Patents

Literature

99results about How to "Improve the modulus of compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid buoyancy material prepared through chemical blowing process

InactiveCN1563134AMeet the requirements of strength-density ratioImprove the modulus of compressionUnderwater equipmentPolysulfide rubberCompressive strength

A solid floatage material is copmosed of core material and surface material of which the core material is made of hard foamed plastic of polyurethane-epoxy and the surface material is water-resisting layer made of epoxy, polysulfide rubber, flaky packing, light packing, coupling agent and curing agent.

Owner:MARINE CHEM RES INST

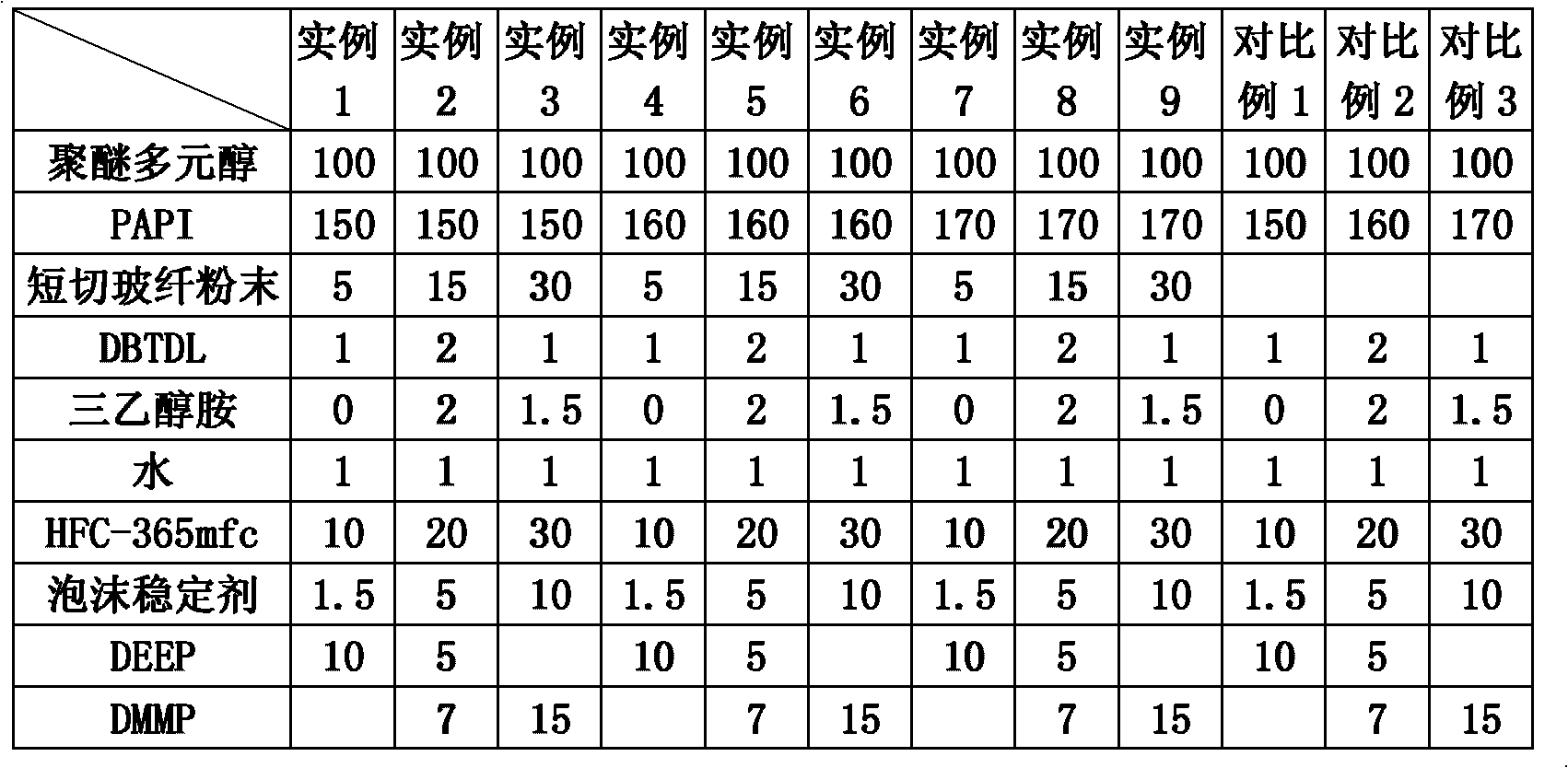

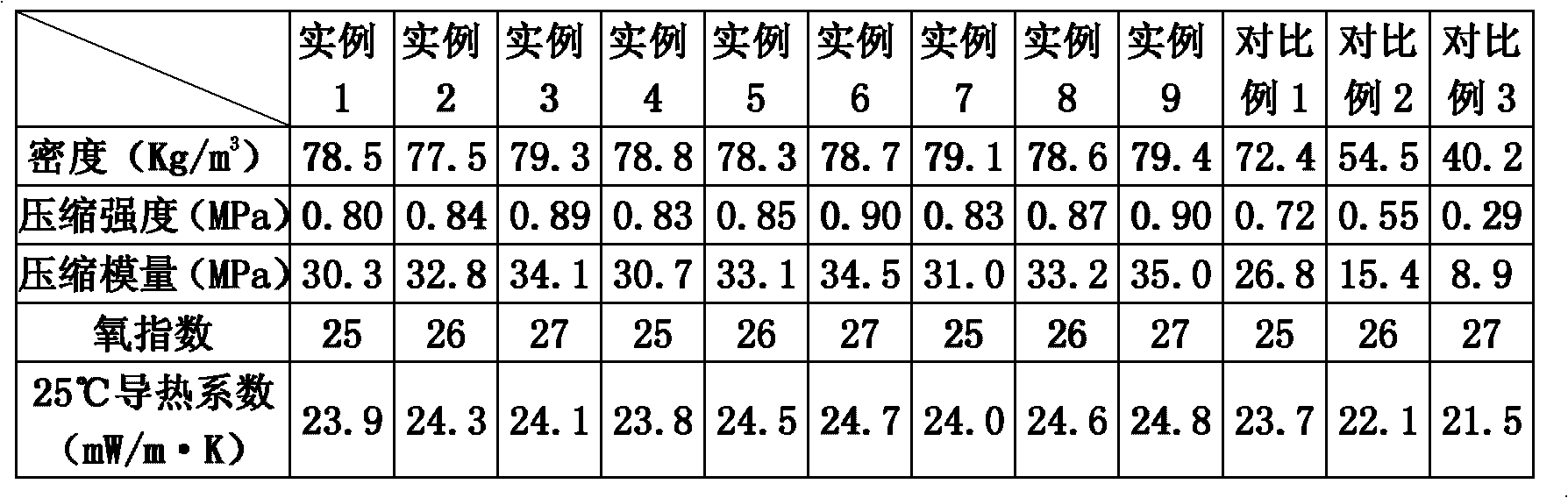

Hard polyurethane adiabatic heat-insulation foam material and preparation method thereof

The invention relates to a hard polyurethane adiabatic heat-insulation foam material and a preparation method thereof. The material contains the following components: polyether glycol, polymethylene polyphenyl isocyanate, chopped glass fiber powder, physical foaming agent, water, fire retardant, catalyst and foam stabilizer. The preparation method comprises that the surface of the chopped glass fiber powder is treated through silane coupling agent; and the polyether glycol, polymethylene polyphenyl isocyanate and the surface-treated chopped glass fiber powder are dried, mixing treatment and polymerization foaming treatment are sequentially conducted thereafter, curing treatment is conducted after a pouring mould blank is obtained and the mould is removed, and finally hard polyurethane foam is obtained. Since the invention adopts the third-generation zero-ozone-consumption latent-energy hydrofluorocarbon foaming agent and the halogen-free high-efficiency fire retardant, the foam material has the advantages of environmental protection, low density and excellent compression property and is suitable for use in the heat insulation field.

Owner:SHANGHAI JIAO TONG UNIV

Combined method for fastening soft soil ground by dual vacuum prepressing and dynamic extruding method

InactiveCN1818227AEffective secondary reinforcementImprove consolidation indexSoil preservationFilling materialsReduction procedure

A method for reinforcement of yielding soil of large area or hollow land includes the following procedures in order: 1. low position vacuum pre-press procedure as building cofferdam, filling in sludge to certain height, paving cloth and bamboo fence on the top, vertically inserting in water emission plastic boards, laying horizontal vacuum pipe net, installing vacuum pre-press system and sealing with mud layer of 0.8-1.5 m thick then vacuum bumping for pre-press; 2. high vacuum rate well point water reduction procedure as applying a high vacuum rate well point water reduction system on the mud sealing layer, removing well point pipe after the first round of water reduction; 3. low power strong tamping procedure as paving a layer of filling material on the mud sealing layer then tamping. Roller compact the surface after 2-3 rounds of procedure 2 and 3.

Owner:张志铁 +1

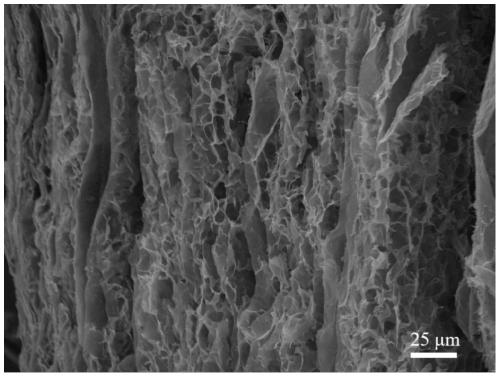

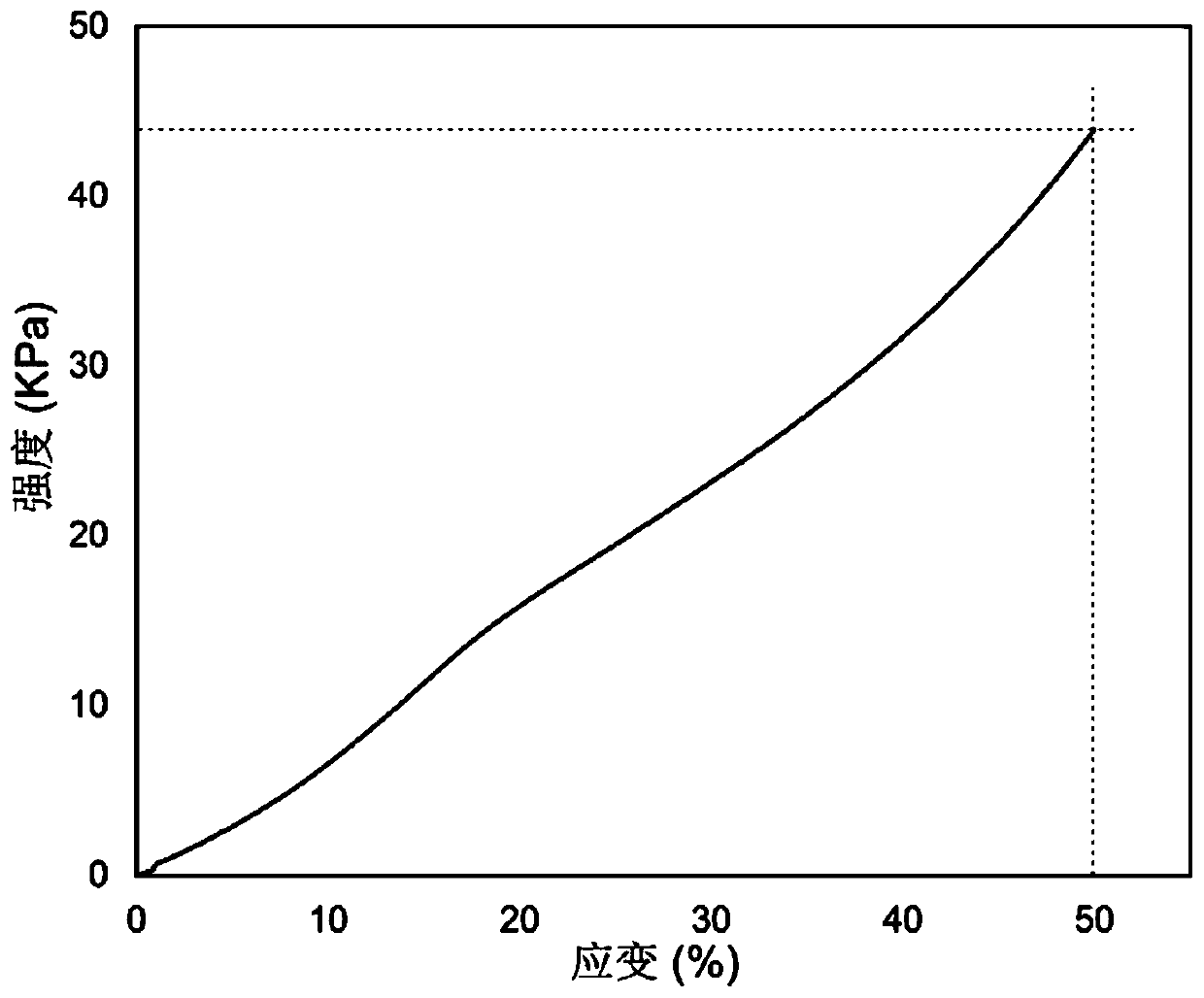

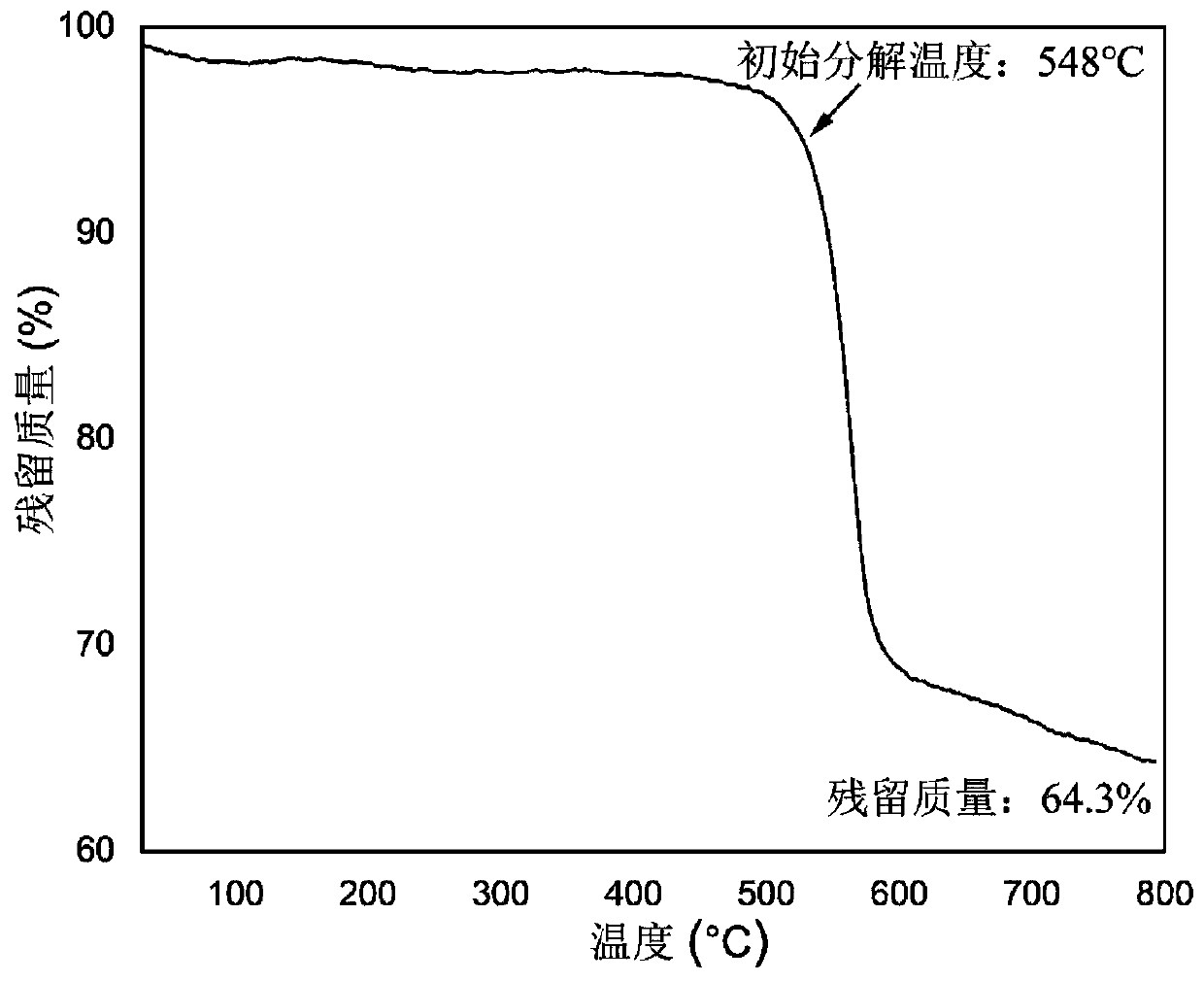

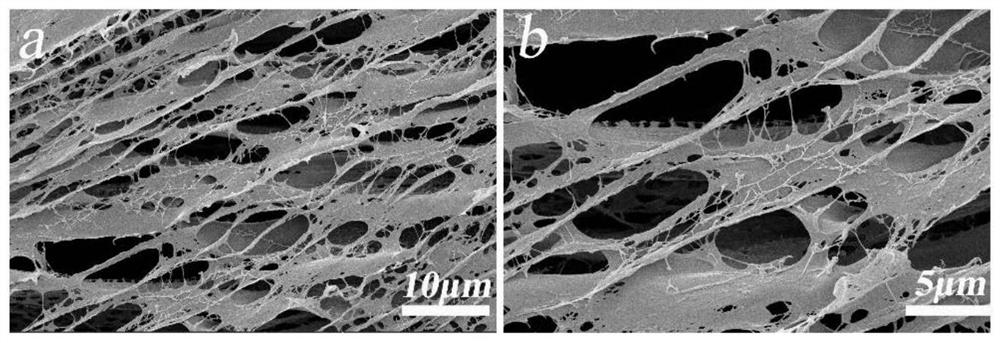

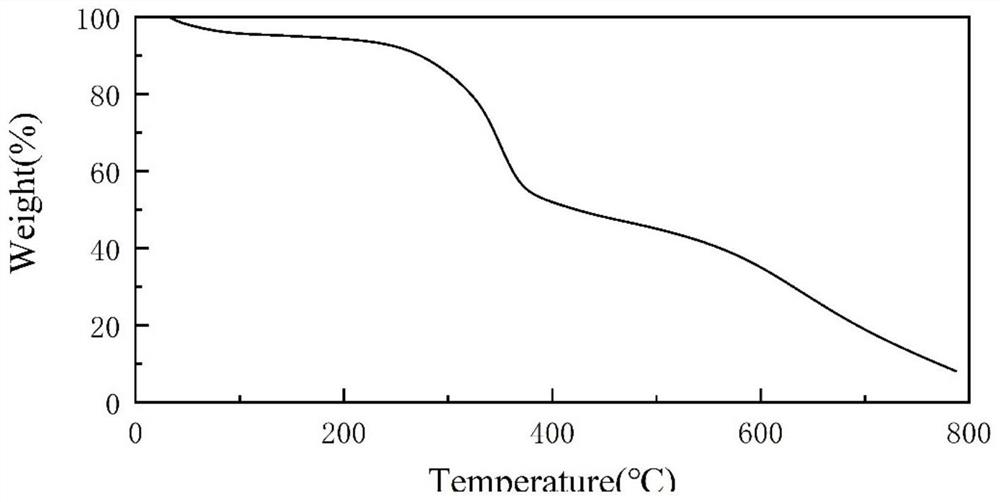

Aramid nanofiber/MXene composite conductive aerogel and preparation method thereof

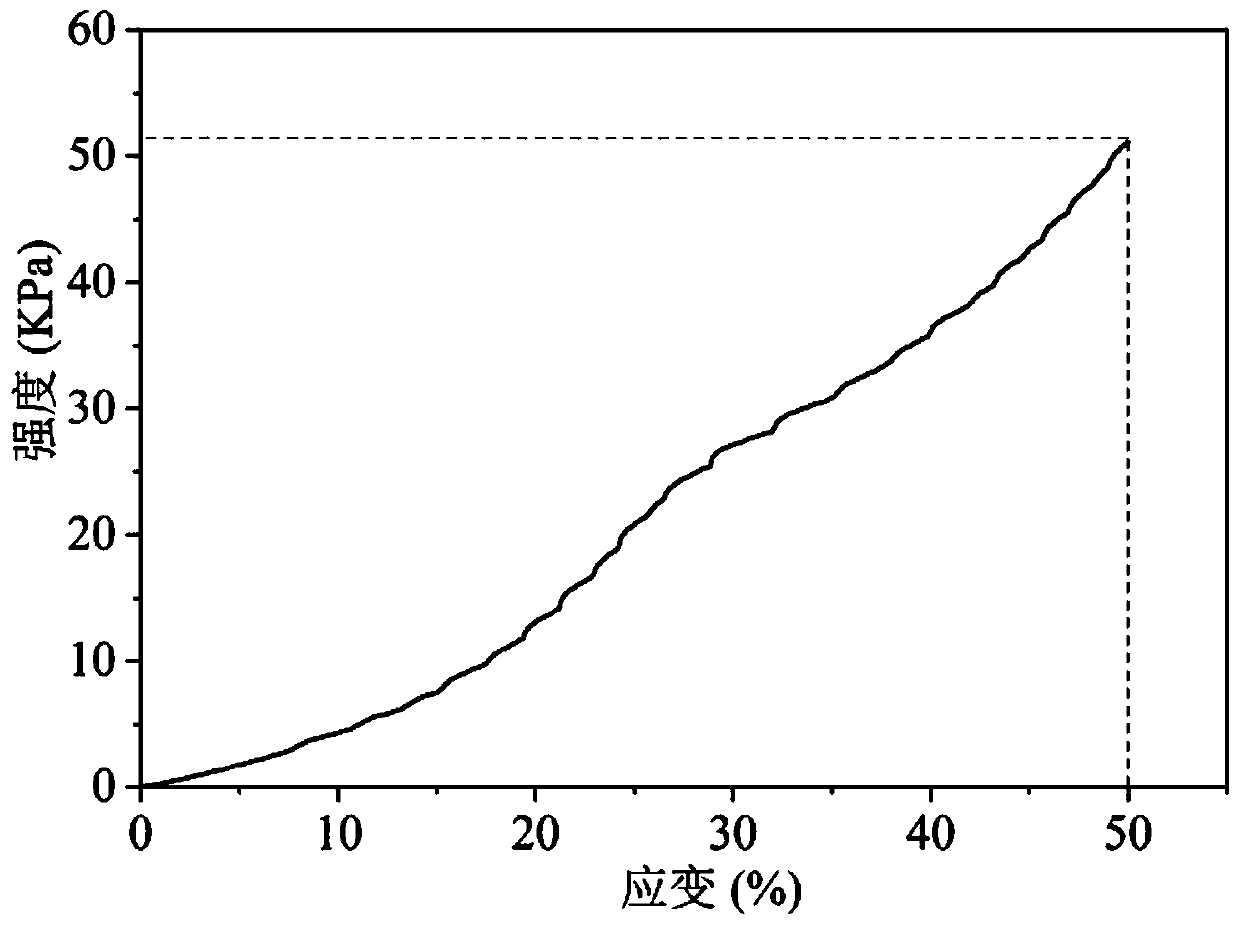

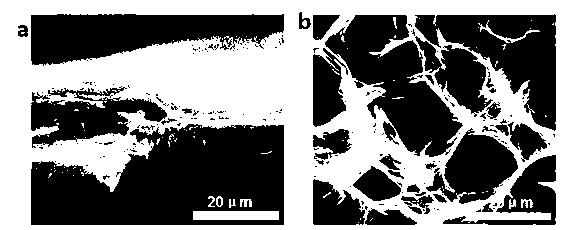

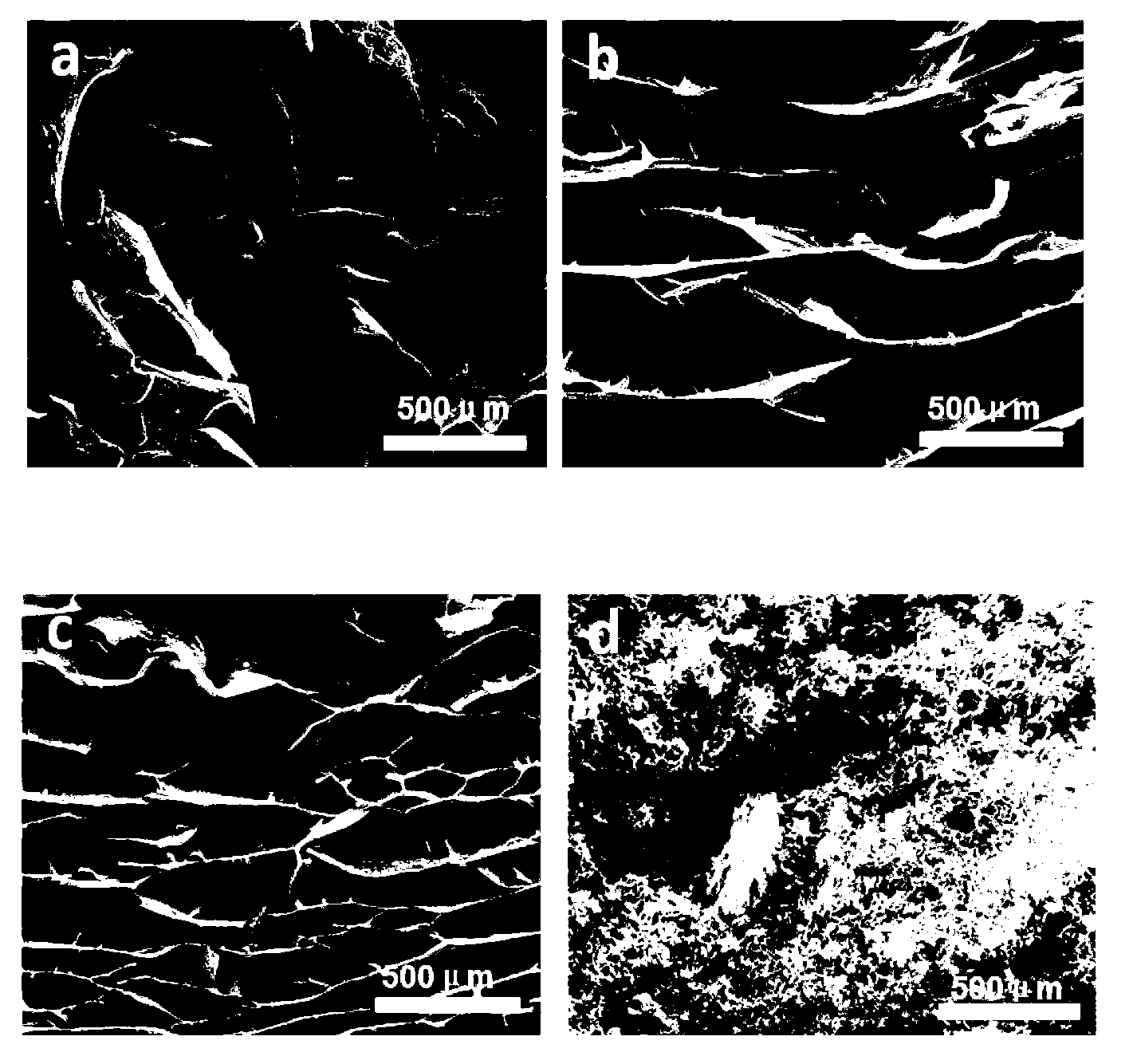

ActiveCN111040238ALarge aspect ratioImprove temperature resistanceForce measurementElectrically conductiveFibrous composites

The invention discloses aramid nanofiber / MXene composite conductive aerogel and a preparation method thereof. By using aramid nanofibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using MXene with excellent conductivity, good chemical stability and a unique two-dimensional nano-film structure as a conductive and fillingcoating material, the aramid nanofiber / MXene composite conductive aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing an MXene dispersion liquid, preparing an aramid nanofiber / MXene composite dispersion liquid, preparing a gelatinous aramidnanofiber / MXene composite material and the like, thereby obtaining the aramid nanofiber / MXene composite conductive aerogel. The preparation process is simple and easy to implement, and the obtained aramid nanofiber / MXene composite conductive aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Silk fibroin/ cellulose 3D printing ink

ActiveCN106267370AGood biocompatibilityHigh viscosityPharmaceutical delivery mechanismTissue regenerationCelluloseHuman body

The invention relates to silk fibroin / cellulose 3D printing ink, which comprises the following main ingredients: water-soluble silk fibroin with good biocompatibility, non-water soluble cellulose micron / nanometer materials with good biocompatibility, non-toxic polyhydric alcohols capable of inducing the silk fibroin to carry out physical crosslinking, bioactive substance capable of accelerating tissues to regenerate, and water. The silk fibroin / cellulose 3D printing ink disclosed by the invention has high viscosity, dynamic viscosity is 1000-5000cP, curing molding speed is high, self-gelation time is 0.5-3min, printing conditions are moderate, and printing temperature is 25-37DEG C; an obtained printing bracket has high precision and good mechanical property, a resolution ratio is 50-300mum, and a modulus of compression is 10-50MPa. The bracket formed by the silk fibroin / cellulose 3D printing ink can be used for the field of the repairing and the reconstruction of various damaged tissues or organs of a human body.

Owner:常州增材制造研究院有限公司

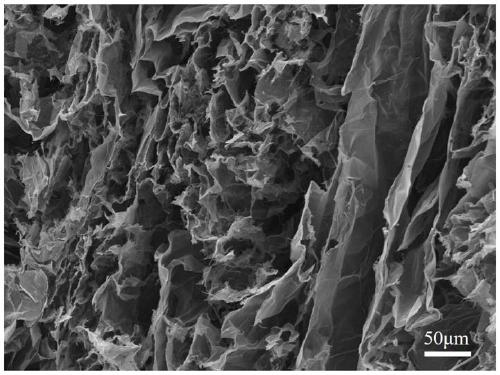

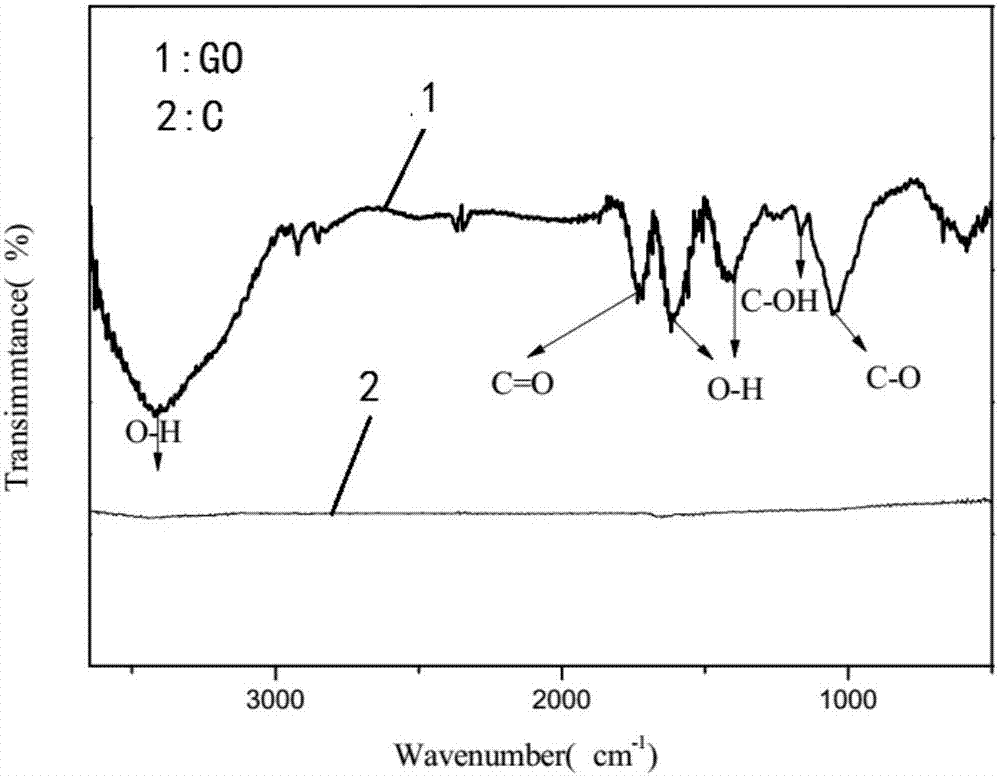

Manufacturing method of graphene foam

ActiveCN103213978ANo generationEasy control of mechanical propertiesGrapheneGraphene flakeEngineering

The invention provides a manufacturing method of graphene foam. The manufacturing method comprises the following steps of: 1) reducing an aqueous dispersion of graphene oxide through a hydrothermal method, and performing self-assembly on graphene sheets to obtain a graphene wet gel block body; 2) freezing the graphene wet gel block body obtained in the step 1) on a metal tray, wherein the metal tray has preset freezing temperature which is controlled within a range of -196 DEG C to -10 DEG C, and the graphene wet gel block body after freezing is completely crystallized to form a gel crystalline solid; and 3) performing vacuum sublimation and drying on the gel crystalline solid obtained in the step 2). The manufacturing method has the advantages of simple process and capability of regulating and controlling a hole structure of the graphene foam, thus the graphene foam has different properties.

Owner:SOUTHEAST UNIV

Method for nanoencapsulation of aerogels and nanoencapsulated aerogels produced by such method

A method for increasing the compressive modulus of aerogels comprising: providing aerogel substrate comprising a bubble matrix in a chamber; providing monomer to the chamber, the monomer comprising vapor phase monomer which polymerizes substantially free of polymerization byproducts; depositing monomer from the vapor phase onto the surface of the aerogel substrate under deposition conditions effective to produce a vapor pressure sufficient to cause the vapor phase monomer to penetrate into the bubble matrix and deposit onto the surface of the aerogel substrate, producing a substantially uniform monomer film; and, polymerizing the substantially uniform monomer film under polymerization conditions effective to produce polymer coated aerogel comprising a substantially uniform polymer coating substantially free of polymerization byproducts.Polymer coated aerogel comprising aerogel substrate comprising a substantially uniform polymer coating, said polymer coated aerogel comprising porosity and having a compressive modulus greater than the compressive modulus of the aerogel substrate, as measured by a 100 lb. load cell at 1 mm / minute in the linear range of 20% to 40% compression.

Owner:NASA

Starch-based hemostasis sponge and preparation method of hemostasis sponge

ActiveCN104623720AImprove water absorptionGood formabilityAbsorbent padsBandagesCross-linkFreeze-drying

The invention relates to a medical hemostasis instrument and in particular relates to a starch-based hemostasis sponge and a preparation method of the hemostasis sponge. The starch-based hemostasis sponge is prepared from the following raw materials in parts by weight: 80-95 parts of starch, 2-10 parts of hydroxypropyl methylcellulose calcium, 2-5 parts of a cross-linking agent and 1-5 parts of a plasticizer. The preparation method of the hemostasis sponge comprises the following steps: step one, crosslinking starch with hydroxypropyl methylcellulose calcium by virtue of the cross-linking agent; step two, purifying; and step three, freeze-drying and sterilizing to prepare the finished starch-based hemostasis sponge. According to the starch-based hemostasis sponge and the preparation method of the hemostasis sponge, the hemostasis sponge is prepared by crosslinking starch with hydroxypropyl methylcellulose calcium; the hydroxypropyl methylcellulose calcium is high in water absorption rate, excellent in formability, high in strength and not liable to break, and has a plurality of functions of stopping bleeding, packing and repairing.

Owner:北京爱特康医疗科技有限公司

High-strength nanoporous ceramizable ablation heatproof composite material and preparation method thereof

ActiveCN110951210AImprove tensile propertiesImprove bending resistancePolymer scienceUltimate tensile strength

The invention relates to a high-strength nanoporous ceramizable ablation heatproof composite material and a preparation method thereof. The composite material comprises 20-60 wt% of hybrid resin and 40-80 wt% of a fiber reinforcement, the hybrid resin comprises silicone hybrid phenolic resin, the thickness of the composite material is 2-50 mm, the density of the composite material is 700-1400 kg / m<3>, and the nanopore diameter is 50-1000 nm. The preparation method comprises the following steps: (1) preparing a hybrid resin sol; (2) impregnating the sol; (3) carrying out a sol-gel reaction; and(4) drying the composite material to obtain the composite material. Compared with like materials in the prior art, the composite material of the invention has the advantages of large binding force ofthe resin and fiber interface, high compression modulus, high bending strength, high tensile strength, ceramization at a high temperature, low thermal conductivity and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Wear-resisting heat-conducting polyurethane bearing as well as preparation method and application thereof

The invention belongs to the field of light-weight wear-resisting materials and discloses a wear-resisting heat-conducting polyurethane bearing as well as an preparation method and an application thereof. The preparation method of the wear-resisting heat-conducting polyurethane bearing comprises the following steps of: soaking a fiber into a copolymer, dispersing ultrasonically, adding a polyurethane prepolymer, a curing agent and a heat-conducting filler, mixing the materials, degassing in vacuum, pouring the degassed mixture into a preheating mold, heating to cure, cooling, and demolding to obtain the wear-resisting heat-conducting polyurethane bearing. The wear-resisting heat-conducting polyurethane bearing prepared by adopting the preparation method has the advantages of light weight, wear resistance (relative volume wear loss of 150mm<3>), good heat conductivity of 4W / m*K, high strength (high modulus of compression of 520Mpa, and notched impact strength of 120J / m), low cost, long service life and the like, is simple in forming process, is suitable for industrial production and can be widely applied to clean-energy power generation equipment.

Owner:JINAN UNIVERSITY

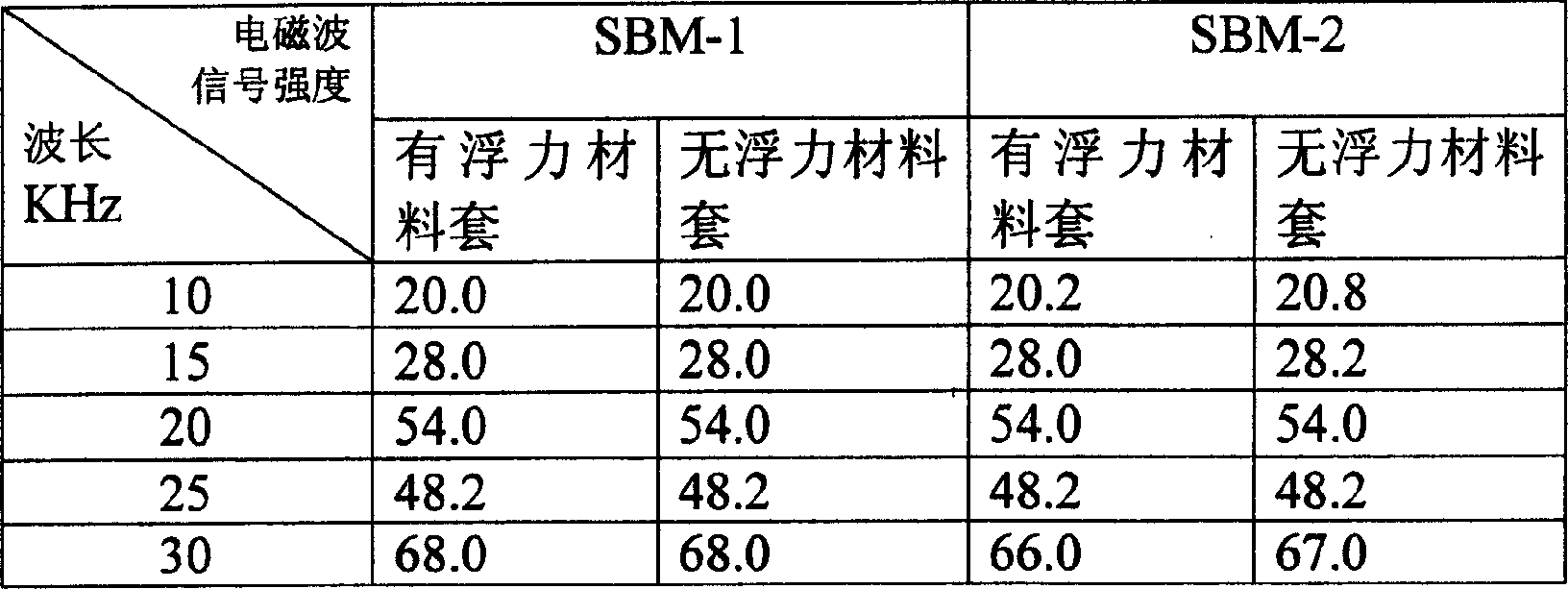

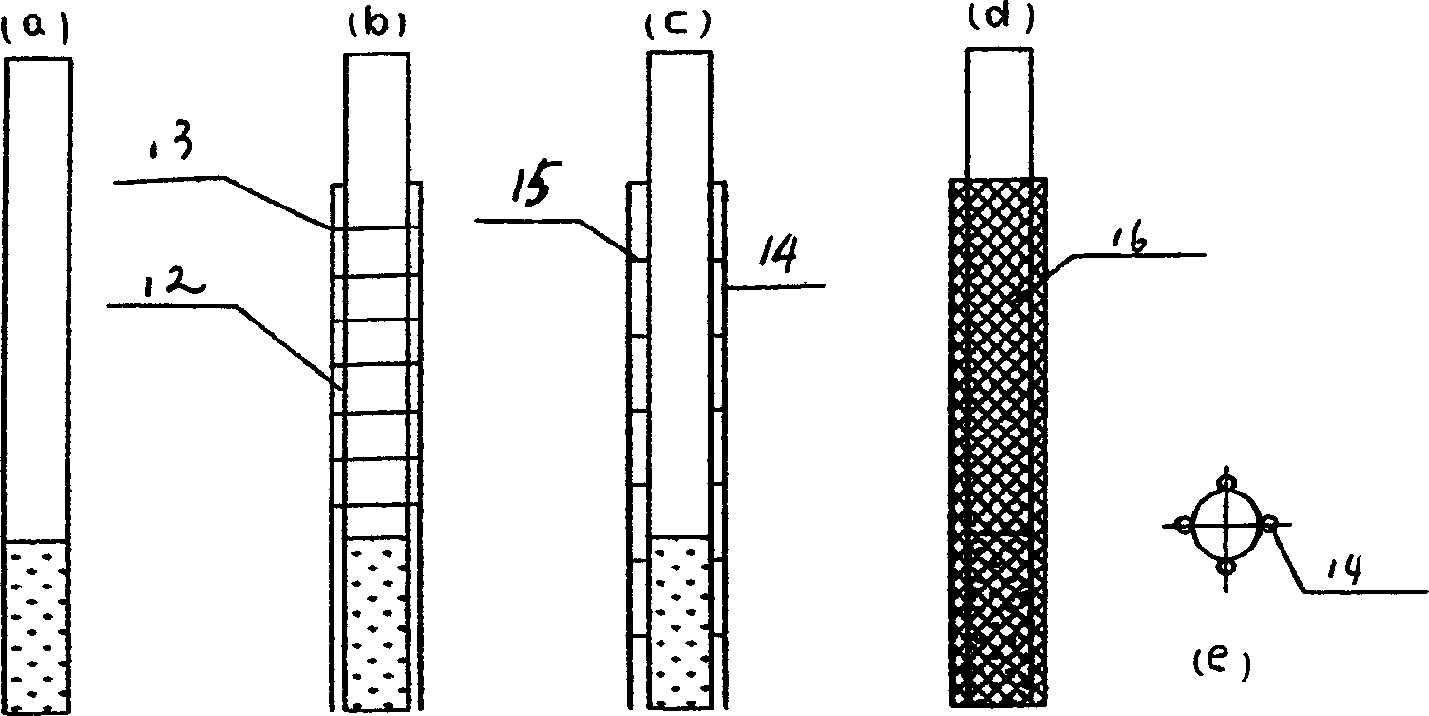

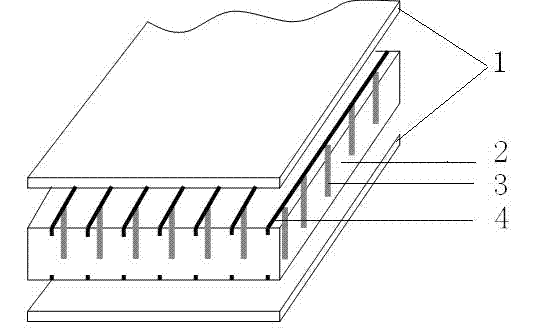

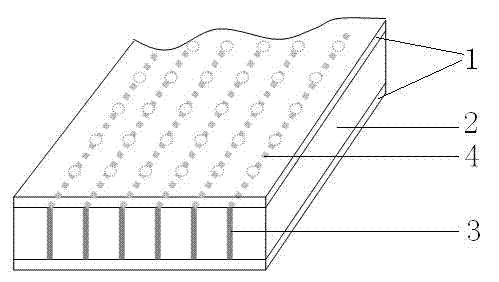

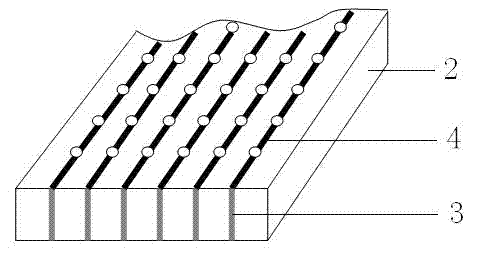

Z-direction enhanced underwater sound absorption sandwich composite material and preparation method for same

ActiveCN102930862ASolve the carrying capacitySolve the problem of sound absorption performanceSynthetic resin layered productsSound producing devicesVacuum assistedOperability

The invention discloses a Z-direction enhanced underwater sound absorption sandwich composite material and a preparation method for the same. The composite material comprises composite material panels, a sound absorption core material and enhancement structures, wherein the enhancement structures are arranged in the thickness direction of the sound absorption core material, namely a Z direction, between the upper and lower panels. The whole structure of the Z-direction enhanced underwater sound absorption sandwich composite material is formed by a vacuum assisted forming process. Compared with an ordinary sound absorption sandwich composite material, the Z-direction enhanced underwater sound absorption sandwich composite material has the advantages that flat compression strength is greatly strengthened, a compression modulus is improved by more than one order of magnitude, bending rigidity is doubled, sound absorption performance is improved by 10 to 85 percent, and sound absorption performance under high water pressure is improved by 50 to 85 percent; and the forming process has the advantages of high operability, high quality consistency, suitability for the formation of a large-sized composite material component, and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

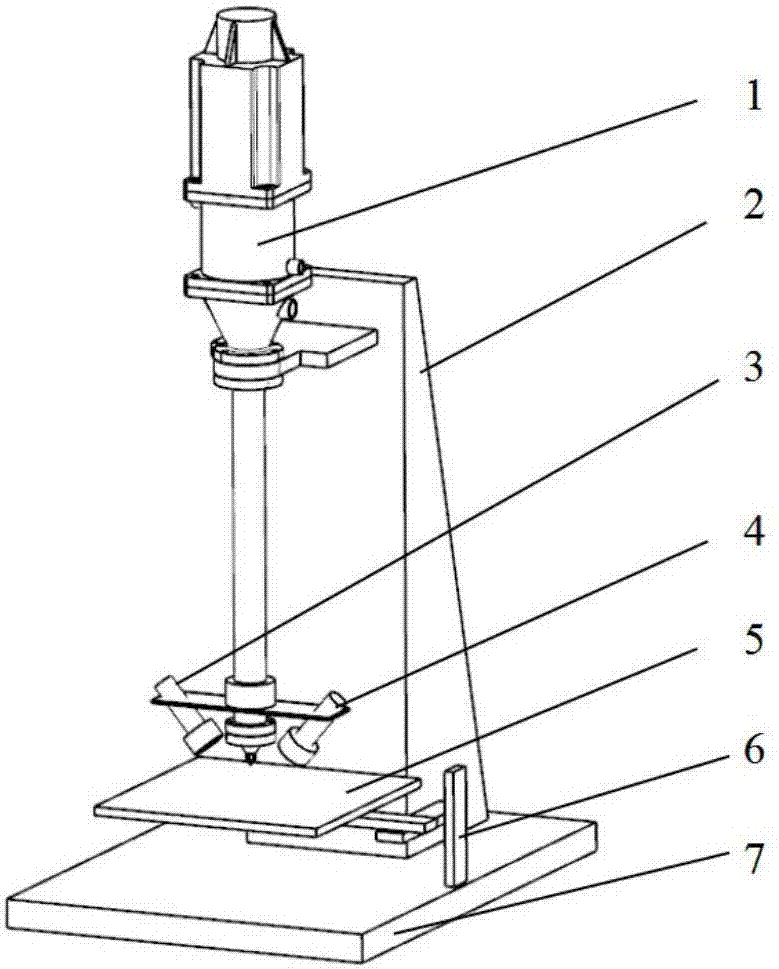

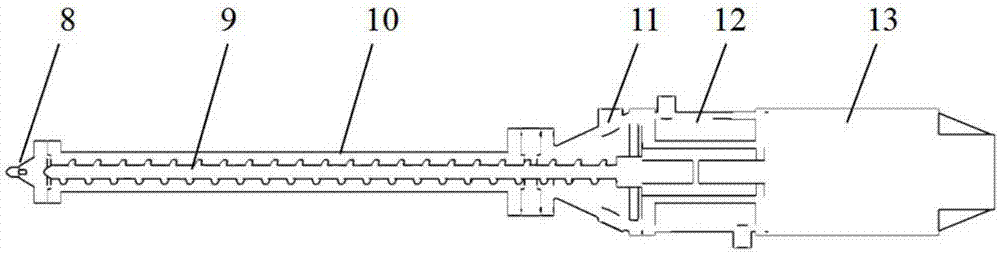

3D printing device and method for high-molecular-weight silicone rubber

ActiveCN107283819AExtended service lifeQuality improvementAdditive manufacturing with liquidsApplying layer meansEngineeringUltimate tensile strength

The invention discloses a 3D printing device and method for high-molecular-weight silicone rubber. A hundred-micron-level micropore nozzle with the high shearing rate and high extruding strength and for screw extruding force is adopted in a 3D printing head system, the flowing viscosity of the high-molecular-weight silicone rubber is greatly reduced, and 3D printing forming of a high-molecular-weight, high-compression-modulus and long-service life silicone rubber material is achieved. The extrusion and expansion stability of the material on the hundred-micron-level micropore nozzle is improved, the dimensional precision of a 3D printing fluid line is accurately controlled, and high quality, high precision and high efficiency in the 3D printing process are achieved. A photo-thermal two-order curing material 3D printing manner is adopted, the curing rate and dimensional precision of the 3D printing material are greatly increased, the high quality and stability of the 3D printing high-molecular-weight silicone rubber material are improved, and the macro-performance and structure adjustability of the 3D printing material are achieved.

Owner:XIAN LIANCHUANG ADVANCED MFG A SPECIALIZED INCUBATOR CO LTD

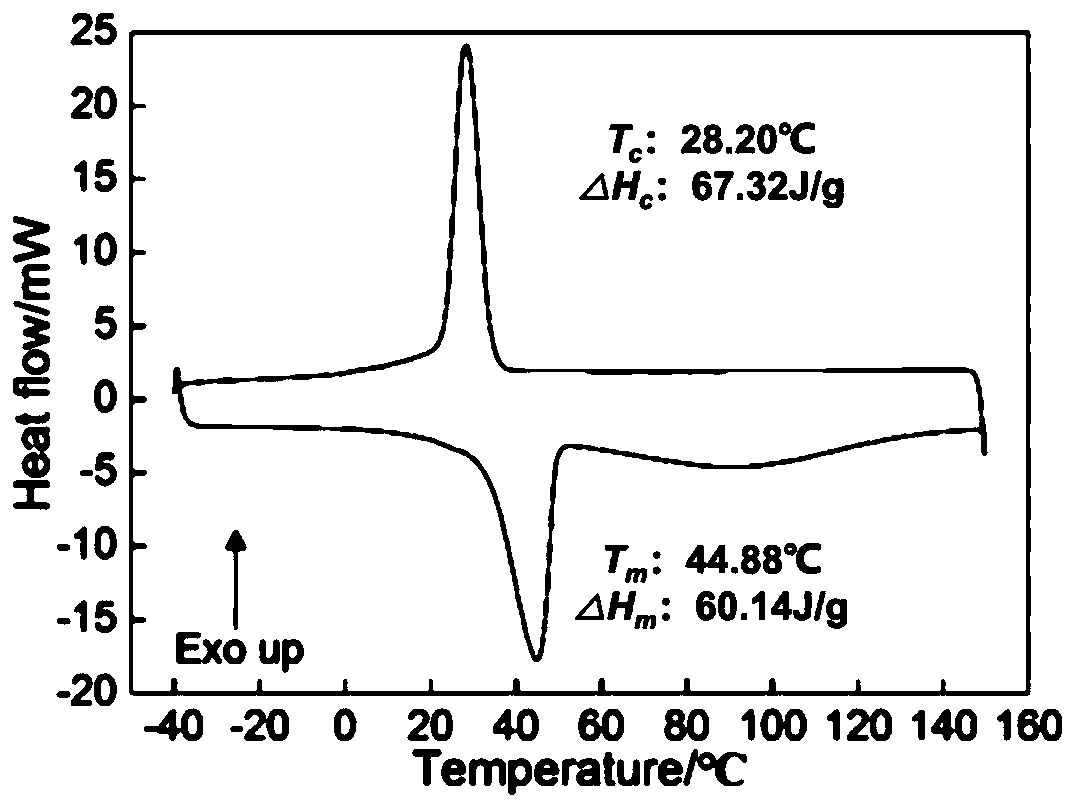

Polyvinyl alcohol porous material and preparation method thereof

ActiveCN106496896AUniform pore sizeIncrease cell densityHeat-exchange elementsCold chainFoaming agent

The invention specifically relates to a polyvinyl alcohol porous material and a preparation method thereof, belonging to the technical field of high polymer materials. The polyvinyl alcohol porous material provided by the invention has a pore diameter of 5 to 300 [mu]m, an opening percent of 10 to 50%, a cell density of 10<5> to 10<10> cells / cm<3>, a dry compression modulus of 4.0 to 7.5 MPa, water-absorbing capacity of 5 to 20 times and latent heat of phase change after water absorption equilibrium of 250 to 320 J / g. The polyvinyl alcohol porous material may be prepared from 40 to 84 parts of polyvinyl alcohol, 15 to 45 parts of a water-containing foaming agent, 0.5 to 5 parts of an inorganic metal salt and 0.5 to 10 parts of a cell adjusting agent by using a thermoplastic processing method. The shape of the prepared polyvinyl alcohol porous material may be diversified. The polyvinyl alcohol porous material provided by the invention has the characteristics of plasticity, no need for special packaging and repeated usability, and water adsorbed by the polyvinyl alcohol porous material does not flow when undergoing phase change after freezing; so the polyvinyl alcohol porous material is extensively applicable as a low-temperature refrigeration material for cold-chain transportation.

Owner:SICHUAN UNIV

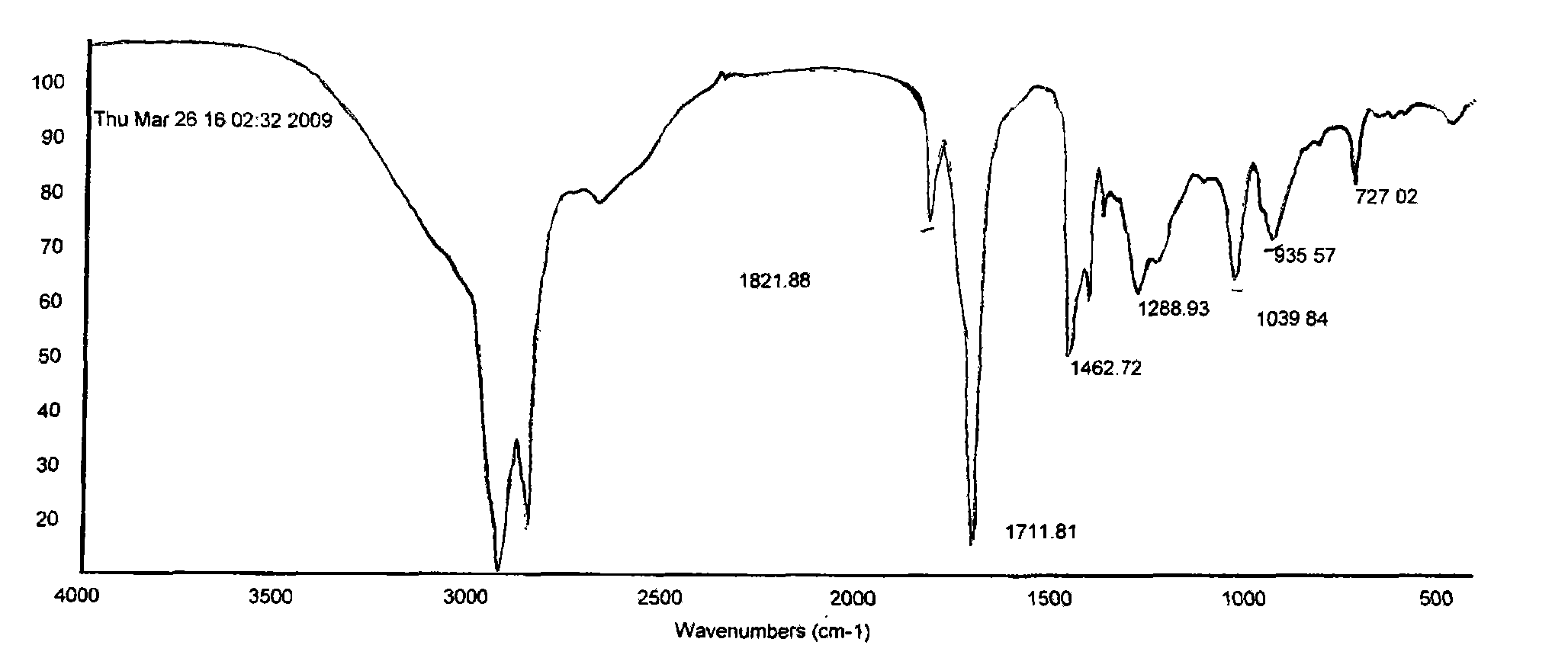

Preparation method of dibasic acid of higher fatty acid and rosin resin acid

InactiveCN101597544ABiodegradableComply with green environmental protectionFatty acid chemical modificationNatural resin chemical modificationFlexural strengthFirming agent

The invention discloses a preparation method of dibasic acid of higher fatty acid and rosin resin acid, comprising the following steps: step 1, appropriate grease is heated up to 150-190 DEG C, which is then catalyzed and hydrolyzed with high pressure to obtain fatty acid used for polymerization reaction; and step 2, the above higher fatty acid and appropriate rosin are premixed and added with a catalyst and a promoter, so that the mixed system is maintained at the pressure of 0.4-1.0MPa, then polymerization addition is carried out at 200-280 DEG C to obtain the required novel dibasic acid. Compared with versamid prepared by ordinary dimer acid, the versamid firming agent synthesized by the novel dibasic acid of the invention has better miscibility with epoxy resin due to the addition of the alicyclic structure of rosin, and the epoxy resin solidifying material has higher mechanical properties of compression strength, modulus of compressibility, bending strength, bending modulus and the like. The invention takes biomass resource grease and rosin as materials, having the biological degradability with which the petrified materials are not provided.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

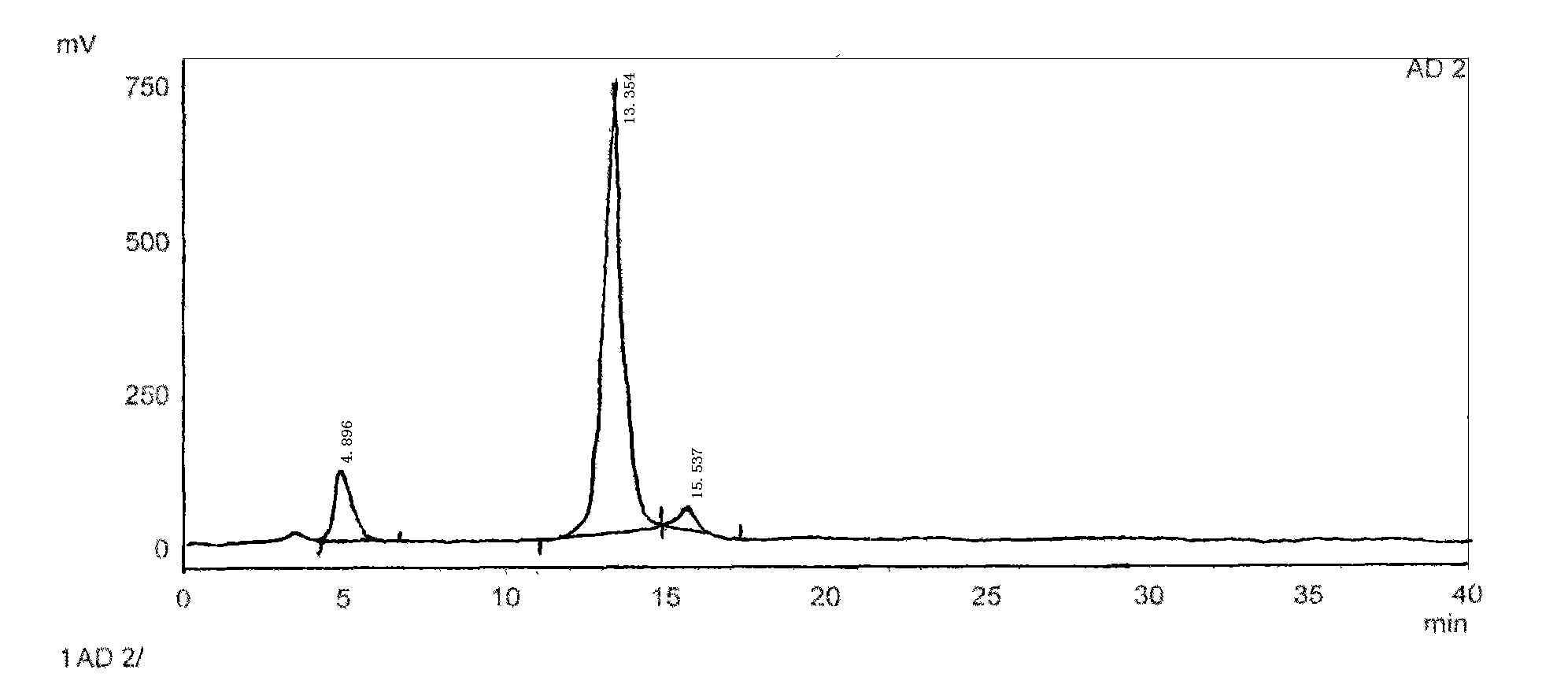

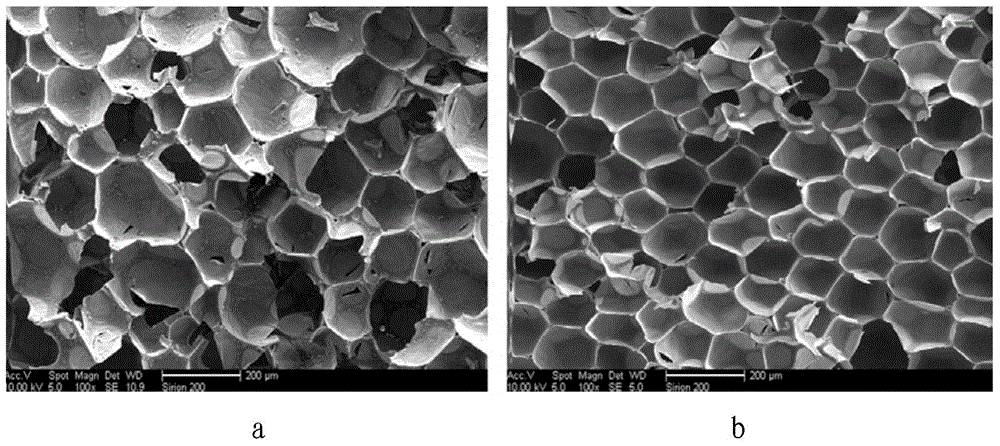

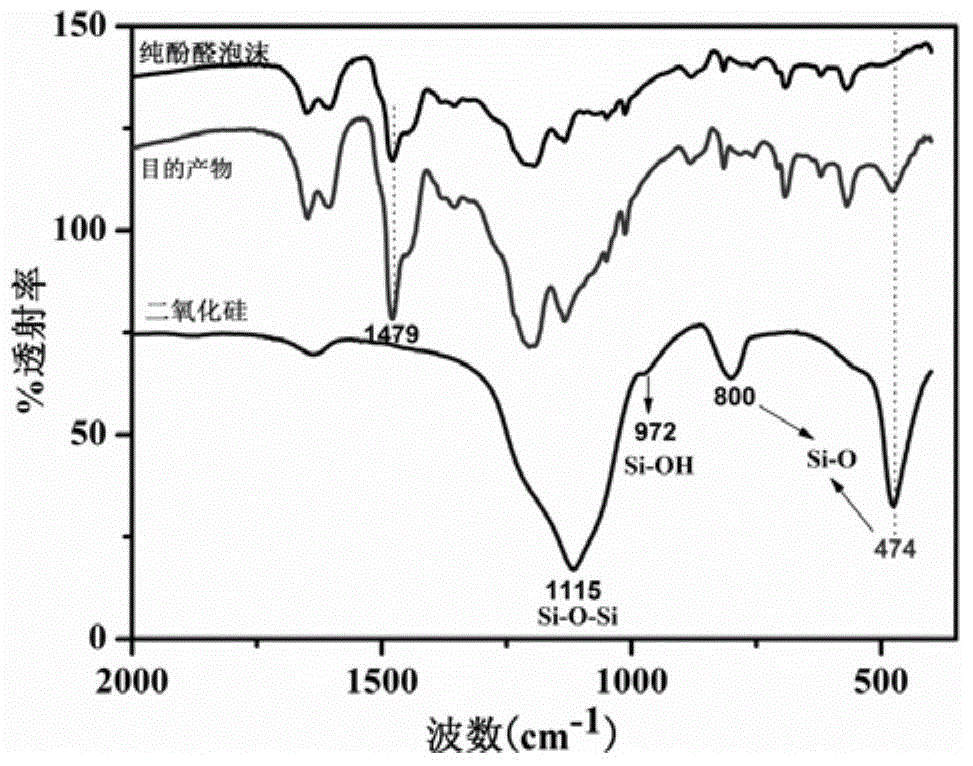

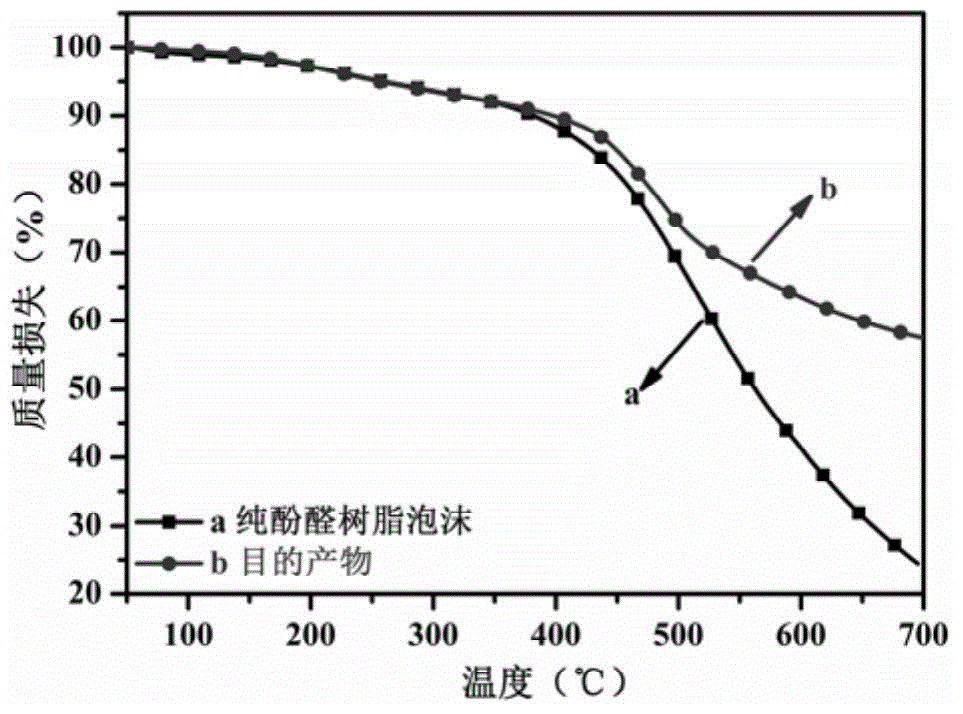

Nano carbon dioxide-phenolic resin composite foam material and preparation method thereof

The invention discloses a nano silicon dioxide-phenolic resin composite foam material and a preparation method thereof. The composite foam material is prepared from silicon dioxide nanoparticles, free phenol, free formaldehyde, a surfactant, a curing agent and sodium chloride as well as phenolic resin, wherein the silicon dioxide nanoparticles are bonded with phenolic resin by virtue of Si-O-C chemical bonds. The method comprises the following steps: firstly, ultrasonically dispersing a SiO2 sol in a formaldehyde solution or a mixed liquid of formaldehyde solution and paraformaldehyde to obtain a mixed solution; then, after mixing the mixed solution, phenol and an alkaline solution, and carrying out polymerization reaction to obtain resol in which the silicon dioxide nanoparticles are uniformly dispersed; then, firstly, carrying out acid neutralization and reduced pressure distillation on the resol; then, mixing and stirring the resol with a foaming agent and the surfactant to obtain mixed resin; and finally, adding the curing agent into the mixed resin and putting into a die to cure and foam to prepare a targeted product. The nano silicon dioxide-phenolic resin composite foam material disclosed by the invention can be widely applied to the fields such as building, aviation, refrigeration and the like commercially.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-strength and high-flame retardation polyurethane composite heat insulation plate

InactiveCN105924942AHigh strengthImprove heat resistanceSynthetic resin layered productsEpoxyInsulation layer

The invention discloses a high-strength and high-flame retardation polyurethane composite heat insulation plate. The high-strength and high-flame retardation polyurethane composite heat insulation plate comprises two backing layers and a polyurethane heat insulation layer positioned between the two backing layers, the polyurethane heat insulation layer is made of a high-performance polyurethane foam material, and raw materials of the high-performance polyurethane foam material comprise a component A and a component B according to a weight ratio of 2:1.2-2.3; raw materials of the component A comprise polyether polyol, pentamethyldiethylenetriamine, trimethylolpropane, pentaerythritol, polyethylene glycol, an organic bismuth catalyst, cyclohexane, water, an organosilicon foaming stabilizer, amino modified carbon nanotubes, expanded perlite, hollow glass micro-beads, silicon whiskers, nanometer aluminum hydroxide, trichloroethyl phosphate, piperazine pyrophosphate, a phosphamide fire retardant, epoxy resin and polyvinyl chloride; and raw materials of the component B comprise diphenylmethane diisocyanate and hexamethylene diisocyanate.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

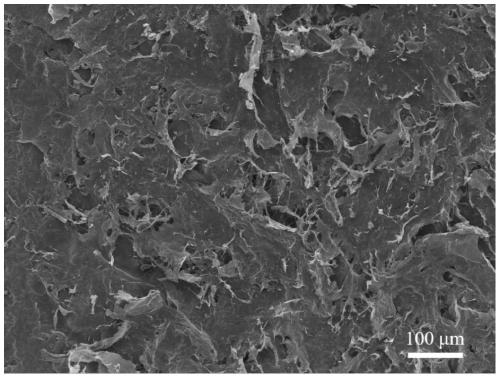

Conductive aramid nanofiber composite aerogel and preparation method thereof

ActiveCN111040237AHigh strengthReduce intensityElectrical/magnetic solid deformation measurementFiberCrystallinity

The invention discloses a conductive aramid nanofiber composite aerogel and a preparation method thereof. By using aramid nano-fibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using whisker carbon nanotubes with high crystallinity and high rigid structure are used as a conductive filler and a reinforced filling material, the conductive aramid nanofiber composite aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing a whisker carbon nanotube dispersion liquid, preparing a whisker carbon nanotube / aramid nanofiber composite dispersion liquid, preparing a gelatinous whisker carbon nanotube / aramid nanofiber composite material, and the like, thereby obtaining the conductive aramid nanofiber composite aerogel. The preparation process is simple and easy to implement, and the obtained conductive aramid nanofiber composite aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

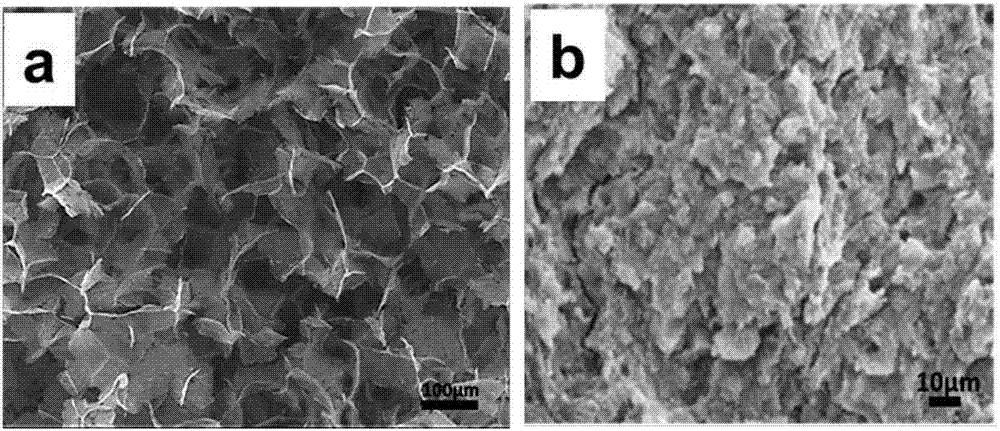

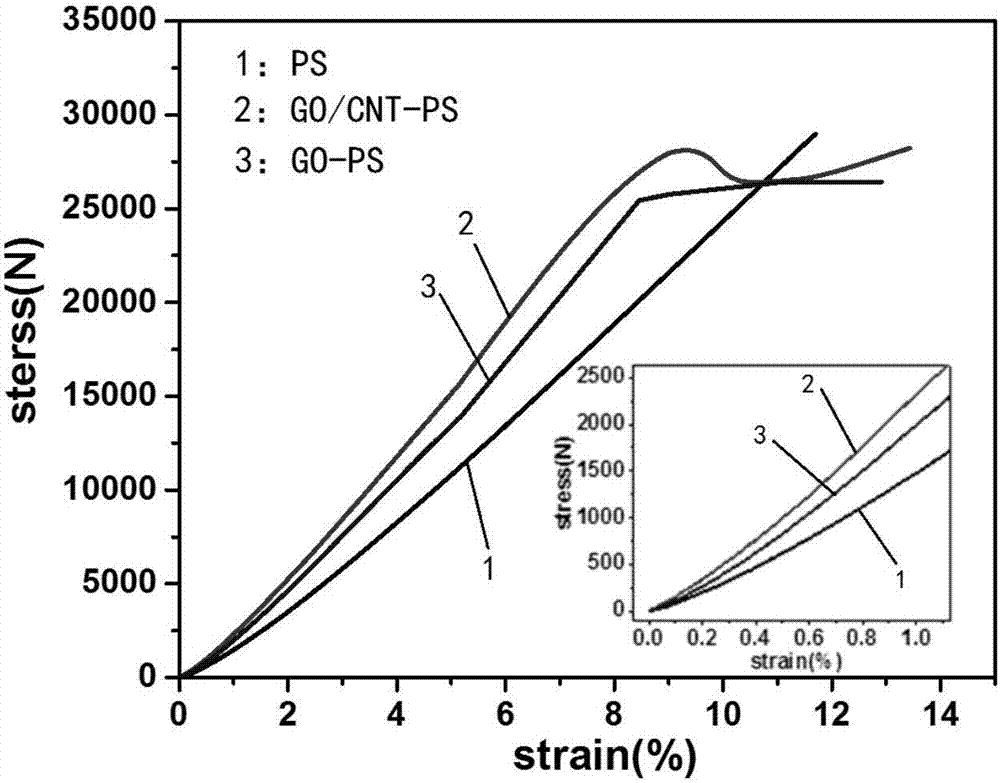

High-performance carbon nano-tube/graphene oxide aerogel/polystyrene composite material and preparation method thereof

The invention discloses a preparation method of a high-performance carbon nano-tube / graphene oxide aerogel / polystyrene composite material. The method includes the steps: firstly, preparing graphene oxide suspension liquid by an improved Hummers method, and performing mixing and freeze drying on the prepared graphene oxide suspension liquid and carbon nano-tubes to prepare carbon nano-tube / graphene oxide aerogel; secondly, filling gaps of the aerogel with mixtures with styrene monomers by a vacuum-assisted impregnation method, and performing in-situ polymerization reaction to obtain a carbon nano-tube / graphene oxide / polystyrene composite material; finally, performing heat treatment on the obtained composite material. The preparation method is simple in process and green and environmentally friendly in process, prepared framework aerogel has the advantages of low density, high porosity and the like, the aerogel and polystyrene are compounded to obtain the composite material, and the composite material has higher strength and modulus as compared with pure polystyrene.

Owner:QINGDAO UNIV

Gangue treatment method and application

ActiveCN110369457ASimple processing methodEasy to operateSolid waste disposalTransportation and packagingSpontaneous combustionMicrosphere

The invention relates to the technical field of gangue treatment, in particular to a gangue treatment method and application. The treatment method comprises the steps of pickling gangue powder; addingwater for granulation after removing pyrites from the gangue powder, and obtaining gangue based microspheres; dipping the gangue based microspheres in solutions containing ferric salt and zinc salt,and obtaining dipped microspheres; performing ozone aeration and ultrasonic treatment to the dipped microspheres, and obtaining activated gangue microspheres; adding alkali to the activated gangue microspheres for solid-liquid separation, and obtaining activated gangue; and mixing the activated gangue and sodium alginate aqueous solutions, and obtaining gangue engineering soil through drying. Recovery and reuse of gangue are achieved, and the pyrite content of the end-product gangue engineering soil is reduced obviously; the phenomena of heat accumulation and gangue heating, even spontaneous combustion in the later accumulation process can be avoided greatly; the security threat is reduced, and the mechanical property of the gangue engineering soil is excellent, and can be applied to grainfor green land, engineering construction land and high-grade highway construction projects.

Owner:北京斯艾尔环境治理科技股份有限公司

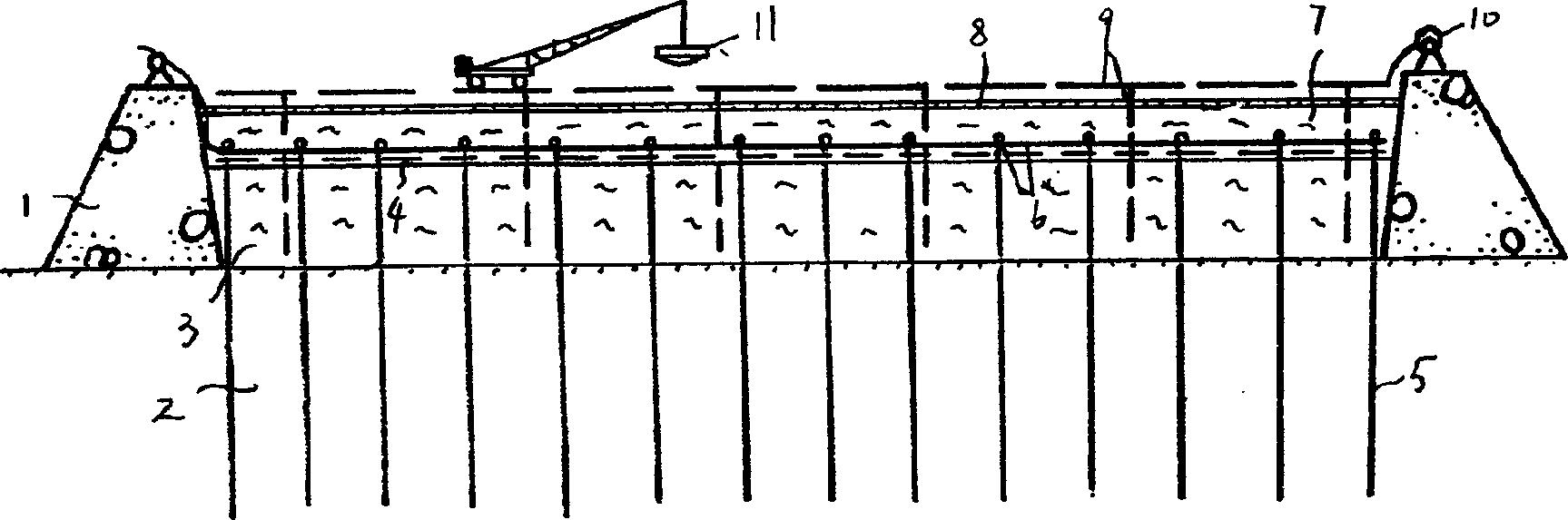

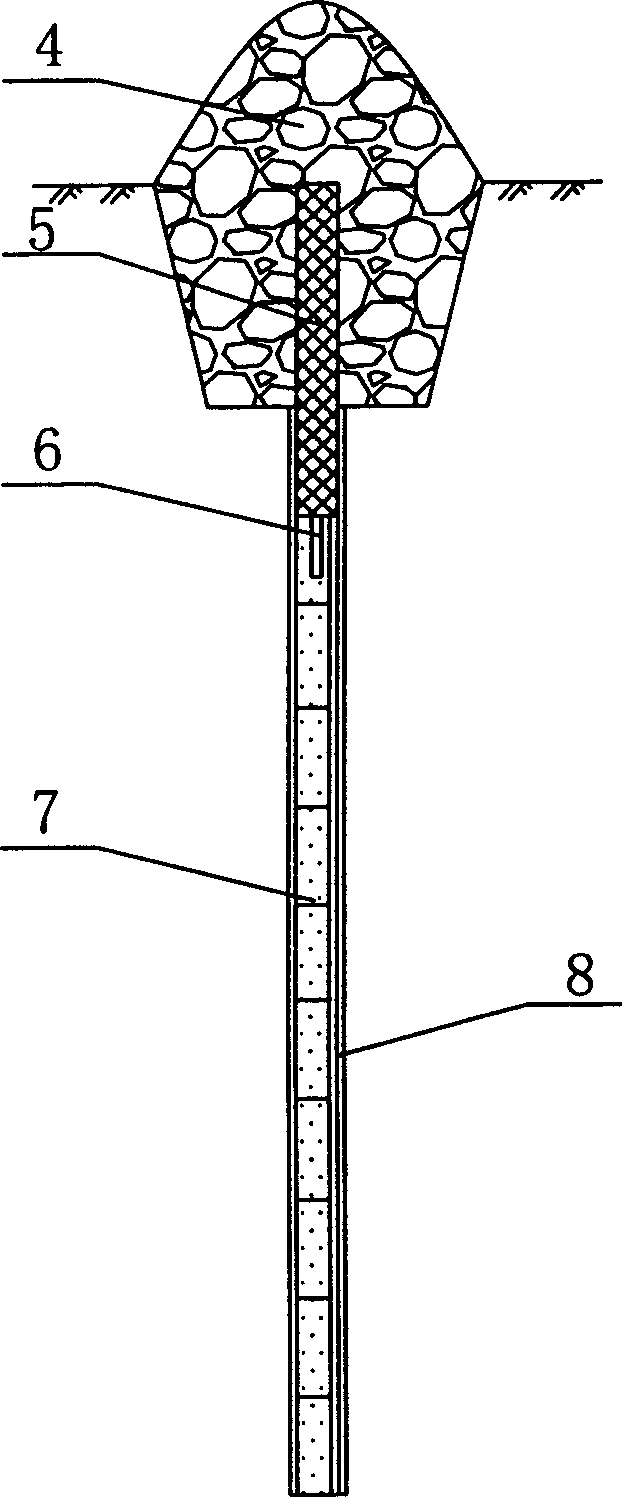

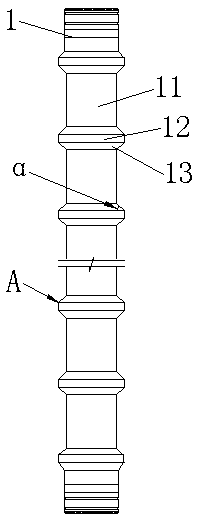

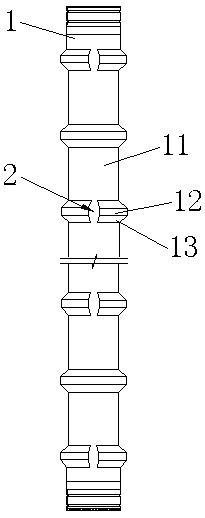

Pipe pile with post-pressure-grouting grouting pipes and construction method of pipe pile

ActiveCN107237319AImprove bearing capacityImprove the modulus of compressionBulkheads/pilesSlurrySpot welding

The invention provides a pipe pile with post-pressure-grouting grouting pipes. The pipe pile comprises a pipe pile body, the grouting pipes which are arranged in the pipe pile body and symmetrically arranged with the axis of the pipe pile body as the center and a steel pile point arranged at the lower end of the pipe pile body. Slurry discharge holes are formed in the positions, corresponding to the pouring pipes, on the steel pile point. Blocking plates which are used for covering the slurry discharge holes and can be jacked up by the grouting pressure are welded to the positions corresponding to the slurry discharge holes in a spot welding manner. The two grouting pipes are vertically arranged. The pipe pile body is formed by the multiple-joint butt joint. Each grouting pipe comprises multiple sections matched with the sections, corresponding to the grouting pipe, of the pipe pile in length. The portions, close to the joints of the pipe pile body, of the sections of the grouting pipes are connected through pipe joints. By the adoption of the pipe pile with the post-pressure-grouting grouting pipes, the single-pile bearing force of the prefabricated concrete pipe pile is improved effectively, the modulus of compression of foundation soil is increased, the settlement of a building is reduced, the pile length is reduced, the number of piles is reduced, the stability of the building is guaranteed, and the building cost is saved.

Owner:MCC TIANGONG GROUP

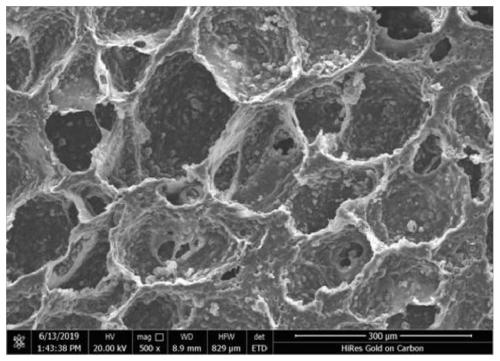

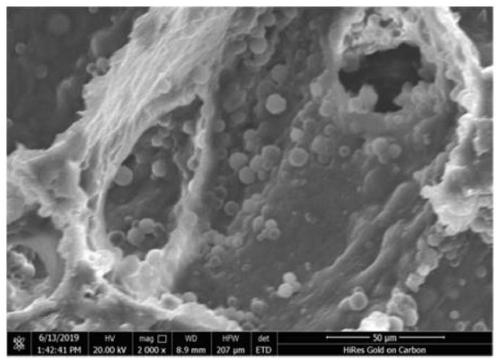

Phase change energy storage porous material and preparation method thereof

InactiveCN110205101AImprove binding forceThe preparation process is matureHeat-exchange elementsEmulsionAqueous solution

The invention discloses a phase change energy storage porous material, and a preparation method thereof, and belongs to the technical field of high molecular material. The preparation method of the phase change energy storage porous material comprises following steps: 1, a polyvinyl alcohol aqueous solution is prepared; 2, a phase change microcapsule emulsion is added into the polyvinyl alcohol aqueous solution so as to obtain a blended solution, wherein in the blended solution, the mass ratio of the phase change microcapsule emulsion to polyvinyl alcohol is controlled to be (1-5) : 1; 3, theblended solution is subjected to stirring foaming so as to obtain a foam solution; and 4, the foam solution is subjected to freeze drying so as to obtain the phase change energy storage porous material. According to the preparation method, solution physical blending foaming method is adopted, so that problems in the prior art that in porous material physical adsorption of phase change microcapsules, adsorption capacity is low, the bonding strength with a base body is poor, and the blending uniformity and stability of phase change microcapsule powder with polymer foaming solution are poor. Thepreparation method is capable of improving the filling capacity of phase change material microcapsules in porous materials, and the bonding strength with the base body, and ensuring the dispersion uniformity of the phase change materials in porous materials.

Owner:XI'AN POLYTECHNIC UNIVERSITY

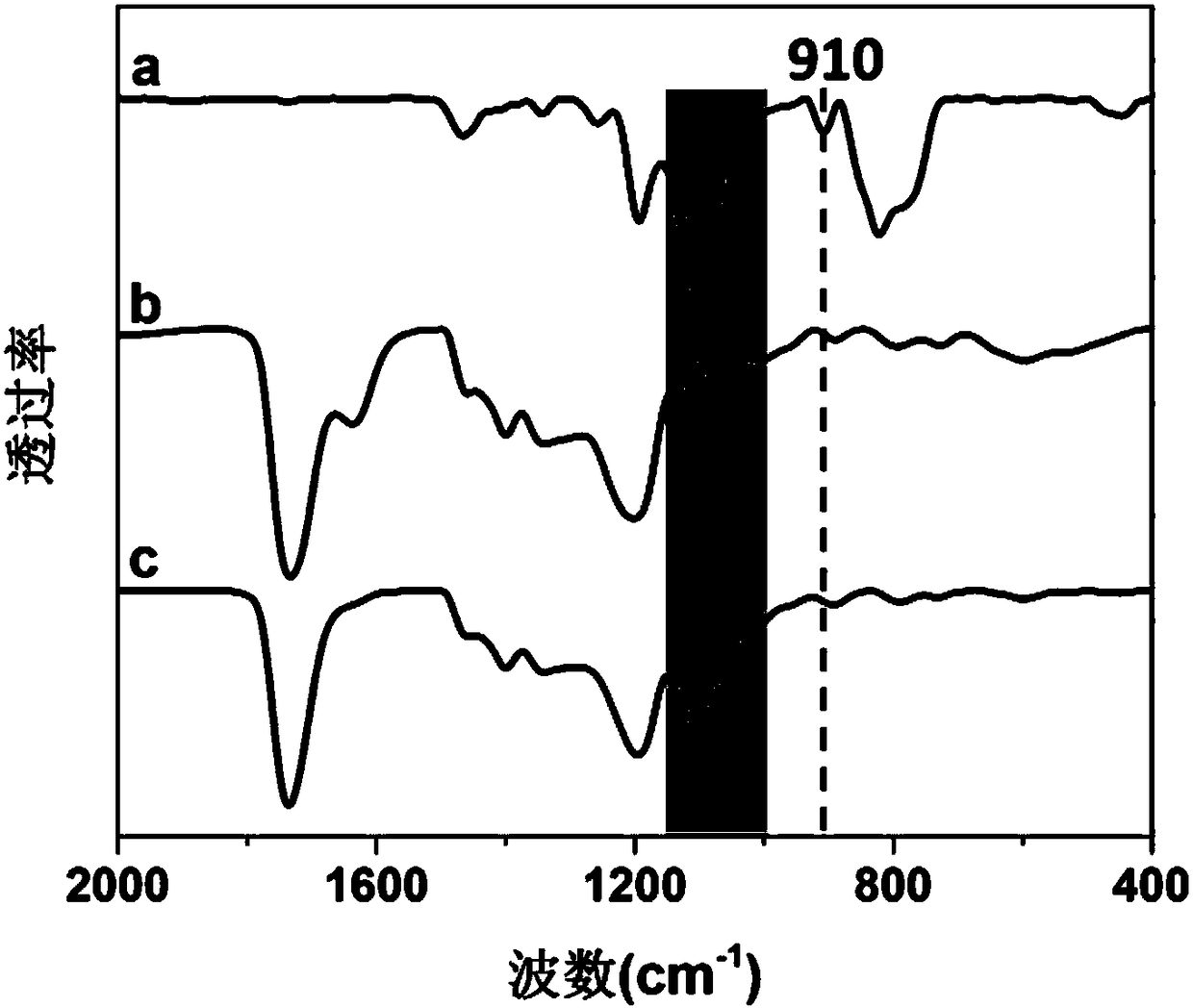

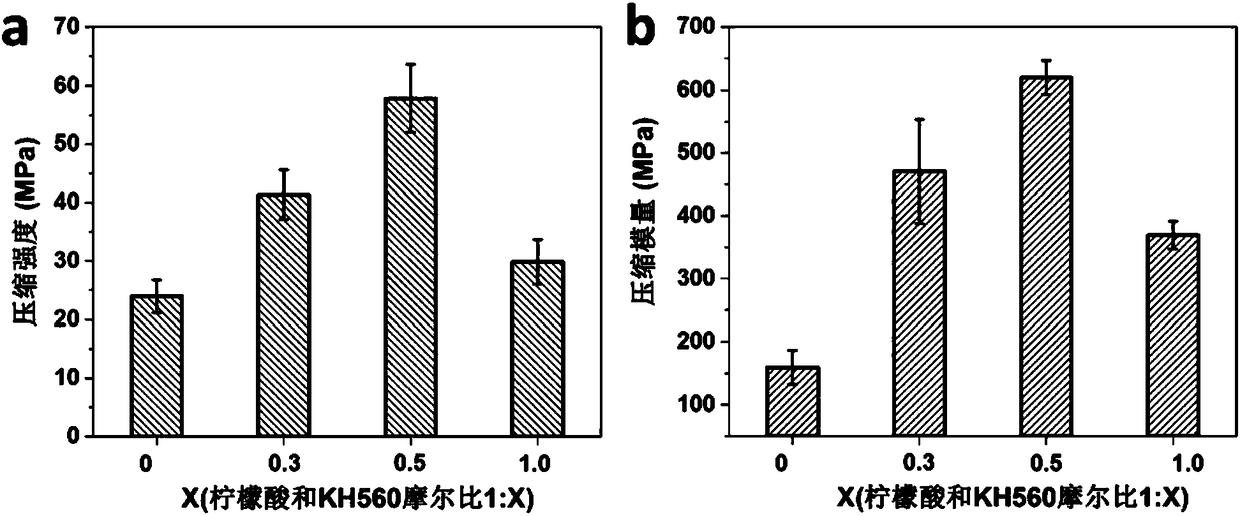

Bioactive composite material as well as preparation method and application thereof

ActiveCN108530851AImprove biological activityImprove mechanical propertiesProsthesisBiocompatibility TestingDrug biological activity

The invention relates to a bioactive composite material as well as a preparation method and application thereof. According to the bioactive composite material, poly-citrate glycol ester is compoundedwith bioactive glass, or the poly-citrate glycol ester is further modified with a saline coupling agent, then good bioactivity, osteoconduction, biocompatibility and controllable biodegradability canbe achieved, meanwhile mechanical properties can be relatively improved, and in addition, the preparation method is simple in process and easy in production.

Owner:华魁科技泰州有限公司

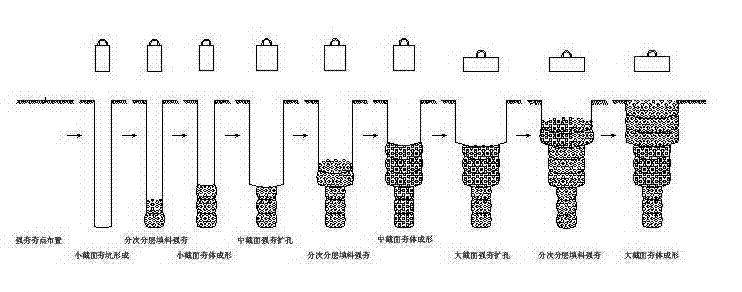

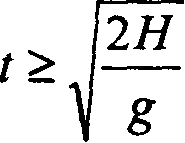

Multi-section type variable cross-section dynamic compaction method

The invention discloses a multi-section type variable cross-section dynamic compaction method, which is the method for treatment of a building foundation, clearing and leveling are firstly performed on a soft foundation space, and multi-section type variable cross-section dynamic compaction construction is further performed on dynamic compaction tamping points which are arranged according to the construction process flow and the technical specifications. During the process of forming a tamping pit and forming tamping bodies, more than two rams in cross sections which are increased gradually are adopted for ramming a soil body of a soft foundation from bottom to top respectively for forming the tamping pit or an expanded hole, dry soil or aggregate is further backfilled into the tamping pit and rammed, tamping of the tamping pit and the backfilled materials is completed section by section, then more than two sections of the dynamic compaction tamping bodies or replacement pier bodies in the cross sections which are gradually increased are formed from the bottom to the top and full compaction operation in a dynamic compaction region is finally performed. After the method is adopted for dynamic compaction and reinforcement, the overall compactness, the strength of the foundation and the bearing capacity are greatly improved, and the foundation is uniform at the upper part and the lower part. The stress stability, the uniformity and the overall rigidity of the foundation soil are significantly increased. The construction quality is more stable, the compression modulus of the foundation is high, and the settlement value and the settlement difference value are obviously reduced.

Owner:谢开生

Synchronous blast-enlarging treatment method for liquified soil foundation of highway

InactiveCN1776110AExplosion effect is goodReduce adverse effectsRoadwaysSoil preservationMiddle lineAdverse effect

This invention relates to synchronous explosion extending method for liquefied foundation of high way. Said method contains distributing explosion extending holes and drainage ditch along road, the hole is filled with explosive, burster and explosive loading pipe for sealing hole, the top of each hole excavated with stone filling pit having volume greater than that of explosion extending cavity, the explosion extending is operated in two time delay. Said invention both forms explosion extending cavity and explosion stone filling with fine water charge and effectively solidifying explosion soil body, greatly reduces the adverse effect to around environment.

Owner:CHINA UNIV OF MINING & TECH

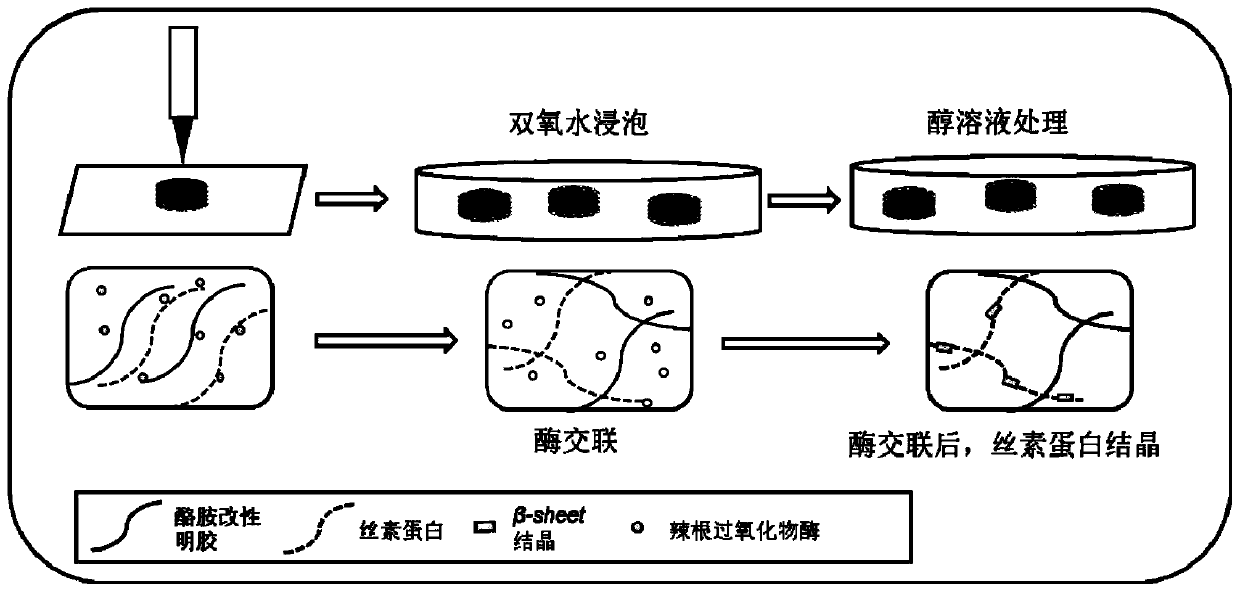

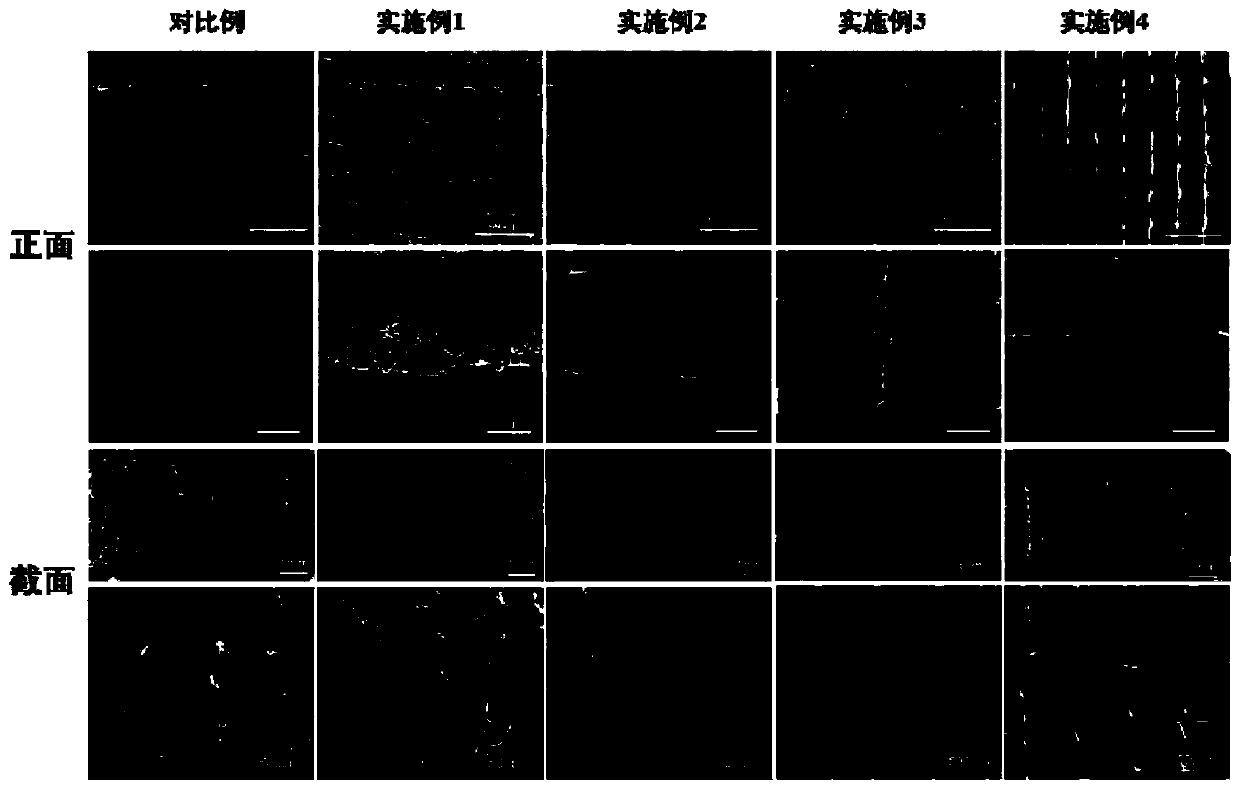

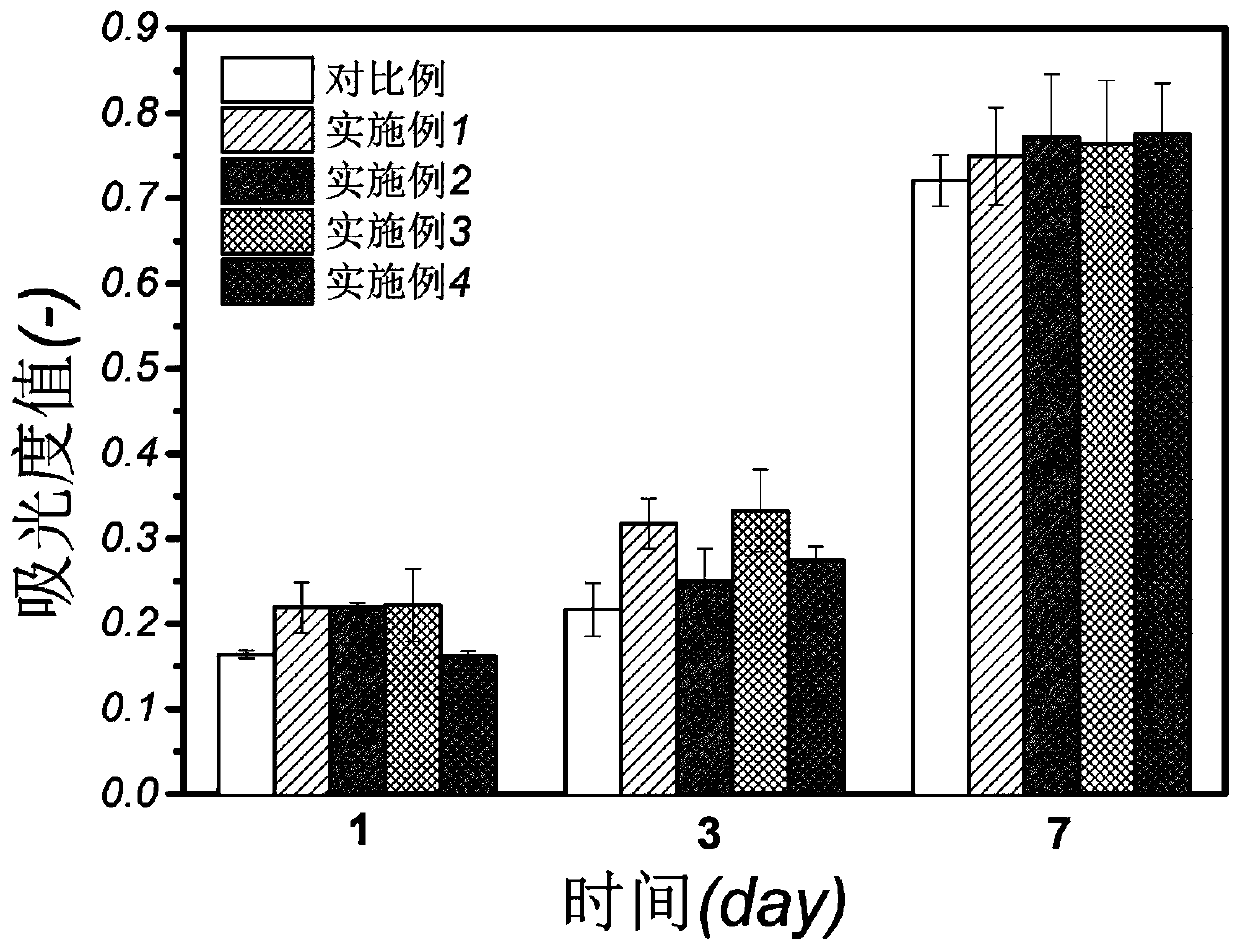

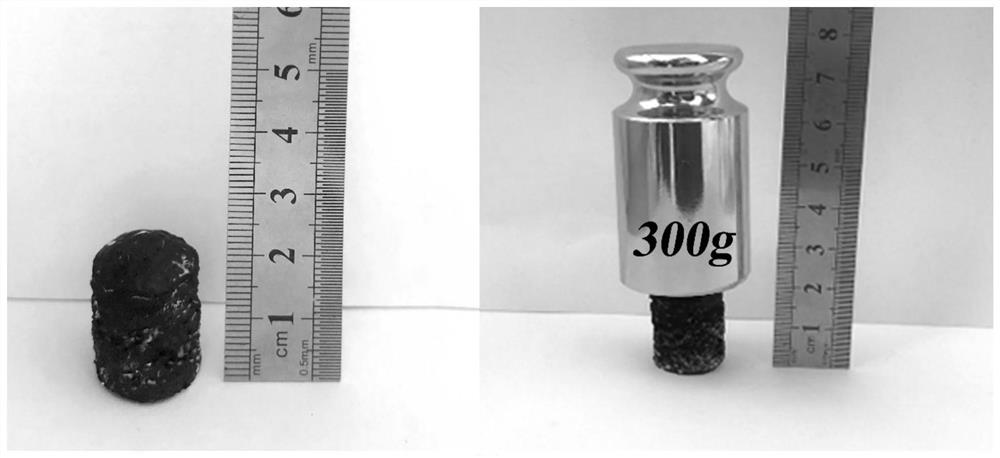

3D printing fibroin/gelatin support used for cartilage repairing, and preparation method thereof

InactiveCN110201225AWide variety of sourcesGood biocompatibilityAdditive manufacturing apparatusTissue regenerationSlurryHorseradish peroxidase

The invention discloses a 3D printing fibroin / gelatin support used for cartilage repairing, and a preparation method thereof. The support takes silk fibroin, tyramine graft modified gelatin and horseradish peroxidase as slurry; the porous hydrogel support is constructed by utilizing a 3D printing technology; enzyme crosslinking can be realized through the immersion of hydrogen peroxide; and mechanical properties can be enhanced by further utilizing an alcoholic solution to process. The support combines the excellent characteristics of the gelatin and fibroin, so that the support can have goodbiocompatibility, mechanical properties and compression fatigue resistance, and can be applied to the regeneration and repairing of cartilage tissues.

Owner:SOUTH CHINA UNIV OF TECH

Graphene/nanocellulose/polyvinyl alcohol ternary composite aerogel and preparation method thereof

The invention relates to the field of preparation of composite materials, and discloses a graphene / nanocellulose / polyvinyl alcohol ternary composite aerogel, and in the graphene / nanocellulose / polyvinyl alcohol ternary composite aerogel, the content of nanocellulose is 15 wt%-50 wt%, and the content of polyvinyl alcohol is 5 wt%-10 wt%. The preparation method of the aerogel comprises the following steps: (1) preparing a graphene oxide / nanocellulose mixed solution; (2) preparing graphene / nano cellulose hydrogel; (3) preparing graphene / nanocellulose / polyvinyl alcohol hydrogel; and (4) preparing the graphene / nanocellulose / polyvinyl alcohol ternary composite aerogel. According to the invention, the problems that the graphene aerogel is insufficient in mechanical property and unitary aerogel composed of a single main body is insufficient in performance and limited in use are solved.

Owner:NORTHEAST FORESTRY UNIVERSITY

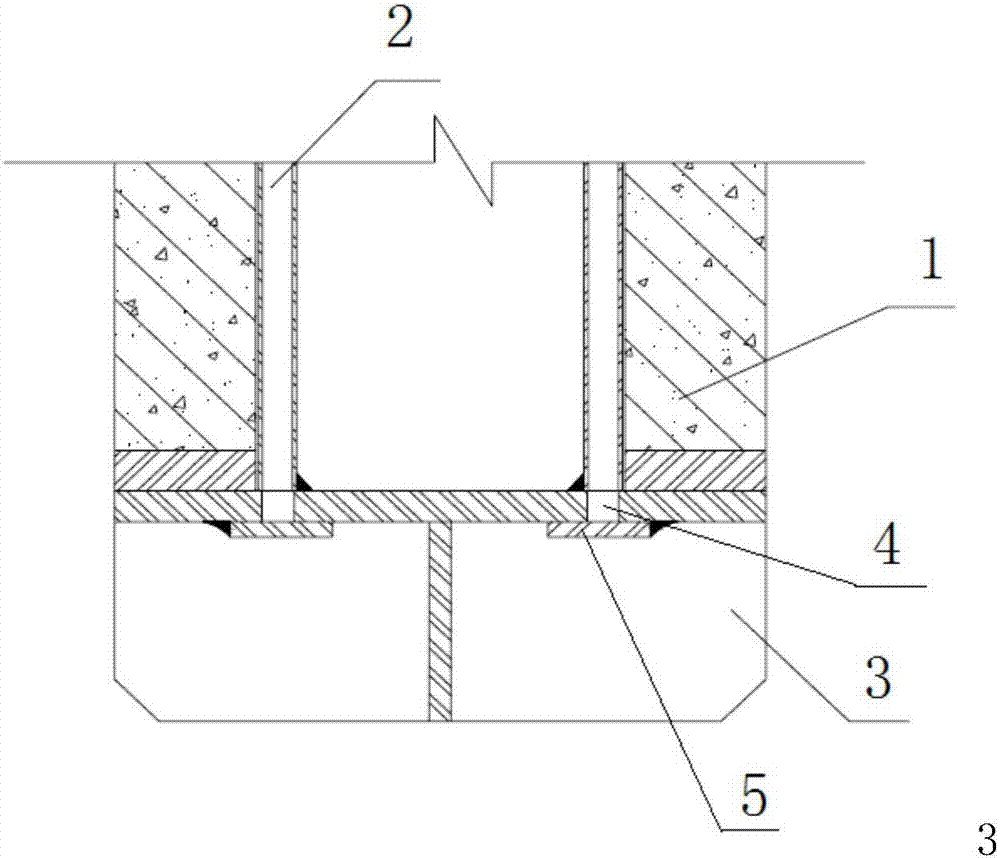

Concrete pile suitable for foundation treatment

ActiveCN107700480AImprove bearing capacityImprove the modulus of compressionPhotovoltaic energy generationBulkheads/pilesEconomic benefits% diameter reduction

The invention discloses a concrete pile suitable for foundation treatment. The concrete pile comprises a pile body which is a variable cross-section structure formed integrally, diameter expansion portions are arranged on the pile body at intervals, a diameter reduction portion is arranged between every two adjacent diameter expansion portions, and the diameter reduction portions and the diameterexpansion portions are connected and fastened through necking down structures; each diameter expansion portion is a closed ring or non-closed ring provided with a notch, and difference value between the radial width of the diameter reduction portions and that of the diameter expansion portions is smaller than or equal to 60 mm. The concrete pile has the advantages of being higher in practicabilityand applicability, the pile body directly make contact with an original soil body in the construction process, no weak link exists, and the foundation soil bearing capacity is promoted remarkably bymeans of expansion and vibration on the soil body by the diameter expansion portions; after the soil body is solidified, loads on the foundation soil are uniformly distributed into the foundation soilthrough the load bearing faces of the diameter expansion portions and the diameter reduction portions, a whole is formed by the foundation soil and soil around the pile, the foundation settlement problem is improved substantially, and the global stability of the foundation is improved; the concrete pile is low in manufacturing cost and good in economic benefits.

Owner:宁波中淳高科股份有限公司

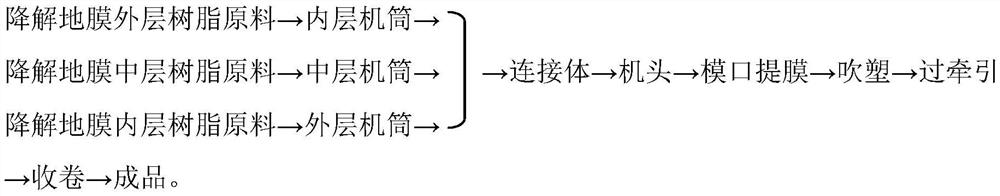

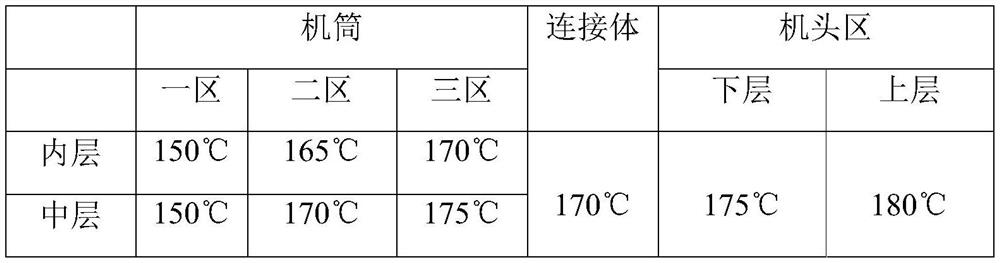

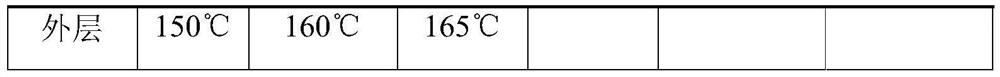

Three-layer composite high-barrier controllable full-biodegradable mulching film and preparation method thereof

ActiveCN112262695ABiodegradableWith mechanical propertiesAgricultural articlesClimate change adaptationAgricultural engineeringPlastic mulch

The invention belongs to the technical field of agricultural film preparation, and particularly relates to a three-layer composite high-barrier controllable full-biodegradable mulching film and a preparation method thereof. The mulching film comprises an inner layer, namely a mulching film slow release layer, a middle layer, namely a mulching film barrier layer, and an outer layer, namely a mulching film service life control layer; the mulching film slow release layer comprises PBAT and PLA; the mulching film barrier layer comprises PBAT, PLA and TPU; and the mulching film service life controllayer comprises PBAT and PLA. The three-layer composite high-barrier controllable full-biodegradable mulching film meets the requirements of farmers for original heat preservation and soil moisture conservation functions of the mulching film, the degradation effect of the mulching film can be controlled within a certain period of time according to the growth requirements of crops, the mulching film can be completely degraded when the crops are harvested, and no pollution is caused to the land environment and soil. The secondary labor cost of the farmers is reduced, and the social secondary pollution is reduced. The preparation method is scientific, reasonable, simple and feasible.

Owner:SHANDONG QINGTIAN PLASTIC IND

Modified tussah silk fibroin 3D printing support and preparation method thereof

ActiveCN110859994AIncreased survival and proliferationImprove mechanical propertiesAdditive manufacturing apparatusPharmaceutical delivery mechanismFibroinHuman Induced Pluripotent Stem Cells

The invention relates to a modified tussah silk fibroin 3D printing support and a preparation method thereof. Core part printing ink prepared by using chemically modified tussah silk fibroin nano microfibers and shell part printing ink prepared by using a chemically modified tussah silk fibroin nano microfiber / gelatin composite system are used for carrying out 3D printing to prepare a modified tussah silk fibroin 3D printing support. The compression modulus of the modified tussah silk fibroin 3D printing support is 100 to 600 MPa after soaking in genipin with the mass concentration of 0.1 to 5wt% and subjection to a cross-linking reaction for 24 h; and after culture for 10 days, the survival rate and the proliferation rate of induced pluripotent stem cells are high. The finally prepared modified tussah silk fibroin 3D printing support comprises printing lines with core-shell structures. According to the invention, the preparation method is relatively simple; and the prepared 3D printing support has excellent mechanical properties, excellent biocompatibility and good tissue repair capability.

Owner:DONGHUA UNIV

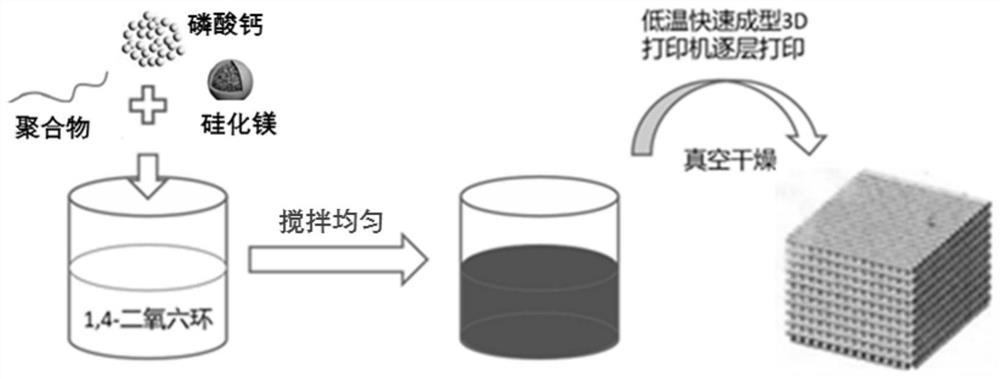

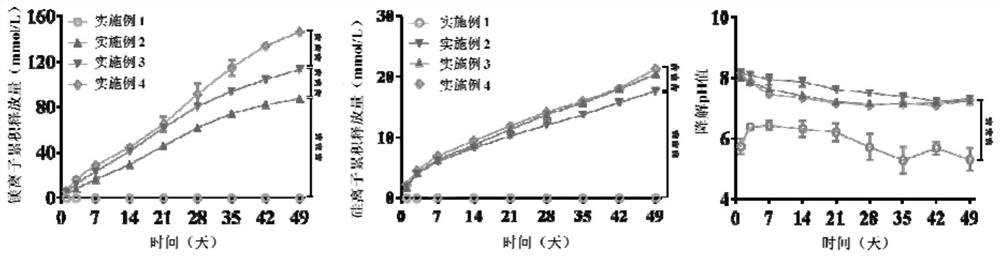

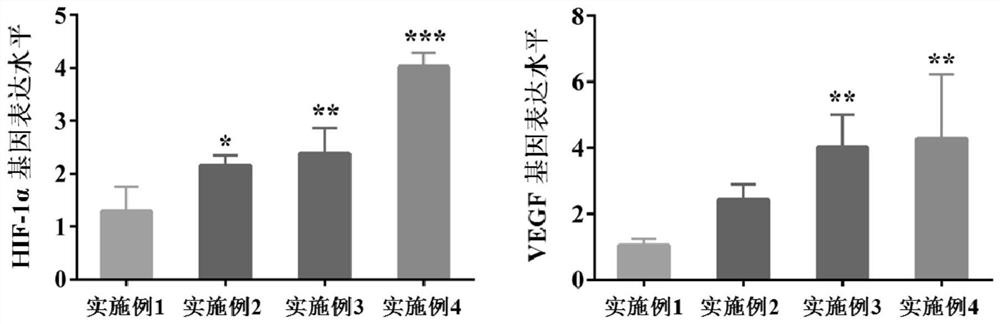

Bioactive composite material for bones as well as preparation method and application of composite material

ActiveCN112972773APromote generationEnabling activityTissue regenerationProsthesisOrganic acidAngiogenesis growth factor

The invention relates to a bioactive composite material for bones as well as a preparation method and application of the bioactive composite material, in particular to a composite material for bones, which is characterized by comprising a substrate of a biodegradable polymer, and the substrate further comprises magnesium silicide; and the biodegradable polymer can be degraded in an aqueous solution environment to generate is micromolecular organic acids. The special effect of magnesium silicide acting on bone injury parts is found for the first time, a biodegradable polymer substrate is degraded in a physiological environment to generate micromolecular organic acids, and the surrounding environment of a stent is slightly acidic, so that degradation of magnesium silicide can be triggered, controllable long-acting release of magnesium ions and silicon ions along with the degradation process of the stent is realized, and osteogenic activity is promoted; and meanwhile, implantation parts are adjusted to form a hypoxic microenvironment, and angiogenesis is promoted. The magnesium silicide-containing composite material for bones shows bioactivity for promoting osteogenesis and vascularization, and can realize effective bone defect repair.

Owner:SHENZHEN INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com