Purple sweet potato wine and preparation method thereof

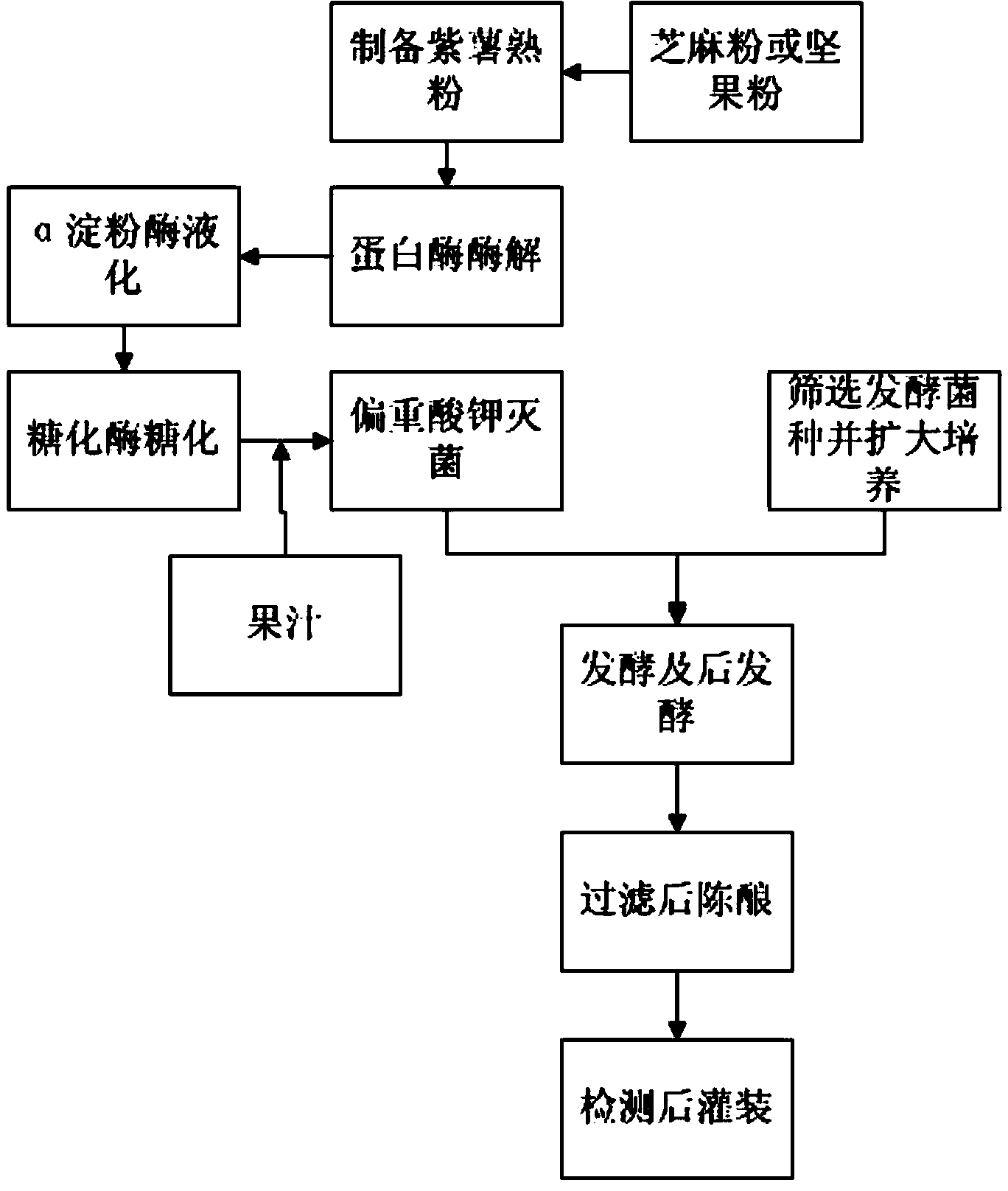

A purple sweet potato wine and purple sweet potato technology, applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, can solve the problems of large loss of nutrients, difficult storage of purple sweet potatoes, and acidification of fermentation liquid. Achieve the effect of rich aroma, simple and time-saving operation, and bright color of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Clean fresh, mildew-free, smooth-skinned purple potatoes, steam peel the purple potatoes with a steam peeler, then slice the peeled purple potatoes with a vegetable slicer, soak the potato chips in 0.5% salt Protect the color in water for 20 minutes, then dry the potato chips at 40-45°C, check that the moisture content is 5%, use a hammer mill to crush the potato chips to make cooked purple sweet potato powder, and make the fine purple sweet potato cooked powder The degree is less than or equal to 80 mesh.

[0042] 10Kg of apples were peeled and squeezed for juice, and 4g of vitamin C was added during the juice to prevent the juice from being oxidized, so as to obtain apple juice for later use.

[0043]Add 0.17Kg of a mixture of sesame powder and walnut powder and 30Kg of water to 10Kg of cooked purple sweet potato powder, and use a press to press and mix to obtain a slurry. Adjust pH to 6.3 with citric acid, add 3×10 5 U neutral protease, enzymatically hydrolyzed in ...

Embodiment 2

[0046] Wash fresh, mildew-free, smooth-skinned purple potatoes, peel them with steam, then cut the peeled purple potatoes into diced potatoes, soak the diced potatoes in 0.5% salt water for 25 minutes, and then peel the potatoes The diced potatoes are dried at 40-45°C, the moisture content is about 4.5%, and the diced potatoes are crushed to make cooked purple sweet potato powder, so that the fineness of the cooked purple sweet potato powder is less than or equal to 80 mesh.

[0047] 5Kg of pears were peeled and squeezed for juice, and 2g of vitamin C was added during the juice to prevent the juice from being oxidized, so as to obtain pear juice for later use.

[0048] Add 0.34Kg of mixed powder of almonds and chestnuts to 10Kg of cooked purple sweet potato powder, beat with 10Kg of water, press and mix. Adjust pH to 6.3 with citric acid, add 3×10 5 U neutral protease, enzymatically hydrolyzed in a constant temperature water bath at 50°C for 70min; heat the slurry after enzym...

Embodiment 3

[0051] The preparation of cooked purple sweet potato powder is the same as in Example 1, and the color protection time is 15 minutes.

[0052] Beat 10Kg of cooked purple sweet potato powder, 0.2Kg of sunflower seeds and 50Kg of water, press and mix. Adjust pH to 6.3 with citric acid, add 3×10 5 U neutral protease, enzymatically hydrolyzed in a constant temperature water bath at 50°C for 70min; heat the slurry after enzymolysis to 120°C and keep it for 15min to inactivate the protease; cool down the slurry after enzymolysis to 40°C, adjust the pH to 6.3, add 6×10 5 U’s high-temperature-resistant α-amylase, keep it at 93°C for 90 minutes, raise the temperature of the liquefied slurry to 120°C and keep it for 15 minutes to inactivate the amylase; adjust the pH of the liquefied slurry to 4.7, add 12×10 5 For saccharification with glucoamylase U, the temperature of the water bath is 60°C, and the action time is 80 minutes. Regulate the soluble solid weight content of the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com