Method for preparing ultra-low molecular weight hyaluronic acid oligosaccharides and salt thereof through combination of solid-liquid biphasic enzymolysis and ultrafiltration

A technology of hyaluronic acid oligosaccharides and hyaluronic acid, applied in the direction of fermentation, etc., can solve the problems of hyaluronic acid time-consuming, labor-intensive, rising, high price of hyaluronidase, etc., and achieve low production costs and reduced production costs , high thermal stability and pH stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] to 1m 3 Add 1m to the stainless steel dissolution tank 3 Purified water, warming up to 20°C, adjusting the pH to 4.5, adding 4.8×10 7 IU of Bacillus hyaluronidase, after stirring for 5 minutes, add 1kg of zirconia dispersion beads with a diameter of 1.8-2.0mm, adjust the stirring speed to 30-40rmp, then quickly add 60kg of potassium hyaluronate with a molecular weight of 20kDa, and the addition time is 2min, continue to stir at this speed for 3-5min after adding, then adjust the stirring speed to 15-20rpm, stir evenly, and obtain a hyaluronic acid-enzymolysis liquid-solid-liquid two-phase enzymatic hydrolysis system; enzymolysis at 15-20rpm After 0.5h, adjust the rotation speed to 30-40rmp again, add 60kg of potassium hyaluronate with a molecular weight of 20kDa, the addition time is 3min, stir for 3-5min after adding, adjust the rotation speed to 15-20rpm, and stir evenly to obtain hyaluronic acid Solid-liquid two-phase enzymatic hydrolysis system; after enzymolysis ...

Embodiment 2

[0045] to 1m 3 Add 1m to the stainless steel dissolution tank 3 Purified water, warming up to 30°C, adjusting the pH to 4.0, adding 5.6×10 7 IU of Bacillus hyaluronidase, after stirring for 5 minutes, add 1kg of zirconia dispersion beads with a diameter of 1.8-2.0mm, adjust the stirring speed to 30-40rmp, then add 70kg of calcium hyaluronate with a molecular weight of 10kDa, and the addition time is 1 -2min, continue to stir at this speed for 3-5min after adding, then adjust the stirring speed to 15-20rpm, stir evenly, and obtain a hyaluronic acid-enzymolysis liquid-solid-liquid two-phase enzymatic hydrolysis system; After solution for 0.5h, adjust the rotation speed to 30-40rmp again, add 70kg of calcium hyaluronate with a molecular weight of 10kDa, the addition time is 2-3min, stir for 3-5min after adding, adjust the stirring speed to 15-20rpm, stir evenly, The hyaluronic acid solid-liquid two-phase enzymatic hydrolysis system was obtained; after enzymatic hydrolysis at 15...

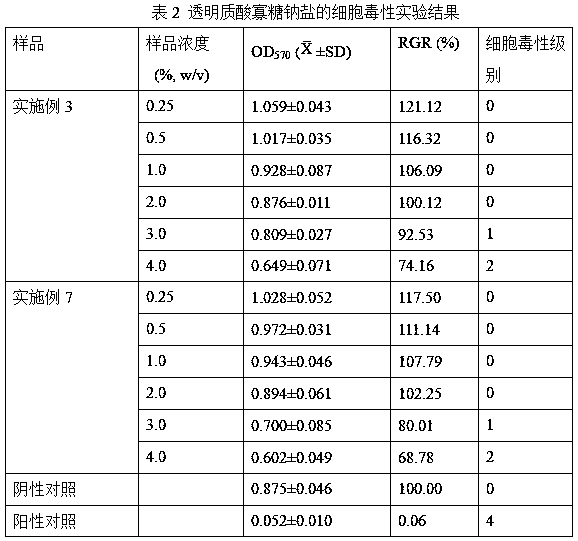

Embodiment 3

[0048] to 1m 3 Add 1m to the stainless steel dissolution tank 3 Purified water, warming up to 35°C, adjusting the pH to 5.0, adding 1.2×10 8 IU of bacillus hyaluronidase, after stirring for 5min, add 1.4kg of zirconia dispersion beads with a diameter of 1.8-2.0mm, adjust the stirring speed to 30-40rmp, then add 100kg of sodium hyaluronate with a molecular weight of 300kDa, and the addition time is 2-3min, continue to stir at this speed for 3-5min after adding, then adjust the stirring speed to 15-20rpm, stir evenly, and get hyaluronic acid-enzymolysis liquid solid-liquid two-phase enzymatic hydrolysis system; at 15-20rpm After 1 hour of enzymatic hydrolysis, adjust the rotation speed to 30-40rmp again, add 100kg of sodium hyaluronate with a molecular weight of 300kDa, the addition time is 3-4min, stir for 3-5min after adding, adjust the stirring speed to 15-20rpm, and stir evenly. The hyaluronic acid solid-liquid two-phase enzymatic hydrolysis system was obtained; after enzy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com