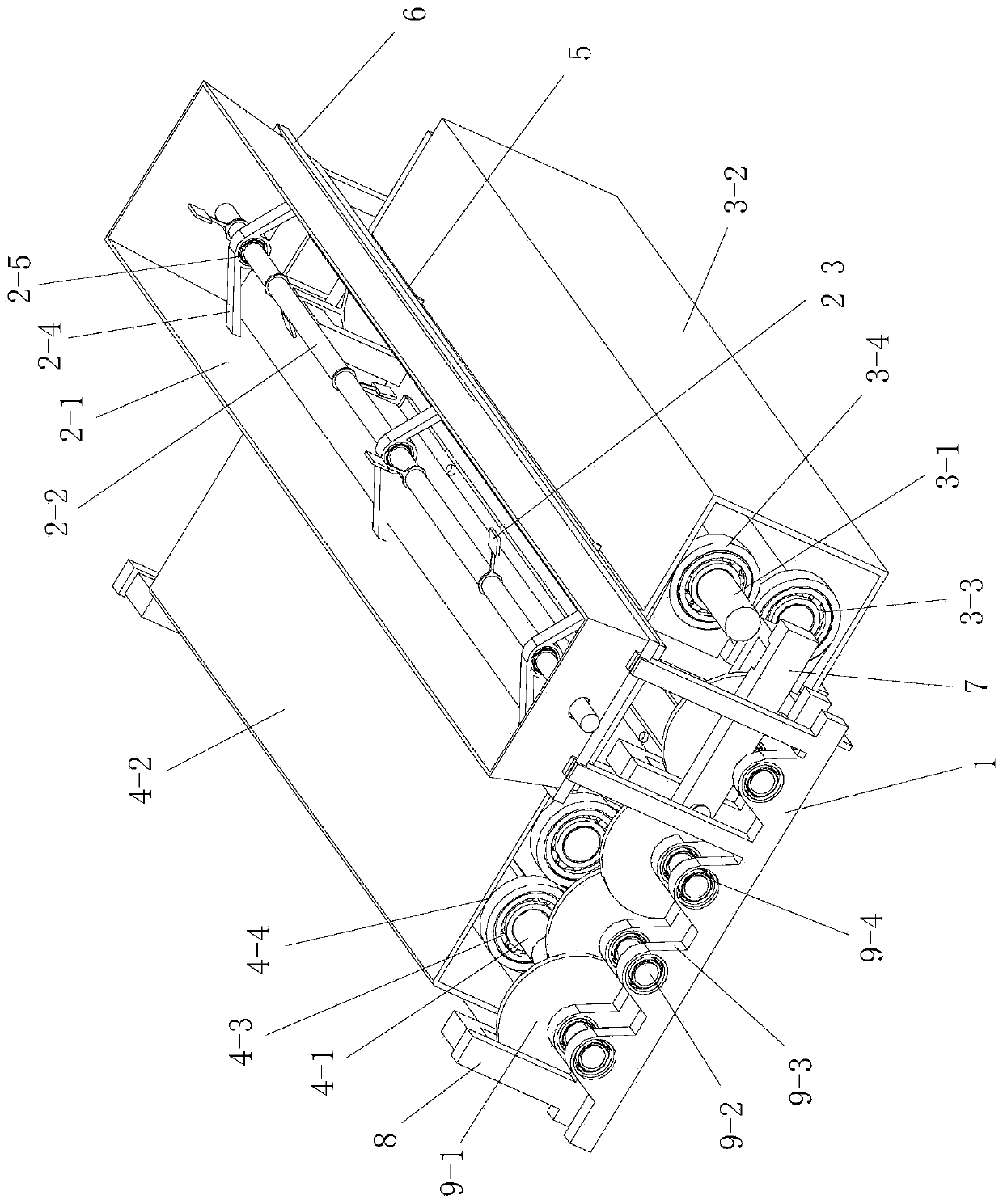

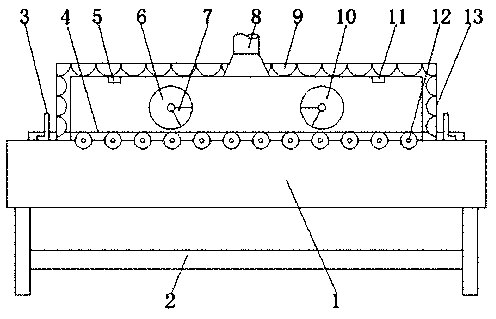

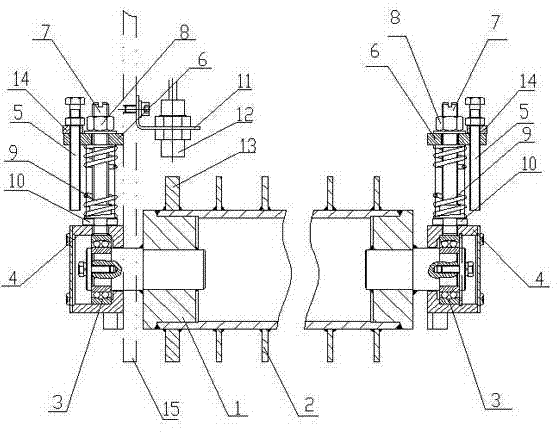

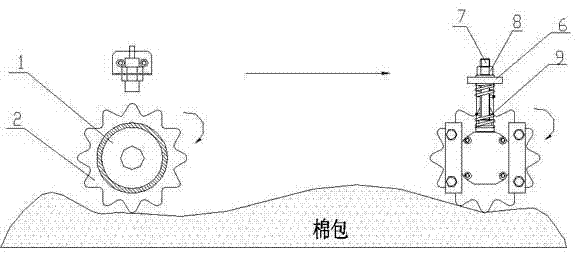

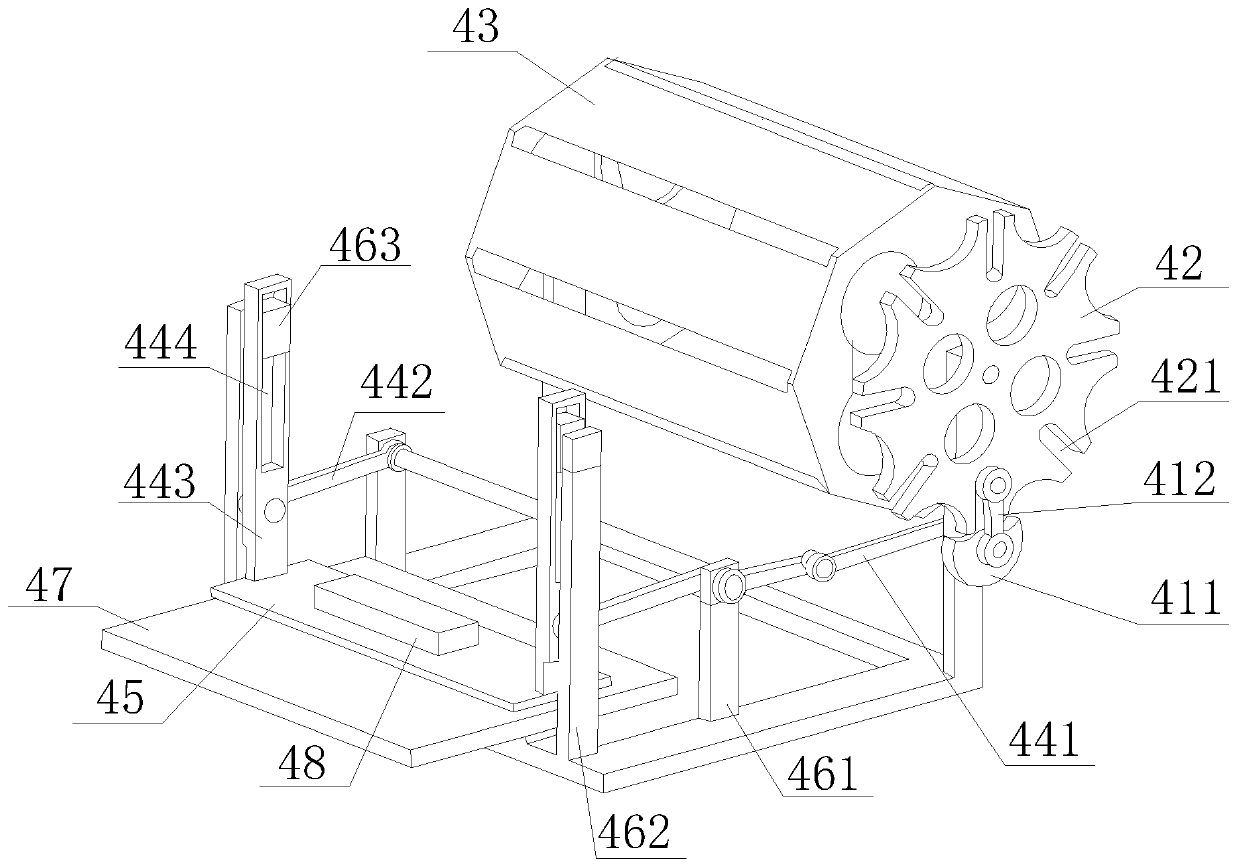

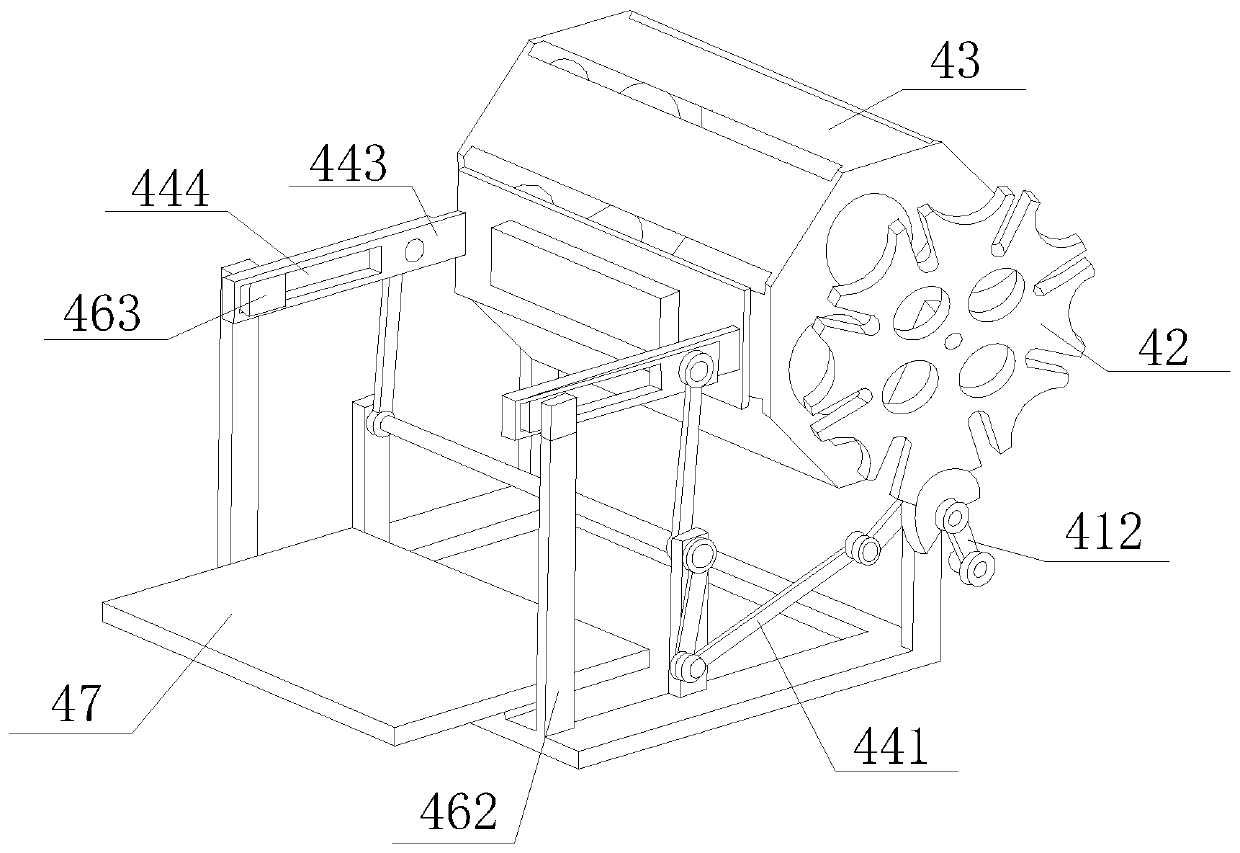

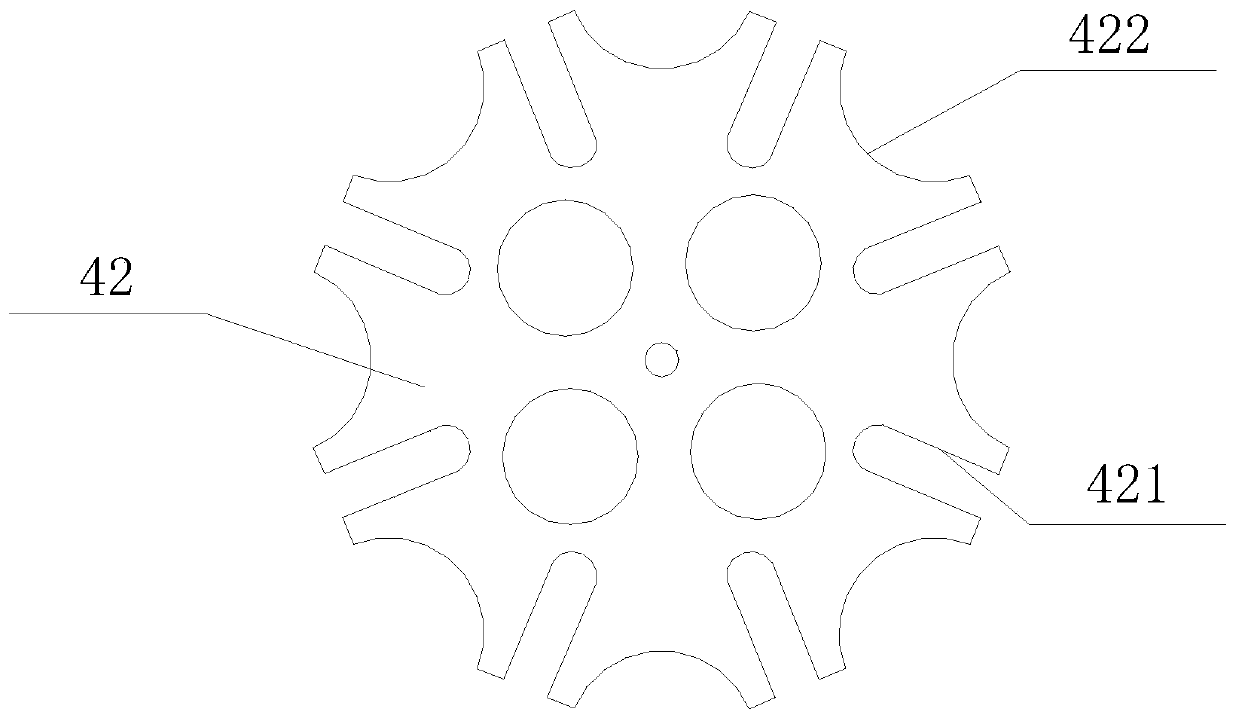

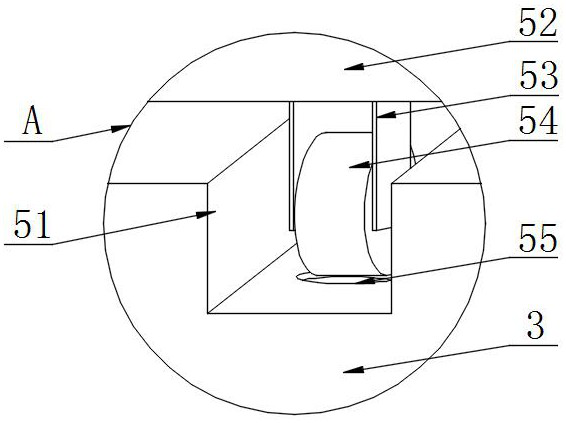

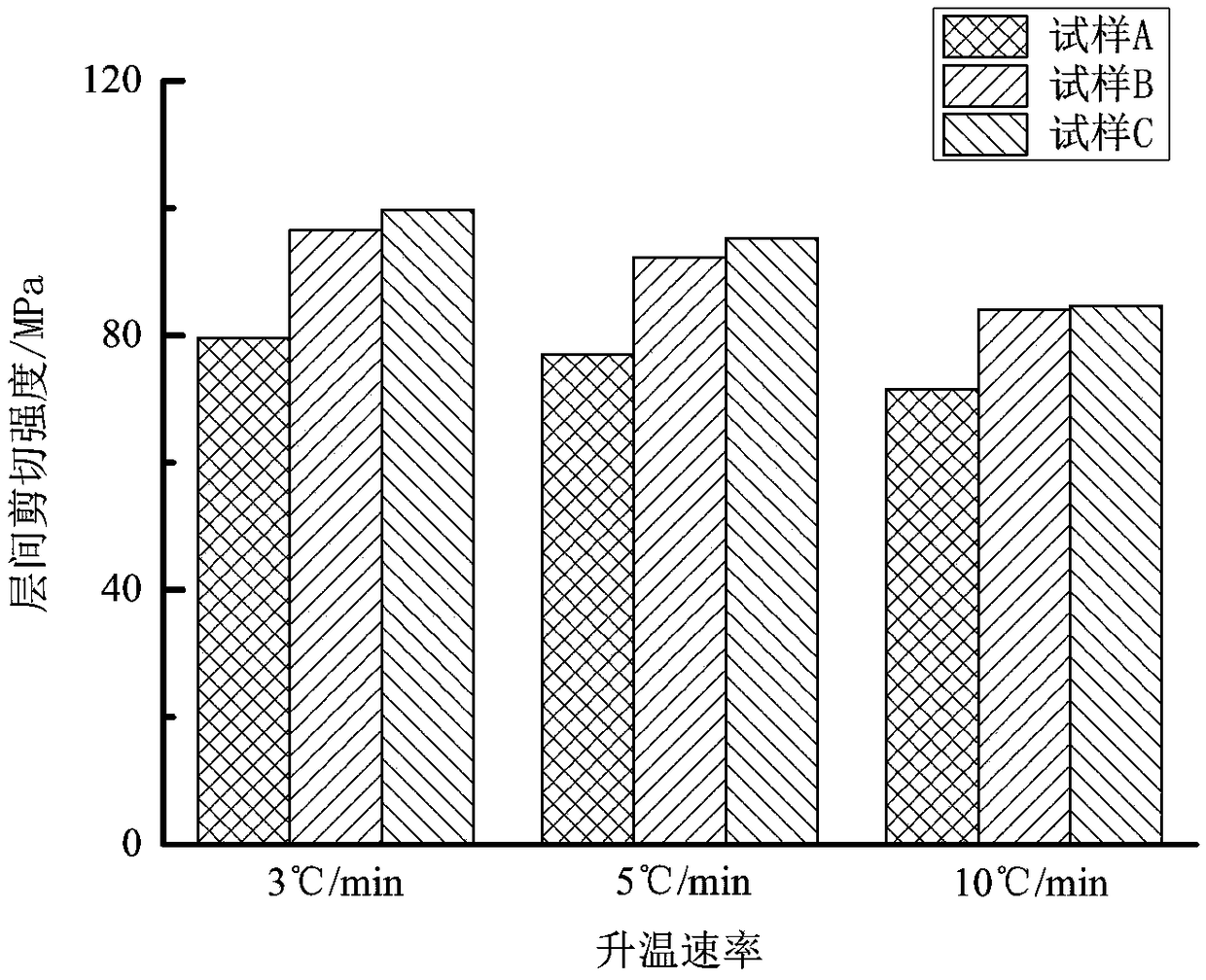

Transmission device of reciprocating bale plucker pressing roller

ActiveCN102995164AMove up and down freelyImprove performanceFibre breaking machinesFiberFree rotation

The invention provides a transmission device of a reciprocating bale plucker pressing roller. The transmission device comprises a grabbing arm, a tower body, a pressing roller barrel, a star-shaped toothed sheet, bearings and bearing blocks which are arranged on the two ends of the pressing roller and wallboards on the two sides of the pressing roller. The transmission device is characterized in that the bearings on the two ends of the pressing roller are rolling bearings, a baffle is arranged on the outer side surface of the wallboard on each side of the pressing roller, plain round holes are respectively formed on the baffles, the two baffles are respectively positioned right above the bearing blocks which correspond to one ends of the pressing roller, each bearing block is respectively connected with a threaded rod which is vertically arranged, a spring support and a compression spring are sleeved on each threaded rod, and the upper end of each threaded rod penetrates through the plain round hole of the corresponding baffle which is arranged above and is fixed through a nut. The transmission device is simple in structure, is convenient to regulate and use, and is low in manufacturing cost; when a reciprocating bale plucker operates, the motor-free rotation of the pressing roller is realized through the friction force between the star-shaped toothed sheet of the pressing roller and fibers so as to realize the purpose of pressing raw materials, and foundation is laid for the bale plucker to grab the raw materials.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

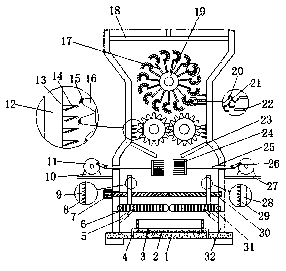

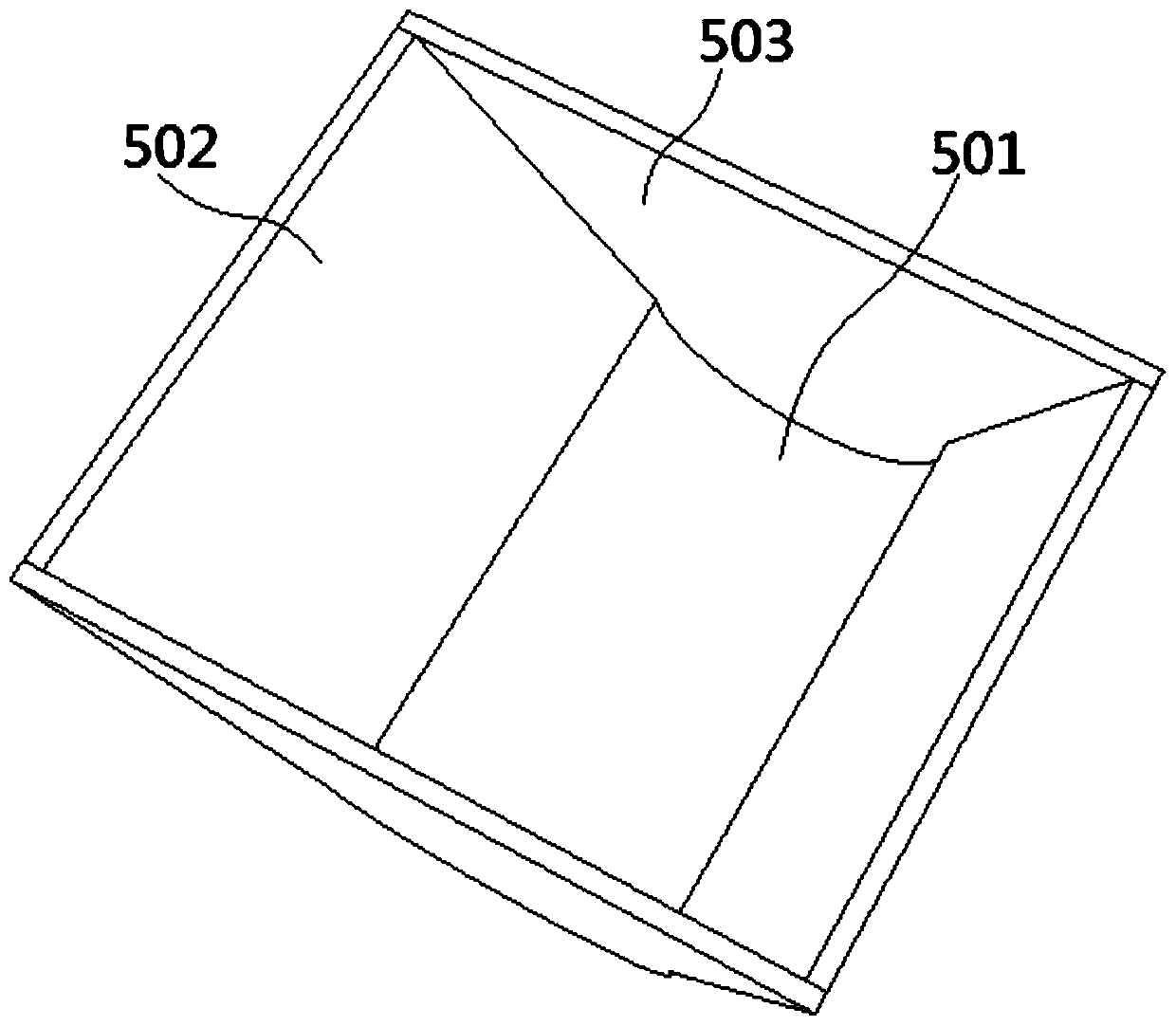

Laser leveling machine for terrace

ActiveCN104533069ALeveling precisionEffective compactionSurveying instrumentsBuilding constructionsElectric machineHigh energy

The invention relates to a laser leveling machine for a terrace. The laser leveling machine for the terrace comprises a laser receiving device, an adjustable flexible strut connected between the receiving device and an adjustable vibrating scrapping bar, a vibration motor located in the center of the vibrating scrapping bar, a horizontal sensing device arranged in the middle of a sliding carriage, the adjustable vibrating scrapping bar connected with the sliding carriage through a parallel mechanism, a servo motor for adjusting the elevation of the vibrating scrapping bar, the sliding carriage which has a smoothing function, a crate which is provided with a high energy battery and is arranged on the sliding carriage and a control box which is arranged the top end of an L shaped support, wherein the leveling machine is used for mechanically and automatically leveling or sloping concrete or sand mortar of high-precision terraces, road surfaces and floors of constructional engineering and municipal engineering. The laser leveling machine provided by the invention is high in construction efficiency, light in weight, excellent in quality, simple to operate and economic and durable to use, thereby being small laser leveling equipment with a broad use.

Owner:四平镭英建筑科技有限公司

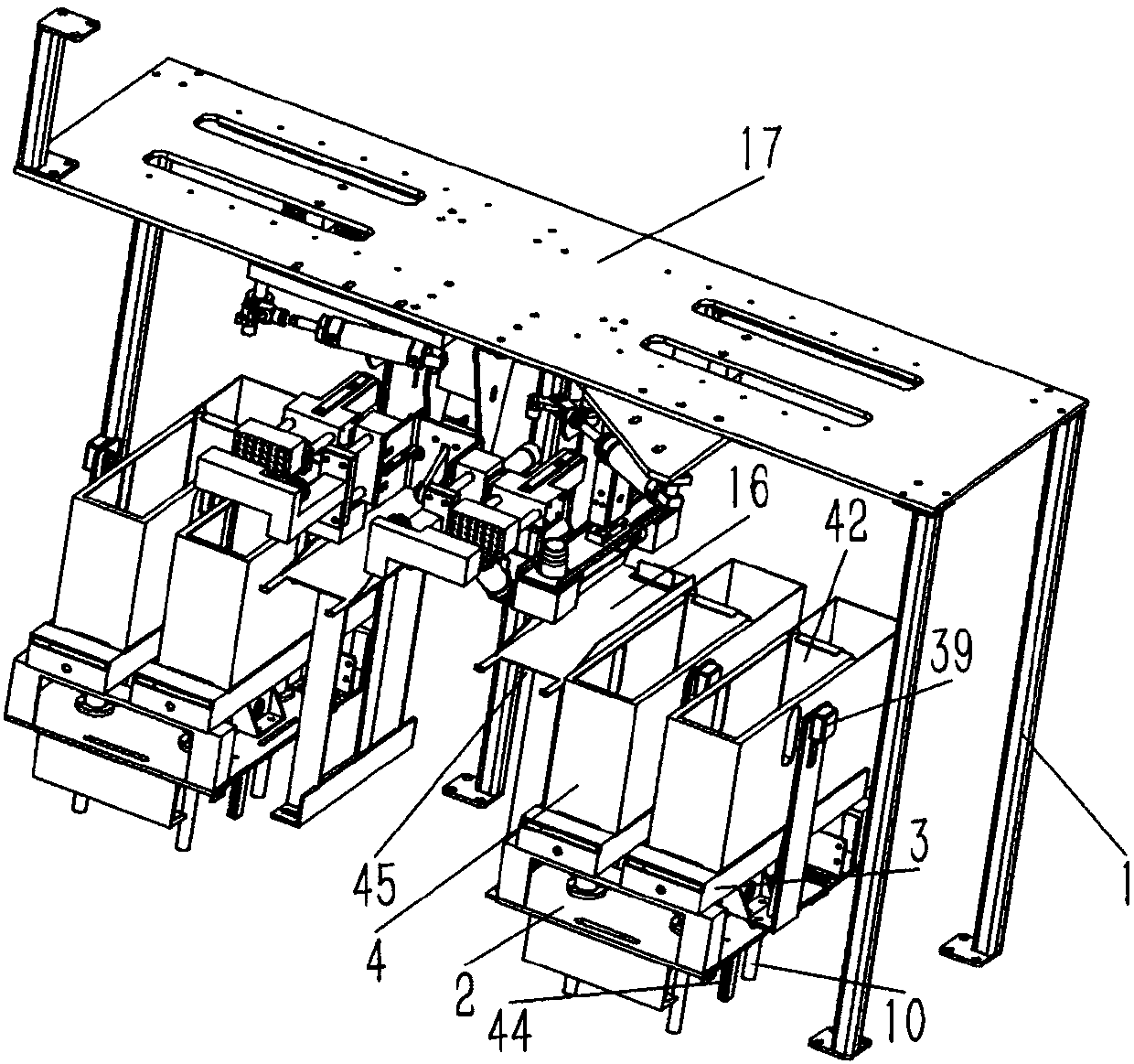

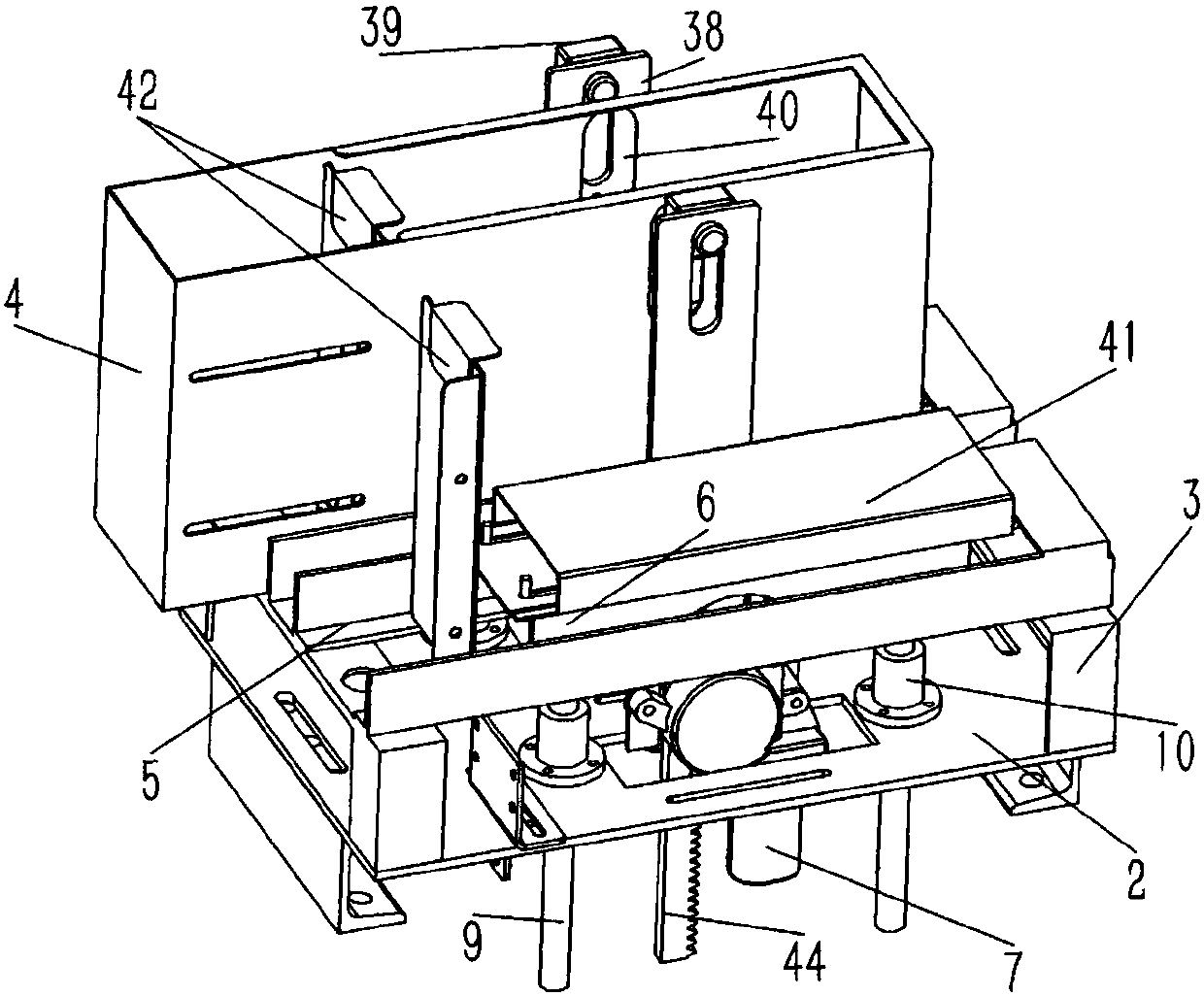

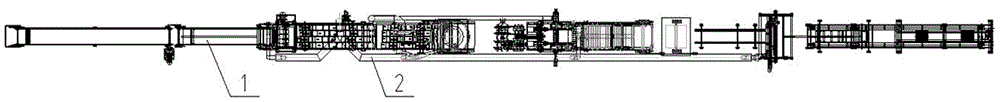

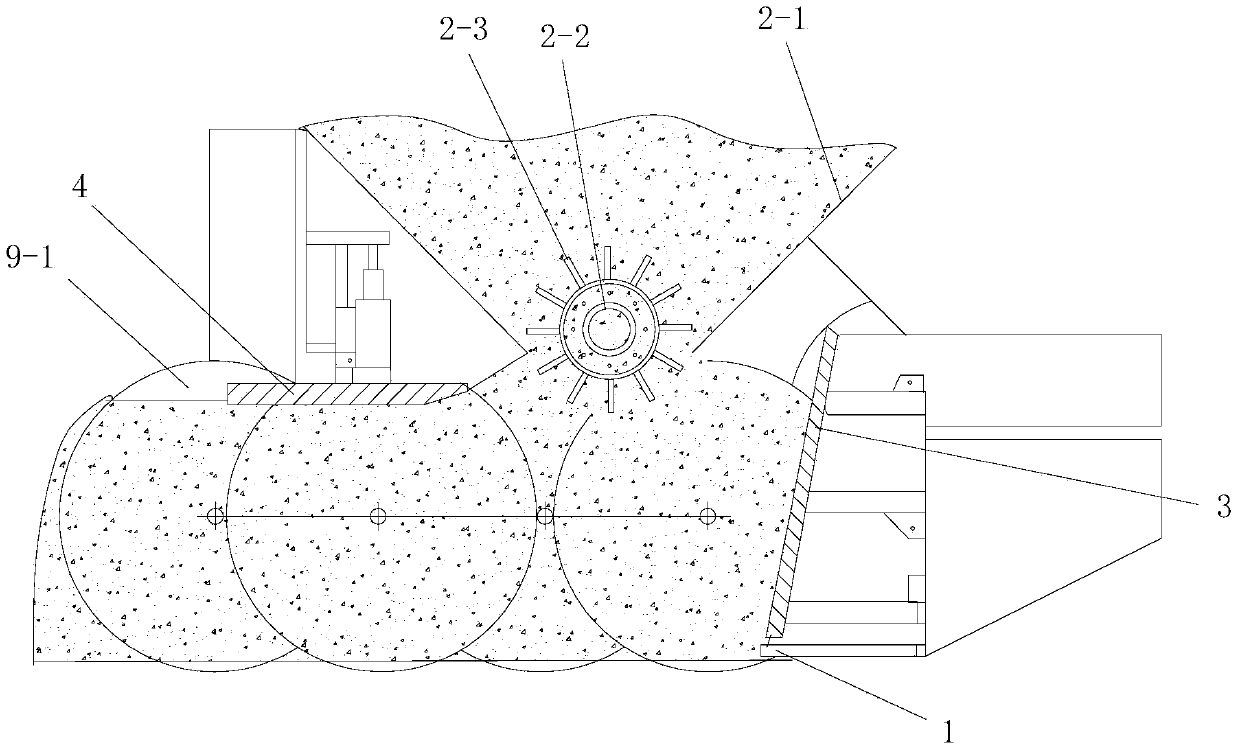

Full-automatic material and bag arranging type packing machine

ActiveCN107600473AOutstanding and Beneficial Technical EffectsPrevent Dry Run ConditionsWrapper twisting/gatheringPackaging automatic controlEdible mushroomEngineering

The invention provides a full-automatic material and bag arranging type packing machine, belongs to the technical field of packing machines, and aims at overcoming the shortages of low automation degree, low production efficiency and high labor input in the prior art. The machine comprises a packing bag absorbing part which is arranged on a rack, a culture material bagging part which is arranged above the packing bag absorbing part, a packing sealing part which is arranged at one side of the culture material bagging part, and a culture material bagged product outlet part which is formed in oneend of the packing sealing part, wherein a display screen for human-machine interaction and a PLC control box are arranged beside the culture material bagged product outlet part. Compared with the prior art, the machine has the advantages of being high in automation degree, high in production efficiency, and low in labor input cost; the machine is applicable to packing bag arranging, etc., and particularly applicable to the environment of massive bagging of edible mushroom culture materials.

Owner:ZHEJIANG HONGYE EQUIP TECH

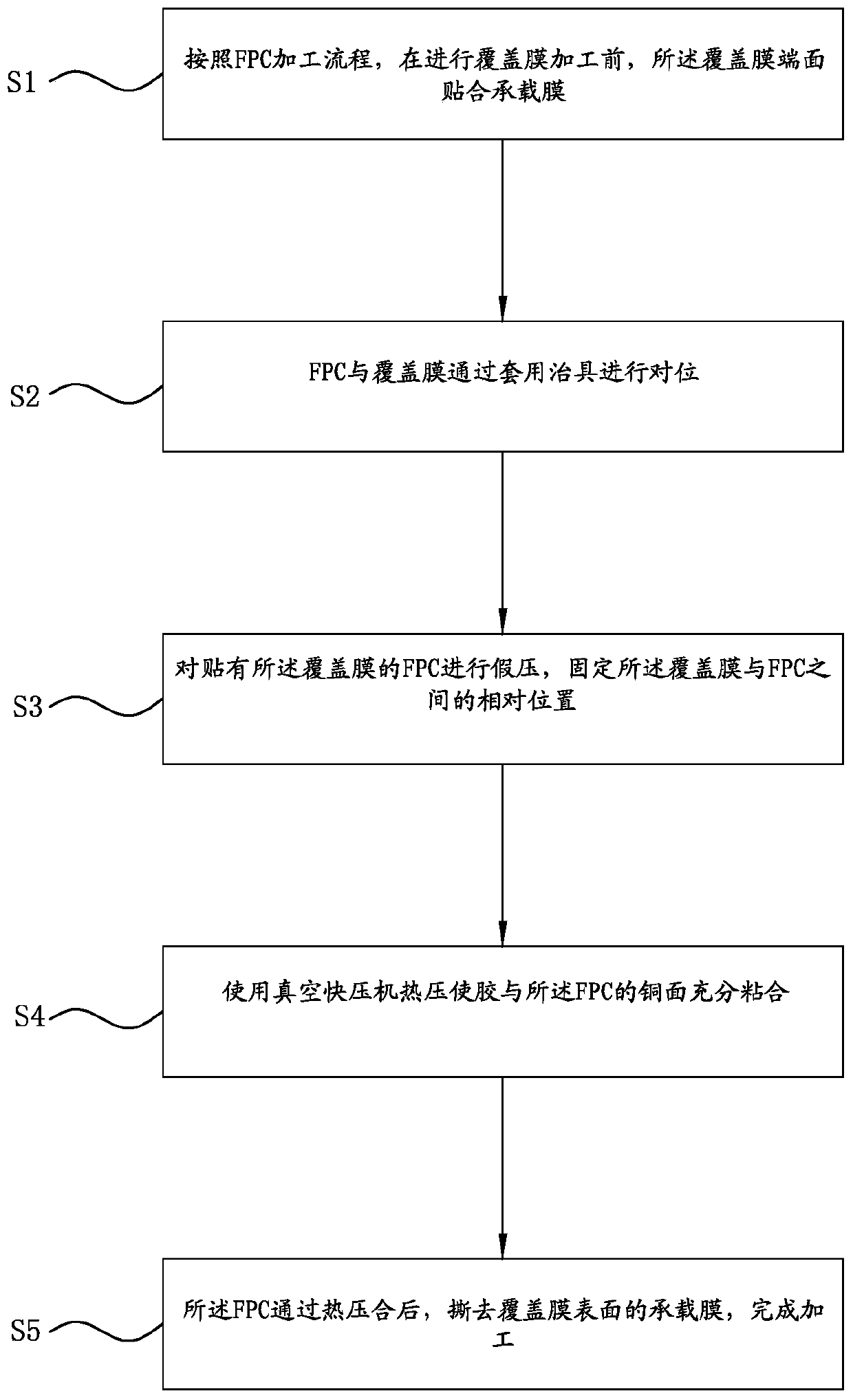

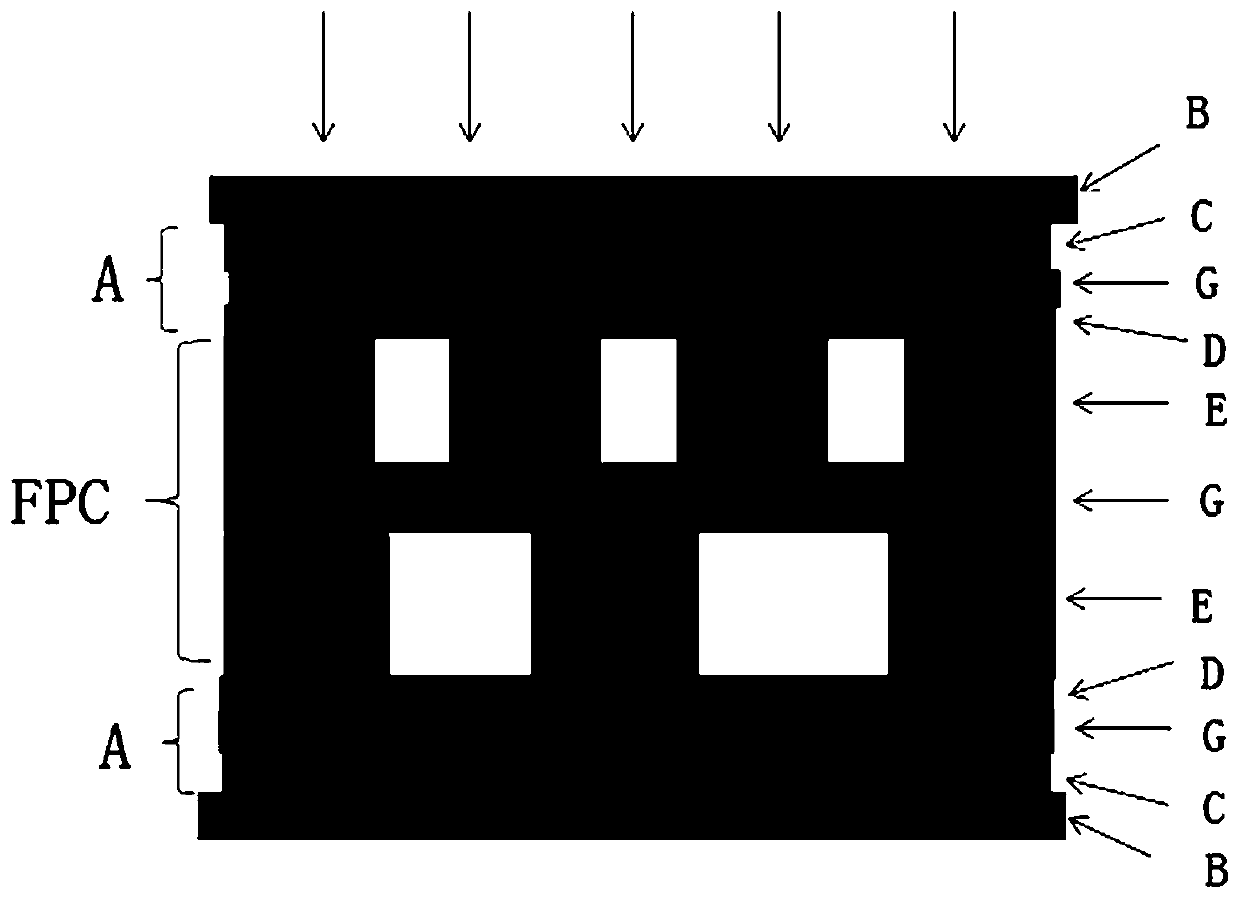

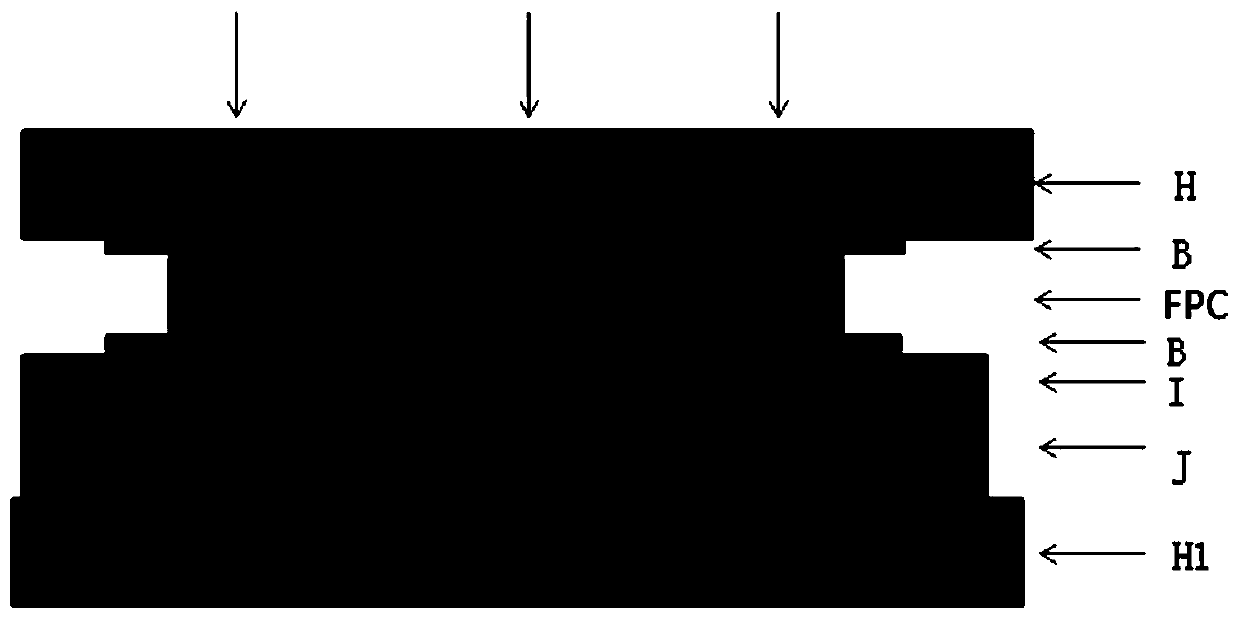

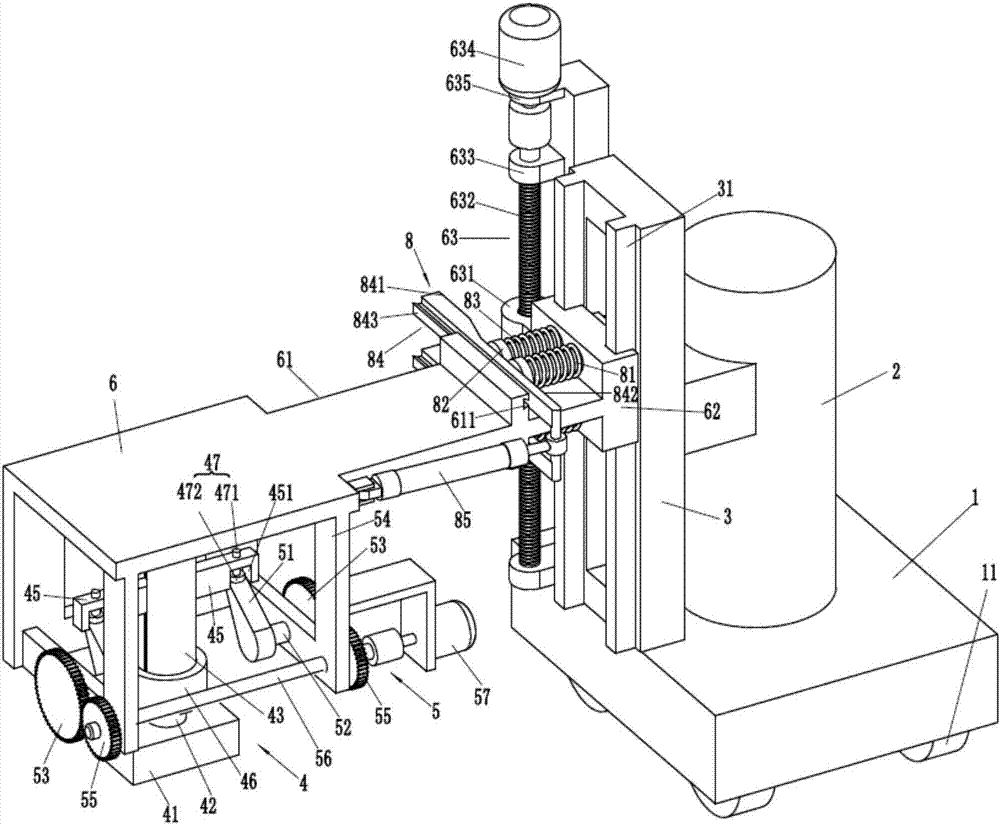

Processing method for laminating thick-copper thin cover film

InactiveCN110557893AAvoid difficultyEasy to operateLaminating printed circuit boardsEngineeringCopper

The invention discloses a processing method for laminating a thick-copper thin cover film, which comprises the steps of S1, laminating a bearing film on the end surface of the cover film before the cover film is processed according to an FPC processing flow; S2, aligning the FPC and the cover film through a sleeving jig; S3, carrying out false pressing on the FPC with the cover film, and fixing the relative position between the cover film and the FPC; S4, performing hot pressing by using a vacuum quick pressing machine to enable the glue to be fully bonded with the copper surface of the FPC; and S5, tearing off the bearing film on the surface of the cover film after the FPC is subjected to thermal lamination so as to finish the processing. The laminating difficulty of a thin cover film issolved, and the operability of selecting and attaching the bearing film is improved; the pyrograph laminating before hot pressing is additionally carried out, the temperature is lower than that of thehot pressuring, glue overflowing is not likely to happen, and the whole PFC can be slightly bonded together; and vacuum lamination is adopted for hot pressing, and air bags are used for filling and laminating, thereby not only being capable of preventing the cover film from being broken, but also being capable of enabling the cover film to be effectively compacted.

Owner:ZHUHAI ALL WINNER FPC

Tamping machine used for buildings

InactiveCN106948334AEffective compactionStable structureSoil preservationArchitectural engineeringCaster

The invention discloses a tamping machine for construction, which comprises a support seat, a column is hinged above the support column, a support plate is fixedly connected to the side wall of the column, and the tamping part is arranged on a right-angle bearing seat. The right-angle bearing seat is slidably connected to the support plate through slide rails arranged on the support plate, and universal wheels are installed on the bottom surface of the support portion. The invention can effectively compact and level the ground, and has the advantages of stable and reliable structure and convenient use.

Owner:HUZHOU ZHONGCHEN CONSTR

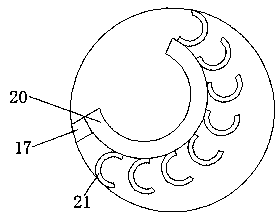

Novel road crack filling machine

ActiveCN107881898AImprove filling efficiencyReduce manual workRoads maintainenceHighway maintenanceElectric machinery

The invention provides a novel road crack filling machine, and particularly relates to the technical field of highway maintenance equipment. The novel road crack filling machine comprises a vehicle body; one end of the vehicle body is provided with an asphalt tank, the vehicle body is provided with a crack filling tube, and a crack filling opening is further movably formed in the crack filling tube; the crack filling opening comprises a crack filling opening seat, and a first crack filling tube opening and a second crack filling tube opening are oppositely formed in the crack filling opening seat; a heater is further arranged at the other end of the vehicle body, and the heater is provided with a heating metal wire; an air pump is further arranged at one end of the vehicle body, and the air pump is provided with an air tube; a scraper plate is further arranged at the bottom of the crack filling opening seat, and springs are symmetrically arranged on the two sides of the scraper plate;and a compaction device is further arranged at one end of the vehicle body and comprises a motor, the motor is arranged on the vehicle body, an output shaft of the motor is provided with a pressing disc, and a plurality of pressing plates are arranged on the outer wall of the pressing disc. The novel road crack filling machine has the advantages that the bonding strength between a crack filling oil material and a road surface is improved, the crack filling quality is improved, the labor intensity of construction personnel is reduced, and the crack filling efficiency is effectively improved.

Owner:江苏炯圣机械有限公司

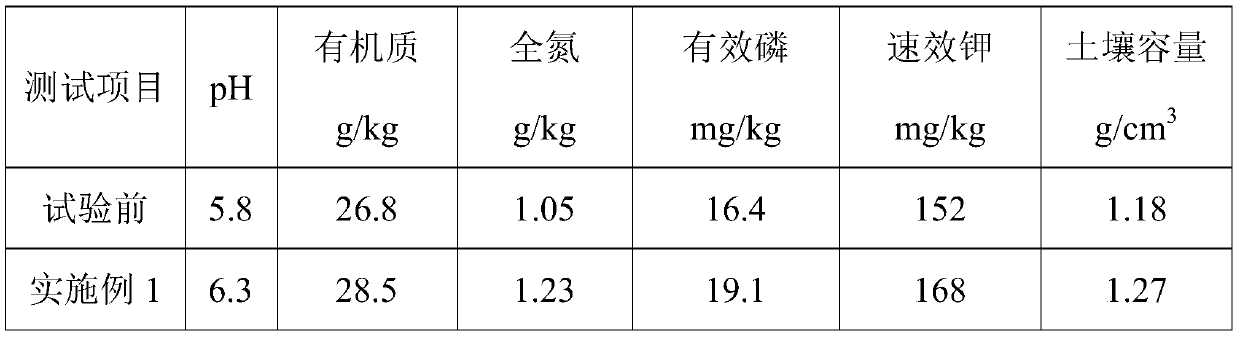

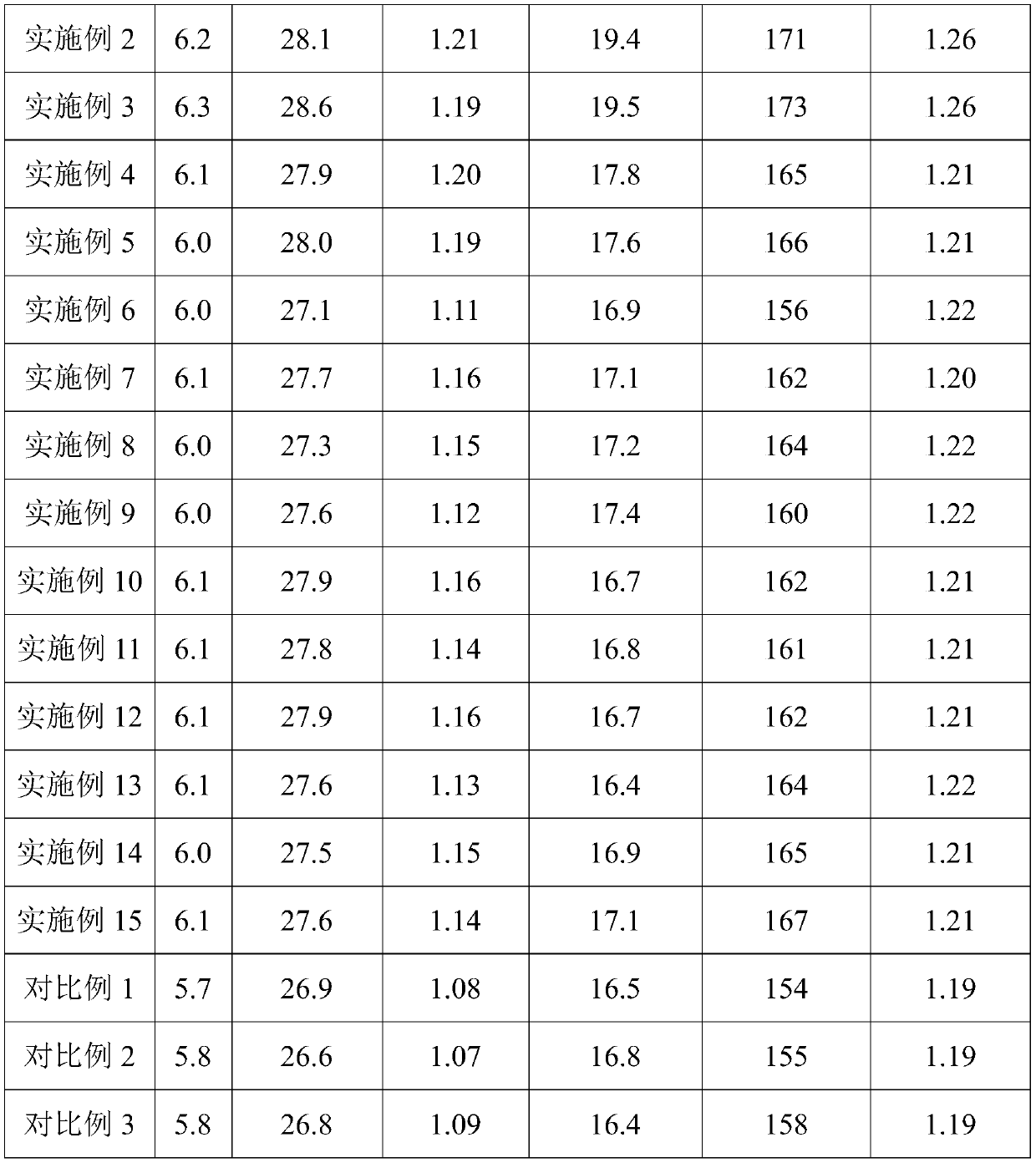

Soil remediation fertilizer prepared from kitchen waste as well as preparation method and application thereof

InactiveCN111320497AShort processing timeHigh recovery rateClimate change adaptationOrganic fertilisersBiological propertySoil remediation

The invention provides a soil remediation fertilizer prepared from kitchen waste as well as a preparation method and an application of the soil remediation fertilizer. The soil remediation fertilizeris prepared from kitchen waste subjected to anaerobic heat treatment, a complex microbial inoculant and a synergistic component. The soil remediation fertilizer prepared from the kitchen waste can reduce resource waste and effectively improve the problems of grease, germs and worm eggs of the kitchen waste, so that the physical, chemical and biological properties of soil are effectively improved,soil nutrients are maintained, and the utilization rate of the soil nutrients is increased.

Owner:时科生物科技(上海)有限公司

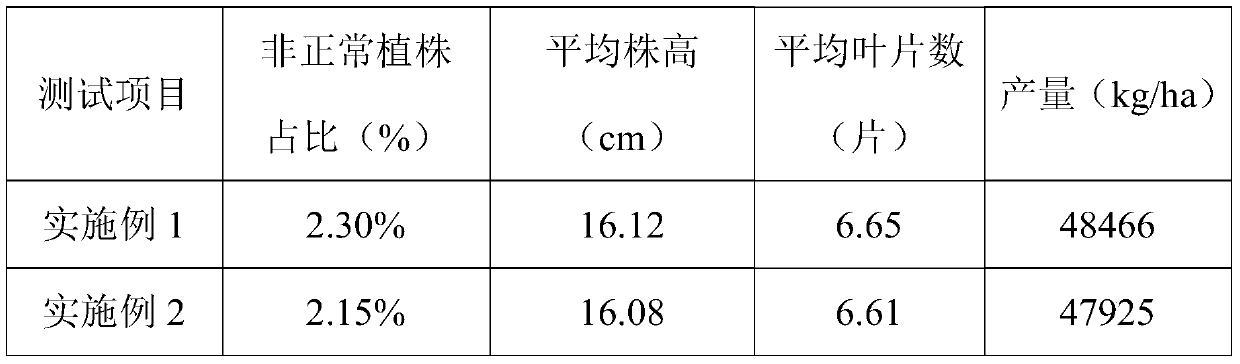

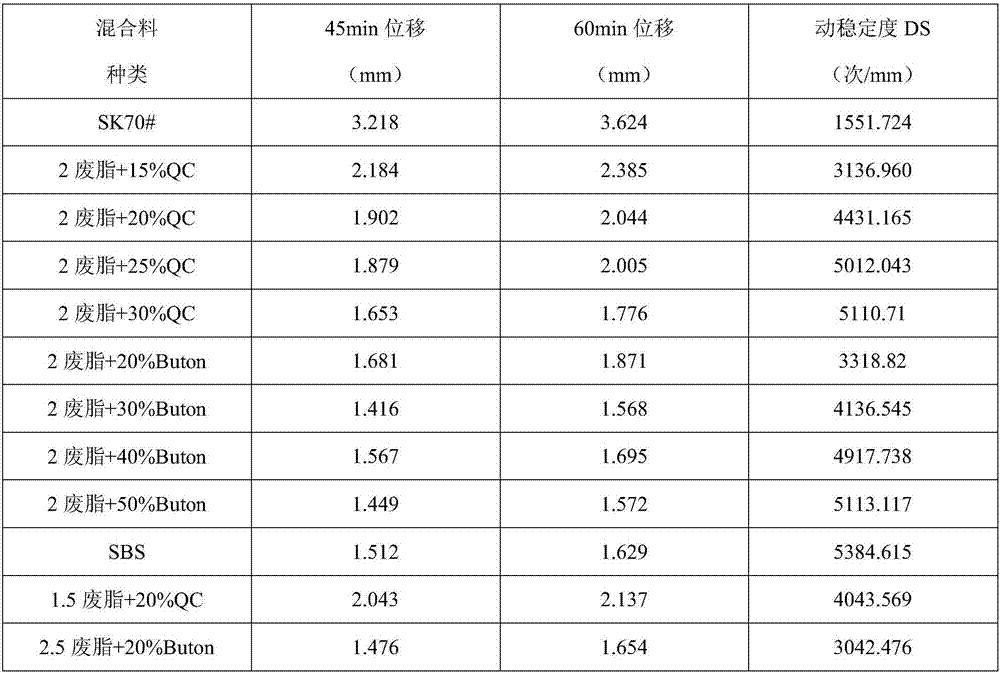

Waste grease premixed reinforced asphalt mixture and preparation method thereof

InactiveCN107500611AEasy constructionImprove workabilityClimate change adaptationGreenhouse gasHigh energy

The invention discloses a waste grease premixed reinforced asphalt mixture and a preparation method thereof. The preparation method comprises the following steps: step 1, adding 1.5 to 2.5 percent o waste grease into matrix asphalt, uniformly stirring, developing, and obtaining waste grease soft asphalt; step 2, premixing aggregates by using the waste grease soft asphalt prepared in step 1, and obtaining a premixed material; step 3, re-mixing the premixed material obtained in step 2 by using rock asphalt powder, and obtaining a remixed material; step 4, adding mineral powder into the remixed material obtained in step 3, and uniformly mixing, thus obtaining the waste grease premixed reinforced asphalt mixture. The waste grease premixed reinforced asphalt mixture can well use the waste grease and can solve the problems in the asphalt mixture pavement laying process such as high energy consumption, emission of a great amount of greenhouse gas and harmful gas and the like.

Owner:CHANGAN UNIV +1

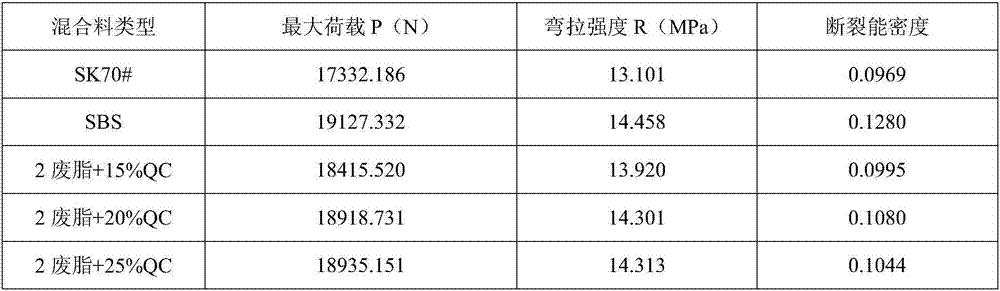

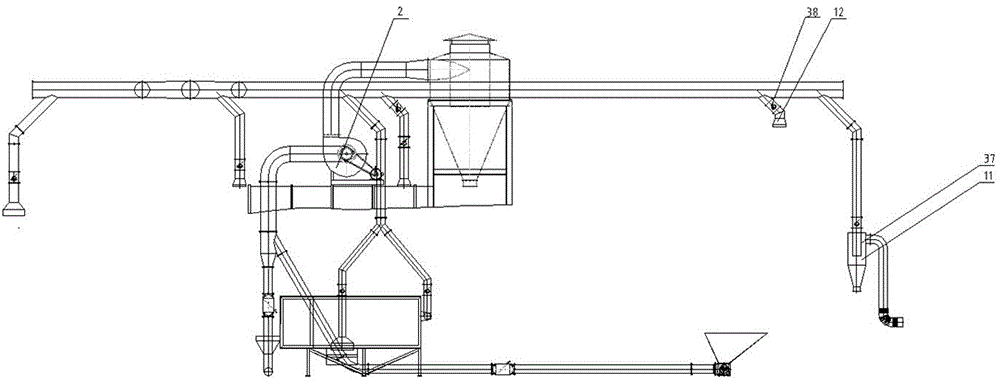

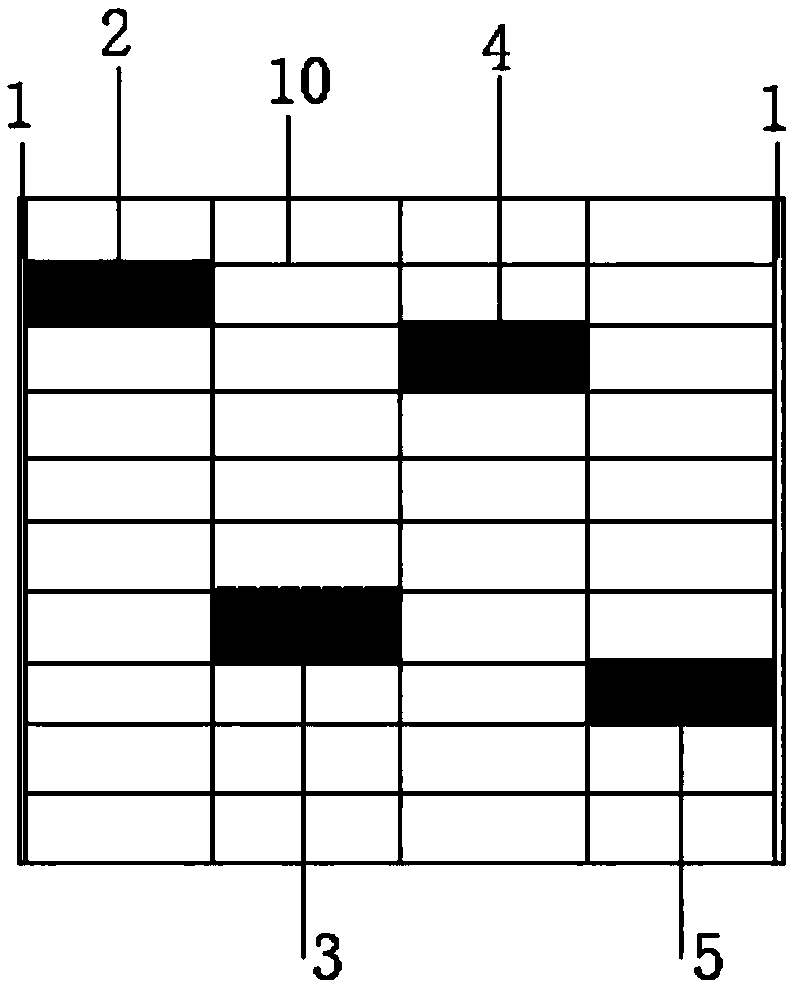

Straw plate producing and processing system

ActiveCN106003280AEquipment collocation is reasonableGood continuityLamination ancillary operationsLaminationRice strawProcess engineering

A straw plate producing and processing system comprises a main production system and a material recycling and dust removing system. The material recycling and dust removing system is arranged at the upper end of the main production system. The main production system is composed of a straw supplying and feeding module, an unbundling module, a stepping separation module, a straw conveying module, a forming module, a conveying module, a cut-off module and an end sealing module. The material recycling and dust removing system is composed of a material recycling module and a dust removing module. The straw supplying and feeding module, the unbundling module, the stepping separation module, the straw conveying module, the forming module, the conveying module, the cut-off module and the end sealing module are sequentially connected from left to right. The material recycling module is connected with the dust removing module. The straw plate producing and processing system is reasonable in overall system device matching, good in continuity and high in transfer efficiency; and in the production process, no auxiliary materials need to be added, straw plates are completely formed by processing straw, and the high-quality, high-strength and purely-natural straw plates can be produced.

Owner:高唐融知融智科技服务有限公司

Construction method for synchronously paving smooth and rough asphalt pavements

ActiveCN108517734AEffective compactionGuaranteed spreading amountIn situ pavingsChipsealArchitectural engineering

The invention discloses a construction method for synchronously paving smooth and rough asphalt pavements. The construction method comprises the following steps: performing construction preparation; mixing pre-coated gravel; transporting materials; paving a micro-base layer; positioning a pre-coated gravel spreading controller in place; evenly spreading the pre-coated gravel; shifting the gravel spreading controller; repeating synchronous paving; performing synchronous rolling; closing the traffic; and detecting smooth and rough asphalt layers. The technology can complete the spreading of thepre-coated gravel in a short time so as to greatly improve the working efficiency, and simultaneously can improve the bonding integrality of the pre-coated gravel and the asphalt layers so as to effectively ensure the overall engineering quality of the road.

Owner:中交一公局第五工程有限公司 +1

Alternanthera philoxeroides straw crushing device for river channel cleaning

ActiveCN109168640APrevent hanging onSolve feeding difficultiesFeeding-stuffCrop conditionersEngineeringAlternanthera

The invention belongs to the technical field of river channel cleaning, in particular to an alternanthera philoxeroides straw crushing device for river channel cleaning. Aiming at the problem that alternanthera philoxeroides straws are intertwined easily and difficult to feed, the following scheme is proposed: the device includes a base; the base is provided with supporting legs in the four corners of the top outer wall thereof, the same box body is arranged on the top outer walls of the four supporting legs; the box body is provided with a feeding inlet in the top outer wall thereof; the boxbody is provided with a first through hole and a first groove in two inner walls near the feeding inlet respectively; and the inner walls of the first through hole and the first groove are rotationally connected with a feeding wheel through bearings. The feeding wheel can be driven to rotate by a first rotating motor. Through a feeding hook and barbs, alternanthera philoxeroides straws can be hooked and fed to crushing rollers. Baffles can prevent the straws from being hooked to the feeding hook. Therefore, the problem that the alternanthera philoxeroides straws are intertwined easily and difficult to feed can be solved.

Owner:嘉兴麦瑞网络科技有限公司

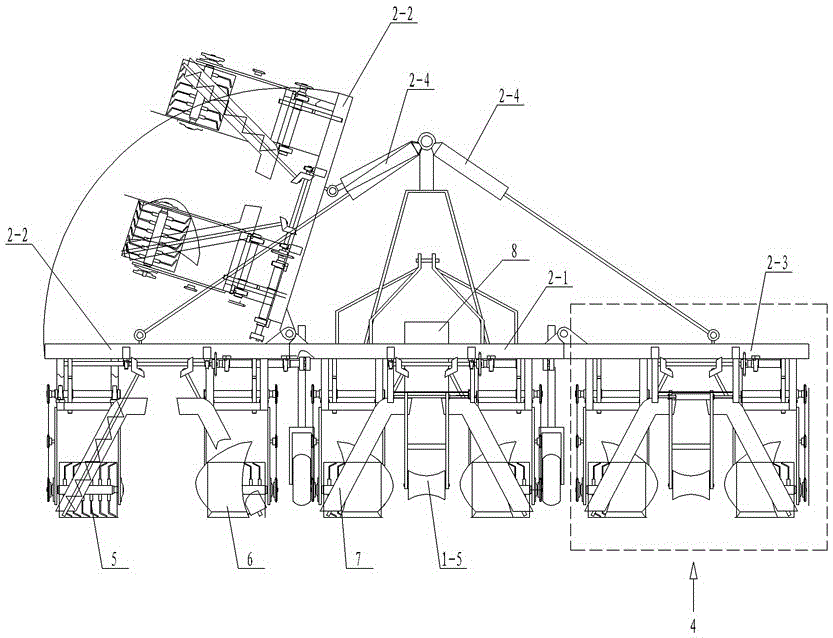

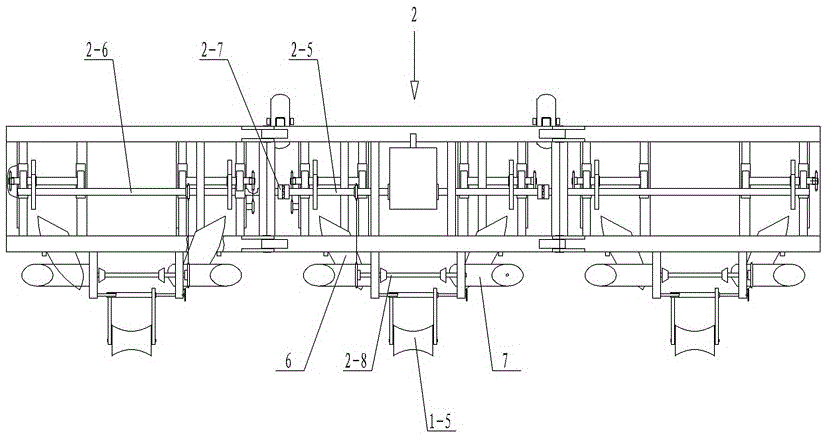

Wide-narrow row sugarcane banking machine with fine-tunable ridge surface shaping devices

InactiveCN106416469AEffective compactionImprove passabilitySoil-working equipmentsGear wheelEngineering

The invention relates to a wide-narrow row sugarcane banking machine with fine-tunable ridge surface shaping devices, and belongs to the technical field of agricultural machinery. The wide-narrow row sugarcane banking machine has a plurality of fine-tunable ridge surface shaping devices, wherein the ridge surface shaping devices are arranged on a rack of the banking machine at intervals. Each ridge surface shaping device includes a motor arranged on the rack, a horizontally-arranged screw rod, a sleeve, an I-shaped frame, a spring pull rod and a shaping wheel. Transmission gear sets are arranged on an output shaft of the motor and one end of the screw rod, screw threads engaged with the screw rod are arranged inside the sleeve, the upper portion of the I-shaped frame is connected with the sleeve in a hinged mode, the middle portion of the I-shaped frame is arranged on the rack through the spring pull rod, the shaping wheel is arranged at the lower portion of the I-shaped frame, sensors are arranged at the two sides of a frame body of the I-shaped frame and are used for detecting and measuring the distance between two sugarcane rows, and the motor is used for receiving the signal from the sensors and driving the I-shaped frame to move left and right through the screw rod. The fine-tunable ridge surface shaping devices can be used for conducting effective compaction on cultivation soils of sugarcane planted in narrow rows and wide rows alternately.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

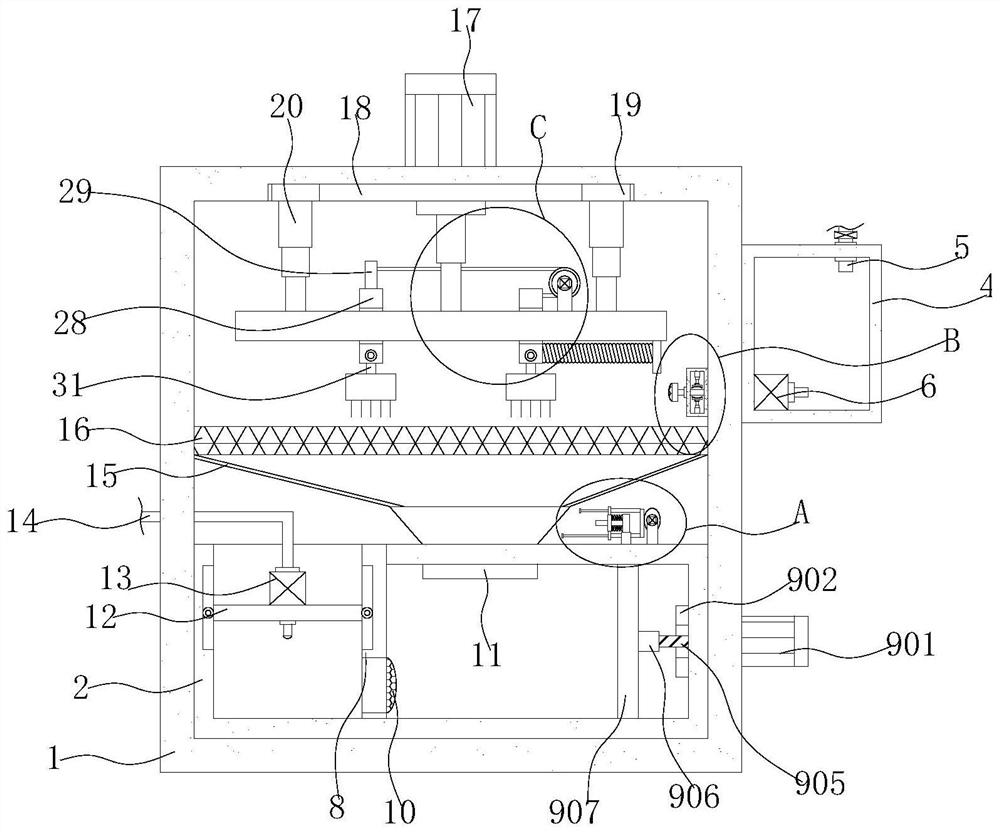

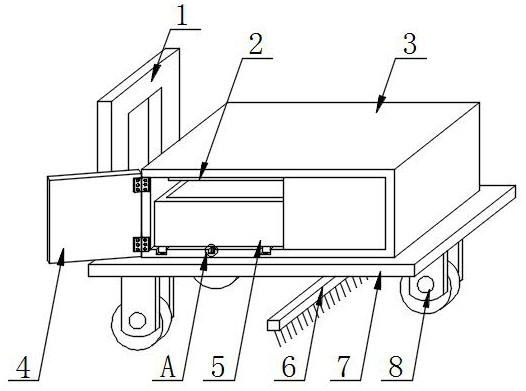

Cleaning device for numerical control milling machine for processing conveying machinery parts

ActiveCN111889777AEffective vibration effectAvoid security impactMilling equipment detailsMaintainance and safety accessoriesNumerical controlProcess engineering

The invention discloses a cleaning device for a numerical control milling machine for processing conveying machinery parts, and relates to the technical field of conveying machinery. The cleaning device for the numerical control milling machine for processing the conveying machinery parts comprises a numerical control milling machine shell, a collecting box is welded and mounted at the bottom of the inner side of the numerical control milling machine shell, a vibrating mechanism is arranged at the top of the collecting box, a cleaning liquid box is welded and mounted on the outer wall of one side of the numerical control milling machine shell, an infusion tube is welded and mounted on the outer surface of the top of the cleaning liquid box, and one end of the infusion tube extends into thecleaning liquid box. According to the cleaning device for the numerical control milling machine for processing the conveying mechanical parts, a certain vibration effect can be effectively carried out when waste materials are collected, the situation that debris remains in the device and cannot be well recycled can be well avoided, the collection rate of the device for collecting the debris can be effectively improved, and the situation that a worker manually recovers the debris, the debris has certain safety influence on the worker can be effectively avoided.

Owner:洛阳米科尼精密机械有限公司

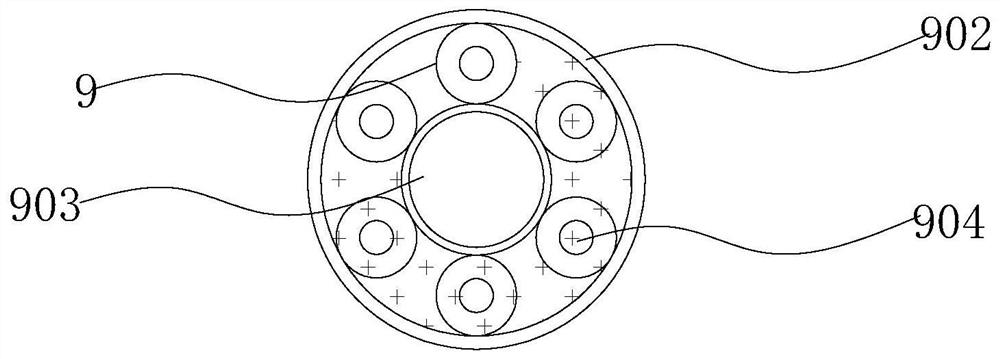

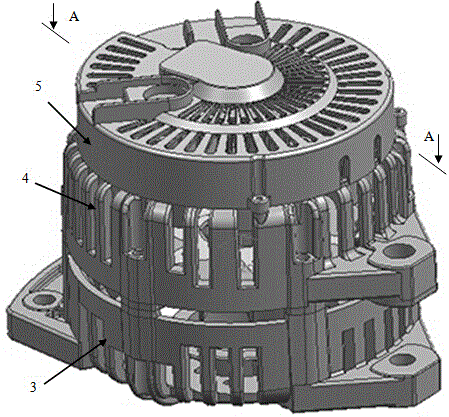

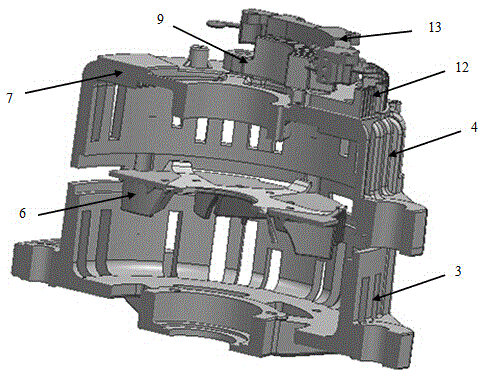

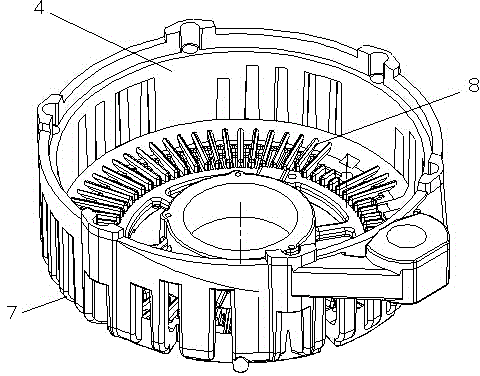

Large power generator

InactiveCN105703543AStrong cooling effectEasy assemblyStructural associationSupports/enclosures/casingsStatorDynamo

The invention discloses a large power generator. The large power generator comprises a motor casing, a stator, a rotor and a main shaft, wherein the motor casing comprises a plastic outer cover, a back cover and a front cover from up to down, a fan is arranged between the front cover and the back cover, and the inner surface of the back cover is provided with heat radiation ribs projecting inwards. According to the large power generator, the inner fan inner heat radiation rib air cooling technology is employed, self temperature can be effectively controlled during large current output, a four-tube parallel structure is employed for rectification, output requirements in different rotating speed states can be satisfied, and a constant output voltage can be simultaneously realized.

Owner:WUXI XINERGAO ELECTRIC

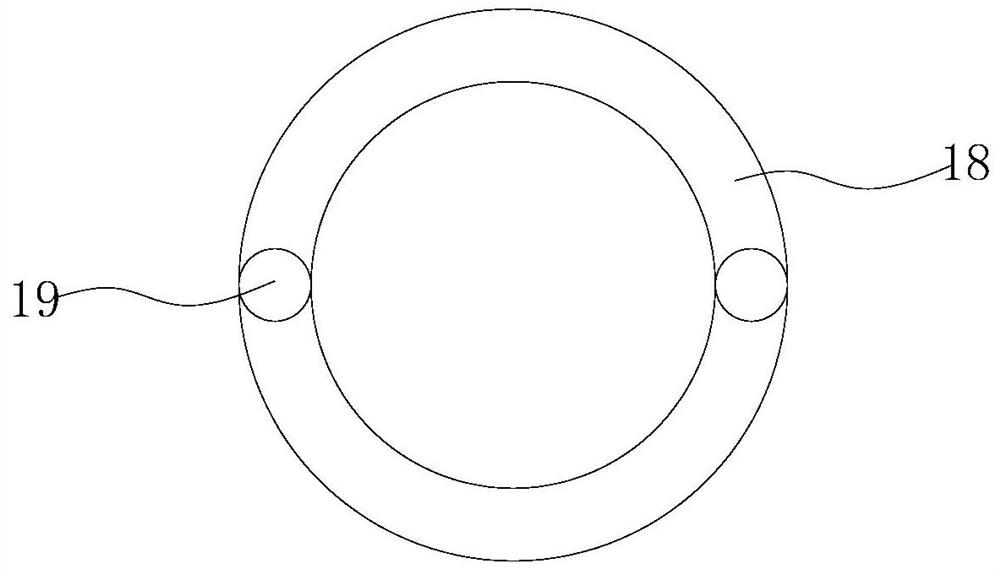

Concrete pavement paving device and method based on weaving mechanism

Owner:CHANGAN UNIV

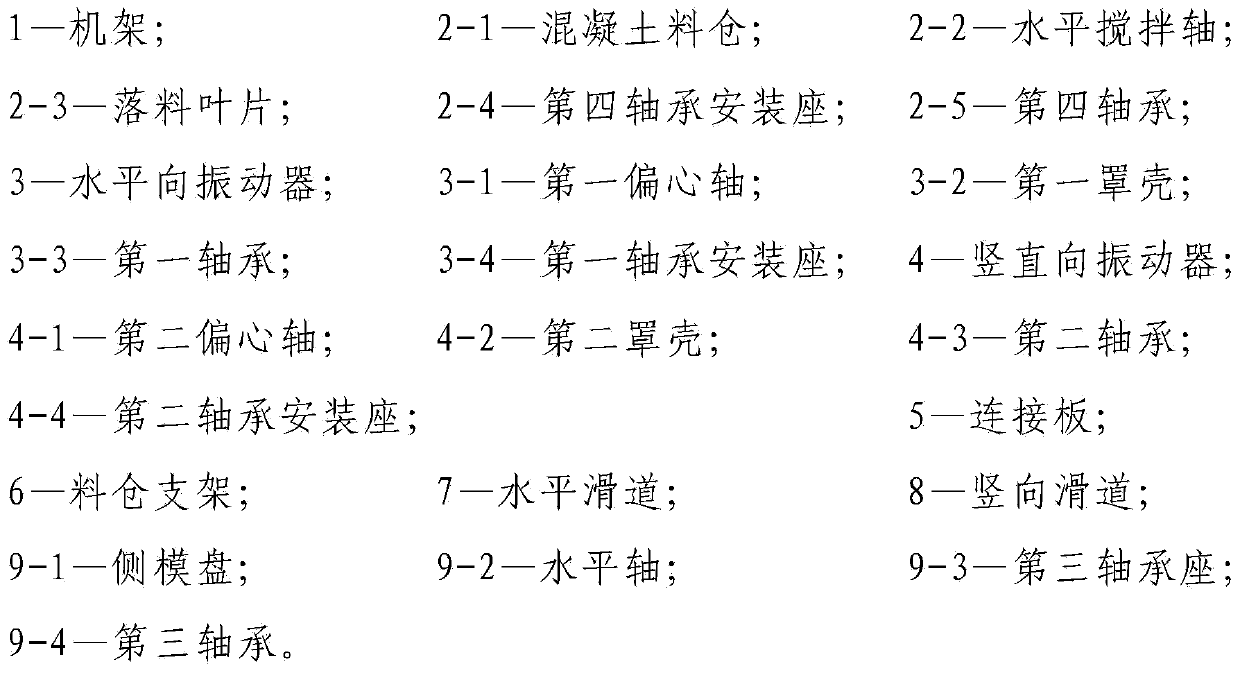

Panel processing equipment for furniture manufacturing

InactiveCN109489394AEffective compactionAvoid deformationDrying solid materials with heatDrying machines with progressive movementsEngineeringMoisture sensor

The invention discloses panel processing equipment for furniture manufacturing. The panel processing equipment comprises a driving machine case, a rack, a conveying belt, a driving press roll, an infrared heating tube and a drying room body. The driving machine case is arranged on the rack and provided with the conveying belt. The drying room body is arranged above the conveying belt and mounted on the driving machine case. A temperature sensor and a humidity sensor are mounted on the top wall inside the drying room body. The infrared heating tube is mounted on the inner wall of the drying room body. The driving press roll and a driven press roll are mounted inside the drying room body. The top of the drying room body is provided with a temperature and humidity adjustment opening. The panel processing equipment for furniture manufacturing is simple in structure and convenient to use; by means of the drying room body, different panels can be better in adaptability, the drying process ismore stable, and the drying effect is better; the panels can be compacted effectively; the problem that the panels deform due to drying is prevented; the drying temperature and humidity are controlled precisely; and the panel processing equipment is stable in performance and good in processing effect.

Owner:泰兴市万福隆红木家具有限公司

Transmission device of reciprocating bale plucker pressing roller

ActiveCN102995164BMove up and down freelyImprove performanceFibre breaking machinesFiberFree rotation

The invention provides a transmission device of a reciprocating bale plucker pressing roller. The transmission device comprises a grabbing arm, a tower body, a pressing roller barrel, a star-shaped toothed sheet, bearings and bearing blocks which are arranged on the two ends of the pressing roller and wallboards on the two sides of the pressing roller. The transmission device is characterized in that the bearings on the two ends of the pressing roller are rolling bearings, a baffle is arranged on the outer side surface of the wallboard on each side of the pressing roller, plain round holes are respectively formed on the baffles, the two baffles are respectively positioned right above the bearing blocks which correspond to one ends of the pressing roller, each bearing block is respectively connected with a threaded rod which is vertically arranged, a spring support and a compression spring are sleeved on each threaded rod, and the upper end of each threaded rod penetrates through the plain round hole of the corresponding baffle which is arranged above and is fixed through a nut. The transmission device is simple in structure, is convenient to regulate and use, and is low in manufacturing cost; when a reciprocating bale plucker operates, the motor-free rotation of the pressing roller is realized through the friction force between the star-shaped toothed sheet of the pressing roller and fibers so as to realize the purpose of pressing raw materials, and foundation is laid for the bale plucker to grab the raw materials.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

Automatic packaging device for colored crepe paper

InactiveCN111377283AEasy to carryAdjustable tightnessPaper article packagingFolding thin materialsCrêpe paperIndustrial engineering

The invention belongs to the technical field of crepe paper packaging, and provides an automatic packaging device for colored crepe paper. The automatic packaging device for the colored crepe paper comprises a bearing frame, an adjusting roller, a paper pressing roller, a labeling device and a folding device; the labeling device comprises an eccentric member, a driven member, a rotating plate anda circulating moving device; the folding device comprises a paper bearing device, a drawing device, an edge folding device, a compacting device and a discharging device; and the discharging device comprises a moving rail and a clamping device located on moving rail, the clamping device comprises an upper clamping plate and a lower clamping plate, wherein the upper clamping plate and the lower clamping plate are connected through a shaft, and an air cylinder is arranged on at the end part of the lower clamping plate. The cutting, edge-folding and discharging compacting of the crepe paper can beeffectively achieved, the working efficiency is improved, and the labor cost is reduced.

Owner:青州偶园纸品有限公司

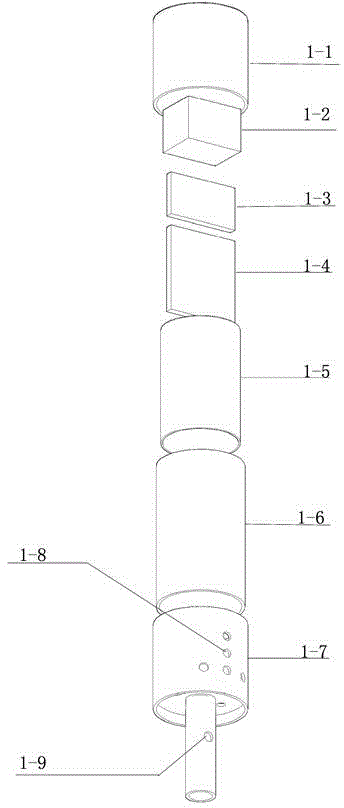

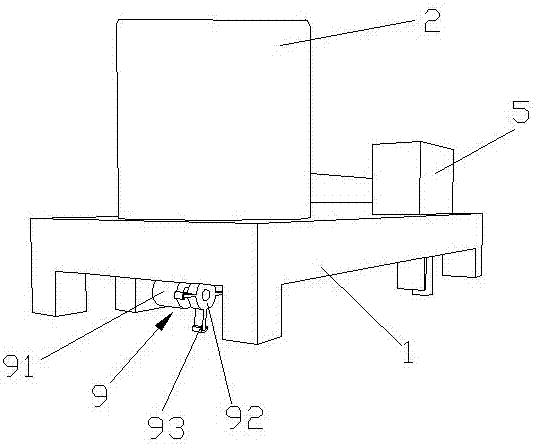

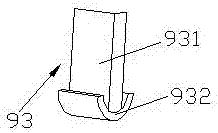

Moon shallow layer sampling tool with sequence preserving and packaging functions

ActiveCN112067345AEffective compactionNot lostWithdrawing sample devicesTool bitStructural engineering

The invention relates to a moon shallow layer sampling tool with sequence preserving and packaging functions, which comprises a cut-in cutter head, a bottom connector, a bottom packaging sheet, a packaging inner tube and a packaging outer tube, the packaging inner tube is sleeved in the packaging outer tube in a sliding manner, and a compaction plunger is arranged in the packaging inner tube. Thecompaction plunger is connected to a top connector at the top of the packaging inner tube through a spring. The bottom packaging sheet is installed at one end of the bottom connector, and the cut-in cutter head is installed at the other end of the bottom connector. One end of the bottom connector is installed at the bottom of the packaging outer tube. Before sampling, the packaging inner tube is partially located in the bottom connector and opens the bottom packaging sheet, and after sampling, the packaging inner tube slides along the packaging outer tube and moves out of the bottom connectorto close the bottom packaging sheet. According to the invention, the assembly with order preserving and packaging functions is integrated at the head position of the sampling tool, so that the acquired lunar soil stratification information can be effectively ensured during lunar soil shallow layer sampling.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

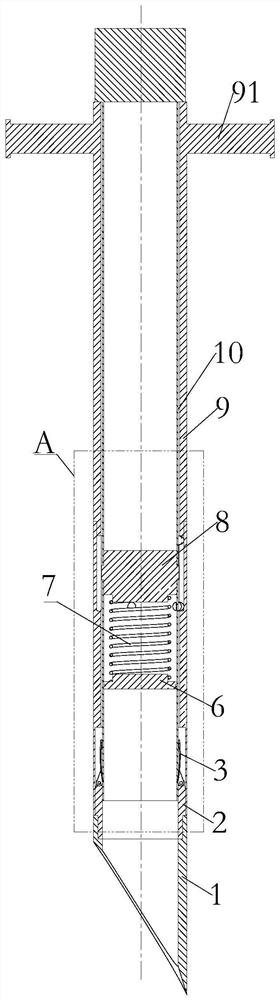

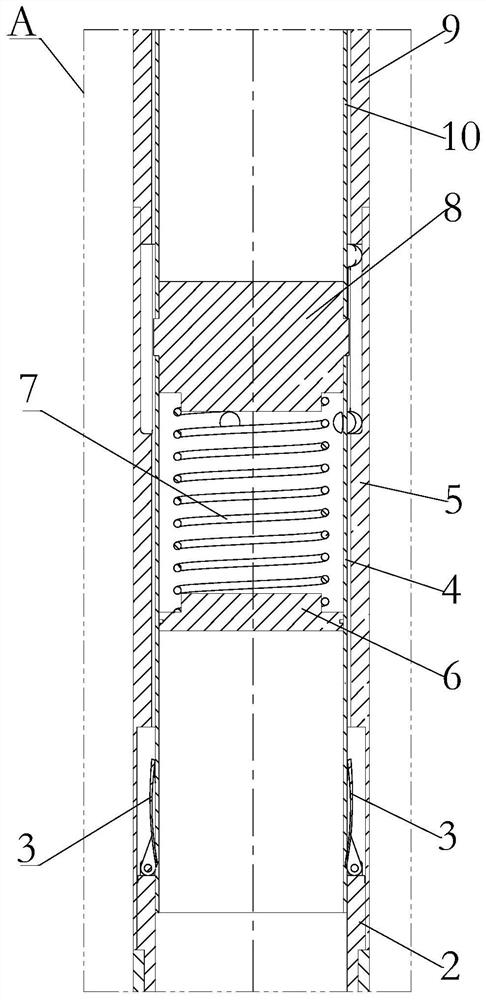

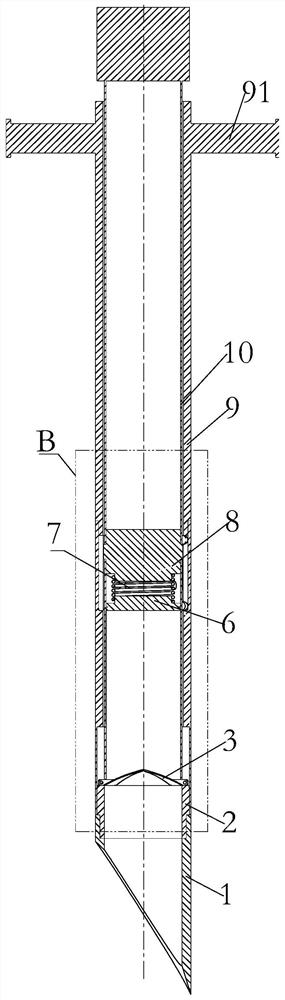

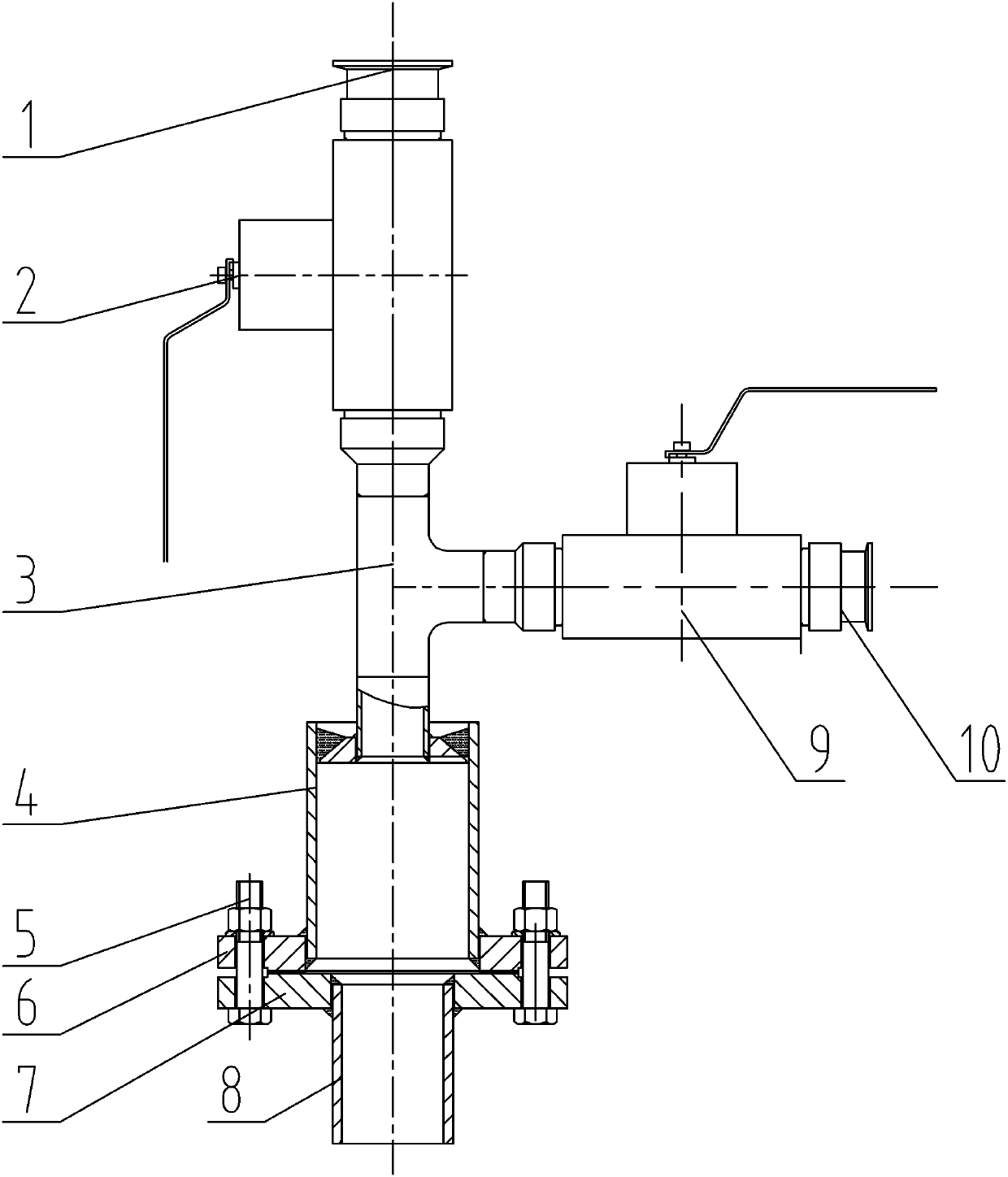

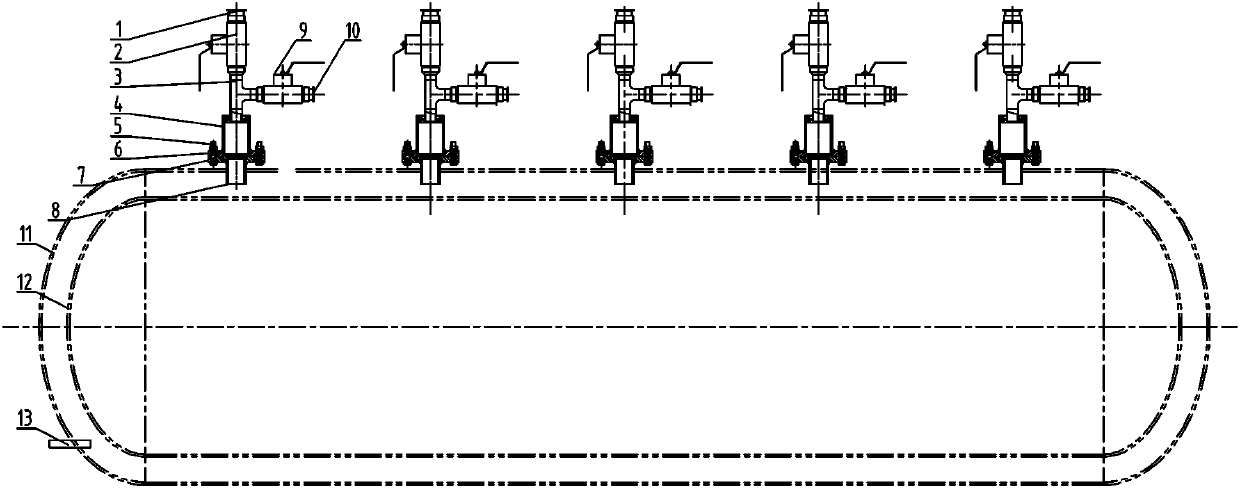

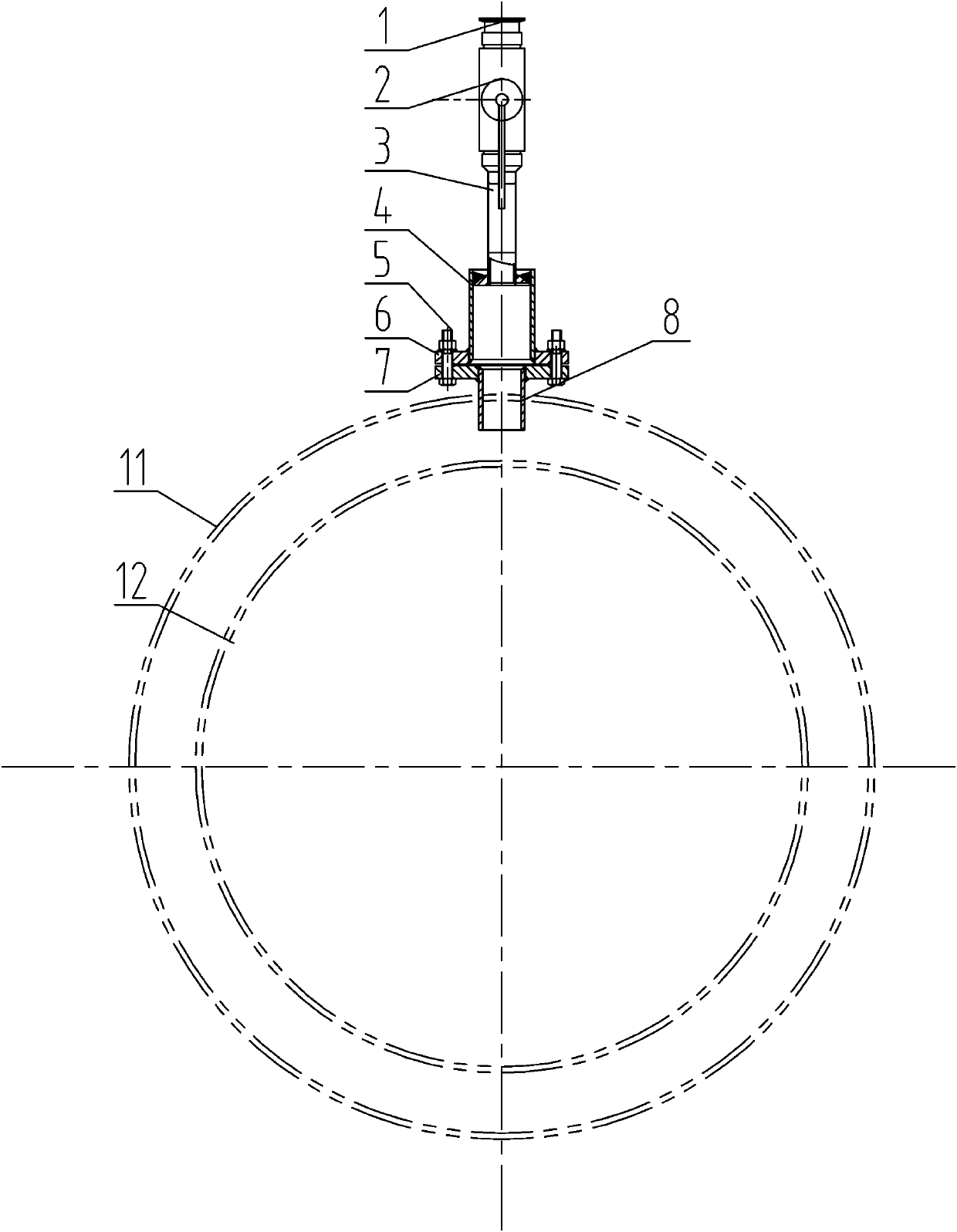

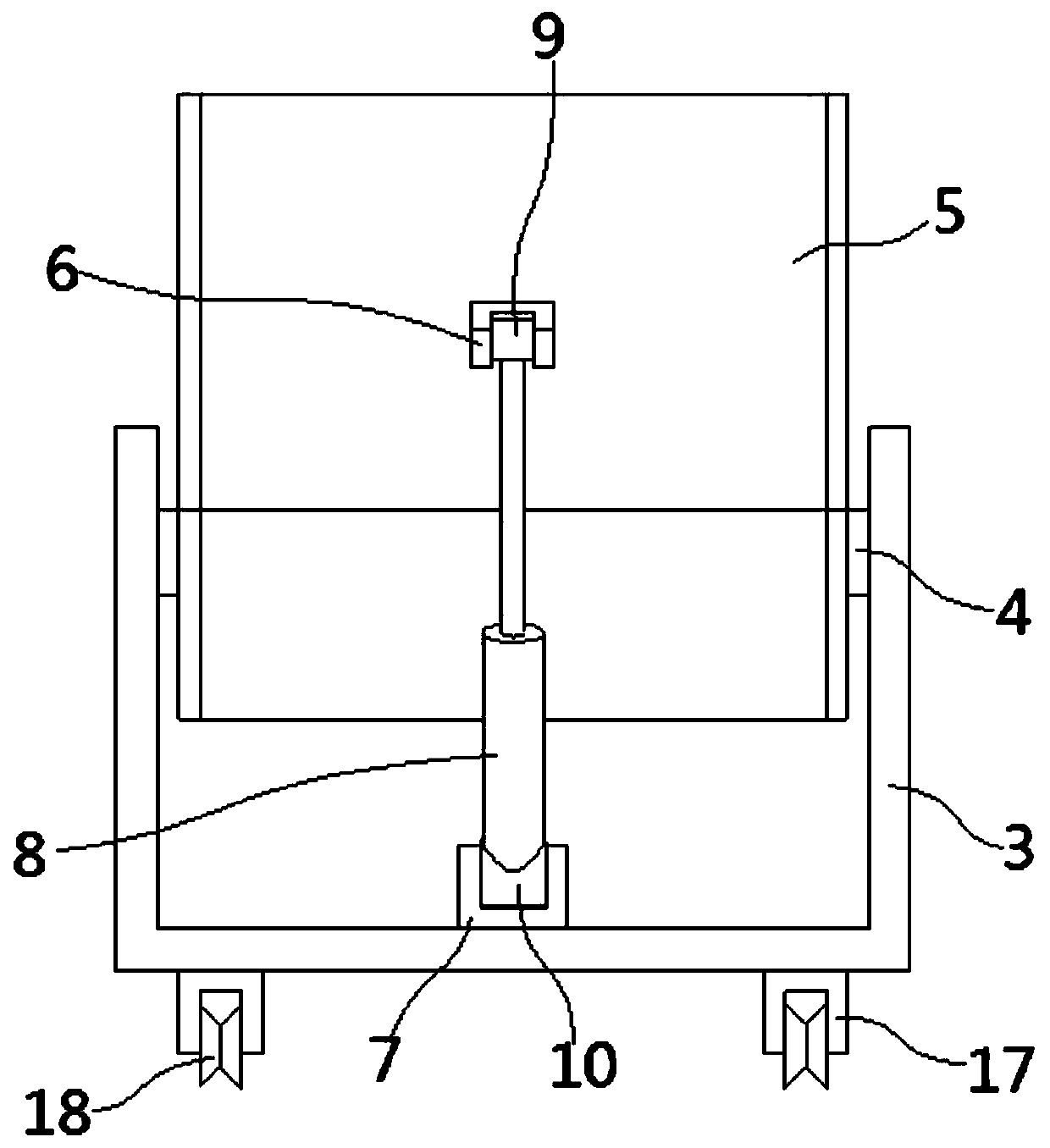

Pearlite sand filling device and method

PendingCN110873278AFast filling speedGood filling effectVessel wallsContainer filling methodsHigh water contentPearlite

The invention provides a pearlite sand filling device and method. The pearlite sand filling device comprises a bottom communication pipe for communicating with and fixing an outer tank of a low-temperature container, wherein a first flange plate is fixed to the top of the bottom communication pipe, the first flange plate and a second flange plate are fixedly connected through flange bolt sets, thesecond flange plate is connected with a top communication pipe, the top communication pipe is fixedly connected with one joint of a three-way joint, a first ceramic ball valve is installed at the middle joint of the three-way joint, and a second ceramic ball valve is mounted at the top joint of the three-way joint. The problem that standard prescribed vacuum degree is not easily achieved when thepearlite sand is vacuumized due to too high water content after the pearlite sand is filled into a low-temperature container interlayer is solved; and the time required for pumping the pearl sand interlayer to a specified vacuum degree is improved, and the production efficiency and effect are greatly improved.

Owner:YICHANG JIANGXIA MARINE MACHINERY +1

Leakage stoppage strengthening method for vibration disturbance resistance honeycomb pitted furnace for underground engineering

InactiveCN106939619AEffective compactionSolve the problem of water seepageArtificial islandsUnderwater structuresEpoxyWater leakage

The invention discloses a plugging and reinforcement method for anti-vibration and disturbance honeycomb pitted surface used in underground engineering. Firstly, cement grouting is used to stop the water of the structure with large leakage water, and the method of pinhole grouting is used to pour low-type modification Epoxy grout, apply cement-based permeable crystalline waterproof material to the leaking parts of the tiny gaps that cannot be grouted, use concrete to squeeze water out of the cracks and pores of the secondary lining, and then use cement-based rigid anti-seepage mortar to spray or Scrape coating, and after the plugging of the root of the embedded parts is completed, slot and fill the sealant; finally, use a drilling tool to drill through the lining structure to release pressure and drain water at the serious water leakage, forming an effective new drainage blind pipe. The method of the invention can effectively tamp the uncompacted honeycomb pitted surface, thereby solving the problems of water seepage and water leakage, and has good treatment effect and high pressure.

Owner:贵州维修大师科技有限公司

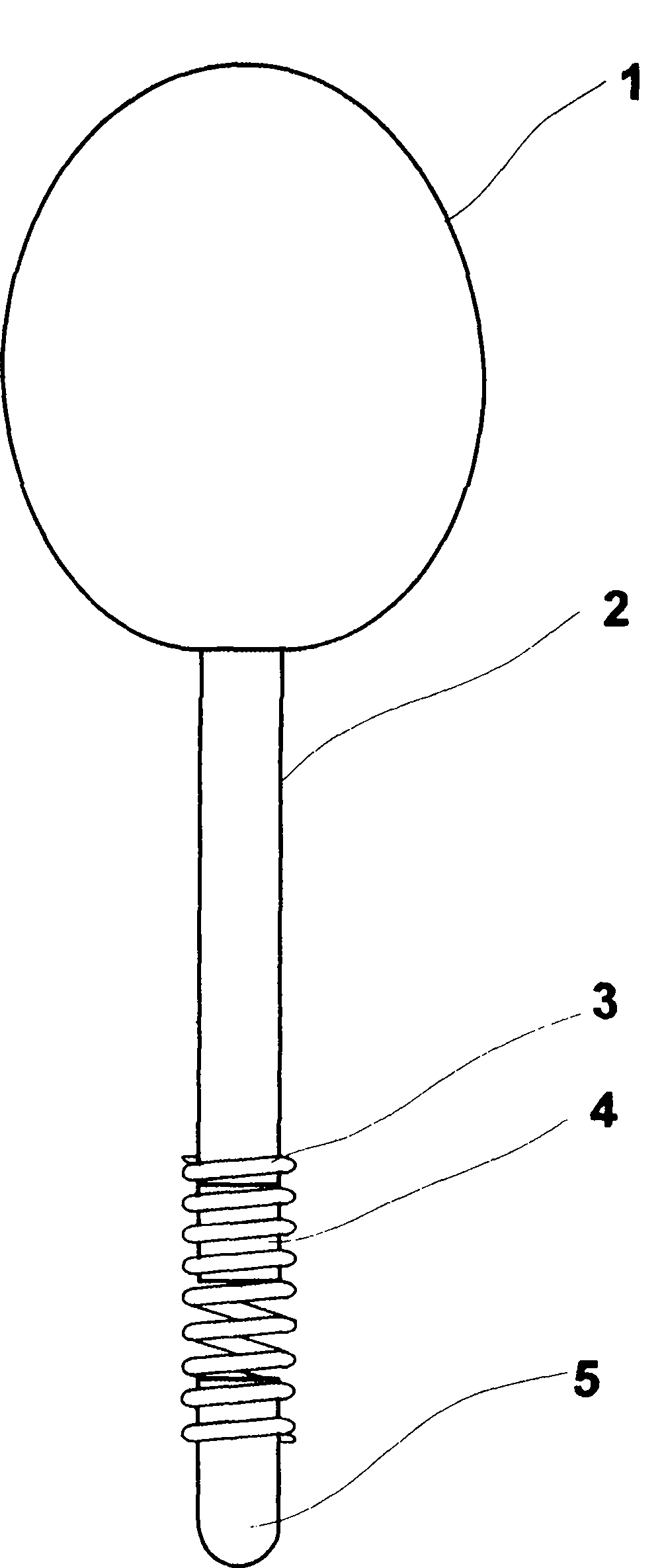

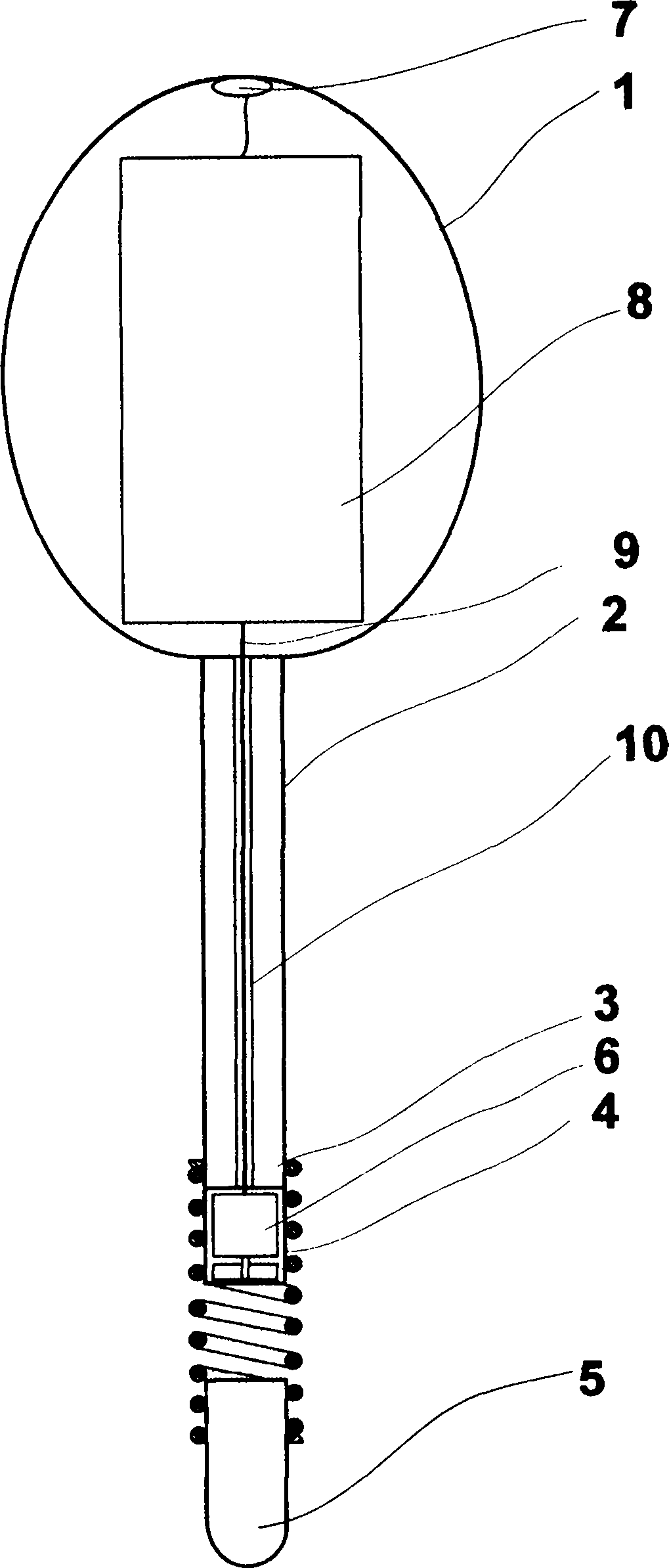

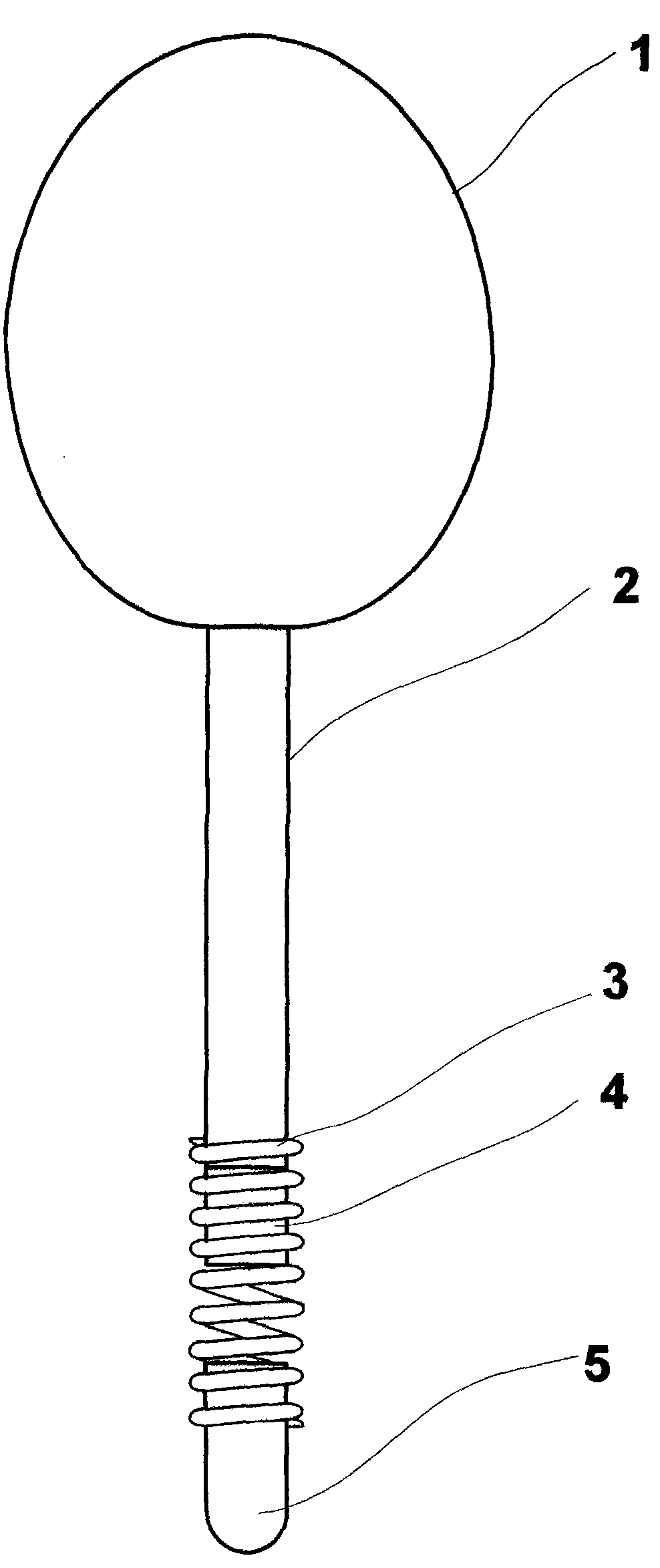

Crushed bone compaction device for bone grafting surgery

The invention discloses a crushed bone compaction device for a bone grafting surgery. The crushed bone compaction device comprises a handle, a straight rod, a vibrator shell and a vibrating head, wherein the handle is internally provided with a power supply and a power supply switch connected with the power supply; the straight rod is connected below the handle, a through hole is formed at the center of the straight rod, and a lead is arranged in the through hole; the vibrator shell is connected at the lower part of the straight rod and is internally provided with an electric vibrator which is connected with the power supply by the lead in the through hole; and the vibrating head is connected below the straight rod by a spring. According to the invention, as compaction on crushed bones can be accelerated by vibration of the electric vibrator, impact and damage on normal bones can be reduced greatly, the success rate of the surgery is enhanced, and the function recovery of the crushed bones can be promoted effectively.

Owner:侯斌

Pavement leaf cleaning device for municipal road maintenance

InactiveCN111962443AEasy to operateGood cleaning effectRoad cleaningAgricultural engineeringEnvironmental geology

The invention relates to the technical field of road leaf cleaning. The invention discloses a pavement leaf cleaning device for municipal road maintenance. A fixing plate is mounted at the lower end of a treatment box; a recovery assembly is mounted in the treatment box in a sliding manner; moving wheels are arranged on the lower surface of the fixing plate in a triangular shape. Leaf inlets are formed in the lower surfaces of the fixing plate and the treatment box correspondingly; a cleaning assembly is installed on the side, located at the leaf inlet, of the lower surface of the fixing plate; an installing plate is installed in the treatment box, and a pressing assembly is arranged at the position, located above the recovery assembly, of the exterior of the installing plate in the treatment box. Through the cleaning assembly, different positions of a pavement can be effectively cleaned through cleaning brushes arranged below a first cleaning plate and a second cleaning plate, operation is easy, and the cleaning effect is good; and through triangular arrangement of the moving wheels, the treatment box can be turned for use, and the labor intensity of workers can be relieved.

Owner:杨玉美

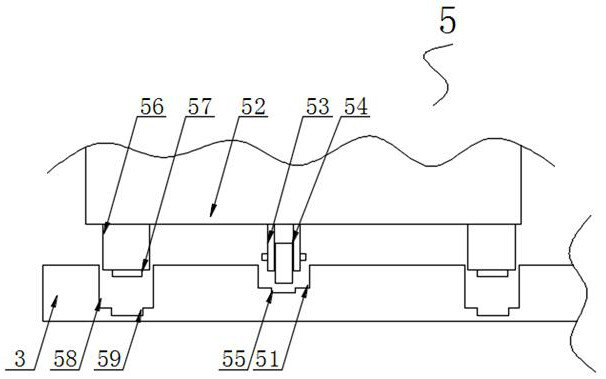

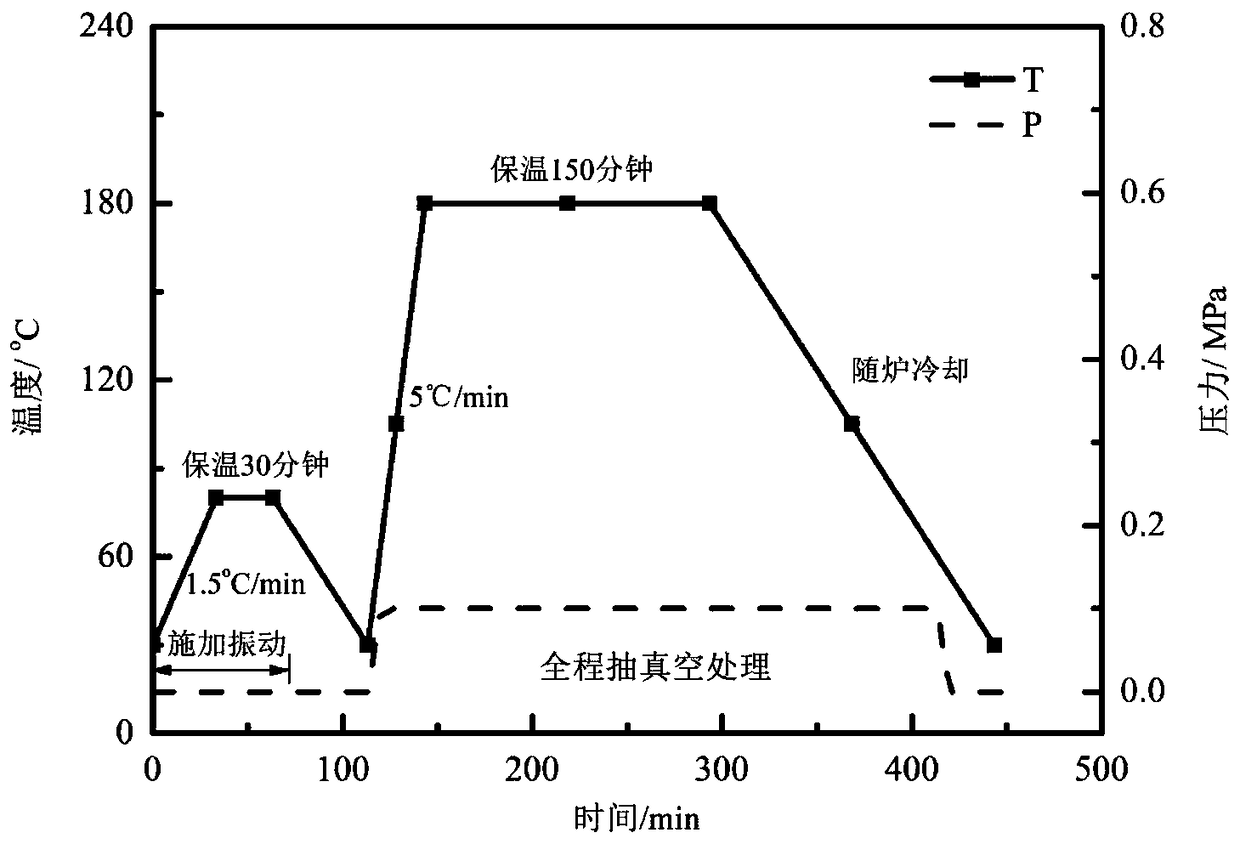

Curing method for composite material

The invention provides a curing method for a composite material. The curing method comprises the following steps: vibration pretreatment; and low-pressure microwave curing. Specifically, the vibrationpretreatment is to subject a to-be-processed composite material to vibration treatment so as to obtain a pretreated composite workpiece; the microwave curing is to cure the pretreated composite workpiece under low pressure and microwave conditions; the composite workpiece is cured both in the vibration pretreatment process and the low-pressure microwave curing process. With such a technical scheme in the invention, the curing method has the following beneficial effects: the combination of vibration pretreatment and low-pressure microwave curing makes the finally prepared composite workpiece basically achieve effect under high pressure conditions in the prior art, and pressure required during molding and curing time are reduced while maintaining the excellent quality and performance of thecomposite workpiece; and thus, production cost is lowered, and a safety factor is increased.

Owner:CENT SOUTH UNIV

Rail transportation device convenient for unloading

PendingCN111016941AImprove transportation efficiencyImprove unloading efficiencyTipping wagonsHydraulic cylinderStructural engineering

The invention discloses a rail transportation device convenient for unloading and relates to the technical field of mechanical transportation. The device comprises a cargo loading and unloading mechanism, wherein a vibration compaction mechanism is fixed on the cargo loading and unloading mechanism; the cargo loading and unloading mechanism comprises a first U-shaped plate and a group of hydrauliccylinders; connecting rods are rotatably connected to the opposite inner walls of the first U-shaped plate through bearings; a cargo compartment is fixed between the two connecting rods; first U-shaped blocks are fixed to the opposite side faces of the cargo compartment; a set of second U-shaped blocks are fixed to the inner wall of the first U-shaped plate; and a second fixing ring is fixed to one end of each hydraulic cylinder. Through mutual cooperation of the group of hydraulic cylinders, the cargo compartment can be driven to rotate around a set of connecting rods, so that a dischargingopening of the cargo compartment is inclined, cargoes in the cargo compartment are poured out, the rail transportation device is higher in unloading efficiency and saves more labor, the cargo transportation efficiency is improved, and the actual cargo transportation requirement is better met.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com