Gasket material

A padding and filling material technology, which is applied in the field of padding materials, can solve the problems of high cost of aramid fiber and reduce the mixing amount of aramid fiber, so as to avoid the high cost of raw materials, increase the tensile strength, and improve the sealing performance Effect

Active Publication Date: 2011-04-27

NIPPON LEAKLESS IND CO LTD +1

View PDF10 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

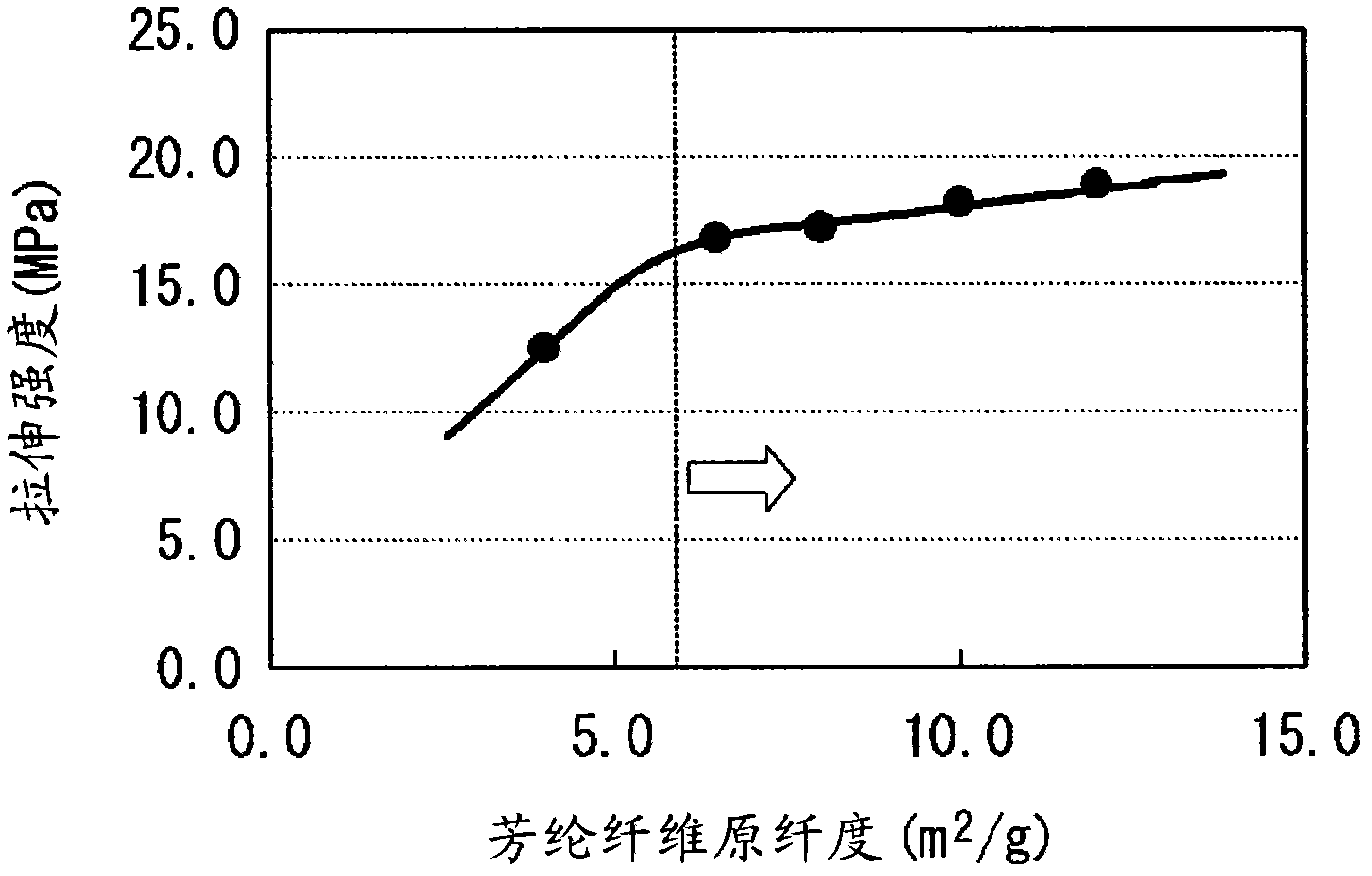

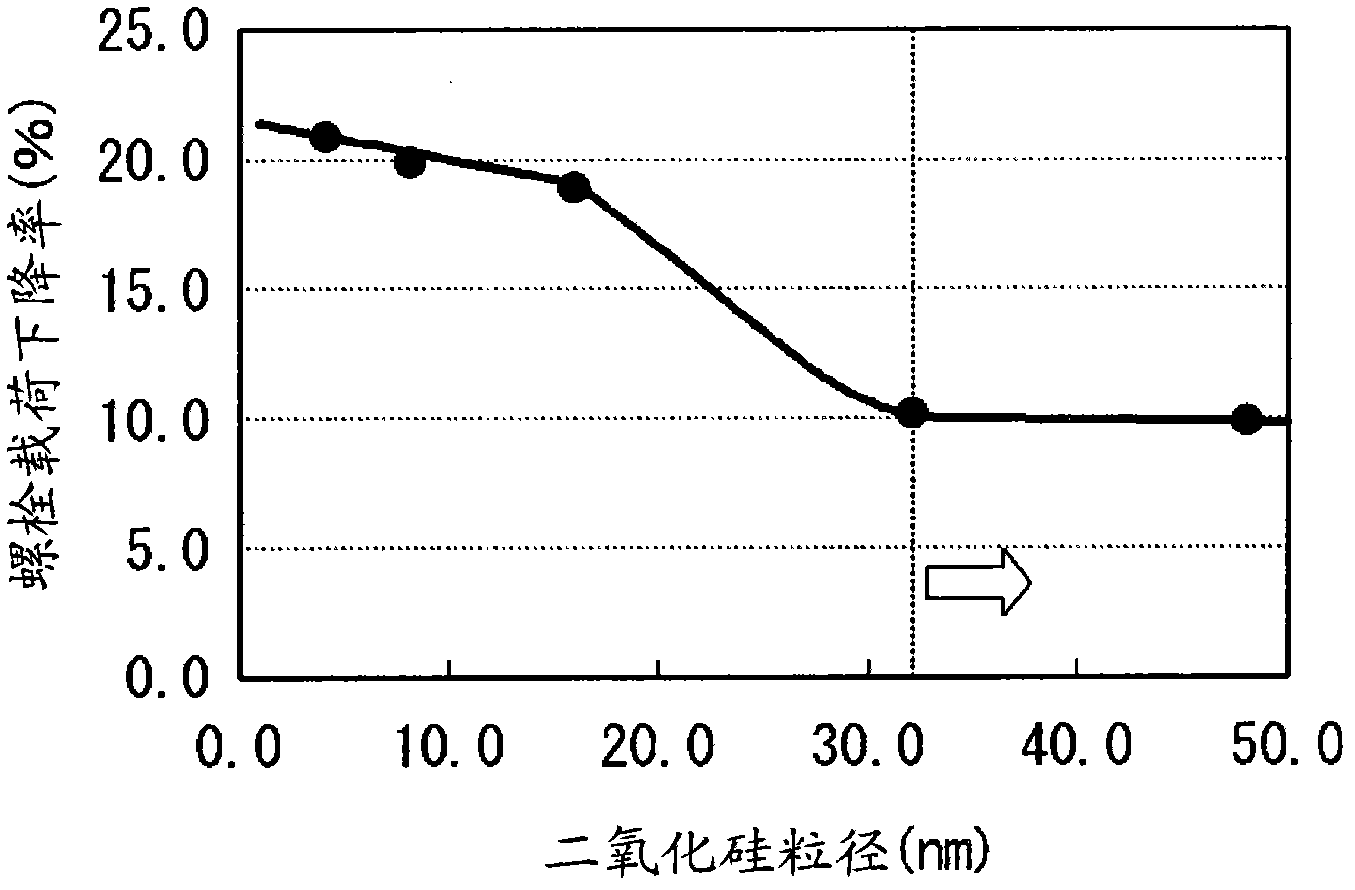

[0038] According to Comparative Examples 1-8 shown in Table 1 and Examples 1-12 of the present invention, the mixing ratios of aramid fibers, acicular dolomite, silica, rubber, and inorganic fillers were changed to prepare bonding pads respectively. The performance of the sheet is confirmed by tensile strength test, bolt load drop rate test, and ultimate sealing pressure test.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

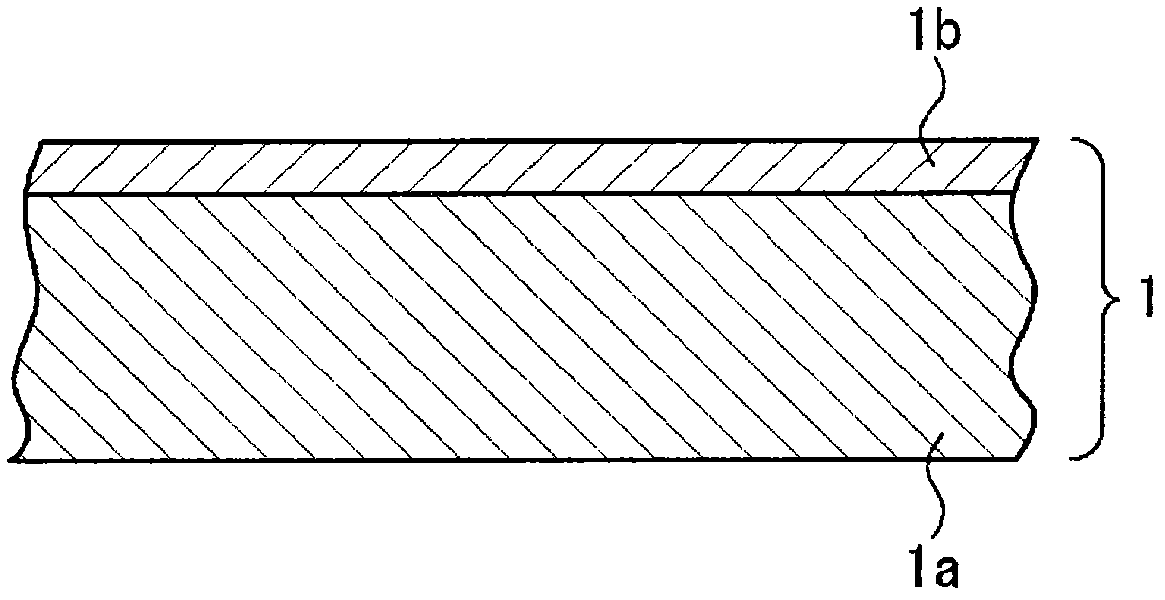

Disclosed is a low-cost gasket material which has improved strength, while maintaining high flexibility. The gasket material is composed of a joint sheet (1) formed by pressure-laminating a raw material, which is obtained by mixing a rubber, a reinforcing fiber and a filler, with calender rolls and vulcanizing the resulting product. The basic composition of the raw material is composed of 16-28 wt% of NBR serving as the rubber, 4-8 wt% of an aramid fiber serving as the reinforcing fiber, 10-20 wt% of a needle-like dolomite serving as the reinforcing fiber, 8-20 wt% of silica particles servingas the filler, and the balance of an inorganic filler serving as the filler.

Description

technical field [0001] The present invention relates to materials used for gaskets of engines and transmissions mounted on vehicles, etc., and particularly relates to joint pads formed by pressing, laminating and vulcanizing raw materials kneaded with rubber, reinforcing fibers, and fillers with calender rolls The sheets constitute the dunnage material. Background technique [0002] Since the engine is repeatedly turned on and off, a large temperature change occurs in a gasket insertion portion between a transmission case combined with the engine and a transmission cover fixed to the case by bolts. Therefore, in the case where a gasket is used for the gasket insertion portion, repeated temperature changes cause repeated relative displacement (fretting wear) of the joint surfaces between the housing and the transmission cover and the gasket. In addition, the rigidity of the structural body decreases due to weight reduction, which may cause fretting wear due to external force...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16J15/10C08K3/00C08K7/08C08K7/18C08L9/02C09K3/10

CPCC09K2200/0243C08L9/02C09K2200/0695C09K2200/0247C09K2200/0612C09K3/10

Inventor 藤原健秋吉浩二浜田义明永井康晃望月信介

Owner NIPPON LEAKLESS IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com