Three-layer composite high-barrier controllable full-biodegradable mulching film and preparation method thereof

A degradable mulch film and high-barrier technology, which is applied in the fields of botany equipment and methods, chemical instruments and methods, plant protection, etc., can solve the problems of low practicability, difficult operation, complex process, etc. for energy saving and consumption reduction, and can achieve degradation time. Control and ensure the effect of barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

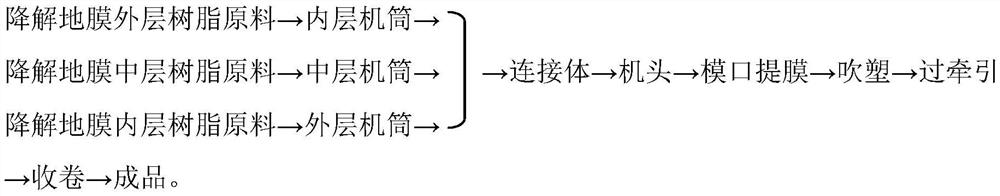

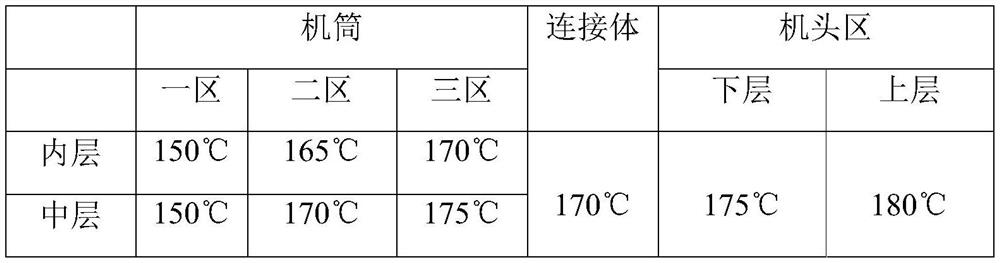

Method used

Image

Examples

Embodiment 1

[0082] The width of the production film is 1.2 meters, the thickness is 0.008mm, and the service life of the degradable film is required to be 90 days to 105 days.

[0083] The three-layer composite high-barrier controllable fully biodegradable mulch film includes an inner layer, a middle layer and an outer layer, and its specific composition is as follows:

[0084] Outer layer: Degradable mulch life control layer resin is made of the following raw materials in mass percentage:

[0085] PBAT: 88wt.%; PLA: 6wt.%; UV absorber: 2wt.%; light stabilizer: 0.5wt.%; antioxidant: 0.5wt.%; lubricant: 1wt.%; dispersant: 2wt. %.

[0086] After the above raw materials are granulated, each bag is 25Kg, including: PBAT 22Kg; PLA 1.5Kg; ultraviolet absorber 0.5Kg; light stabilizer 0.125Kg; antioxidant 0.125Kg; lubricant 0.25Kg; dispersant 0.5Kg.

[0087] Middle layer: Degradable mulch barrier layer resin is made of the following raw materials in mass percentage:

[0088] PBAT: 87wt.%; PLA:...

Embodiment 2

[0117] The width of the production film is 1.2 meters, the thickness is 0.008mm, and the service life of the degradable film is required to be 105 days to 115 days.

[0118] The three-layer composite high-barrier controllable fully biodegradable mulch film includes an inner layer, a middle layer and an outer layer, and its specific composition is as follows:

[0119] Outer layer: Degradable mulch life control layer resin is made of the following raw materials in mass percentage:

[0120] PBAT: 86.6wt.%; PLA: 7wt.%; UV absorber: 2wt.%; light stabilizer: 0.6wt.%; antioxidant: 0.8wt.%; lubricant: 1wt.%; dispersant: 2wt .%.

[0121] After the above raw materials are granulated, each bag is 25Kg, including: PBAT 21.65Kg; PLA 1.75Kg; ultraviolet absorber 0.5Kg; light stabilizer 0.15Kg; antioxidant 0.2Kg; lubricant 0.25Kg; dispersant 0.5Kg.

[0122] Middle layer: Degradable mulch barrier layer resin is made of the following raw materials in mass percentage:

[0123] PBAT: 87wt.%; ...

Embodiment 3

[0140] The width of the production film is 1.2 meters, the thickness is 0.008mm, and the service life of the degradable film is required to be 115 days to 130 days.

[0141] The three-layer composite high-barrier controllable fully biodegradable mulch film includes an inner layer, a middle layer and an outer layer, and its specific composition is as follows:

[0142] Outer layer: Degradable mulch life control layer resin is made of the following raw materials in mass percentage:

[0143] PBAT: 85.2wt.%; PLA: 8wt.%; UV absorber: 2.2wt.%; light stabilizer: 0.8wt.%; antioxidant: 0.8wt.%; lubricant: 1wt.%; dispersant: 2wt.%.

[0144] After the above raw materials are granulated, each bag is 25Kg, including: PBAT 21.3Kg; PLA 2Kg; ultraviolet absorber 0.55Kg; light stabilizer 0.2Kg; antioxidant 0.2Kg; lubricant 0.25Kg; dispersant 0.5Kg.

[0145] Middle layer: Degradable mulch barrier layer resin is made of the following raw materials in mass percentage:

[0146] PBAT: 87wt.%; PLA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com