Preparation method of dibasic acid of higher fatty acid and rosin resin acid

A technology of higher fatty acid and rosin resin acid, applied in the production of fatty acid, chemical modification of fatty acid, chemical modification of natural resin, etc., can solve the problems of low hardness, poor mutual solubility of epoxy resin, poor heat resistance of polyamide resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

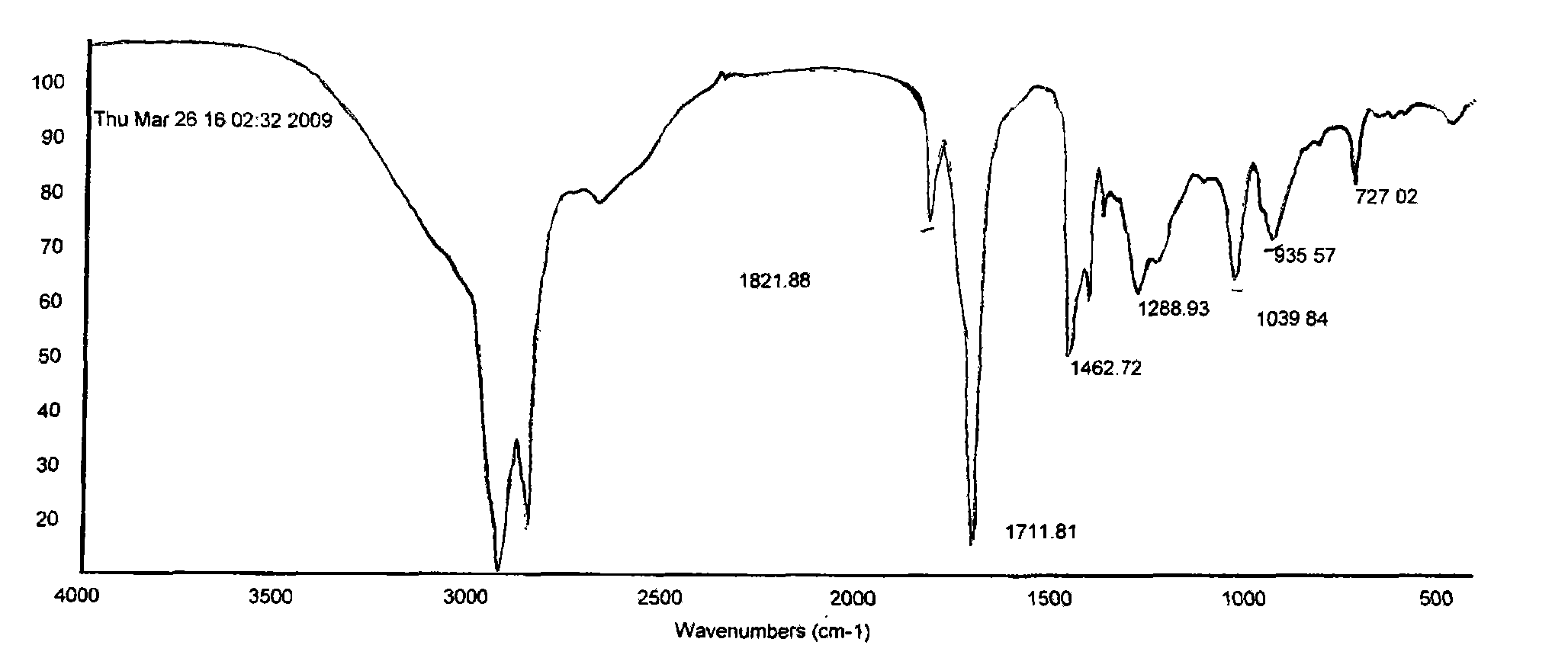

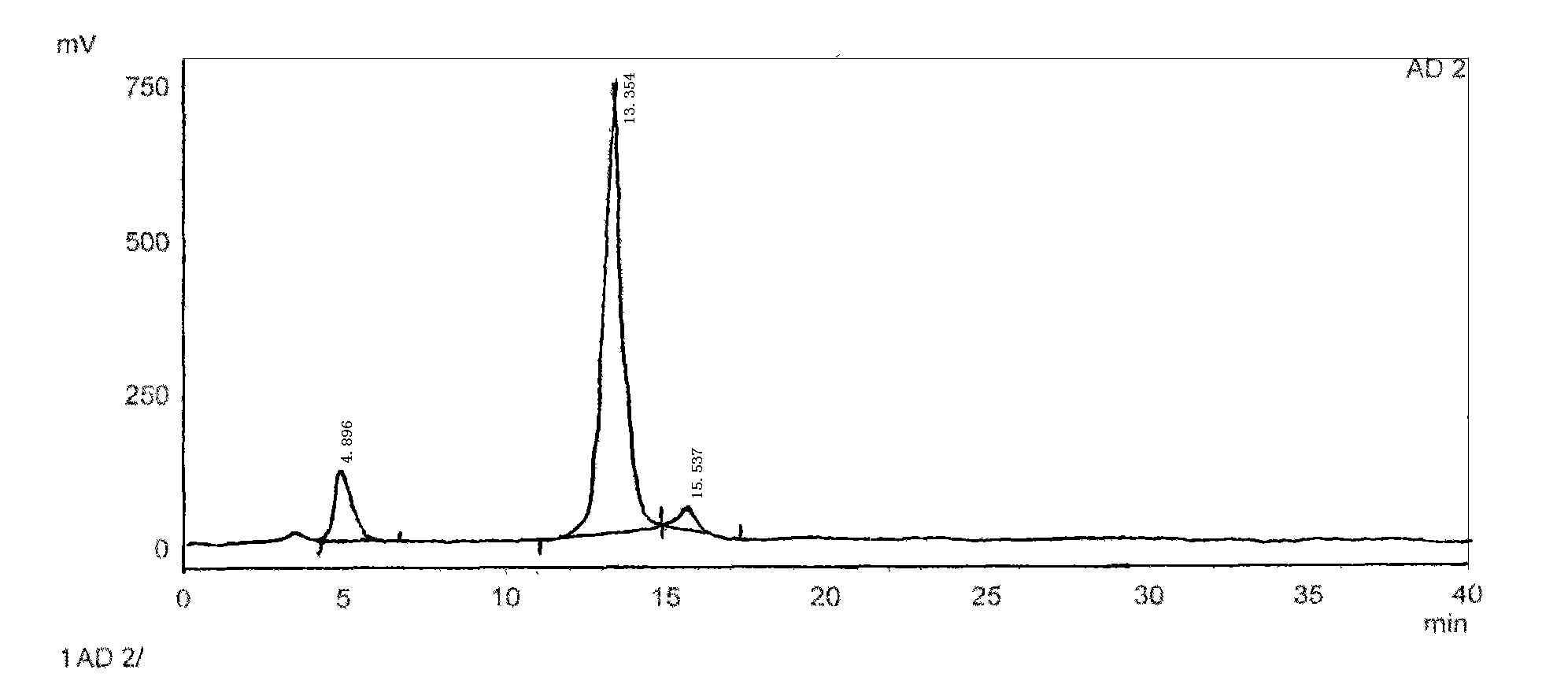

Image

Examples

Embodiment 1

[0032] dibasic acid of eucalyptus oleic acid and rosin resin acid

[0033] (1) Preparation of eucalyptus oleic acid

[0034] In an autoclave equipped with a stirring device and a thermometer, add 100 grams of eucalyptus seed oil, 0.5 grams of zinc oxide and 70 grams of water, stir evenly, heat to 180 ° C, and react for 4-8 hours. After the reaction, cool down to 60-90°C and neutralize with sulfuric acid to pH 3-5. The water in the lower layer was separated, and the oleic acid layer was washed to neutral, and the water in the lower layer was separated. Distill and dehydrate under the condition of 100-120°C / 1-15mmHg to obtain 90 grams of fatty acid for the next step of polymerization.

[0035] (2) Polymerization reaction:

[0036] In an autoclave equipped with a stirring device and a thermometer, add 50-95 grams of glabra oleic acid, 5-50 grams of rosin, 3-10 grams of lithium carbonate and 15-30 grams of activated clay to maintain a pressure of 0.4-1.0 MPa At 200°C-280°C, ca...

Embodiment 2

[0038] Dibasic acid of soybean oil and rosin resin acid

[0039] (1) Hydrolysis of soybean oil

[0040] In an autoclave equipped with a stirring device and a thermometer, add 100 grams of soybean oil, 0.5 grams of zinc oxide and 70 grams of water, stir evenly, heat to 180° C., and react for 4-8 hours. After the reaction, cool down to 60-90°C and neutralize with sulfuric acid to pH 3-5. The water in the lower layer was separated, and the oleic acid layer was washed to neutral, and the water in the lower layer was separated. Distill and dehydrate under the condition of 100-120°C / 1-15mmHg to obtain 90 grams of fatty acid for the next step of polymerization.

[0041] (2) Polymerization reaction:

[0042] In an autoclave equipped with a stirring device and a thermometer, add 50-95 grams of the above-mentioned oleic acid, 5-50 grams of rosin, 3-10 grams of manganese acetate and 15-30 grams of montmorillonite, and maintain a pressure of 0.4-1.0 MPa , carry out polymerization reac...

Embodiment 3

[0044] Diacids of Oleic Acid and Rosin Resin Acid Prepared from Tung Oil

[0045] (1) Hydrolysis reaction of tung oil

[0046]In an autoclave equipped with a stirring device and a thermometer, add 100 grams of tung oil, 0.5 grams of magnesium oxide and 60 grams of water, stir evenly, heat to 170 ° C, and react for 4-8 hours. After the reaction, cool down to 60-90°C and neutralize to pH 3-5 with phosphoric acid. The lower layer of water is divided, and then the tung oil layer is washed to neutrality, and the lower layer of water is separated. Distill and dehydrate under the condition of 100-110° C. / 1-15 mmHg to obtain 90 grams of fatty acid for the next step of polymerization.

[0047] (2) Polymerization reaction:

[0048] In an autoclave equipped with a stirring device and a thermometer, add 50-95 grams of eutrophic acid, 5-50 grams of rosin, 3-10 grams of iodine and 15-30 grams of activated clay. Polymerize at -280°C for 3-6 hours, cool to 80°C; measure the pH of the syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com