Patents

Literature

59results about How to "High compression resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

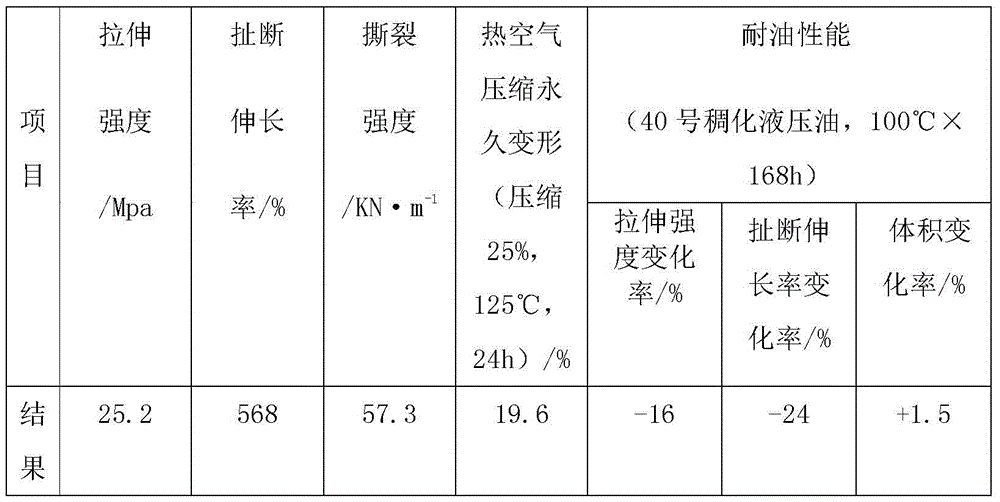

Silicon rubber/polyurethane rubber composite hydraulic sealing gasket and preparation method thereof

The invention relates to a silicon rubber / polyurethane rubber composite hydraulic sealing gasket and a preparation method thereof. The silicon rubber / polyurethane rubber composite hydraulic sealing gasket is prepared from methylvinylsiloxane rubber, polyether based polyurethane rubber, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, diphenyl silanediol, hexamethyldisilazane, gas-phase white carbon black, modified wollastonite and the like. The methylvinylsiloxane rubber, which has the advantages of excellent heat resistance, excellent freezing resistance, excellent ozone resistance, excellent atmospheric aging resistance and small permanent compression set, and the polyurethane rubber with favorable mechanical properties are compounded and blended, so that the respective advantages are displayed, thereby enhancing the sealing property of the sealing material; and in the blending process, the organically / inorganically modified wollastonite is added to obviously improve the dispersity of the wollastonite in the rubber, thereby enhancing the mechanical strength, oil resistance, wear resistance, high temperature resistance and other properties of the sealing material.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

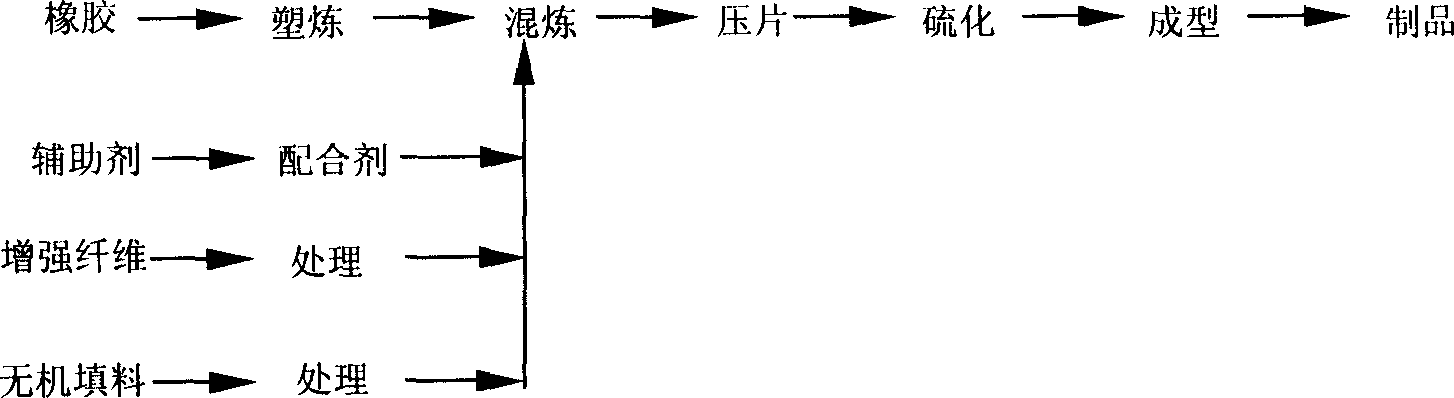

Nonasbestos mixed fiber enhanced rubber base sealing composite materials and method for making same

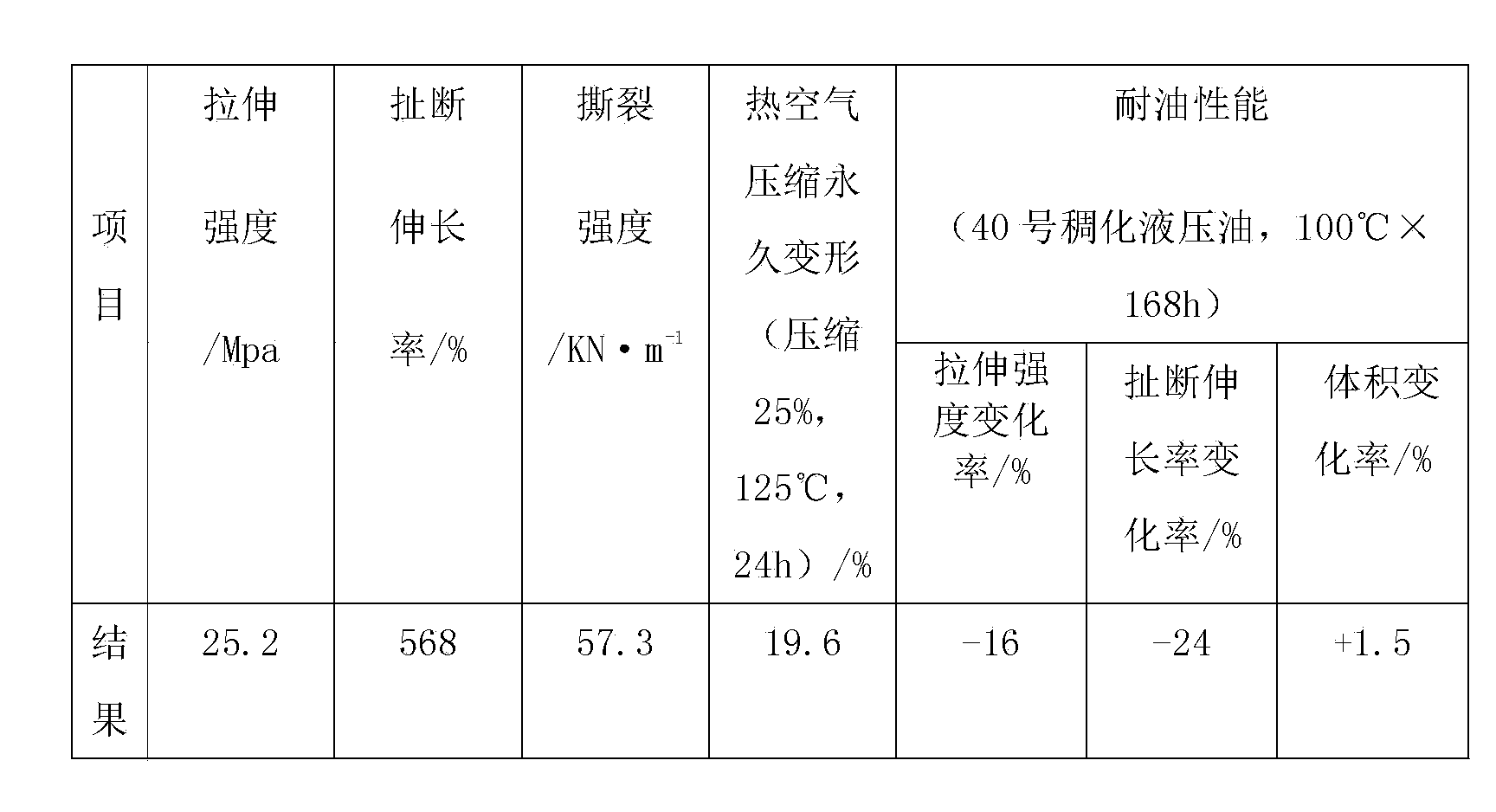

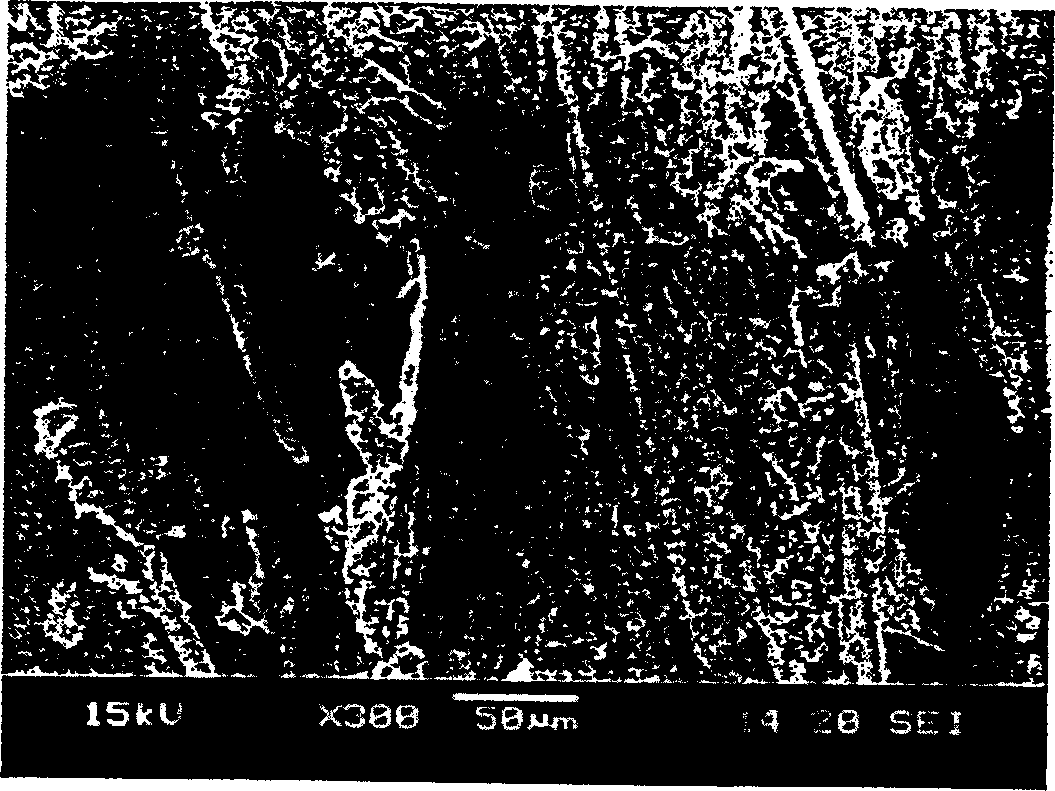

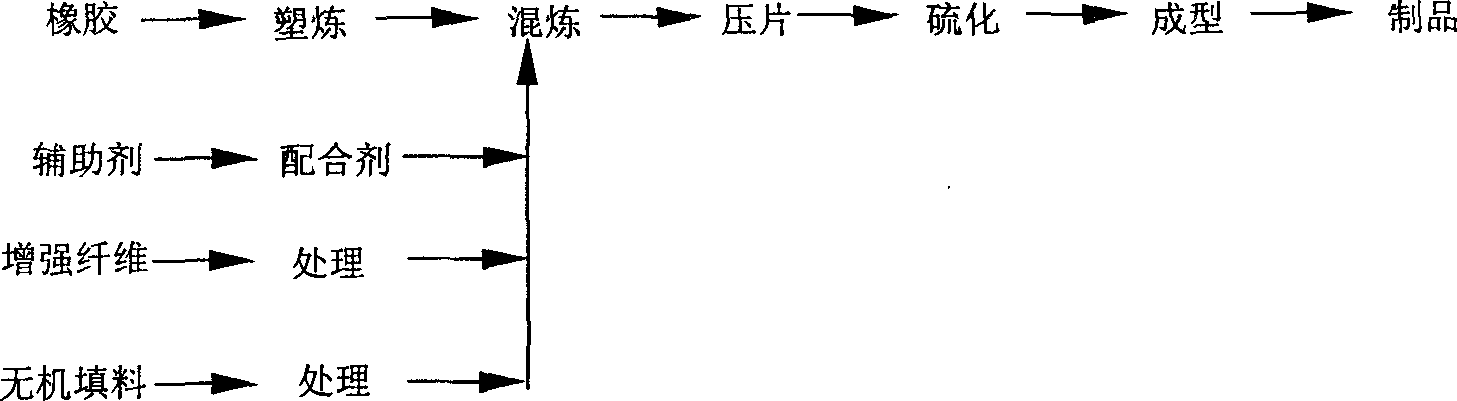

InactiveCN1631954AHigh mechanical strengthHigh compression resilienceOther chemical processesPolymer scienceMass ratio

The invention relates to a pre- preoxidated string, aramid fiber or mixed fiber strengthened rubber sealing compound material and its producing technique. The components comprises of : 1, strengthened fiber, 2. enlarged-volume fiber, 3. flexible sticker, 4. filling material, 5. assistant; the mass ratios of each component are: strengthened fiber 10%-36%, enlarged-volume fiber 40-65%, flexible sticker 10-23%, filling material 9.6-21%, assistant 1.6-4.7%. The strengthened fiber is the mixture of pre- preoxidated fiber and aramid fiber or, assistant is accelerant, activator, vulcanizing agent and antioxidant, the technique of the compound material is : plasticate the flexible sticker, mixing the strengthened fiber, inorganic filling material having been prepared, the enlarged-volums fiber and assistant, press into slices, sulfurate to acquire the product. The material has solved the problems such as the unsatisfying range of temperature of the present material NAFC, high productive cost, bad antitensile stress and aging, it is a new NAFC resistant to high temperature, with low cost.

Owner:NANJING UNIV OF TECH

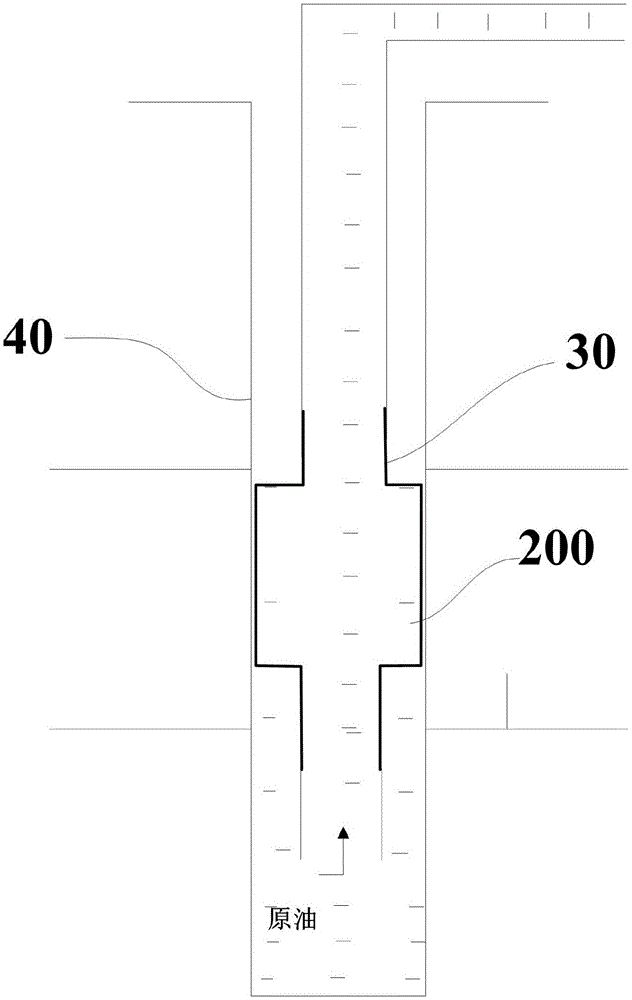

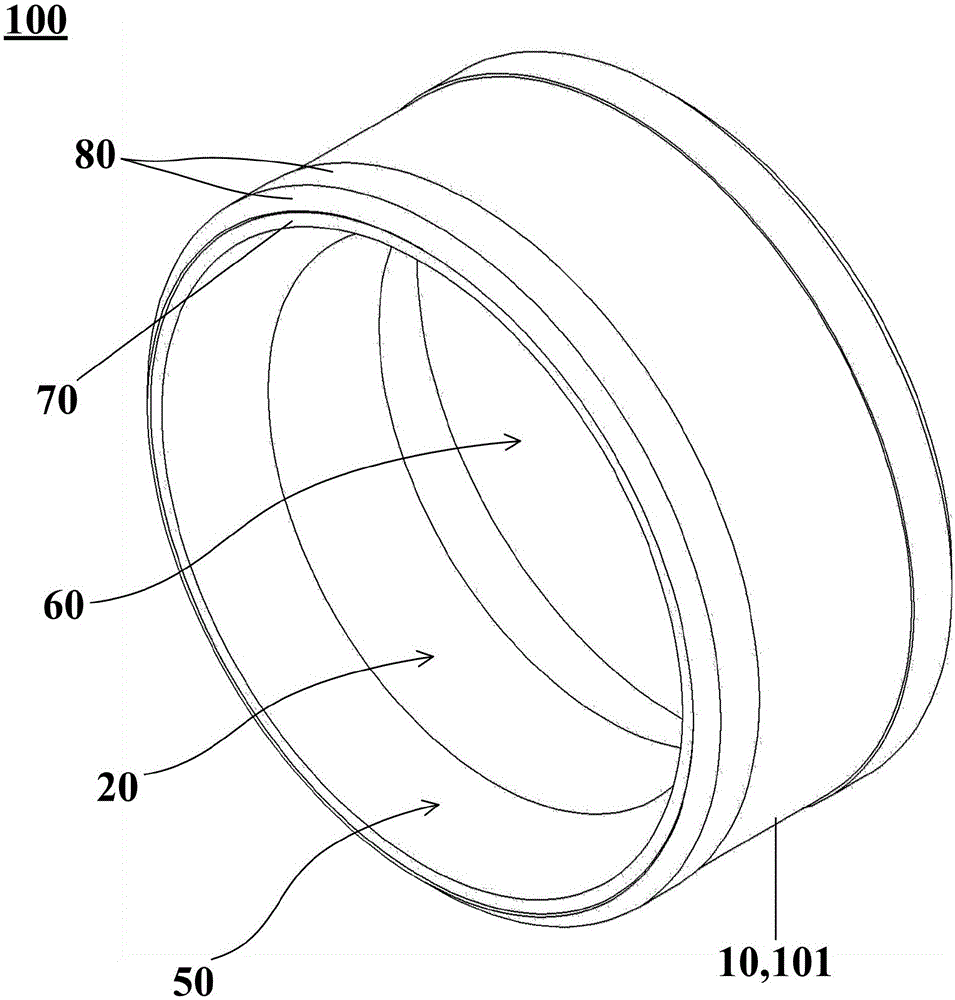

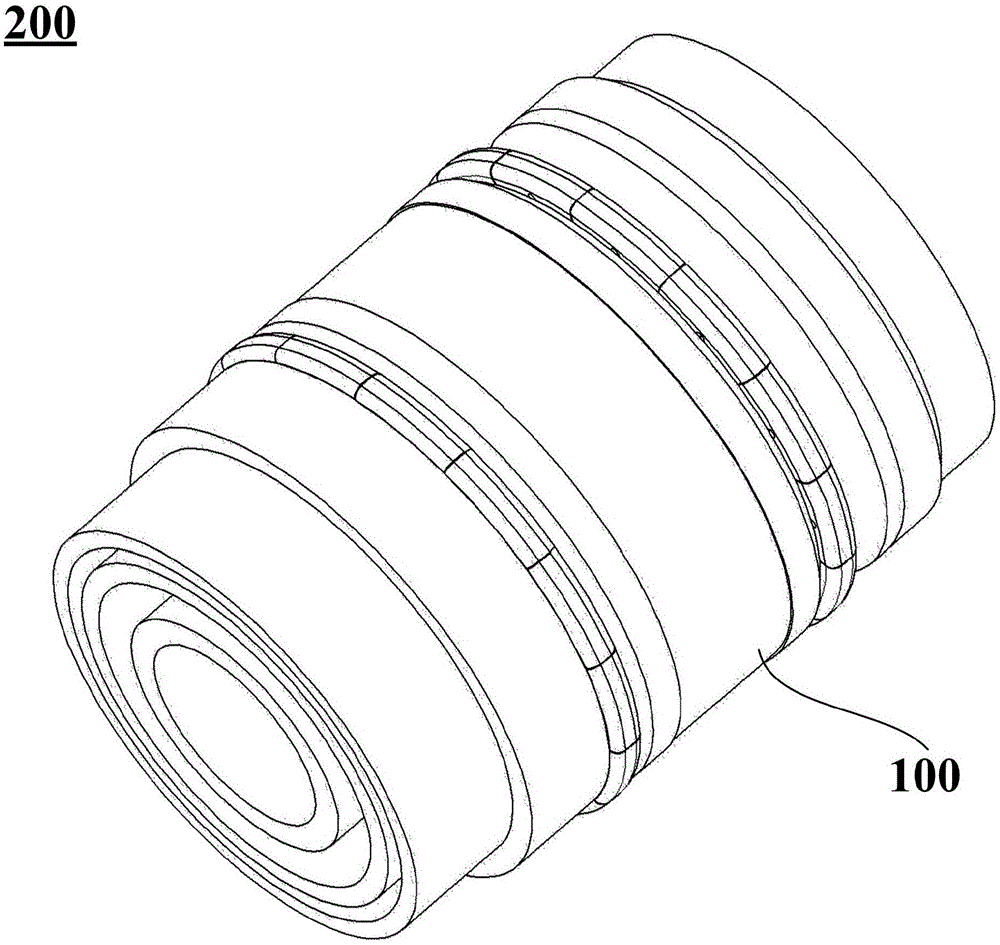

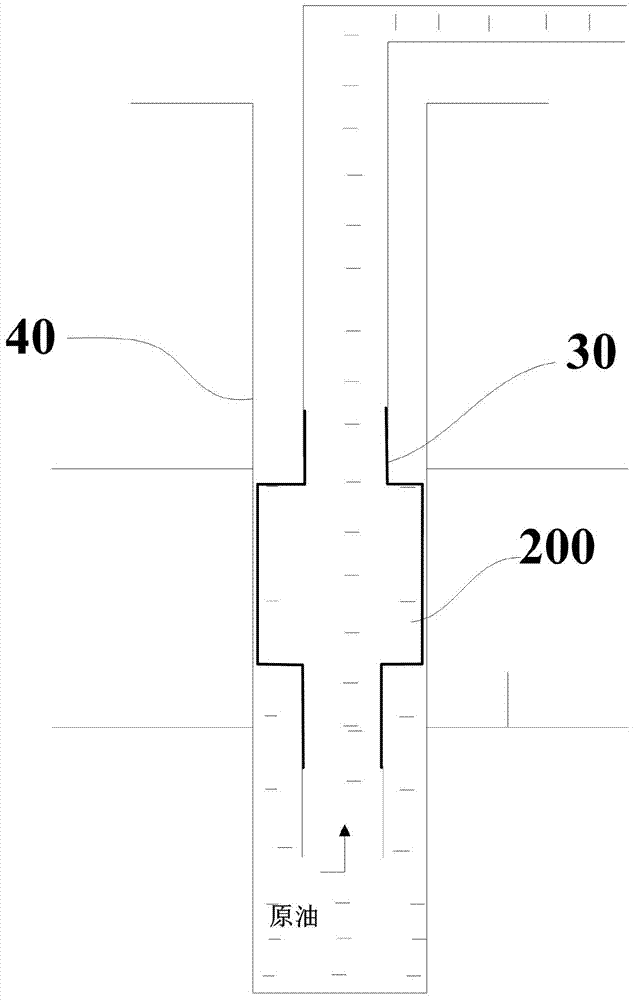

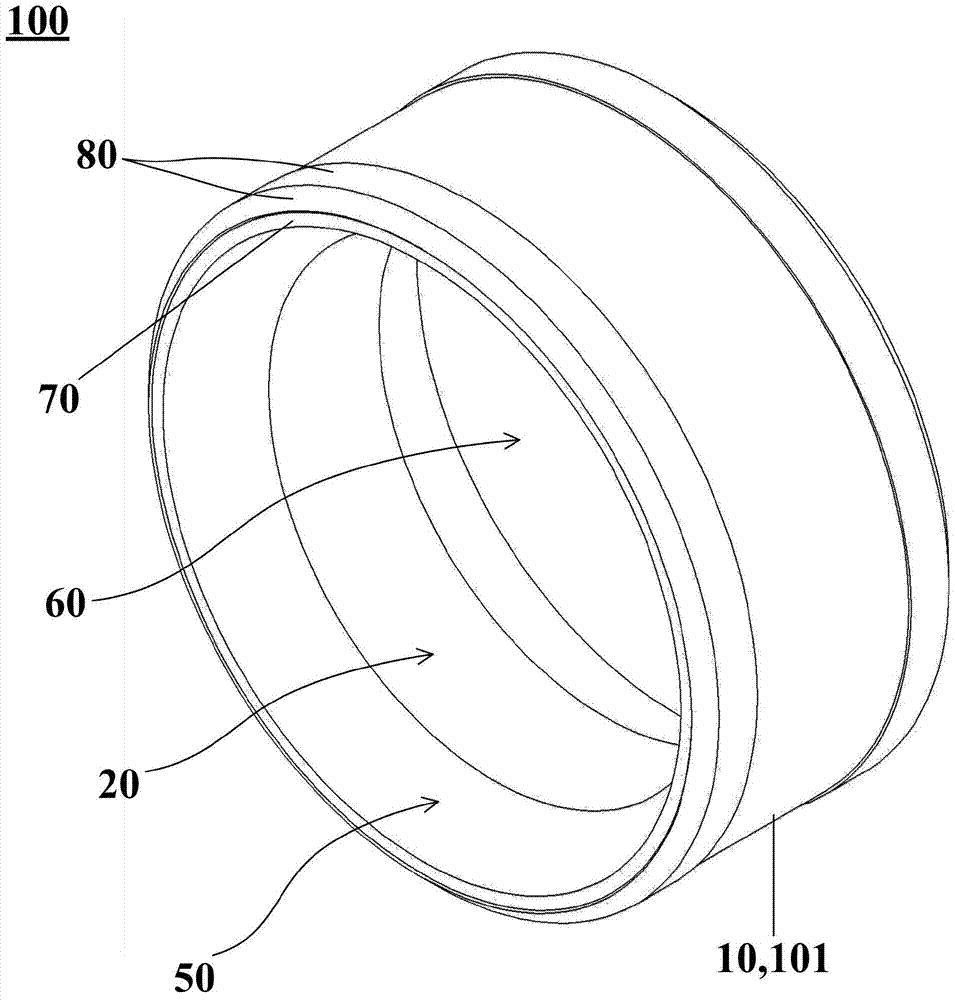

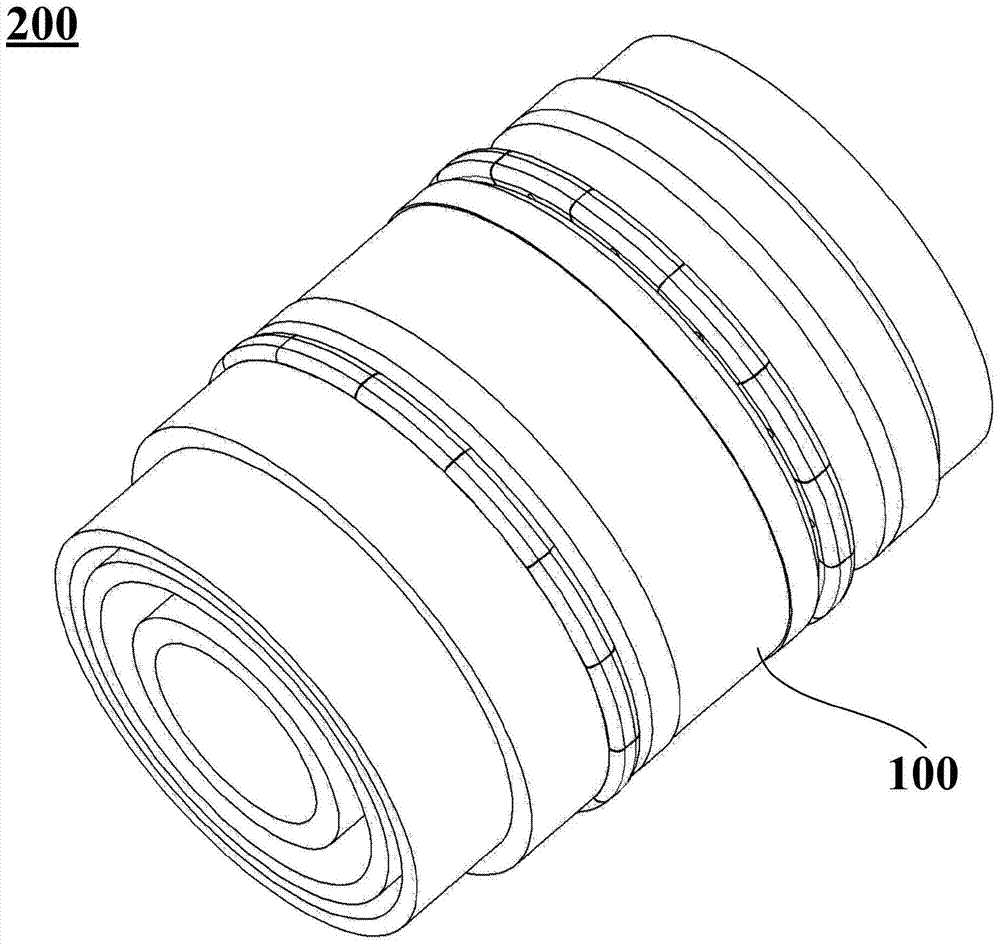

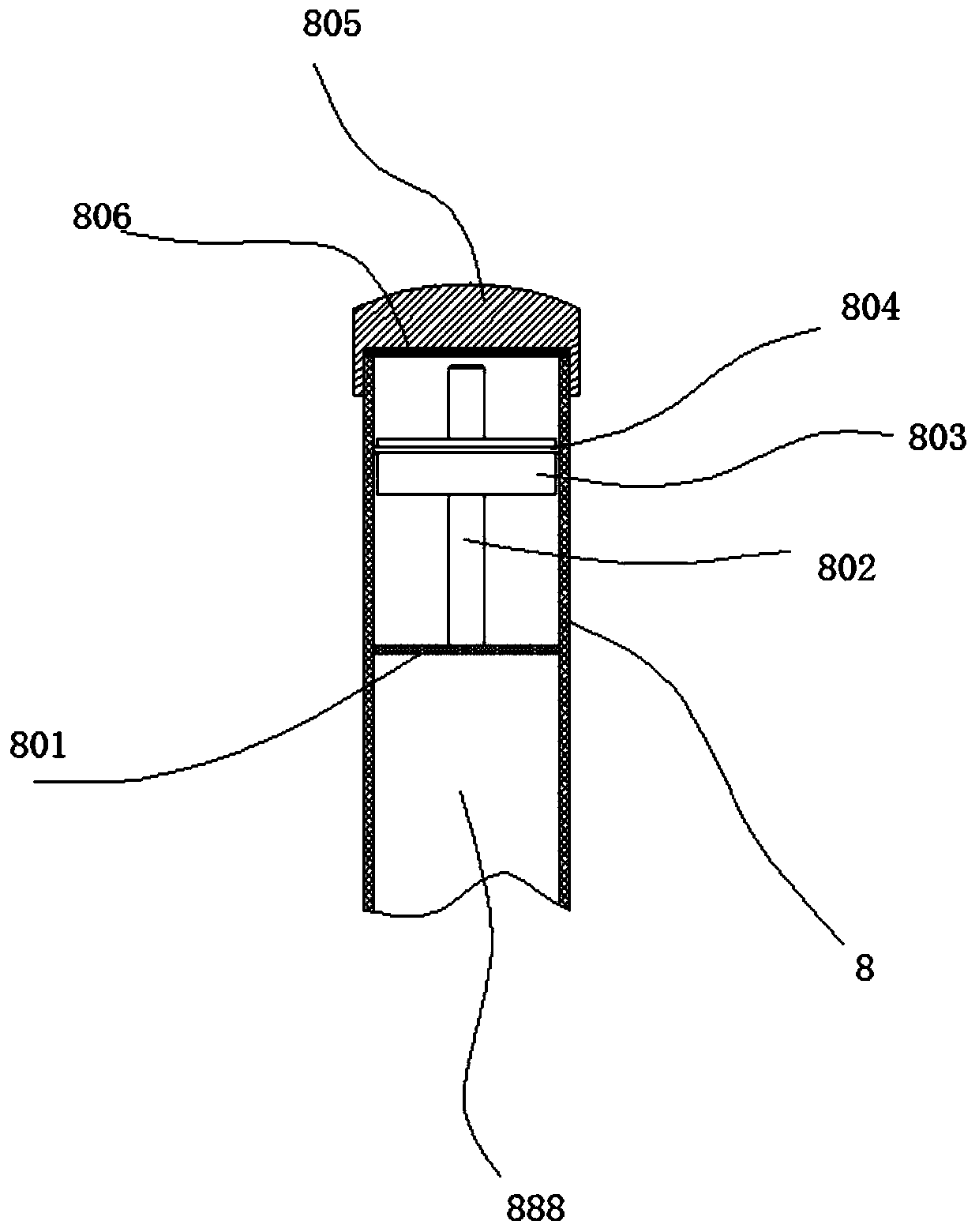

Sealing element and compression type packer

ActiveCN105156065AImprove deformation abilityAvoid unsealableEngine sealsSealing/packingMechanical engineering

Owner:TIANDING SEALING TECH BEIJING CO LTD

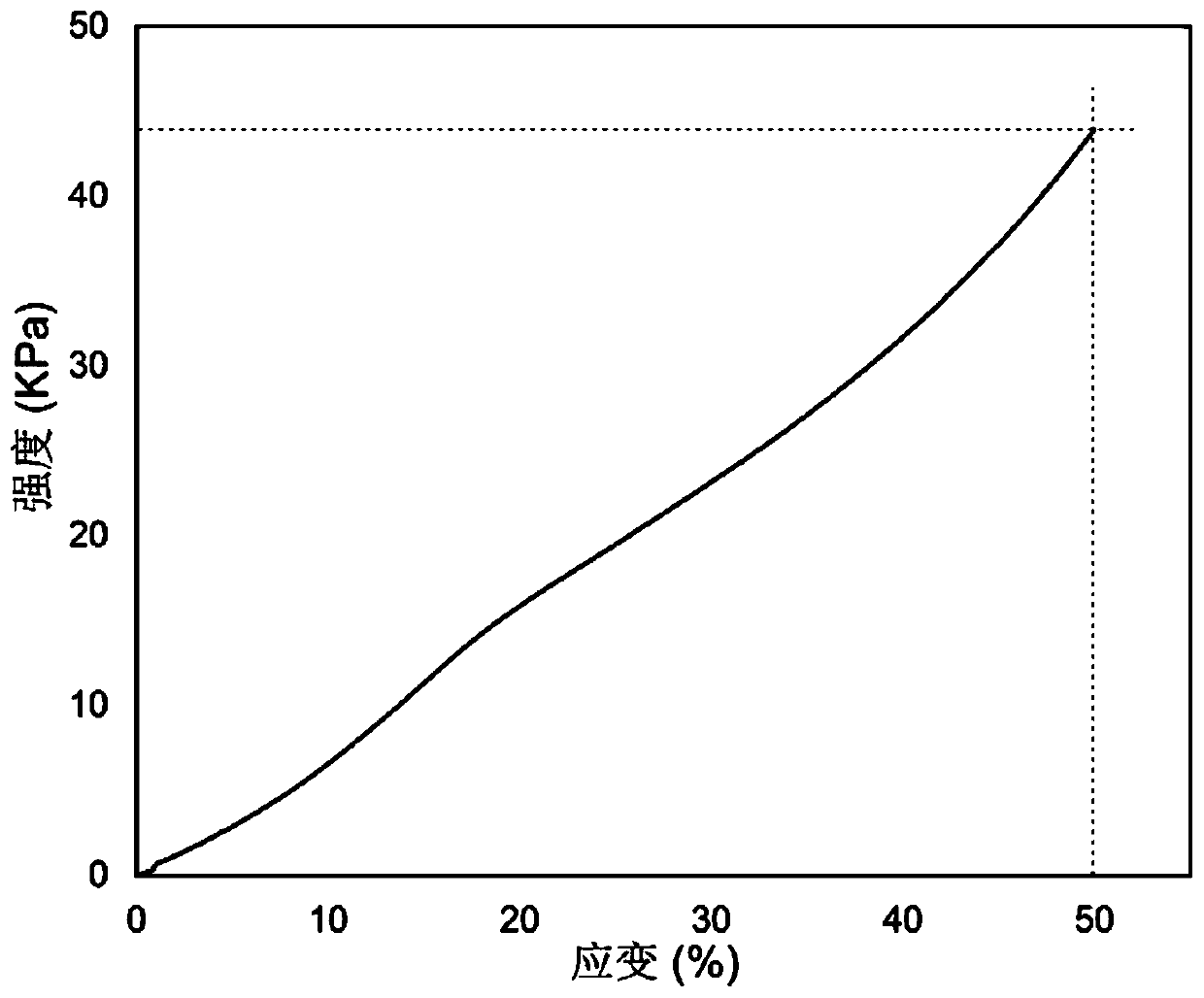

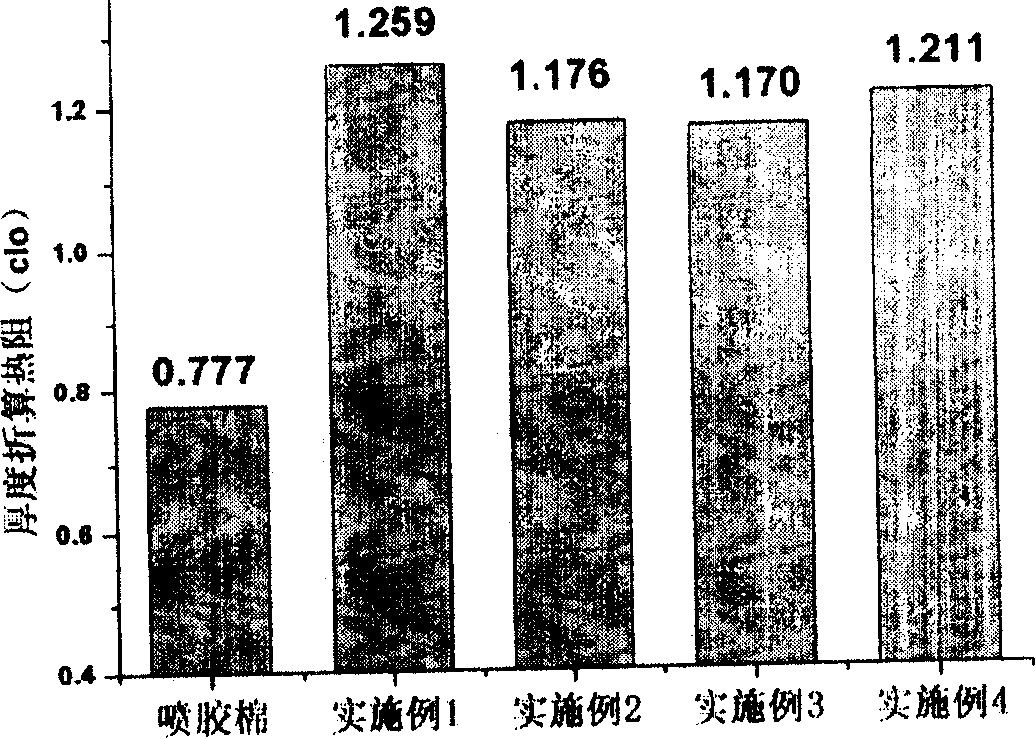

Nanofiber flocculus with sandwich structure and preparation method of nanofiber flocculus

ActiveCN111485329ASmall diameterLarge diameterElectro-spinningNon-woven fabricsPolymer scienceSpinning

The invention relates to a nanofiber flocculus with a sandwich structure. The nanofiber flocculus is provided with a bottom layer, a middle layer and an upper layer with the longitudinal volume density being changed, the bottom layer and the upper layer are compact fiber layers, and the middle layer is a fluffy fiber layer; fibers, making contact with each other, in the nanofiber flocculus are crosslinked; the volume density of the compact fiber layers is 30-40 mg / cm3; the volume density of the fluffy fiber layer is 5-20 mg / cm3; and the compression resilience ratio of the nanofiber flocculus reaches 90% or above, and the CLO value is 2-4 clo. The nanofiber flocculus is prepared through an electrospinning technique, a polymer and a cross-linking agent are dissolved and dispersed in a solvent firstly, and sufficient stirring is conducted to obtain a spinning solution; and then continuous electrospinning is conducted under a specific humidity condition to obtain a composite nanofiber layer with the longitudinal volume density being changed, the composite nanofiber layer is subjected to crosslinking heat treatment, and the nanofiber flocculus is obtained.

Owner:DONGHUA UNIV

Vehicle brake pad with composite material

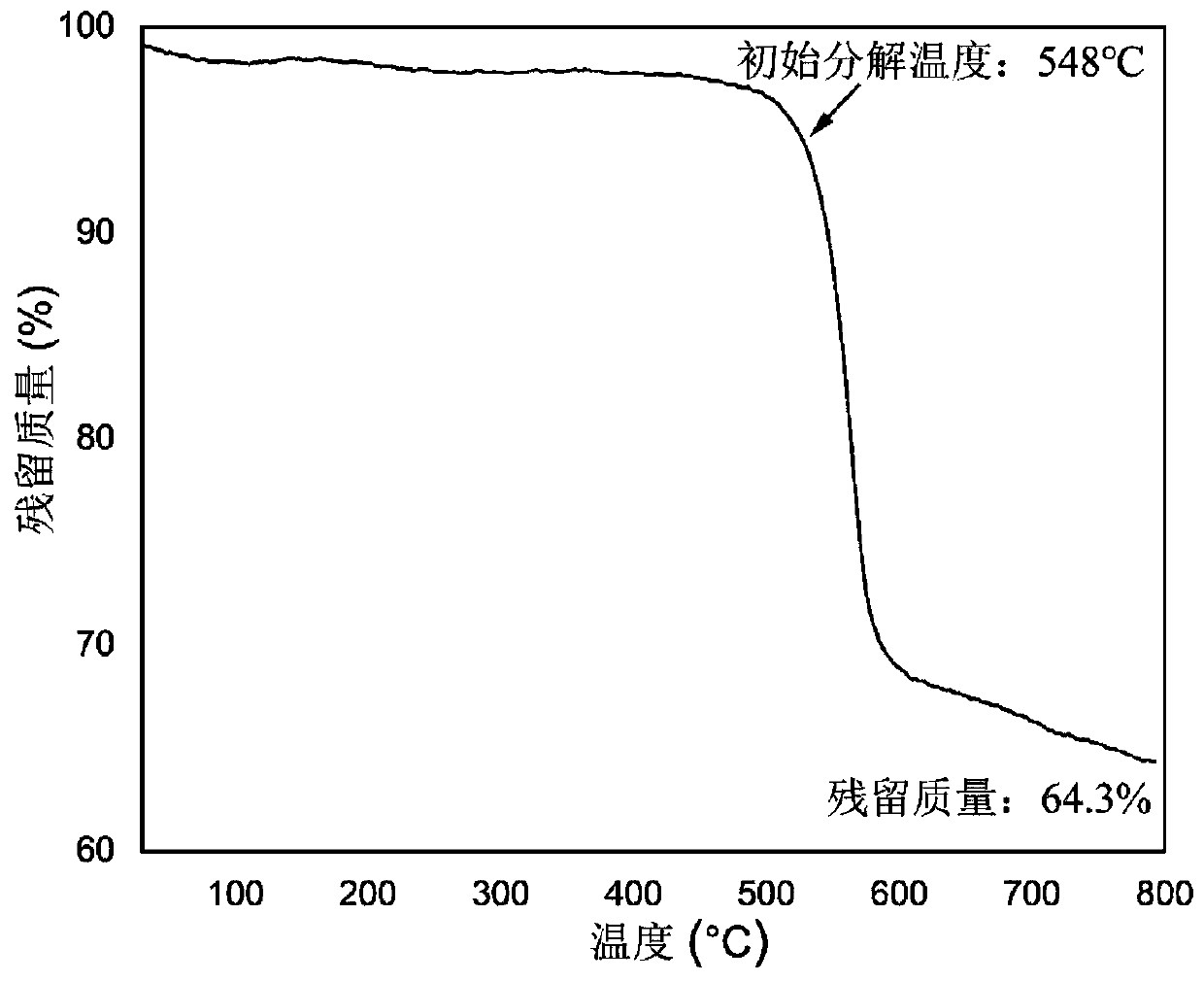

InactiveCN106438791AImprove high temperature resistanceImprove heat stabilityOther chemical processesFriction liningCarbon fibersSisal fiber

The invention discloses a vehicle brake pad with a composite material. The vehicle brake pad comprises a steel sheet and a friction block; and the friction block includes raw materials of: boron modified phenolic resins, organic silicon modified phenolic resins, barium phenolic resins, phenylacetylene phenolic resins, terminal epoxy liquid reaction nitrile rubber, butadiene rubber, molybdenum disulfide, sisal fibers, carbon fibers, aluminum fibers, molybdenum fibers, polyphenylene benzodioxazole fibers, zinc oxide whiskers, montmorillonoid, vermiculite, nanometer aluminum oxide, cerium oxide, zirconium boride, aluminum silicate hollow spheres, oxidized graphene, copper powder, carbon nanotubes, nanometer carbon black, powder butadiene styrene rubber, ammonium molybdate, and octaphenyl silsesquioxane. The vehicle brake pad with the composite material is excellent in high-temperature resistance and heat resisting stability, high in wear resistance and long in service life.

Owner:CHONGQING SHUAIBANG MACHINERY CO LTD

Conductive aramid nanofiber composite aerogel and preparation method thereof

ActiveCN111040237AHigh strengthReduce intensityElectrical/magnetic solid deformation measurementFiberCrystallinity

The invention discloses a conductive aramid nanofiber composite aerogel and a preparation method thereof. By using aramid nano-fibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using whisker carbon nanotubes with high crystallinity and high rigid structure are used as a conductive filler and a reinforced filling material, the conductive aramid nanofiber composite aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing a whisker carbon nanotube dispersion liquid, preparing a whisker carbon nanotube / aramid nanofiber composite dispersion liquid, preparing a gelatinous whisker carbon nanotube / aramid nanofiber composite material, and the like, thereby obtaining the conductive aramid nanofiber composite aerogel. The preparation process is simple and easy to implement, and the obtained conductive aramid nanofiber composite aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation process of gamma-aminopropyl triethoxysilane

ActiveCN104961762AIncreased wet and dry flexural strengthEnhanced wet and dry flexural strengthGroup 4/14 element organic compoundsTextile printerAdhesive

The invention relates to a preparation process of gamma-aminopropyl triethoxysilane, and belongs to the technical field of fine chemical engineering. The preparation process comprises the following steps of: reacting gamma-chloropropyl triethoxysilane and liquid ammonia at the weight ratio of 1:3, the temperature controlled at 90 DEG C and the pressure controlled at 4 MPa for 8 hours in an ammoniation kettle; filtering and separating, and then aging and stirring a crude product for 2-6 hours; adding a catalyst, keeping aging temperature at 120 DEG C, and reacting to obtain a gamma-aminopropyl triethoxysilane product with low total chlorine (less than or equal to 5ppm) and content more than or equal to 99.5%. The preparation process disclosed by the invention is simple and low in production cost and meets the requirements for enhancing the mechanical strength, electrical property and anti-aging property of a composite material on application in industries, namely glass steel, plastics, adhesives, casting, textile printing and dyeing and the like, at present.

Owner:JINGZHOU JIANGHAN FINE CHEM

Preparation method for polyurethane solid tire used for mining vehicle

The invention provides a preparation method for a polyurethane solid tire used for a mining vehicle. The preparation method comprises the following steps: (1) allowing binary acid to react with polyolso as to prepare polyester polyol; (2) subjecting the polyester polyol prepared in the step (1), a chain extender and p-phenylene diisocyanate to a prepolymerization reaction so as to prepare a hydroxyl-terminated oligomer a, and mixing the hydroxyl-terminated oligomer a with hydroxyl-terminated liquid rubber, an organosilicone foam stabilizer, a catalyst and a foaming agent so as to obtain a component A; (3) subjecting polycarbonate polyol, polytetrahydrofuran polyol and the p-phenylene diisocyanate to a prepolymerization reaction so as to prepare a hydroxyl-terminated oligomer b, and subjecting the hydroxyl-terminated oligomer b and isocyanate to a prepolymerization reaction so as to obtain a component B; and (4) mixing the component A and the component B, pouring an obtained mixture into a tire mold, and carrying out curing so as to obtain a product. The preparation method provided by the invention improves tear strength and wear resistance of a polyurethane tire, overcomes the disadvantage of poor anti-slipping performance of the polyurethane tire, reinforces rigidity, reduces the load deformation quantity of a tire, and reinforces compression resilience, hydrolysis resistanceand aging resistance.

Owner:JIAXING HEXIN CHEM IND

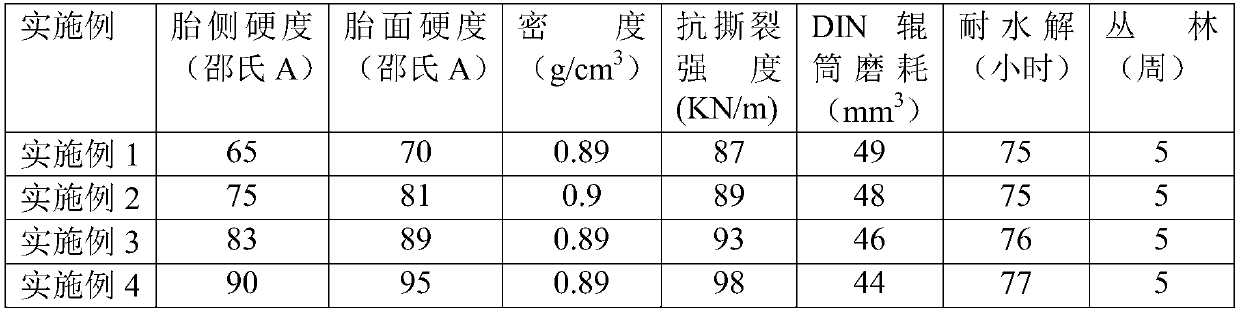

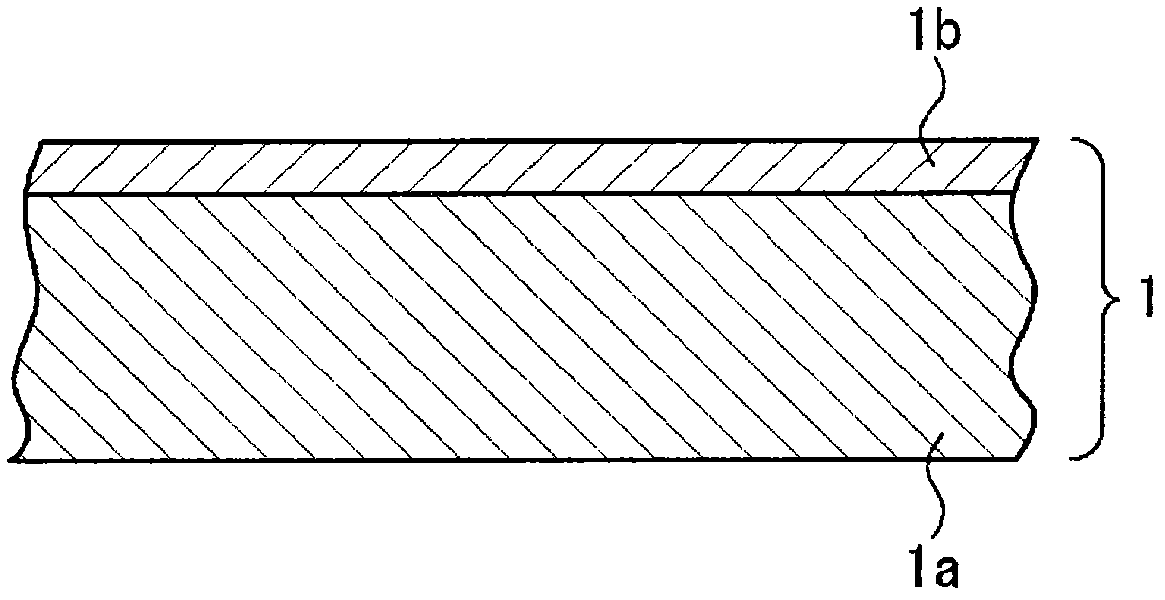

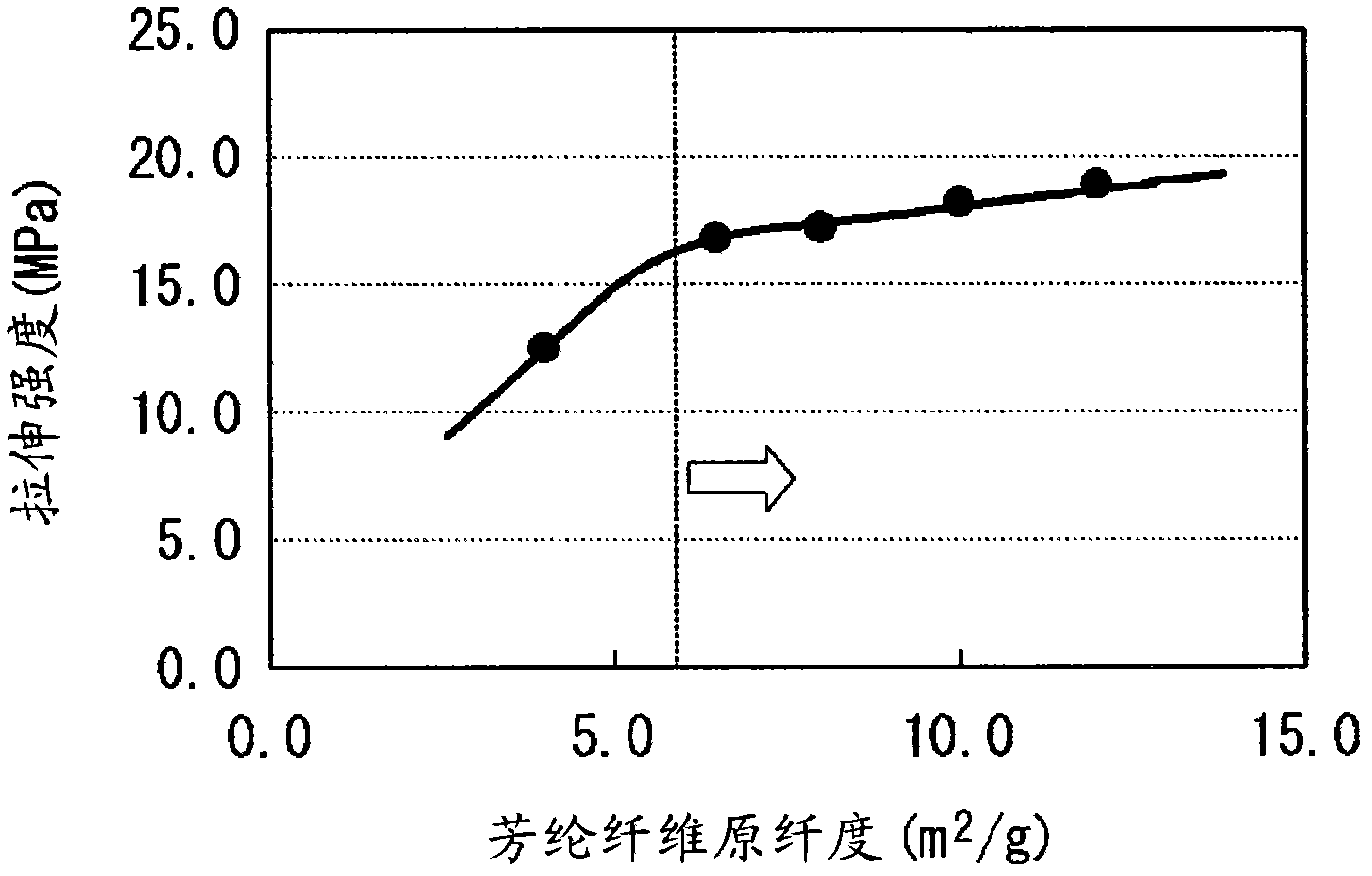

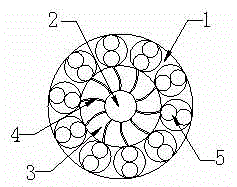

Gasket material

ActiveCN102037262AHigh tensile strengthHigh compression resilienceEngine sealsOther chemical processesFilling materialsDolomite

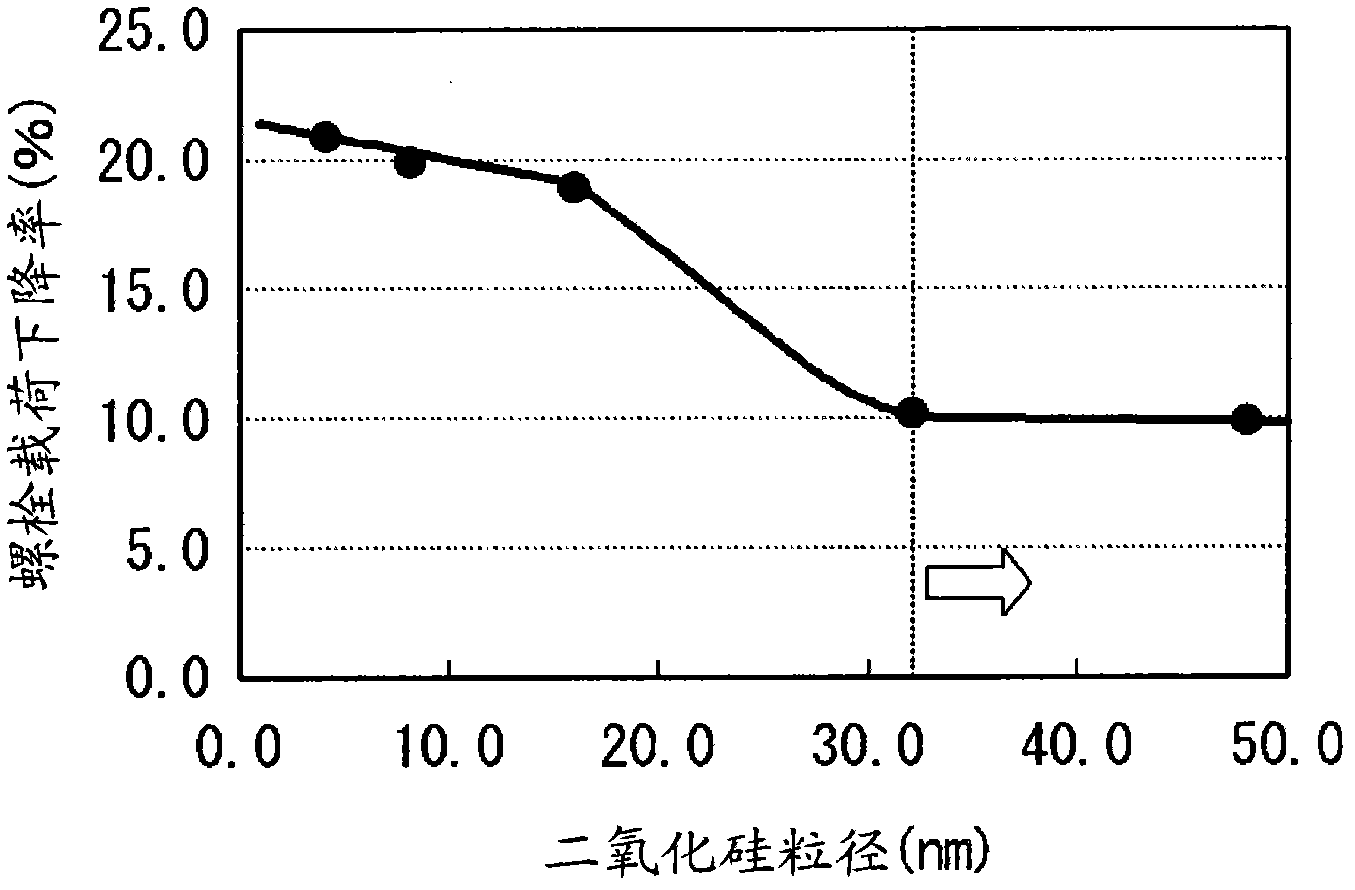

Disclosed is a low-cost gasket material which has improved strength, while maintaining high flexibility. The gasket material is composed of a joint sheet (1) formed by pressure-laminating a raw material, which is obtained by mixing a rubber, a reinforcing fiber and a filler, with calender rolls and vulcanizing the resulting product. The basic composition of the raw material is composed of 16-28 wt% of NBR serving as the rubber, 4-8 wt% of an aramid fiber serving as the reinforcing fiber, 10-20 wt% of a needle-like dolomite serving as the reinforcing fiber, 8-20 wt% of silica particles servingas the filler, and the balance of an inorganic filler serving as the filler.

Owner:NIPPON LEAKLESS IND CO LTD +1

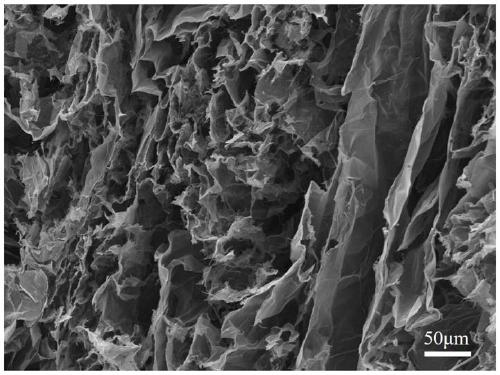

Graphene oxide aerogel, reduced graphene oxide aerogel as well as preparation methods and applications of graphene oxide aerogel and reduced graphene oxide aerogel

ActiveCN109096526AAct as a physical anchorEasy to manufactureCarbon compoundsNetwork structureChitin formation

An embodiment of the invention relates to the technical field of functional materials and particularly relates to graphene oxide aerogel, reduced graphene oxide aerogel as well as preparation methodsand applications of the graphene oxide aerogel and the reduced graphene oxide aerogel. The graphene oxide aerogel adopts a 3D network structure and comprises graphene oxide sheet layers, a gap surrounded by the graphene oxide sheet layers and double electrical chitin nanofiber located between the graphene oxide sheet layers or adsorbed on the surfaces of the graphene oxide sheet layers, and the obtained graphene oxide aerogel has anisotropy and higher compression resilience. On the basis of the graphene oxide aerogel, the reduced graphene oxide aerogel is obtained through further reduction, and the performance of the reduced graphene oxide aerogel is further optimized.

Owner:QINGDAO UNIV OF SCI & TECH

Production method of silk cotton wadding material

InactiveCN100383307CHigh compression resilienceMaintain propertiesNon-woven fabricsAdhesivesFiberUltimate tensile strength

A kapok fibre wadding with high insulating performance and light weight is proportionally prepared from natural kapok fibres, the fibres with low fusing point, and chemical fibres with high compressional resilience through mixing, opening, netting and adhering.

Owner:DONGHUA UNIV

Ultrathin silk-like cotton

InactiveCN103614862AHigh bulkinessHigh compression resilienceNon-woven fabricsTextile shapingFiberPolyester

The invention discloses ultrathin silk-like cotton which is made by bonding polyacrylonitrile fiber and polyester staple fiber through ES fiber. The front and back of the silk-like cotton are lustered by a natural luster finishing machine. The polyacrylonitrile fiber is 35-38% in mass percent, the polyester staple fiber is 48-52% in mass percent, and the ES fiber is 12-15% in mass percent. Lustering is performed at the temperature of 120-125DEG C. Therefore, the surface flatness of the ultrathin silk-like cotton can be improved, no hair sticks to the ultrathin silk-like cotton, the ultrathin silk-like cotton feels fine and smooth, the thickness of the ultrathin silk-like cotton is reduced, the weight of the ultrathin silk-like cotton is reduced, and the ultrathin silk-like cotton is improved in terms of bulkiness, compressive resilience, insulation, strength and washability.

Owner:CHANGSHU JINYU FIBER PROD

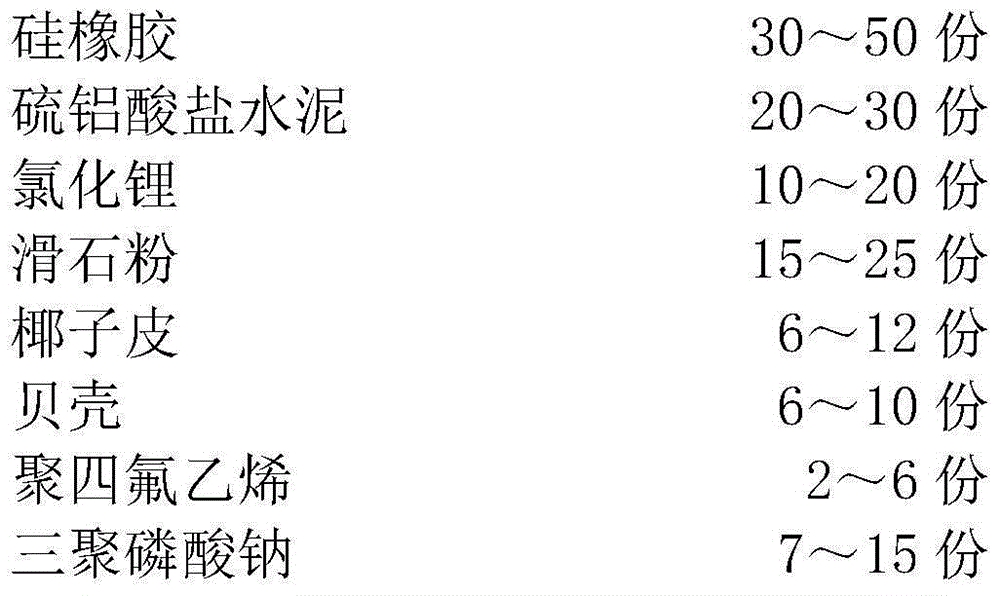

High-elasticity waterproof plugging agent

InactiveCN105038742AGood flexibilityHigh compression resilienceDrilling compositionLithium chlorideMethyl cellulose

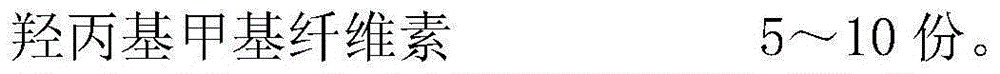

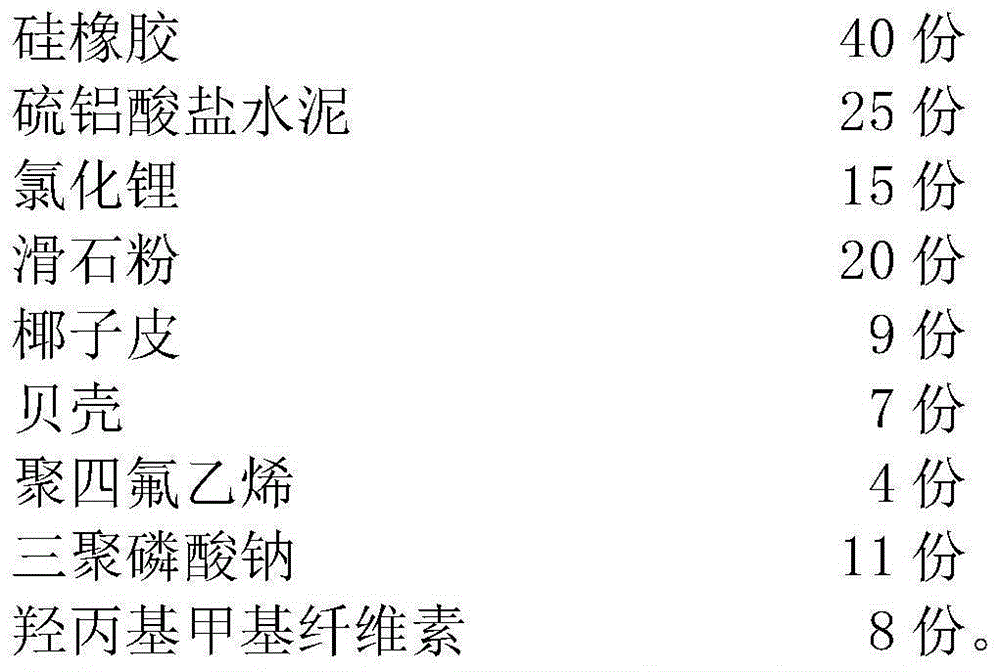

The invention relates to the technical field of plugging agents, particularly a high-elasticity waterproof plugging agent. The high-elasticity waterproof plugging agent is prepared from the following raw materials in parts by weight: 30-50 parts of silicon rubber, 20-30 parts of sulfoaluminate cement, 10-20 parts of lithium chloride, 15-25 parts of talcum powder, 6-12 parts of coconut root-barks, 6-10 parts of shells, 2-6 parts of polytetrafluoroethylene, 7-15 parts of sodium tripolyphosphate and 5-10 parts of hydroxypropyl methyl cellulose. The high-elasticity waterproof plugging agent provided by the invention has high compression elasticity, and is remarkable and efficient in plugging effect and strong in leakage layer lingering property, and a plugging layer is high in loading capacity within a short time, good in flowability and elastic and variable in shaped under pressure.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Preparation method of hydrophilic flexible graphite composite sealing material

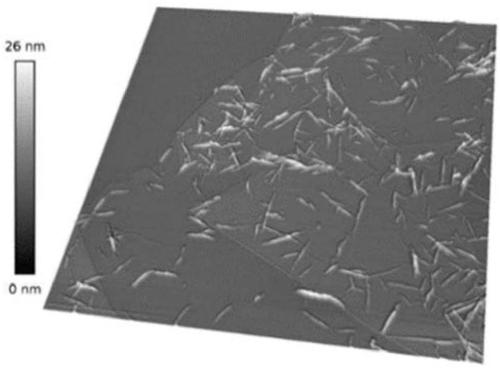

ActiveCN109778591AGood dispersionChange the microstructureInorganic fibres/flakesNatural cellulose pulp/paperVulcanizationPolyvinyl alcohol

The invention relates to a preparation method of a hydrophilic flexible graphite composite sealing material. The method comprises the following steps: preparing a polyvinyl alcohol solution; uniformlymixing flexible graphite and the polyvinyl alcohol solution; then adding urea resin as a crosslinking agent; drying; dispersing into water to obtain a hydrophilic flexible graphite solution; mixing and defibering plant fibers, aramid fibers and mineral fibers; adding the hydrophilic flexible graphite solution, kieselguhr and calcium carbonate; uniformly mixing; adding aluminum sulfate, styrene-butadiene latex, a sulfur dispersoid, CPAM and bentonite; fully stirring; uniformly dispersing; performing neutral papermaking process, pressing, drying and vulcanization to obtain the hydrophilic flexible graphite composite sealing material. According to the method, the surface of the flexible graphite is covered by polyvinyl alcohol, so that a large quantity of hydroxide radicals are introduced, and the hydrophily is improved; then the urea resin crosslinking agent is added, so that the capacity of the hydrophilic flexible graphite composite sealing material combining with other raw materialsis improved, and finally the uniform sealing material is prepared, and as a result, the compressing resilience of the sealing material is improved, and the product sealing performance is improved.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of non-asbestos gasket resistant to low temperature and temperature change

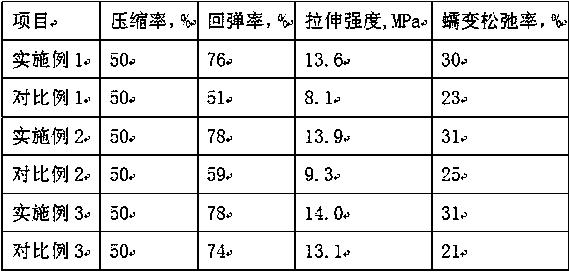

The invention discloses a preparation method of a non-asbestos gasket resistant to low temperature and temperature change, and the preparation method comprises the following operation steps: (1) adding zirconium dioxide, gallium oxide, cerium oxide, aluminum nitride and cerium oxide to a ball mill, carrying out compression moulding to obtain a biscuit, calcining and grinding to prepare an inorganic filler; (2) adding the inorganic filler to deionized water, adding expanded graphite thereto, centrifuging to obtain a precipitate, drying, calcining and grinding the precipitate to obtain an inorganic filler / EG; and 3) mixing acrylonitrile-butadiene rubber and styrene-butadiene rubber into a disintegrator to obtain fiber-disintegrating granules, and breaking the fiber-disintegrating granules, butadiene-acrylonitrile latex, the inorganic filler / EG, melamine cyanurate, and sodium molybdate dehydrate to obtain slurry, making sheets, drying and vulcanizing to obtain the asbestos-free gasket resistant to low temperature and temperature change. The non-asbestos gasket resistant to low temperature and temperature change is remarkable in low-temperature-resistant effect, the compression-resilience property, and f the non-asbestos gasket resistant still has good compression resilience performance, tensile strength and creep relaxation rate after being subjected to low-temperature frequent treatment.

Owner:合肥绿普包装材料有限公司

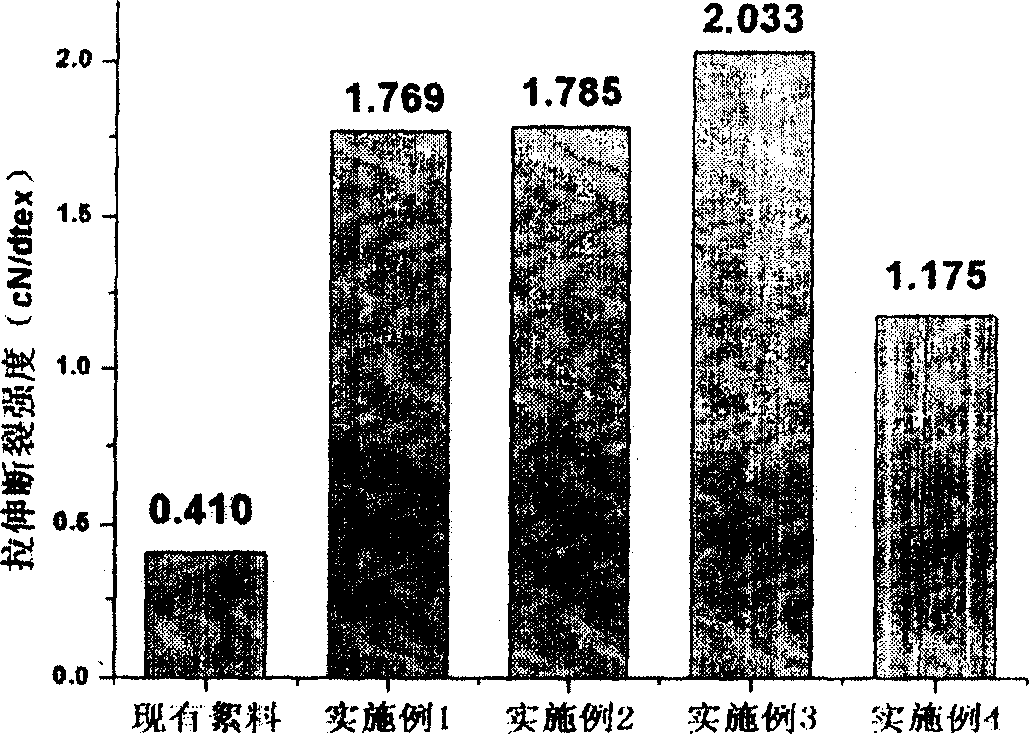

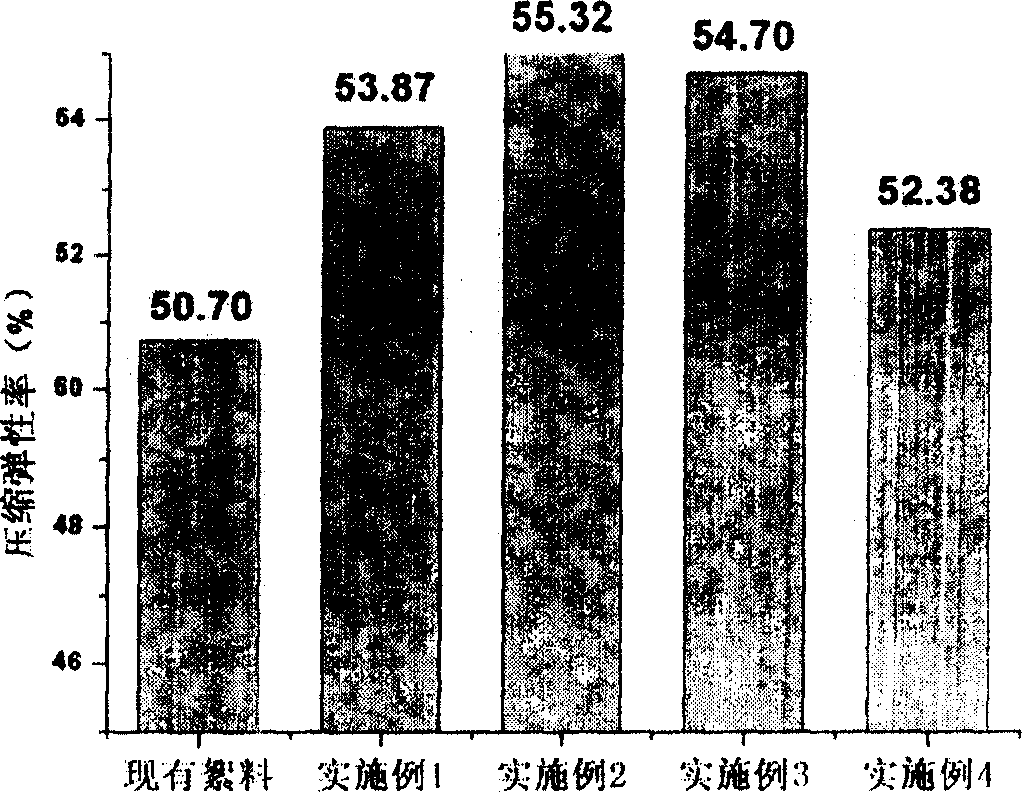

Preparation method of modified polyacrylonitrile fiber paper-based rubber composite sealing material

InactiveCN109468873AHigh tensile strengthHigh compression resilienceInorganic fibres/flakesPaper/cardboardVulcanizationPolymer science

The invention relates to a preparation method of a high-performance modified polyacrylonitrile fiber paper-based rubber composite sealing material. The preparation method comprises the following steps: firstly uniformly stirring polyacrylonitrile pulp-like fiber with an NaOH solution and absolute ethyl alcohol, cooling after a thermostatic waterbath, neutralizing with acetic acid until the PH is 6to 7, washing with ionized water, and drying to obtain modified polyacrylonitrile fiber; then carrying out defibering on aramid fiber pulp, FKF compound mineral fiber, Lapinus mineral fiber, needlebush fiber and modified polyacrylonitrile fiber in water, then adding talcum powder, expanded graphite, calcium carbonate, aluminum sulfate, styrene-butadiene latex, butyronitrile latex, a sulfur ingredient, CPAM, bentonite and the like in sequence, sufficiently stirring for uniform dispersion, papermaking, and carrying out squeezing, drying and vulcanization to obtain the paper-based rubber composite sealing material. According to the preparation method, the interception adsorption capacity of tiny components such as fillers is increased, and the tensile strength and compressive resilience performances of the paper-based rubber composite sealing material are further improved.

Owner:ZHEJIANG SCI-TECH UNIV

Graphene reinforced rubber sealing material and preparation method thereof

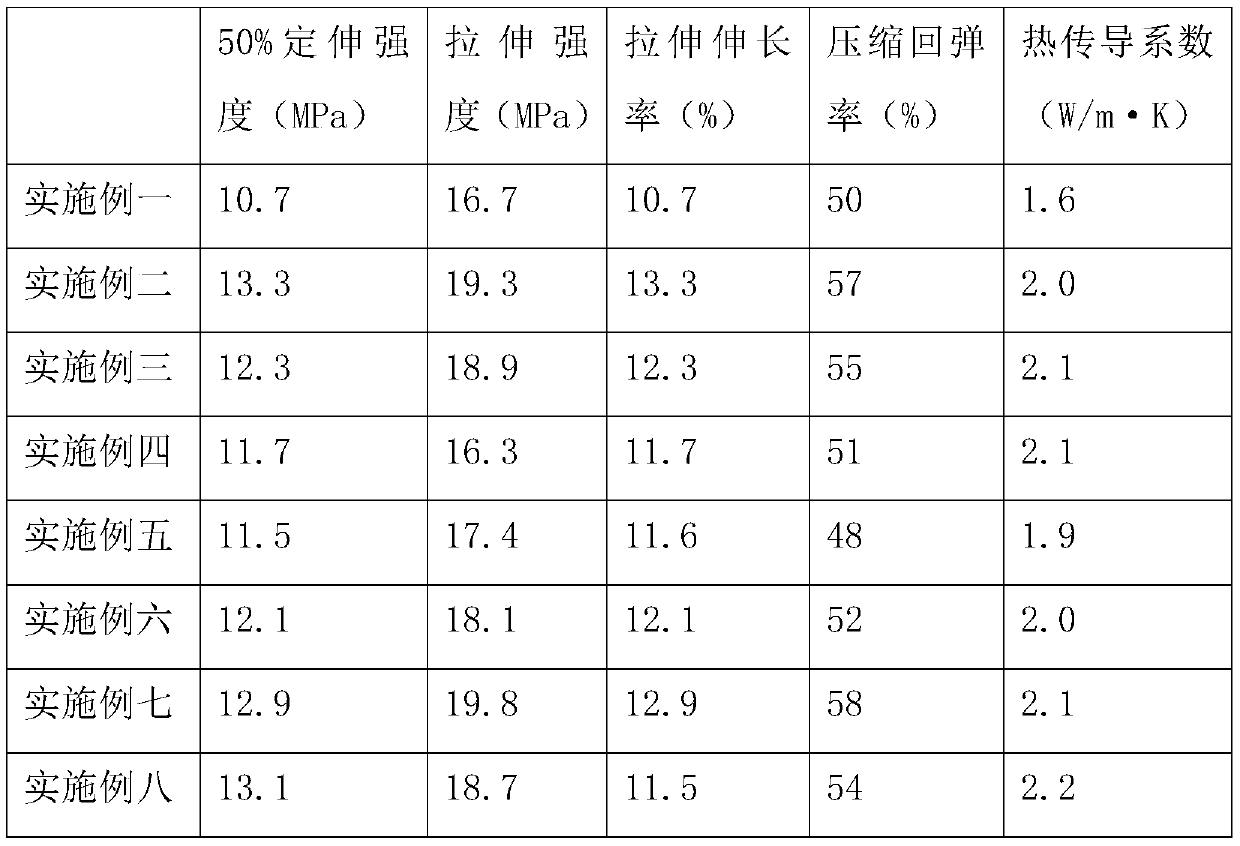

The invention discloses a graphene reinforced heat transfer sealing material and a preparation method thereof. The material is prepared by adding the following raw materials into 100 parts of nitrilerubber by mass part: 2-8 parts of aramid fiber, 3-10 parts of graphene, 3-7 parts of zinc oxide, 2-6 parts of calcium oxide, 0.6-1.4 parts of zinc stearate, 3 parts of an accelerant CZ, 1-3 parts of an accelerant TT, 1-3 parts of an antiager RD, 1-3 parts of an antiager 4010NA, 2-6 parts of vinyl silicone resin, and 2-4 parts of sulfur; preparation steps are as follows: masticating the nitrile rubber, sequentially mixing with an additive, a filler and multi-scale fiber in the above components, and finally performing press forming and vulcanization. The graphene reinforced heat transfer sealingmaterial with tensile strength, thermal conductivity, compression rebound rate, and the like can bear a large pressure.

Owner:ANHUI UNIV OF SCI & TECH

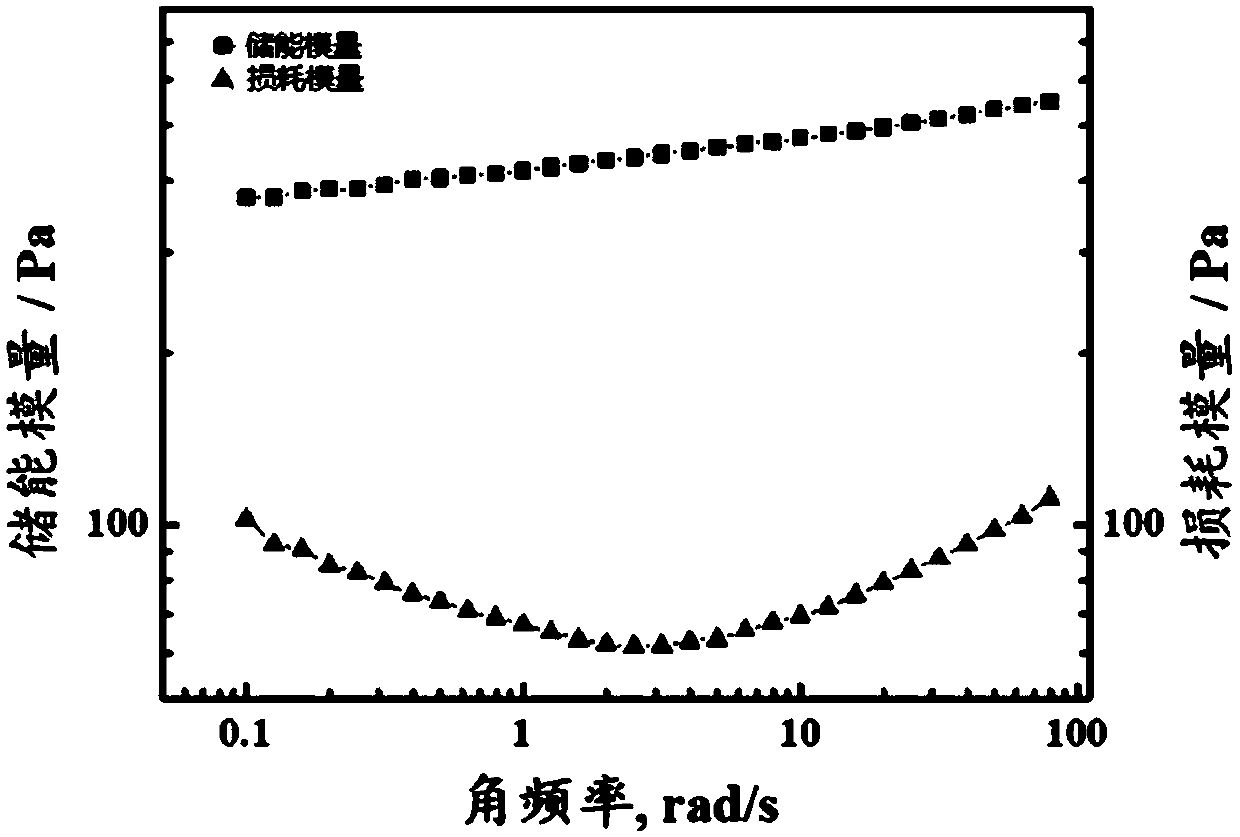

Graphene conductive elastomer and its preparation method and sensor

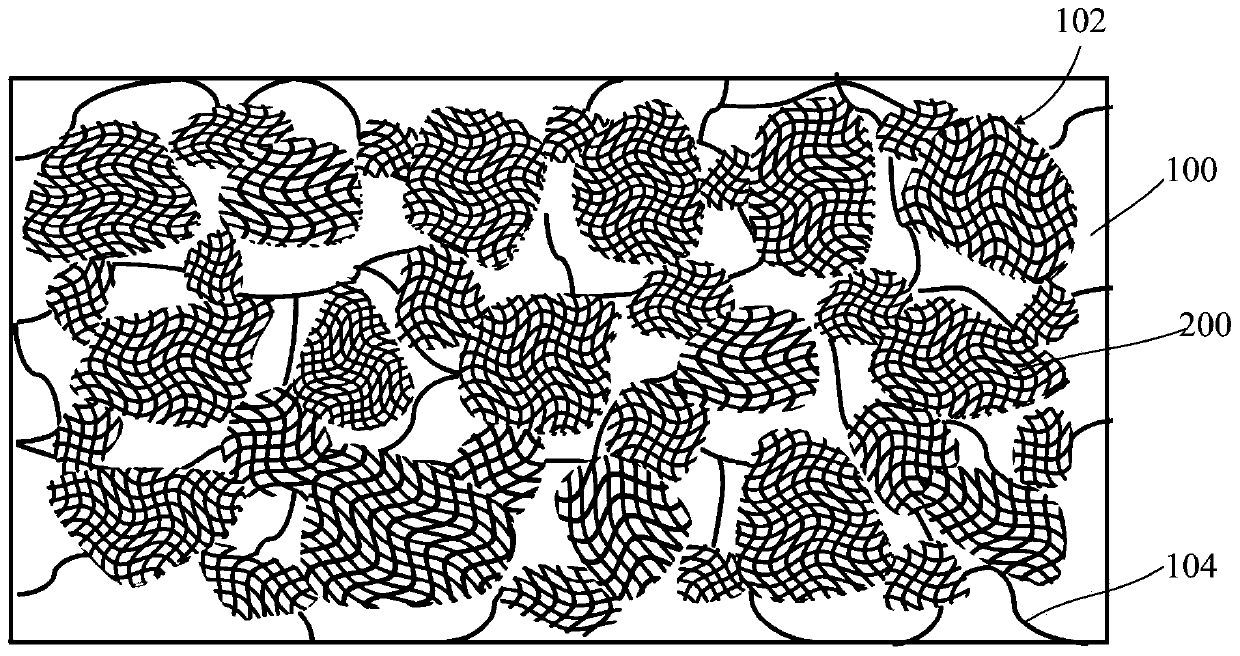

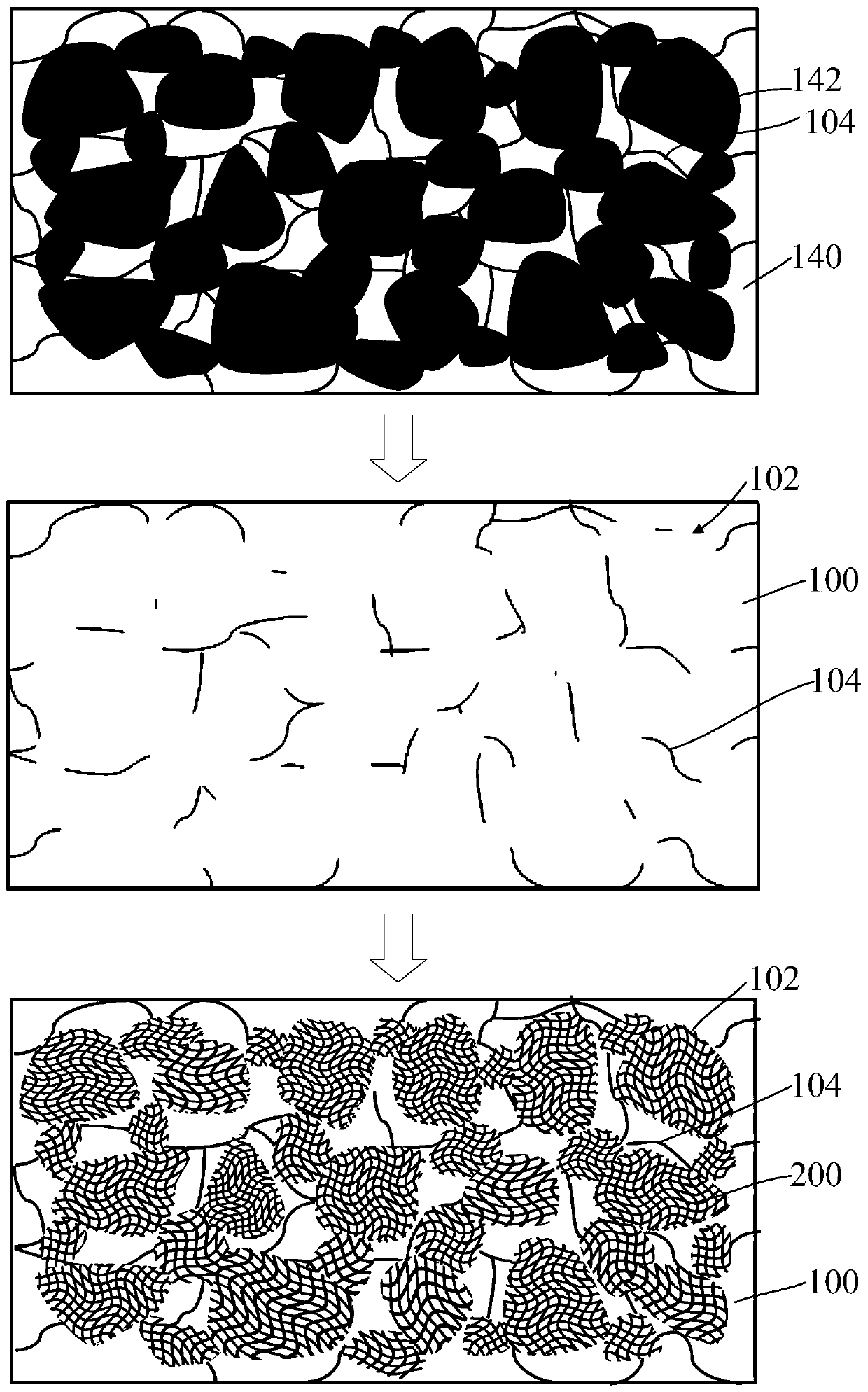

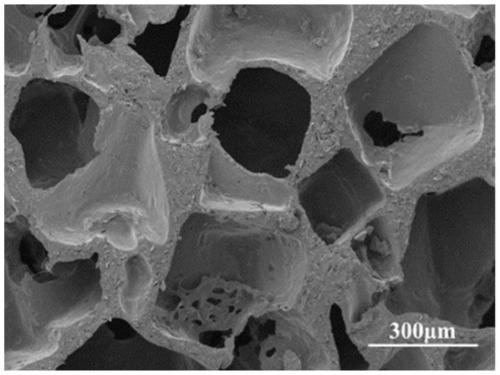

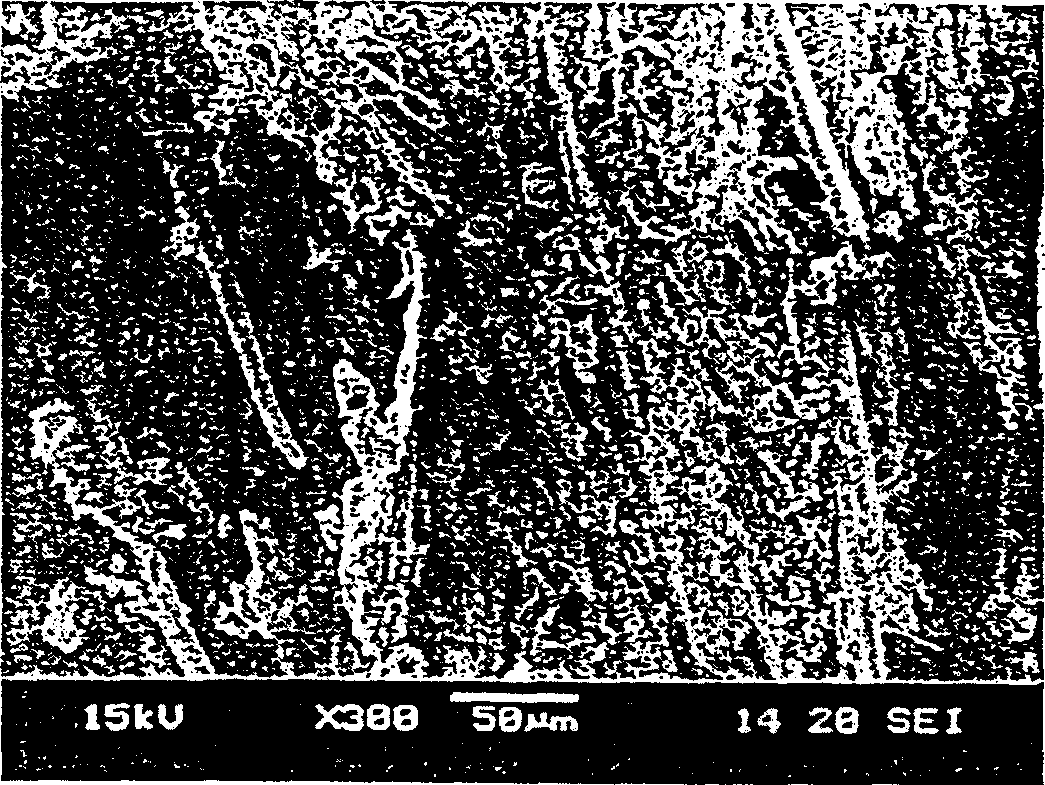

ActiveCN110763379BIncrease the conductive pathImprove reliabilityFluid pressure measurement using ohmic-resistance variationForce measurementNetwork structureGraphite oxide

The invention discloses a graphene conductive elastomer which comprises an elastic base body and graphene three-dimensional network structures. Holes are formed in the elastic base body, the communication rate between the holes is 30%-80%, the holes are filled with the graphene three-dimensional network structures, and at least part of graphene in the graphene three-dimensional network structuresis intrinsic graphene or reduced graphene oxide. The invention also discloses a preparation method of the graphene conductive elastomer. The invention also discloses a sensor.

Owner:北京石墨烯技术研究院有限公司

Nonasbestos mixed fiber enhanced rubber base sealing composite materials and method for making same

InactiveCN1247680CHigh mechanical strengthHigh compression resilienceOther chemical processesPolymer scienceMass ratio

The invention relates to a pre- preoxidated string, aramid fiber or mixed fiber strengthened rubber sealing compound material and its producing technique. The components comprises of : 1, strengthened fiber, 2. enlarged-volume fiber, 3. flexible sticker, 4. filling material, 5. assistant; the mass ratios of each component are: strengthened fiber 10%-36%, enlarged-volume fiber 40-65%, flexible sticker 10-23%, filling material 9.6-21%, assistant 1.6-4.7%. The strengthened fiber is the mixture of pre- preoxidated fiber and aramid fiber or, assistant is accelerant, activator, vulcanizing agent and antioxidant, the technique of the compound material is : plasticate the flexible sticker, mixing the strengthened fiber, inorganic filling material having been prepared, the enlarged-volums fiber and assistant, press into slices, sulfurate to acquire the product. The material has solved the problems such as the unsatisfying range of temperature of the present material NAFC, high productive cost, bad antitensile stress and aging, it is a new NAFC resistant to high temperature, with low cost.

Owner:NANJING TECH UNIV

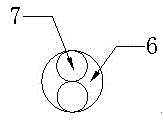

Reinforced breathable polyester staple fiber

InactiveCN106555238AHigh compression resilienceImprove bulk properties indexHollow filament manufactureFilament/thread formingFiberPolyester

The invention relates to a reinforced breathable polyester staple fiber which comprises a core layer and a skin layer. The core layer and the skin layer are arranged inside and outside. A cavity which is used for air circulation is arranged between the core layer and the skin layer. A number of connection parts are arranged in the cavity, and used for connecting the core layer and the skin layer and dividing the cavity into a number of air flow passages. The cross section of the skin layer is shaped like 8 sleeved by a ring structure. According to the reinforced breathable polyester staple fiber provided by the invention, the fiber has high compressive rebound performance through the cavity between the core layer and the skin layer; the fiber has certain air circulation, and has the great performances of warm keeping, moisture absorption and ventilation; in addition, the cross section of the skin layer is shaped like 8 sleeved by a ring structure, so that the fiber can produce much compact permanent self-crimp twist; and the bulky characteristic index of the fiber and the rigidity and pressure resistance of the fiber are improved.

Owner:YANGZHOU GUANGTAI CHEM FIBER

Rubber plug for cementing well

The invention provides a rubber plug for cementing a well and belongs to the field of rubber products. In order to solve the problem that existing rubber for cementing the well is easy to age and needs to be frequently exchanged, the invention provides the rubber plug for cementing the well. The rubber plug for cementing the well comprises the following components in parts by weight: 100 parts of natural rubber NR, 2-8 parts of lignocellulose, 20-40 parts of fine particle calcium carbonate, 5-25 parts of zinc oxide, 4 parts of magnesium oxide, 5-10 parts of an accelerant DM, 1-5 parts of an antiaging agent NBC, 5-20 parts of a vulcanizing agent BP and 2-5 parts of a rubber peptizer SJ-103. By selecting the raw materials in content, the prepared rubber product is high in strength, less in creep deformation, great in compression elasticity and good in leakproofness, has excellent oil resistance and aging resistance and can be widely used to cement heads in petroleum drilling and exploitation to play a role of isolating different liquids in a cementing job.

Owner:成都棕通石油配件有限公司

Well cementing rubber stopper preparation method

The present invention provides a well cementing rubber stopper preparation method, and belongs to the field of rubber product production. In order to solve the problems of easy aging and requirement of frequent replacement of the existing well cementing rubber, the present invention provides a well cementing rubber stopper preparation method, which comprises: modifying lignocelluloses short fibers with malonic acid, preparing a raw rubber, mixing, and carrying out heating molding. According to the present invention, the raw rubber, the modified lignocelluloses short fibers, fine particle calcium carbonate, zinc oxide, magnesium oxide, an accelerator DM, an anti-aging agent NBC, a rubber peptizer and a vulcanizing agent BP are sequentially added to a twin-roller roll mill to carry out mixing, and the prepared rubber product has characteristics of high strength, low creep, high compression resilience, good sealing property, excellent oil resistance and excellent aging resistance, can be widely used in the cementing head in the petroleum drilling and extracting, and provides the effect of separation of different liquids in the well cementing operation.

Owner:成都棕通石油配件有限公司

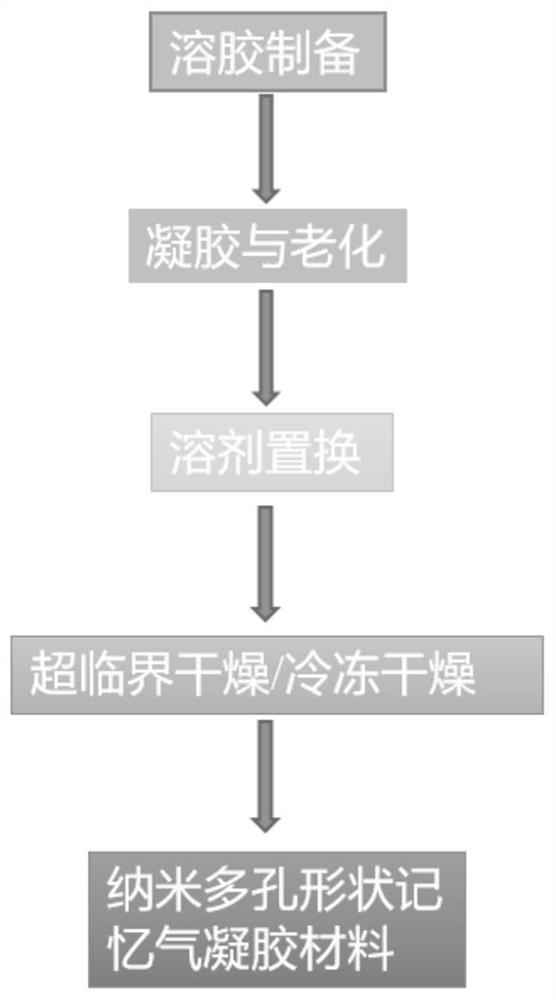

Shape memory aerogel and preparation method thereof

ActiveCN113651992ALight weightImprove heat insulationAerogel preparationColloidal chemistry detailsSupercritical dryingPtru catalyst

The invention provides a preparation method of shape memory aerogel, which comprises the following steps: step a) in a non-alcohol organic solvent, under anaerobic and stirring conditions, carrying out a first reaction on a sulfydryl reagent and an olefin reagent under the action of a benzoyl polymerization catalyst; step b), carrying out a second reaction on the reaction mixture obtained in the step a) under the action of aromatic tertiary amine under oxygen-free and stirring conditions; c) carrying out a third reaction on the reaction mixture obtained in the step b) under the action of water and a phase transfer catalyst, and carrying out aging and solvent replacement on the obtained reaction mixture to obtain gel; and d) carrying out carbon dioxide supercritical drying on the gel obtained in the step c). The method provided by the invention is simple in process, high in controllable degree, high in accuracy and simple and convenient to operate, and the obtained shape memory aerogel has the characteristics of high porosity, low density, high shape recovery rate, glass-transition temperature range of-60 to 180 DEG C and the like.

Owner:UNIV OF SCI & TECH OF CHINA

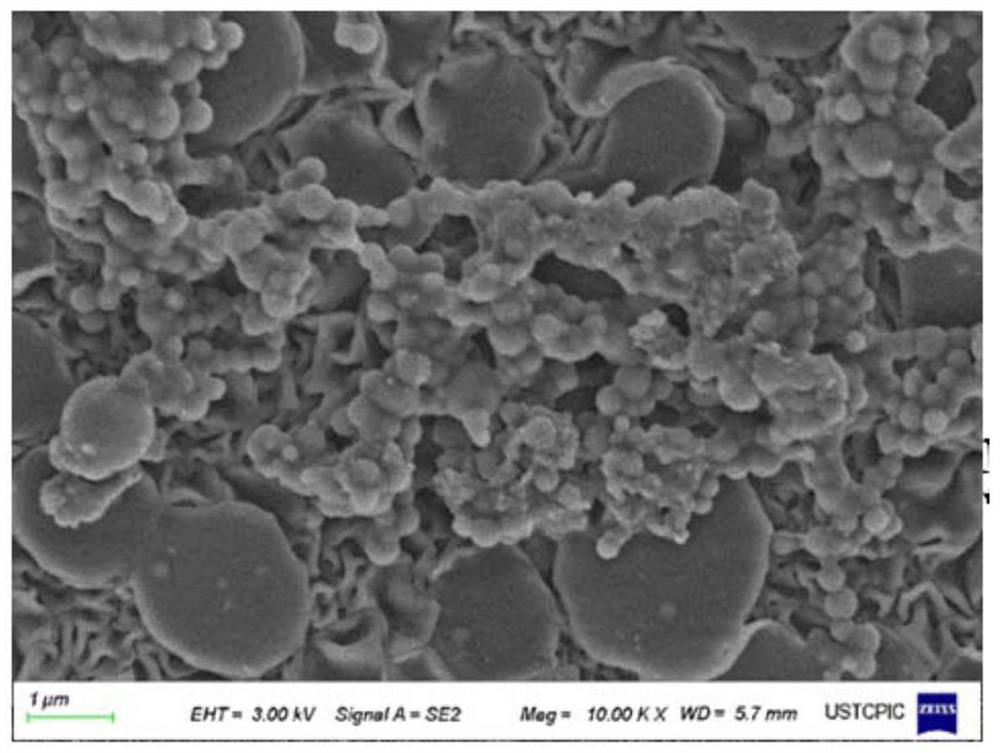

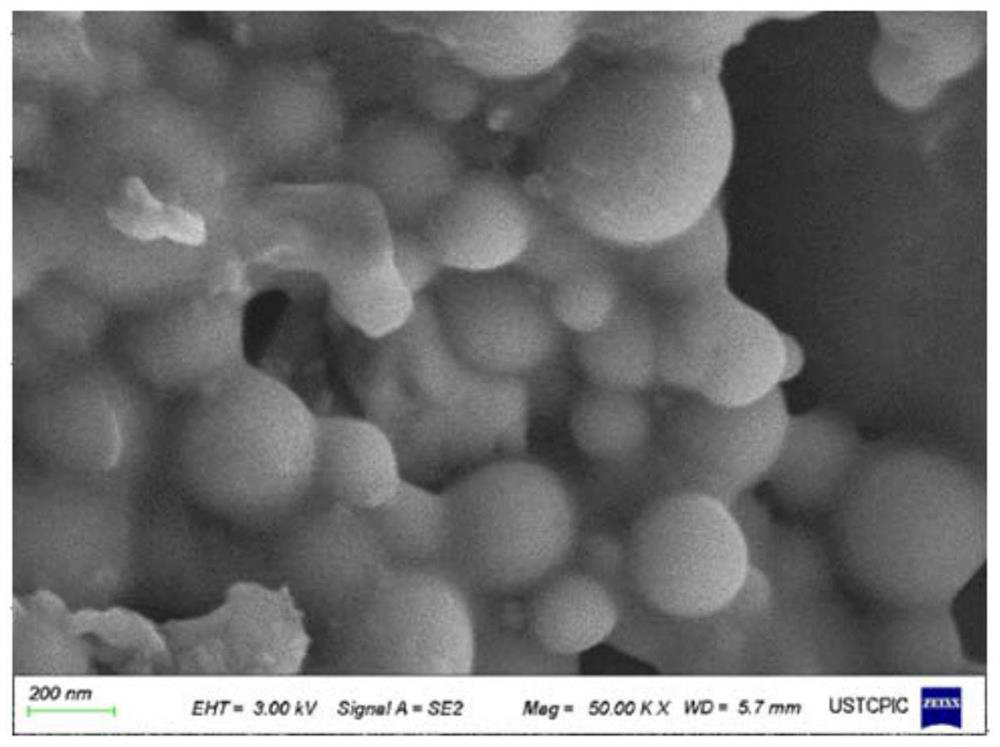

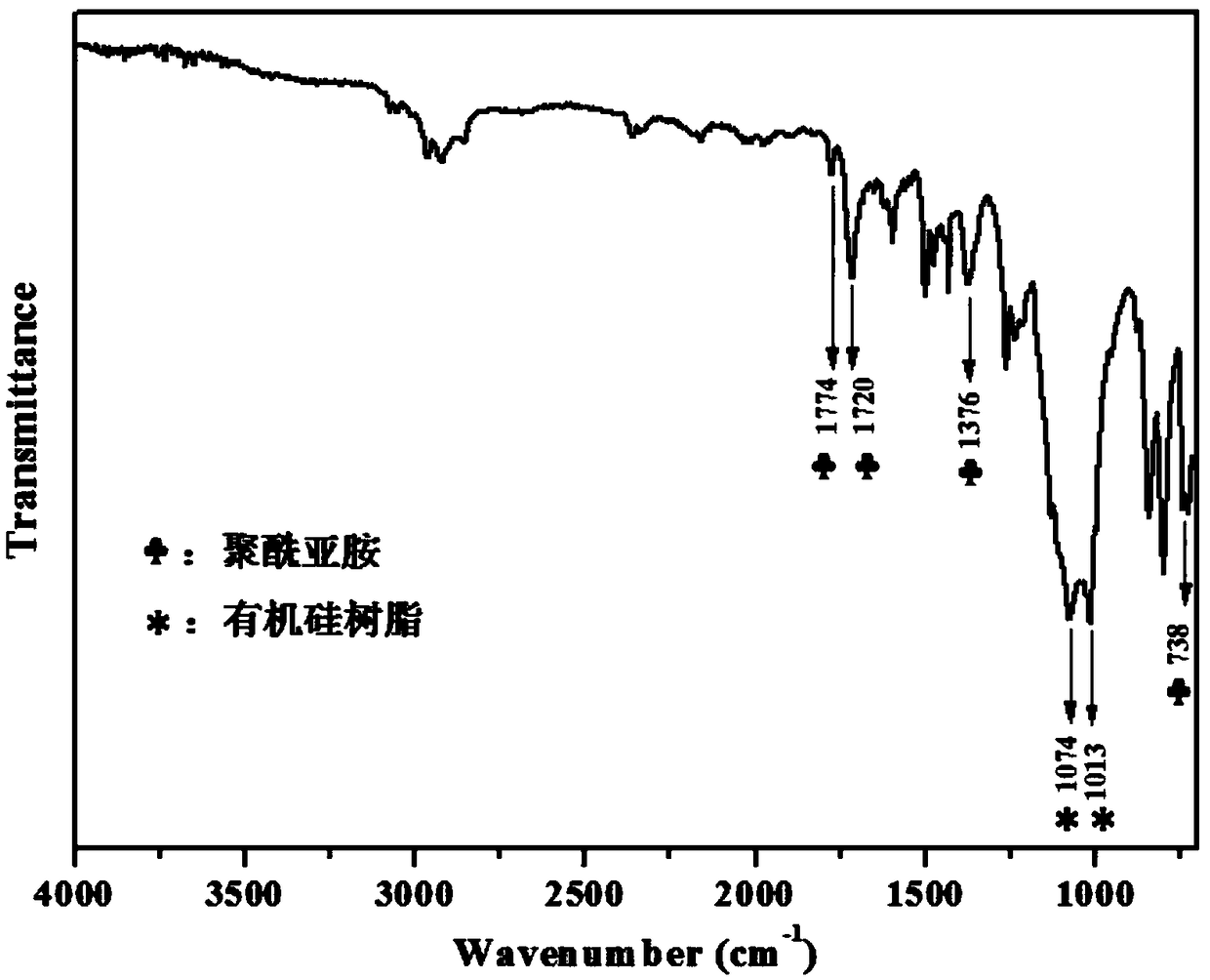

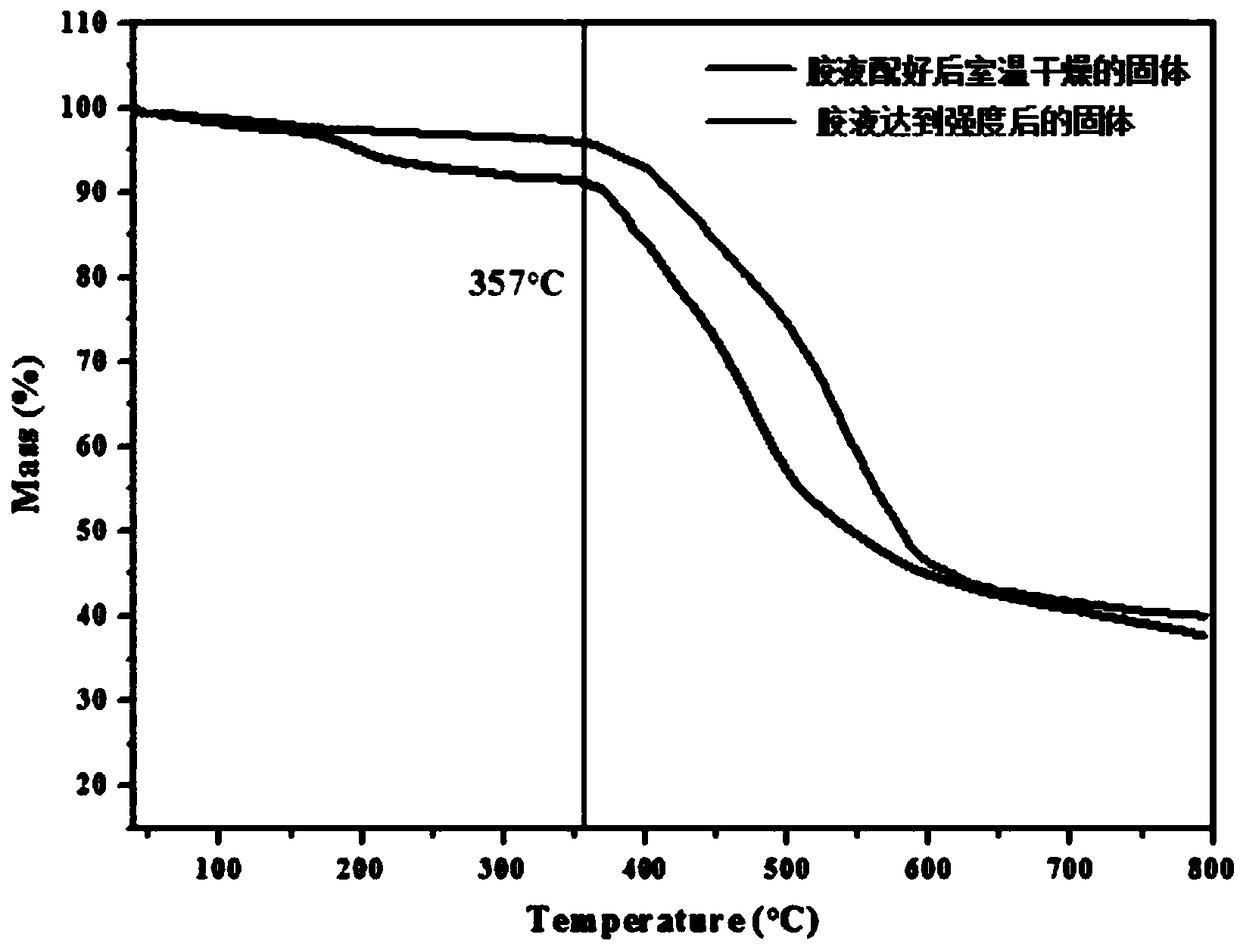

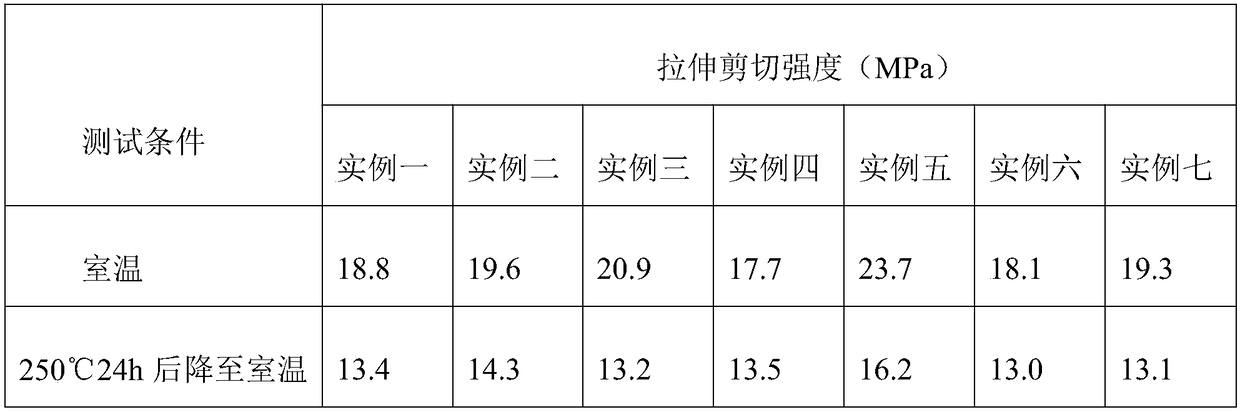

Environment-friendly type polyimide-based high temperature-resistant adhesive and preparation method thereof

InactiveCN109233734AAvoid degradationImprove water resistanceNon-macromolecular adhesive additivesAdhesivePollution

The invention relates to an environment-friendly type polyimide-based high temperature-resistant adhesive, and belongs to the technical field of organic polymer adhesive compositions. The environment-friendly type polyimide-based high temperature-resistant adhesive is prepared by the following steps of enabling dianhydride and diamine to generate condensation reaction to form polyamide acid; precipitating, and preparing polyamide acid salt; further forming a water dispersion body; mixing modified organosilicone resin and a proper amount of additive. The environment-friendly type polyimide-based high temperature-resistant adhesive has the beneficial effects that the rigidity and crispness of an adhesive layer after drying can be effectively reduced, the introduction of a flexible structureby a chemical copolymerizing manner is not required, the manufacturing process is simplified, and the cost is also reduced; compared with a common polyimide high-temperature adhesive, the volatility is lower, and the injury to the body health of a worker and the pollution to the environment by the volatile substances are reduced.

Owner:富优特(山东)新材料科技有限公司

Environment-friendly strain-resistance antibacterial radiation protection latex mattress and preparation technology thereof

The invention discloses an environment-friendly strain-resistance antibacterial radiation protection latex mattress and a preparation technology thereof. The environment-friendly strain-resistance antibacterial radiation protection latex mattress comprises a latex mattress body, and the latex mattress body is prepared from natural rubber components, water, protein, natural resin, saccharides, ashand the like. According to the latex mattress and the preparation technology, firstly, a natural latex mixed solution is adopted for preparing a material A, a material B and a material C for standby use, wherein the material A contains silver ion antibacterial agents and is beneficial for inhibiting bacterial breeding, the material B contains amidogen propyl trimethoxy silane and can improve moisture resistance and compression resilience, the silicone material has a certain stain resistance effect, and the material C contains expanded perlite and improves the thermal insulation performance ofthe latex mattress; the material A, the material B and the material C are uniformly mixed, so that distribution of the materials A, B and C is more uniform, silver fibers are embedded in the bottom ofa mold and the top of the mixed solution, the radiation protection performance of the latex mattress is achieved, and therefore the environment-friendly strain-resistance antibacterial radiation protection latex mattress is obtained.

Owner:江苏老裁缝家纺工业有限公司

Seals and Compression Packers

ActiveCN105156065BImprove deformation abilityAvoid unsealableEngine sealsSealing/packingInternal pressureEngineering

Owner:TIANDING SEALING TECH BEIJING CO LTD

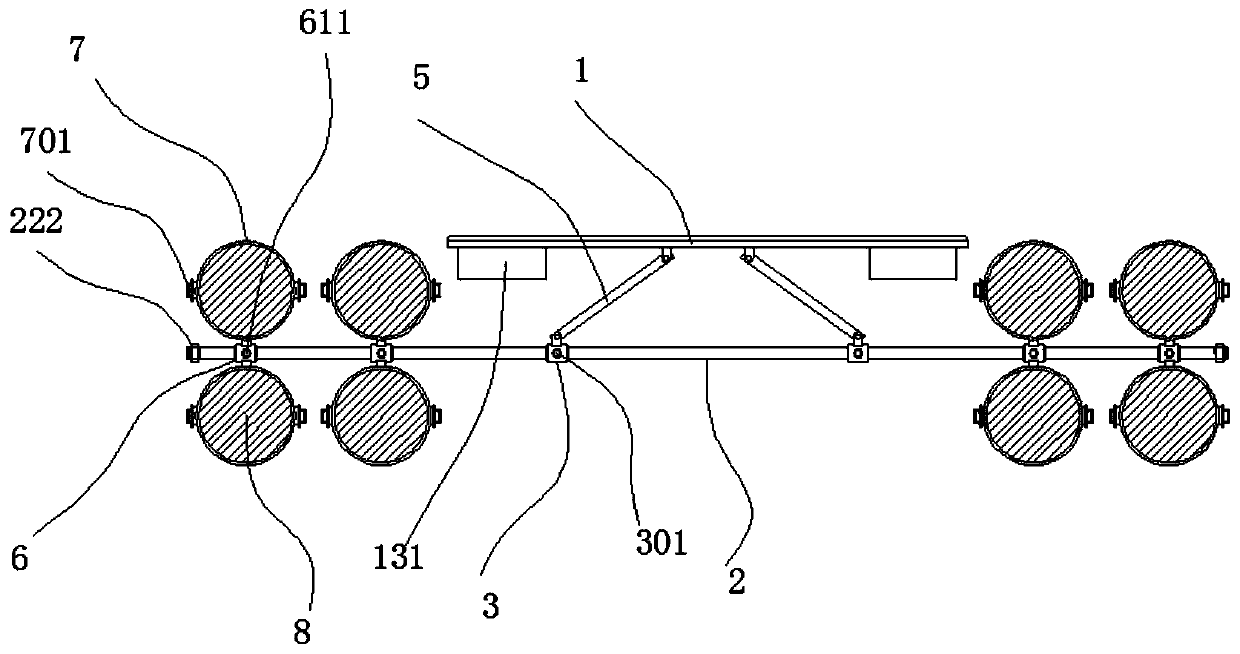

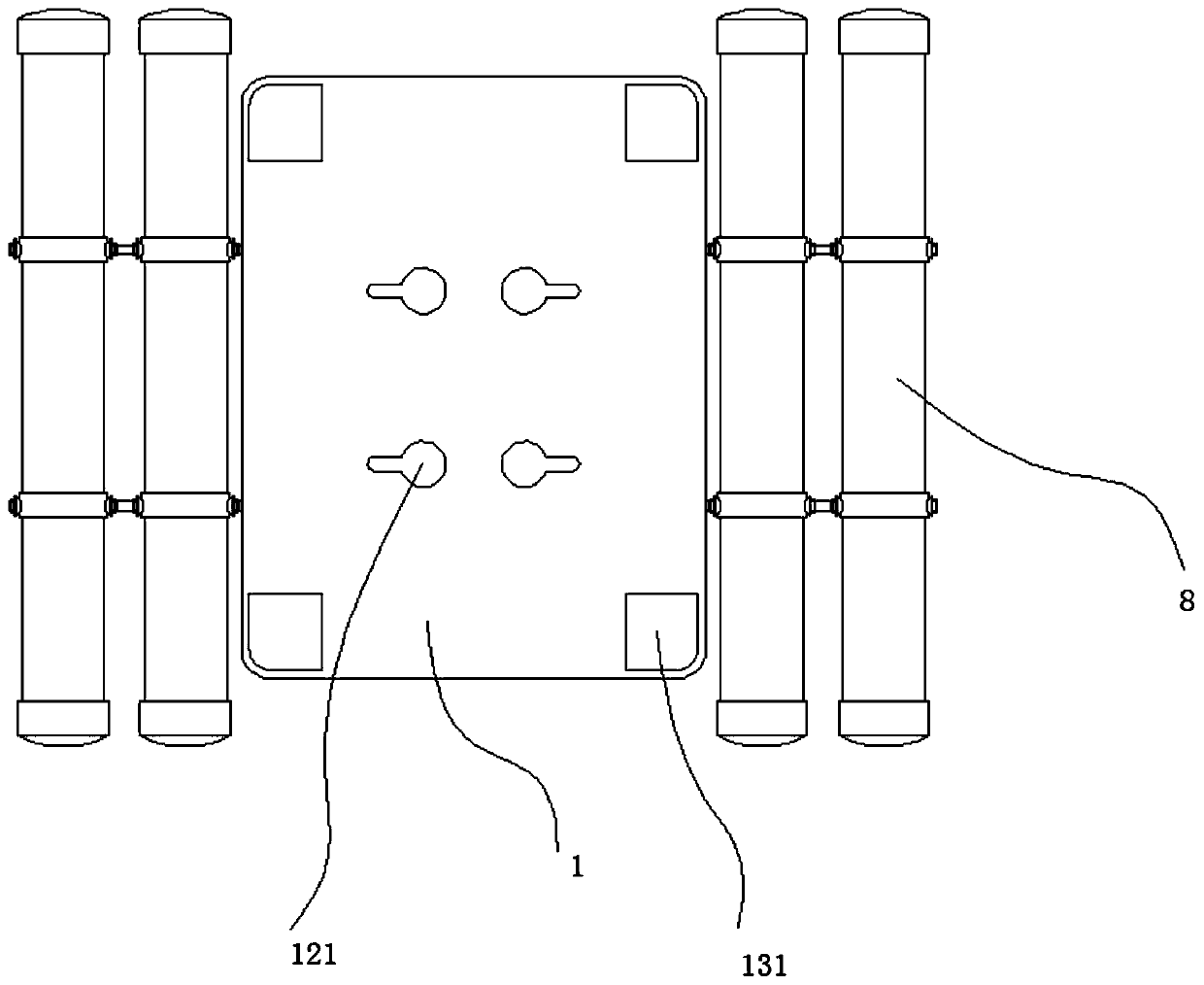

Floating mechanism of reactor

ActiveCN110203341AGood modification effectReduce crystallinityWater/sewage treatment by irradiationWaterborne vesselsEngineeringMechanical engineering

Owner:北京林源利景科技发展有限公司

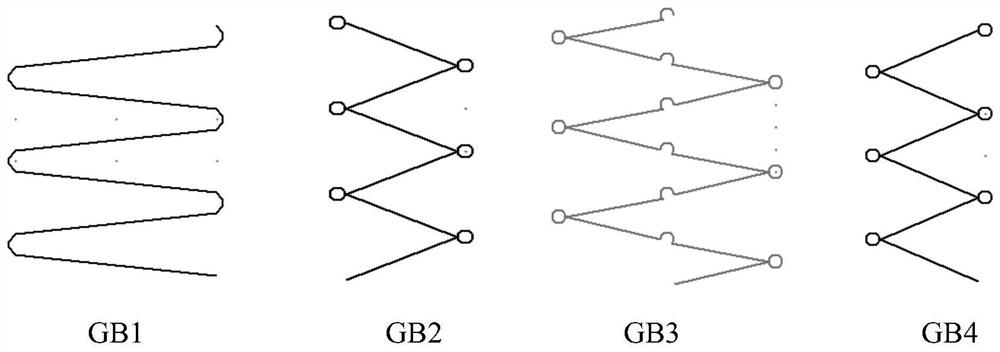

Lightweight compression-resistant warp-knitted elastic imitation leather fabric and preparation process thereof

PendingCN114318890AProcess environmental protectionAvoid layer slipWarp knittingEngineeringPolyurethane coating

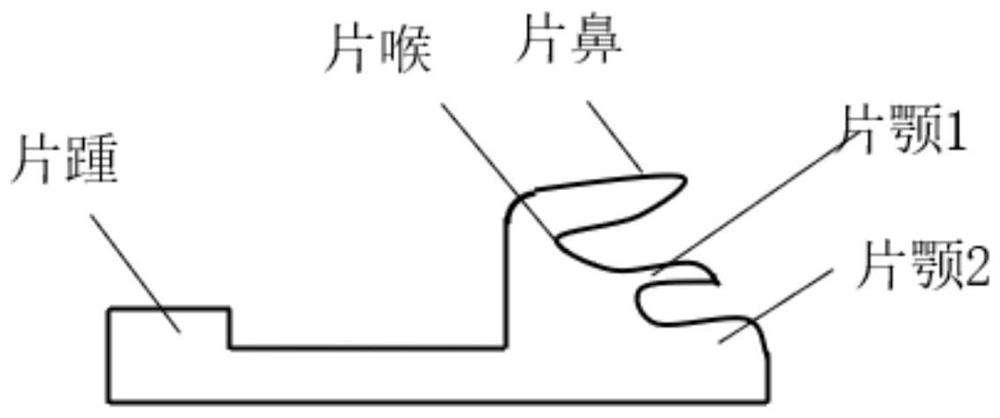

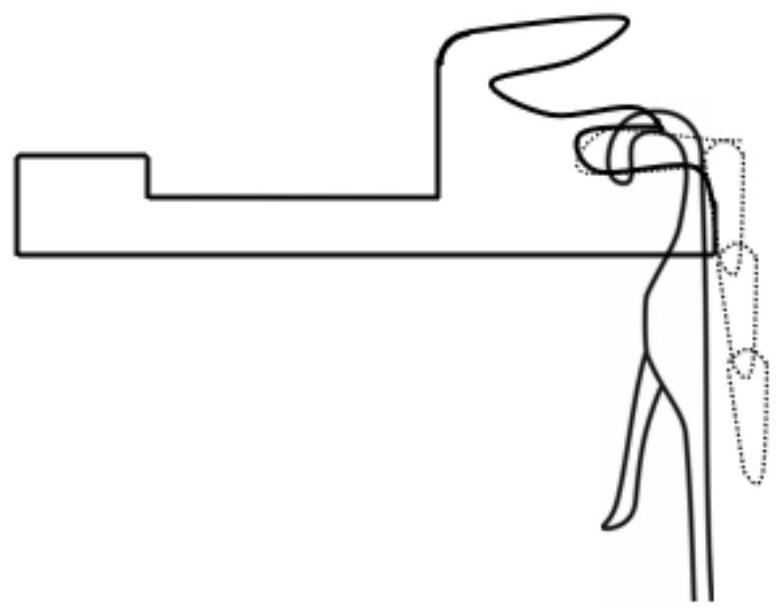

The invention discloses a light compression-resistant warp-knitted elastic imitation leather fabric and a preparation process thereof, and belongs to the technical field of warp-knitted imitation leather fabrics and production thereof. According to the invention, a four-bar two-needle bar warp knitting machine is used for weaving an integrated warp-knitted sandwich-structured fabric as a base material of the leather-imitating fabric, and the base material is compounded with an elastic polyurethane coating to obtain the light compression-resistant warp-knitted elastic leather-imitating fabric; wherein the guide bar GB1 and the guide bar GB2 are fully penetrated and only form a surface layer on a front needle bed through yarn laying; the guide bar GB3 is connected with the front and rear needle beds in a full penetrating manner to form a sandwich-structured core layer; a guide bar GB4 is fully penetrated and only loops on a rear needle bed to form a base layer; the guide bar GB1 adopts elastic yarns, and the guide bar GB2, the guide bar GB3 and the guide bar GB4 adopt non-elastic yarns; meanwhile, a sinker with two piece jaws is adopted in the weaving process, the piece jaw 1 is higher than the piece jaw 2, the elastic yarn passes through the piece jaw 1, the non-elastic yarn passes through the piece jaw 2, and the let-off amount of the elastic yarn is 600-800 larger than that of the non-elastic yarn.

Owner:江苏三联新材料股份有限公司 +1

A kind of silicone rubber/polyurethane rubber composite hydraulic sealing gasket and preparation method thereof

The invention relates to a silicon rubber / polyurethane rubber composite hydraulic sealing gasket and a preparation method thereof. The silicon rubber / polyurethane rubber composite hydraulic sealing gasket is prepared from methylvinylsiloxane rubber, polyether based polyurethane rubber, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, diphenyl silanediol, hexamethyldisilazane, gas-phase white carbon black, modified wollastonite and the like. The methylvinylsiloxane rubber, which has the advantages of excellent heat resistance, excellent freezing resistance, excellent ozone resistance, excellent atmospheric aging resistance and small permanent compression set, and the polyurethane rubber with favorable mechanical properties are compounded and blended, so that the respective advantages are displayed, thereby enhancing the sealing property of the sealing material; and in the blending process, the organically / inorganically modified wollastonite is added to obviously improve the dispersity of the wollastonite in the rubber, thereby enhancing the mechanical strength, oil resistance, wear resistance, high temperature resistance and other properties of the sealing material.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

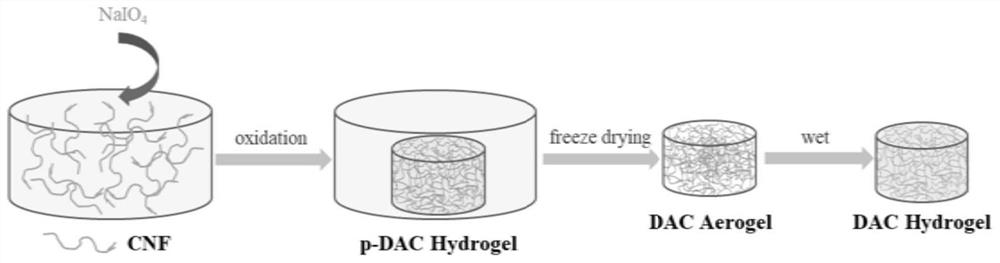

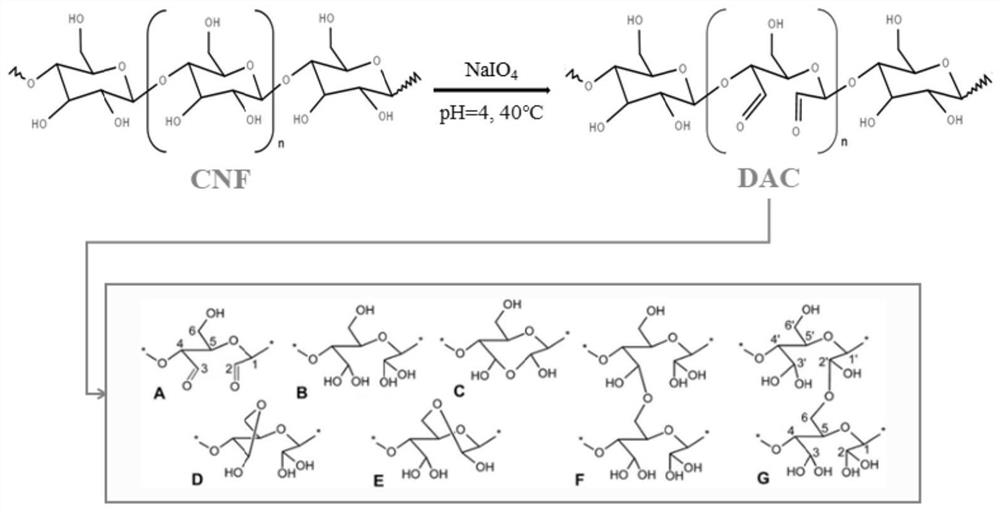

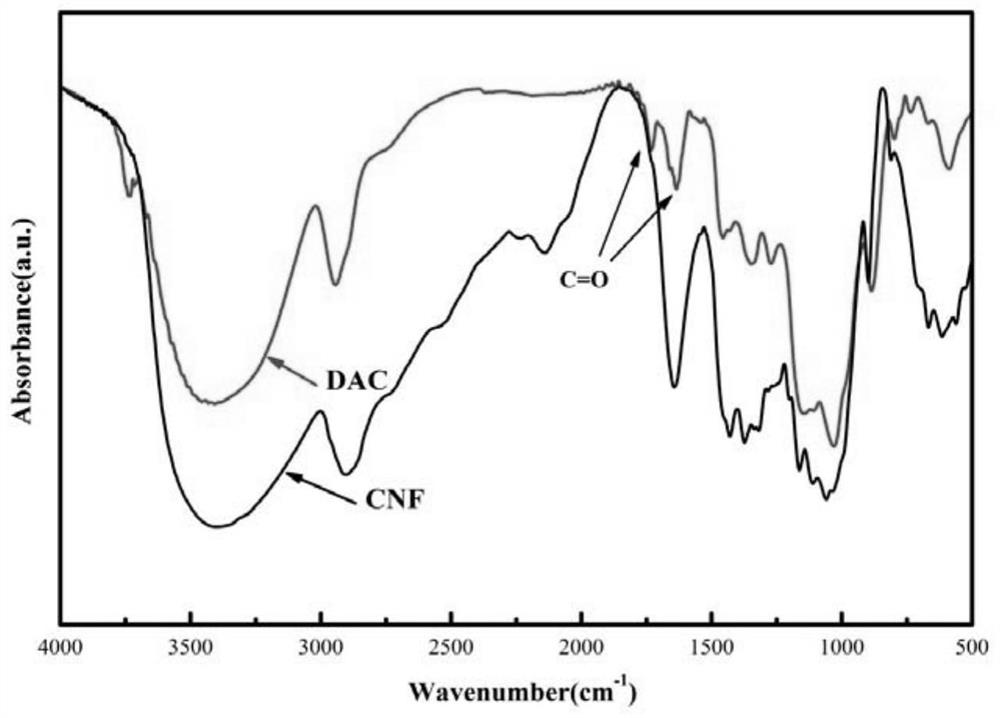

A kind of dialdehyde nanocellulose three-dimensional flexible material and its preparation method and application

ActiveCN113292762BLarge specific surface areaMany active groupsOther chemical processesAlkali metal oxides/hydroxidesFreeze-dryingSorbent

The invention discloses a dialdehyde nanocellulose three-dimensional material and a preparation method and application thereof. The preparation method of the dialdehyde nanocellulose three-dimensional material of the present invention includes the following steps: (1) High oxidation of the matrix: mixing the nanocellulose dispersion with an oxidizing agent, adjusting the pH to an acidic value, mixing uniformly, and heating the reaction in the dark to obtain the initial hydrogel; (2) freeze-drying of the matrix: the initial hydrogel is washed with water, frozen in liquid nitrogen, freeze-dried in vacuum, and washed with water again to obtain a three-dimensional dialdehyde nanocellulose material. The material of the invention has a flexible network structure, has extremely high modification value, can still maintain its shape in a wet environment, has good compression resilience and water resistance; the surface also has abundant hydroxyl and aldehyde groups, which can be used as The active sites were further functionalized, and the obtained dialdehyde nanocellulose solid amine adsorbent could adsorb acid gases.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com