Aramid nanofiber/MXene composite conductive aerogel and preparation method thereof

A nanofiber and composite conductive technology, which is applied in the field of aramid nanofiber/MXene composite conductive aerogel and its preparation, can solve the problem of poor compression resilience, aramid nanofiber aerogel has no conductivity, and cannot apply pressure. Sensors and other issues, to achieve the effect of high compression resilience, good chemical stability, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of aramid nanofiber / MXene composite conductive aerogel, comprising the following steps:

[0033] Step 1: Prepare aramid nanofiber dispersion, mix 1 g of aramid chopped fibers with a length of 6 mm, 1.5 g of potassium hydroxide, 500 ml of dimethyl sulfoxide, a certain amount of deionized water, and the volume of deionized water is the same as that of 2 The volume ratio of methyl sulfoxide is (1:50~1:15); firstly add potassium hydroxide, then add deionized water, stir with magnetic stirrer for 5min~20min, then add aramid chopped fibers and The order of addition of dimethyl sulfoxide was placed in a sealed beaker, and a magnetic stirrer was used to stir and react for 2h to 4h at a rotational speed of 1200r / min to 1500r / min, to obtain a mass concentration of 0.2% dispersed in dimethyl sulfoxide. The aramid nanofiber dispersion in the aramid nanofiber, wherein the diameter of the aramid nanofiber is 12-15nm and the length is 4-7μm;

[0034] Step 2: Prep...

Embodiment 1

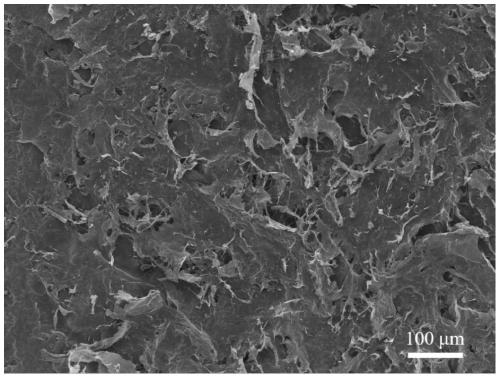

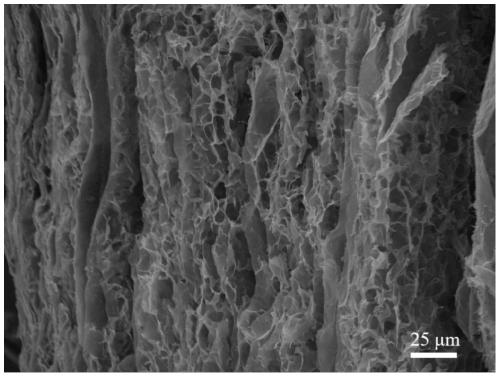

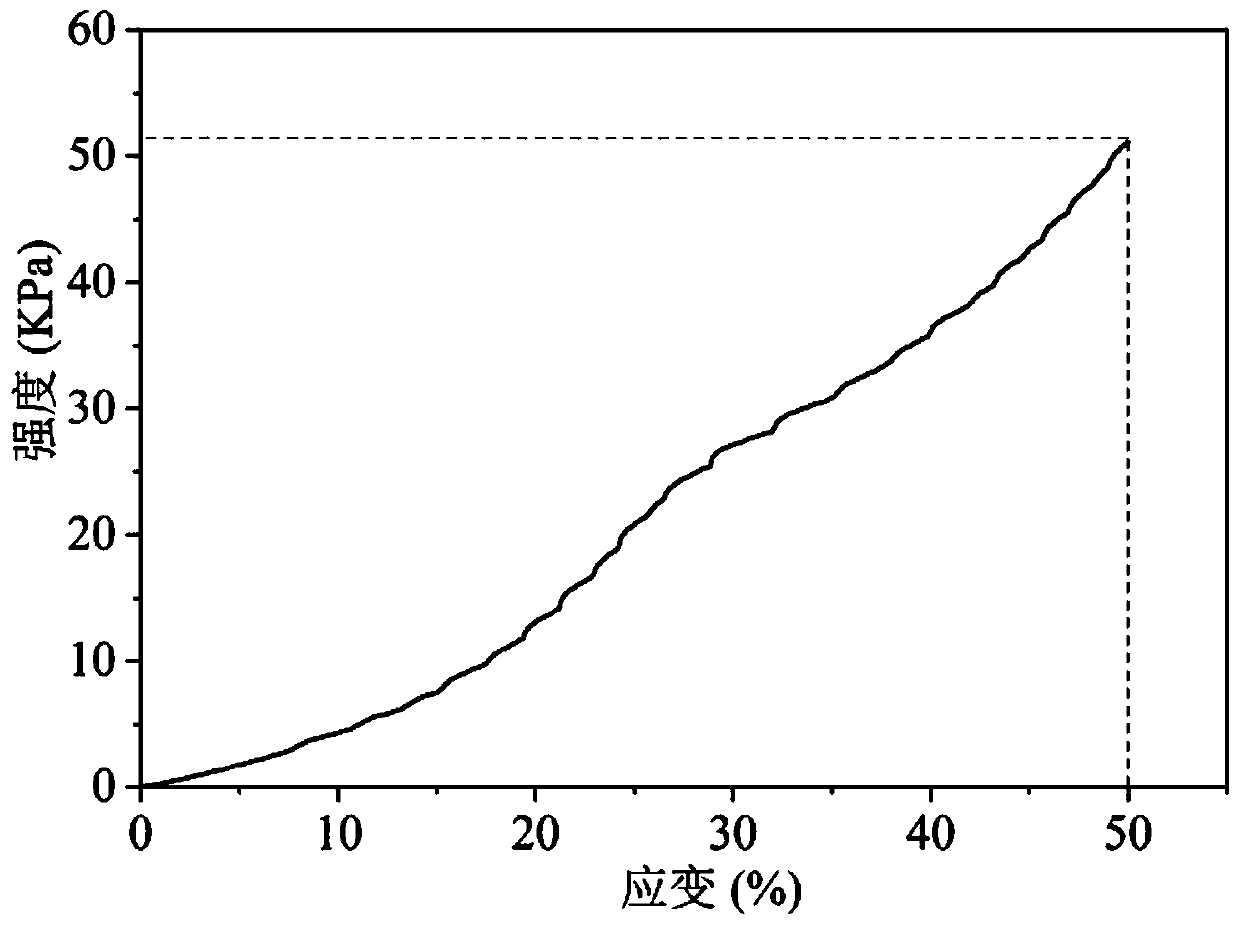

[0041] An aramid nanofiber / MXene composite conductive aerogel, the aramid nanofiber / MXene composite conductive aerogel is composed of aramid nanofiber and MXene, and the mass ratio of aramid nanofiber and MXene is 40:60; The mass of the aramid nanofiber / MXene composite conductive aerogel is 600 mg and the density is 40 mg / cm 3 .

[0042] A preparation method of aramid nanofiber / MXene composite conductive aerogel, comprising the following steps:

[0043] Step 1: Prepare aramid nanofiber dispersion, mix 1 g of aramid chopped fibers with a length of 6 mm, 1.5 g of potassium hydroxide, 500 ml of dimethyl sulfoxide, a certain amount of deionized water, and the volume of deionized water is the same as that of 2 The volume ratio of methyl sulfoxide is 1:50; according to the order of adding potassium hydroxide first, then adding deionized water, mixing and stirring with a magnetic stirrer for 5 minutes, then adding aramid chopped fibers and dimethyl sulfoxide in turn It was placed i...

Embodiment 2

[0049] An aramid nanofiber / MXene composite conductive aerogel, the aramid nanofiber / MXene composite conductive aerogel is composed of aramid nanofiber and MXene, and the mass ratio of aramid nanofiber and MXene is 45:55; The mass of the aramid nanofiber / MXene composite conductive aerogel is 500 mg and the density is 30 mg / cm 3 .

[0050] A preparation method of aramid nanofiber / MXene composite conductive aerogel, comprising the following steps:

[0051] Step 1: Prepare aramid nanofiber dispersion, mix 1 g of aramid chopped fibers with a length of 6 mm, 1.5 g of potassium hydroxide, 500 ml of dimethyl sulfoxide, a certain amount of deionized water, and the volume of deionized water is the same as that of 2 The volume ratio of methyl sulfoxide is 1:40; according to the order of adding potassium hydroxide first, then adding deionized water, mixing and stirring with a magnetic stirrer for 8 minutes, then adding aramid chopped fibers and dimethyl sulfoxide in turn It was placed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com