Hard polyurethane adiabatic heat-insulation foam material and preparation method thereof

A technology of rigid polyurethane and thermal insulation, which is applied in the field of foaming materials and their preparation, can solve the problems of ignoring the thermal conductivity of materials and the inability to use thermal insulation materials, etc., and achieve excellent thermal insulation performance, high compression modulus, and high compression performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The first step, the surface treatment of chopped glass fiber powder: soak the chopped glass fiber powder in a 9:1 ethanol / water mixed solution, adjust the pH value to 4-6 with acetic acid, and add 10% by mass The KH-550 silane coupling agent was stirred with a magnetic force for 6 hours, and the mixture was ultrasonicated at 30W for 30-40 minutes, and filtered using a Buchner funnel for use.

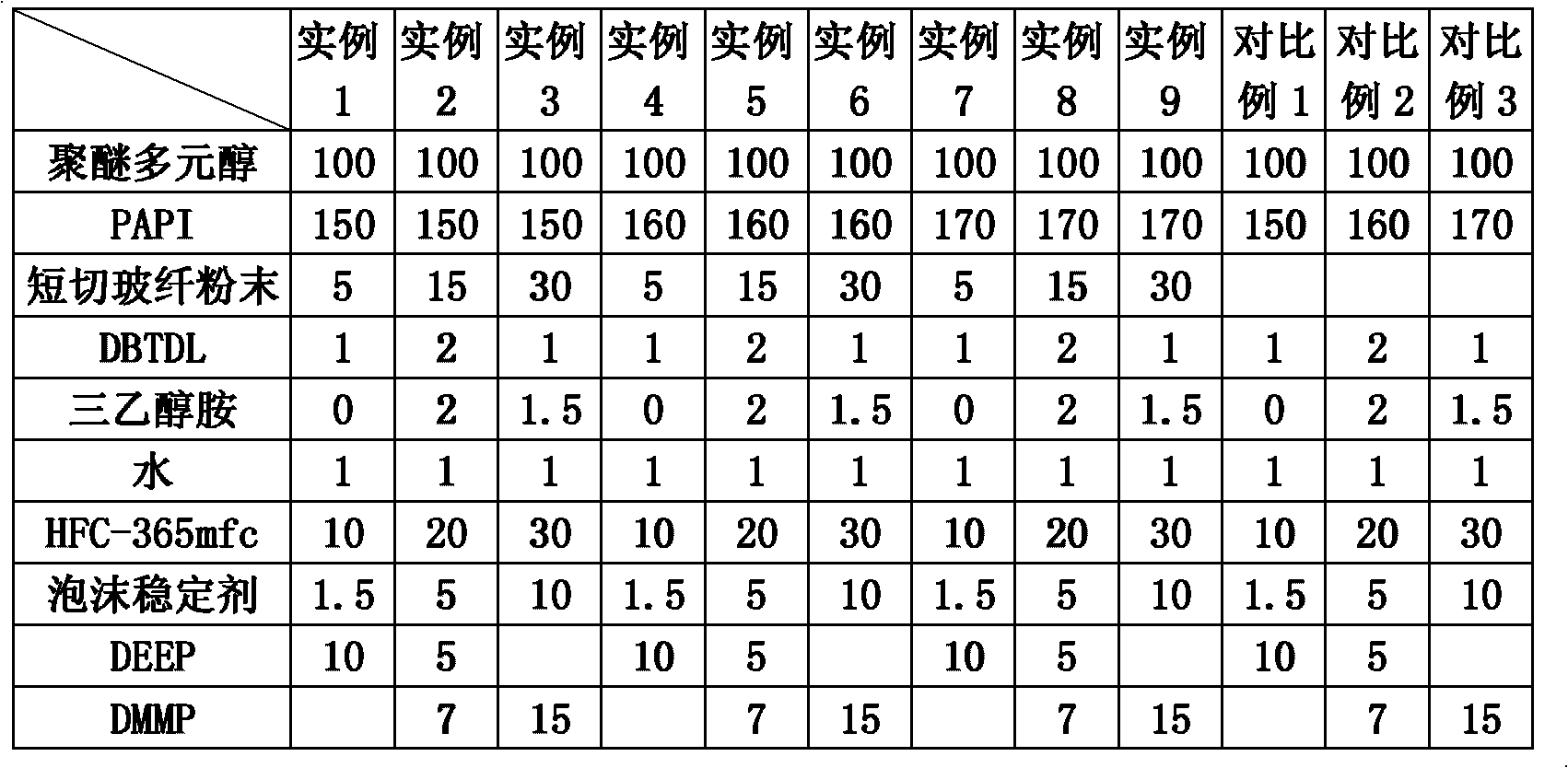

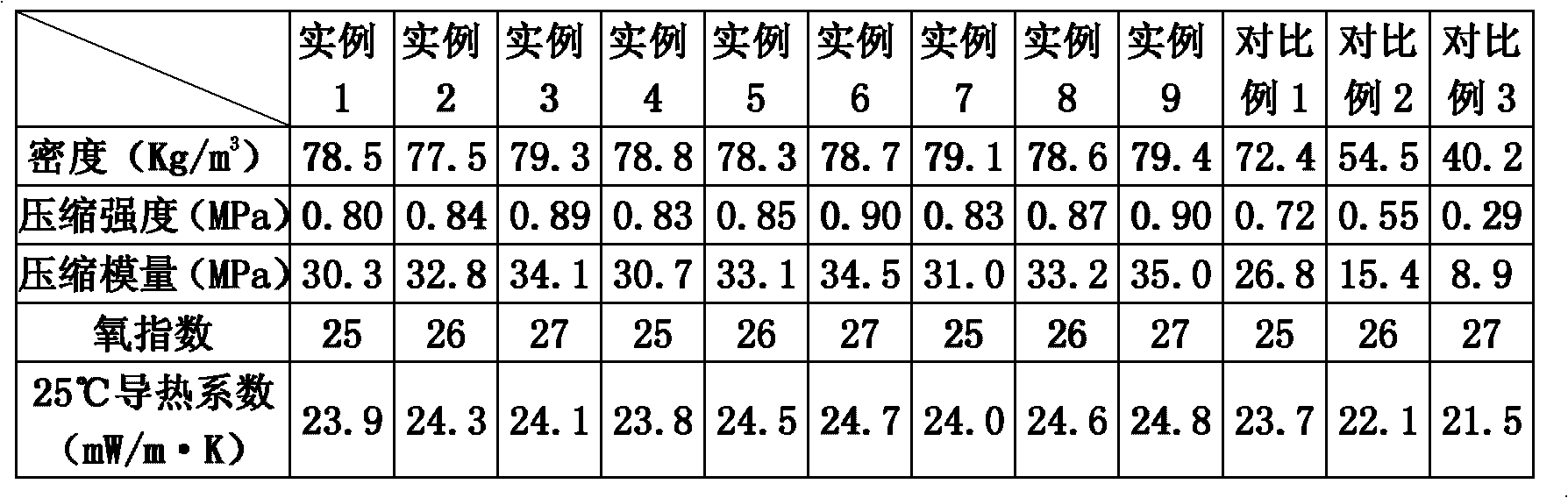

[0032] In the second step, the polyether polyol and isocyanate are vacuum-dried at 40°C for 8 hours, the surface-treated chopped glass fiber powder is dried at 120°C for 6 hours, and left at room temperature for use. The formulations of Examples 1-9 are shown in Table 1. The surface-treated chopped glass fiber powder is weighed according to the formulation and added to the polyether polyol, and water, flame retardant, catalyst, and foam stabilizer are added according to the formulation. Fully stir with a mechanical stirring device, mix evenly, then add the physical foaming agent H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com