Shape memory aerogel and preparation method thereof

An aerogel and memory technology, applied in the field of materials, can solve the problems of low possibility of repeatable industrial production, complex operation process, small adjustable range, etc., and achieve high shape recovery rate, high degree of controllability, and extended application. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

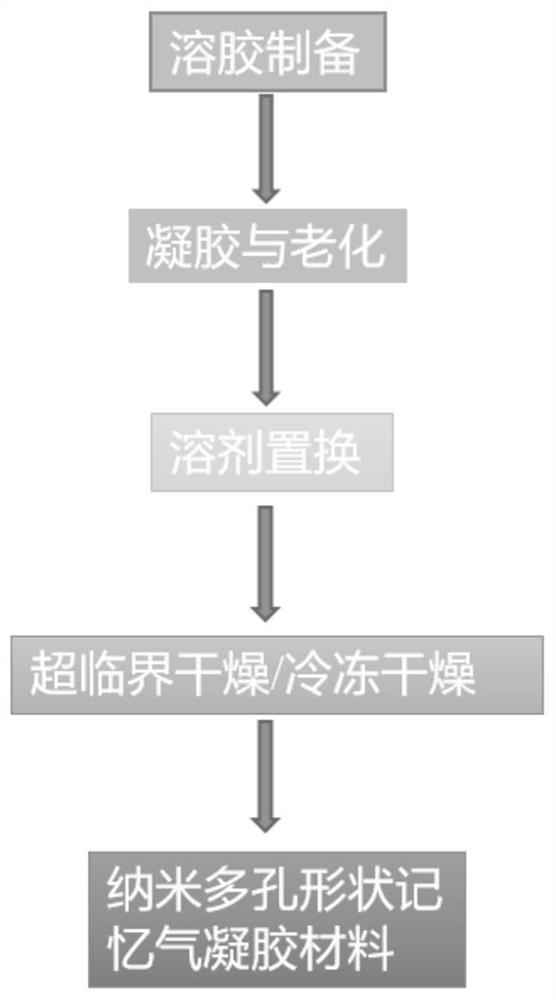

[0052] see figure 1 , figure 1 The schematic diagram of the preparation process of the shape memory airgel provided by the embodiment of the present invention, firstly, the sol is prepared by using specific raw materials and methods, and then it is converted into a gel, and then subjected to aging, solvent replacement, supercritical drying and / or freeze drying After that, the nanoporous shape memory airgel can be obtained. The specific process is as follows:

[0053] Get 6.28g of HDI trimer and 5.889g of (3-mercaptopropyl) trimethoxysilane and mix, add 400ml of acetone solution to the mixed solution, and quickly add 2.00g of azobisisoheptanonitrile, load React in a Schlenk bottle, stir the solution for 30 minutes, add 6ml of p-ethoxyaniline, stir the solution for 4 hours, add 1.62ml of water and 1ml of 25% ammonia solution, stir for 10 minutes, pour the above uniform solution into the mold and seal it, and heat it at 60°C Aging is carried out in a dry environment, and the a...

Embodiment 2

[0059] Take 9.97g of triallyl isocyanurate and 23.56g of (3-mercaptopropyl) trimethoxysilane and mix, add 400ml of acetone solution to the mixture, and quickly add 1.28g of azobisiso Put the butyronitrile into a Schlenk bottle for reaction, stir the solution for 30min, add about 6ml of N,N dimethylbutylamine, stir the solution for 4h, add 6.48ml of water and 1ml of 0.5% sodium hydroxide solution, stir for 10min, and After the above homogeneous solution was poured into a mold and sealed, it was aged in a dry environment at 60° C. for 3 days. After aging, the formed gel was taken out, and the solvent was replaced with acetone solution for 3 days, and carbon dioxide supercritical drying was carried out at a drying pressure of 20MP and a drying time of 4 days to obtain a shape memory aerogel.

[0060] The airgel is heated on a hot plate at 200°C, and the temperature distribution is analyzed with an infrared thermal imager, and the results can be found in Figure 5 , Image 6 wit...

Embodiment 3

[0063] Take 9.97g of triallyl isocyanurate and 23.56g of (3-mercaptopropyl) trimethoxysilane and mix, add 300ml of acetone solution to the mixture, and quickly add 1.28g of azobisiso Put the butyronitrile into a Schlenk bottle for reaction, stir the solution for 40min, add about 5ml of N,N dimethylaniline, stir the solution for 4h, add 6.48ml of water and 2ml of 0.5% sodium hydroxide solution, stir for 10min, and mix the above After the uniform solution was poured into the mold and sealed, it was aged in a dry environment at 60°C for 3 days. After aging, the formed gel was taken out, and the solvent was replaced with acetone solution for 3 days, and carbon dioxide supercritical drying was carried out at a drying pressure of 20MP and a drying time of 4 days to obtain a shape memory aerogel.

[0064] see Figure 8 , Figure 8 The thermal gravimetric decomposition diagrams of the shape memory aerogels prepared in Examples 1 and 3 of the present invention, wherein Curve 1 is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com