Patents

Literature

52results about How to "High shape recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable macromolecule composite material with shape memory function and its preparation method and use

InactiveCN101240116AGood magnetic responseHigh elastic modulusStentsSurgeryPolypyrroleMechanical property

The invention relates to a biodegradable polymer composite material having shape memory function, comprising a biodegradable polymer material, which is characterized in that the molecular weight of the biodegradable polymer material is 20000 to 1500000, 1 to 20 parts of nano-scopic or micron-sized organic conductive particles and / or inorganic magnetic particles are added in the 100 parts by weight of the polymer, wherein, the organic conductive particles is one of polypyrrole, polyaniline, poly3,4-dioxane ethyl thiophene or the mixture of them, the inorganic magnetic particles is one of ferroferric oxide and ferric oxide magnetic particles or the mixture of them. The mechanical property and mechanical property of the materials, with good elasticity modulus, well elasticity, high shape recovery rate, easy shape memory and changing operation and fast shape recovery speed.

Owner:SOUTHWEST JIAOTONG UNIV

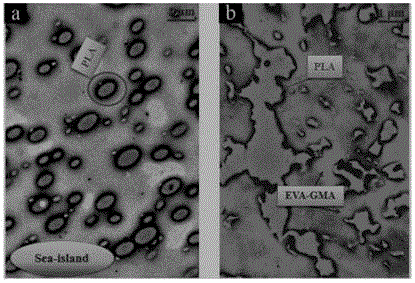

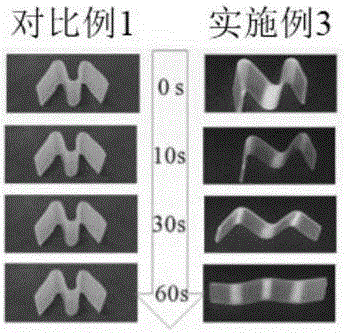

Body-heat-excited polylactic-acid-base biodegradable shape memory material, and preparation method and application thereof

The invention discloses a body-heat-excited polylactic-acid-base biodegradable shape memory material, and a preparation method and application thereof. The material is composed of the main components polylactic acid and thermoplastic elastomer in a mass ratio of (70-90):(30-10), and also composed of 10-40 phr of plasticizer. The preparation method comprises the following steps: mechanically mixing the main components into a premix, adding into an extruder, and carrying out melt blending to obtain the shape memory material. The shape memory material is used for manufacturing fixers for medical treatment. The shape recovery temperature of the polylactic-acid-base biodegradable shape memory material can be adjusted to near body temperature, thereby implementing the body-heat-excited effect. The shape memory material can be better applied to biological medical materials to greatly enhance the market competitiveness of the product.

Owner:SOUTH CHINA UNIV OF TECH

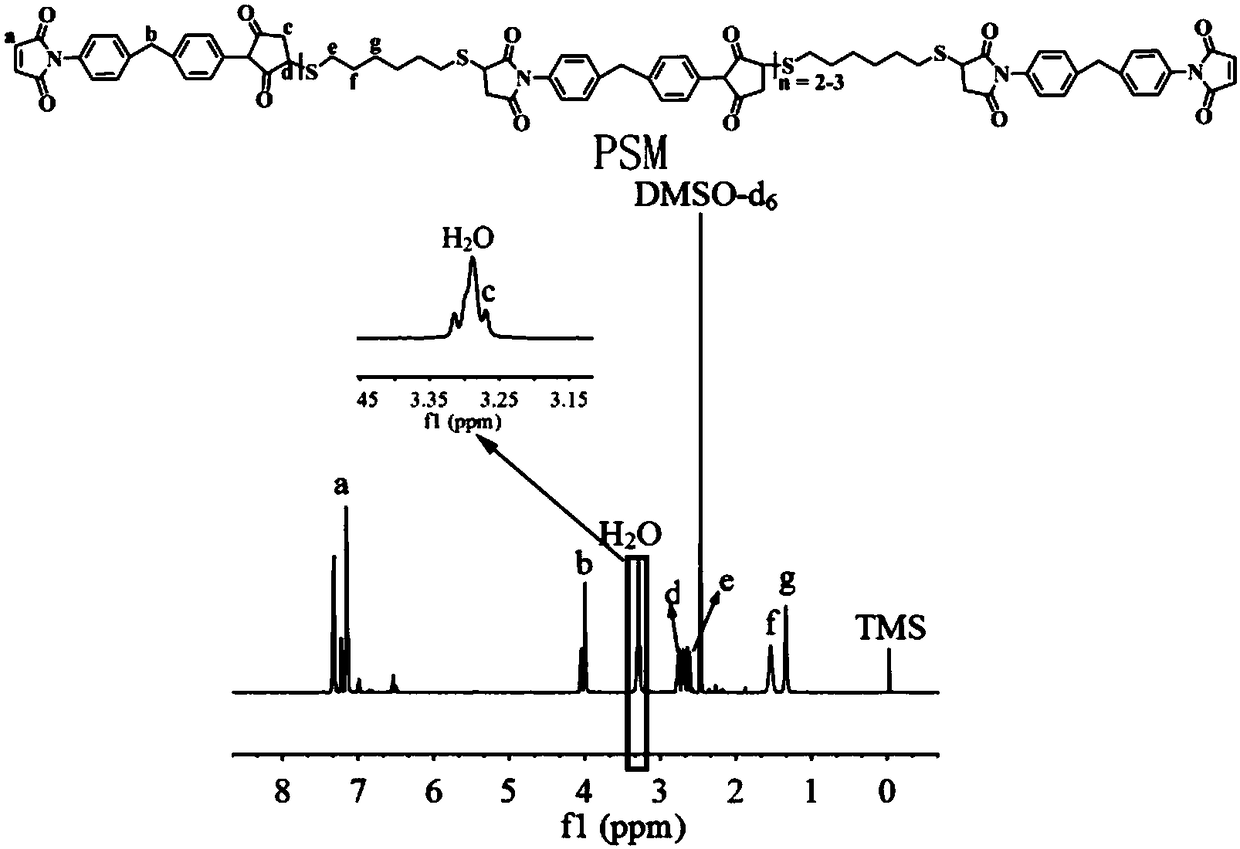

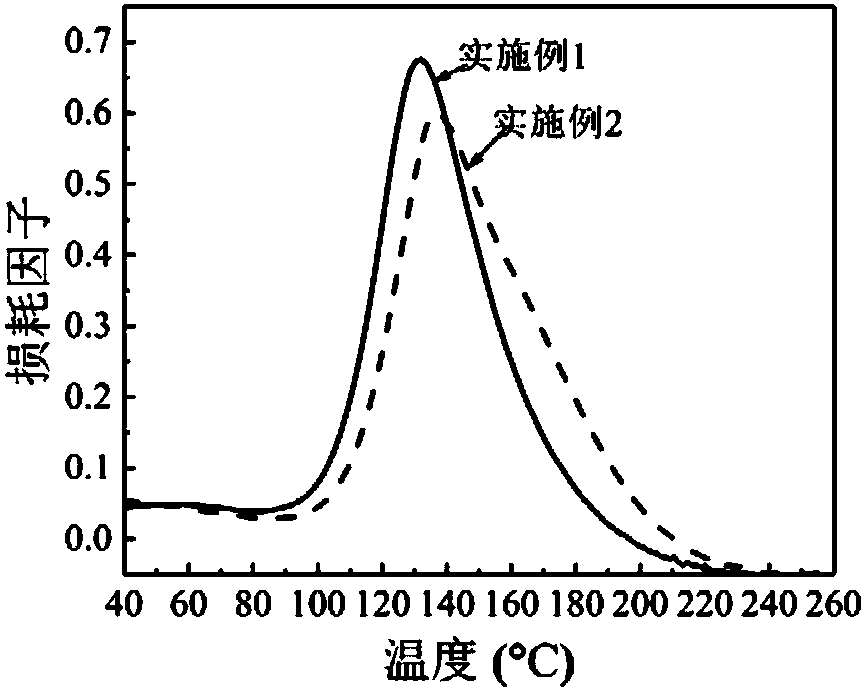

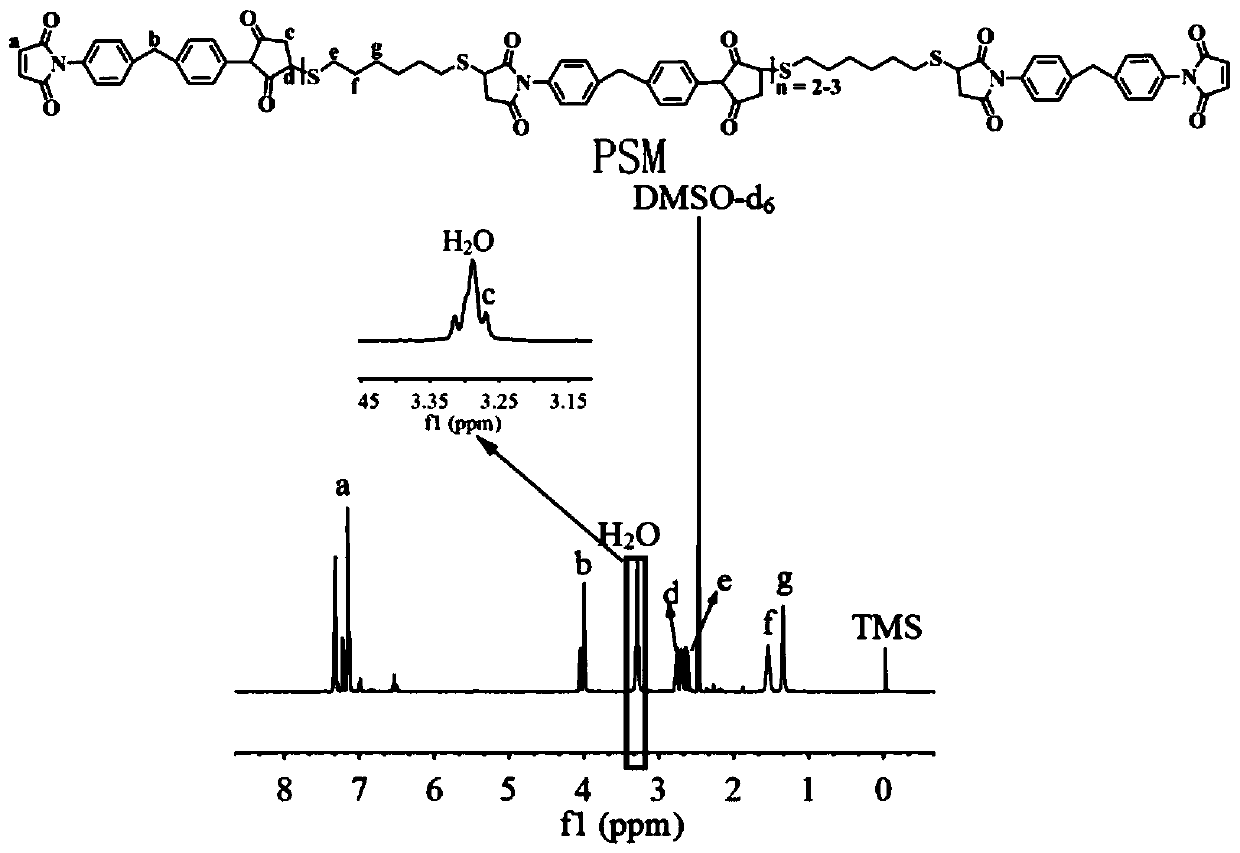

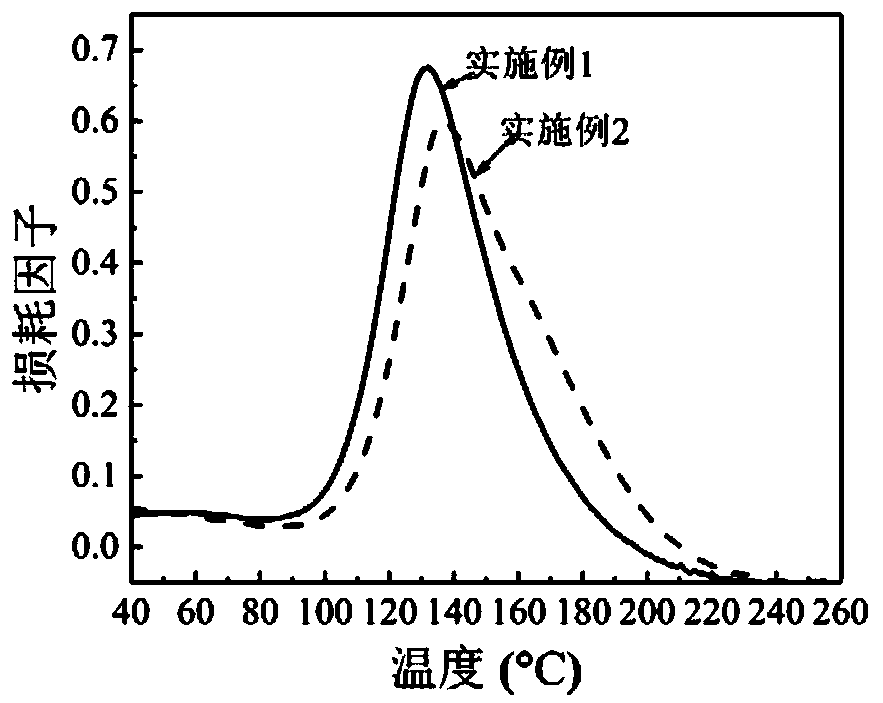

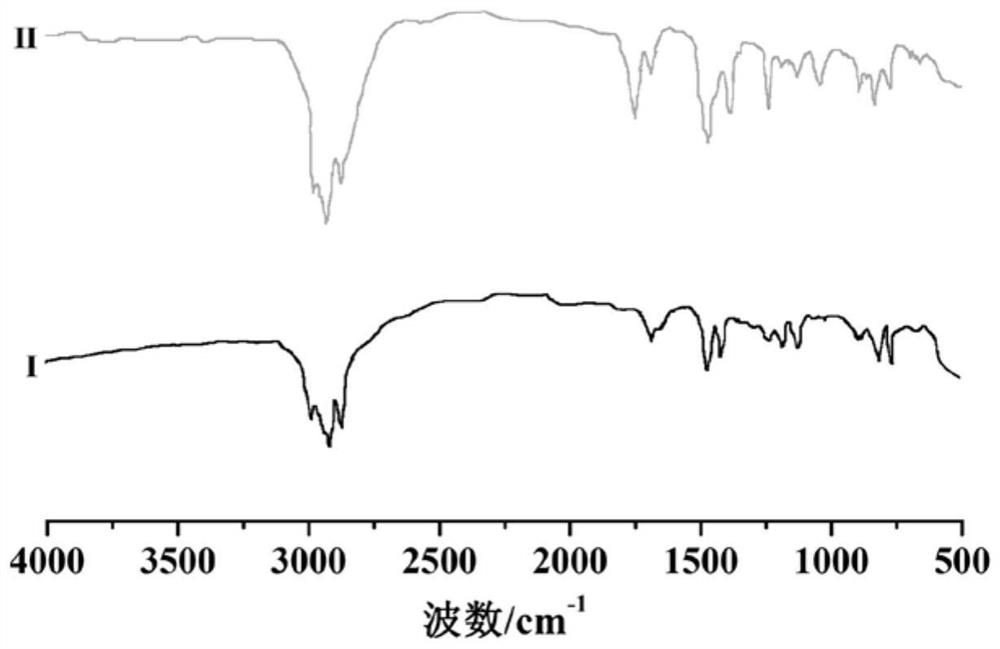

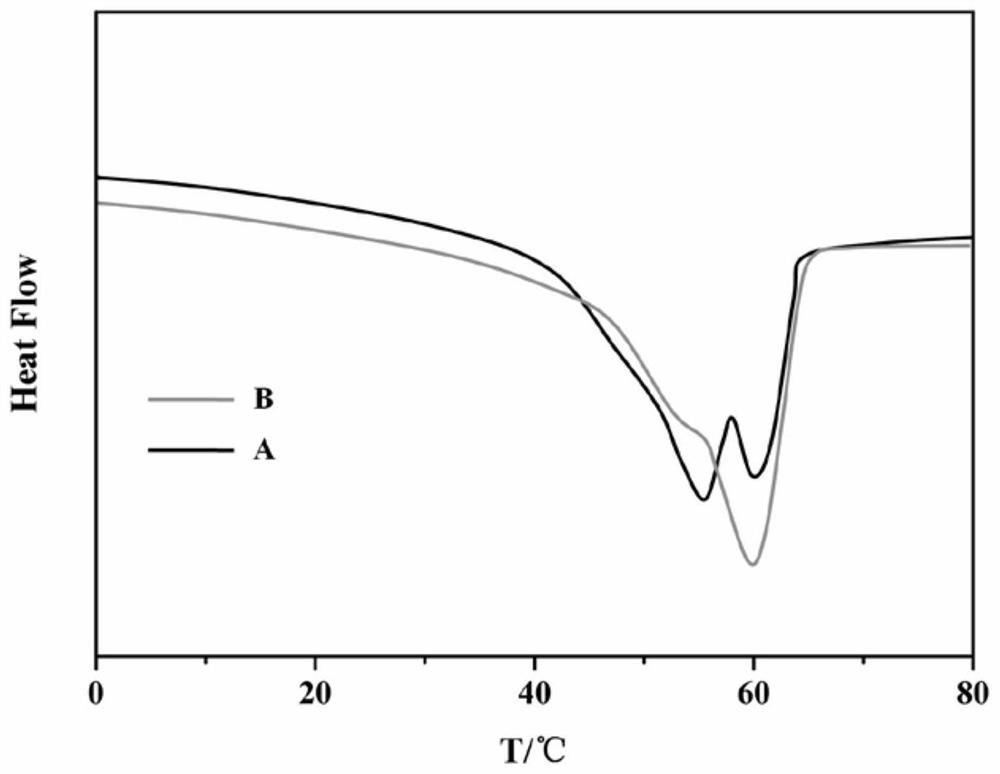

Thermosetting shape memory resin based on bismaleimide and preparation method thereof

The invention relates to high-deformation thermosetting shape memory resin based on bismaleimide and a preparation method thereof. The method includes the following steps that the bismaleimide and 1,6-ethanthiol are added into m-cresol to form a solution; triethylamine is added into the solution dropwisely, and under the protection of N2 and a stirring condition, a reaction is carried out at roomtemperature to obtain a linear oligomer; the bismaleimide, the linear oligomer and O,O'-diallylbisphenol A are mixed by mass, and the reaction is carried out at 130-150 DEG C for 25-45 min to obtain aprepolymer; the prepolymer is subjected to vacuum defoamation at the temperature of 130-150 DEG C, and through solidification and post-treatment, the thermosetting shape memory resin based on the bismaleimide is obtained. Compared with the prior art, the resin has a high deformation capability, and the breaking elongation of the resin at programming temperatures is higher than 30%; moreover, thethermosetting resin has both high glass-transition temperature (larger than 131 DEG C) and initial decomposition temperature (larger than 370 DEG C), high tenacity and outstanding shape memory performance.

Owner:SUZHOU UNIV

PVC-U (polyvinyl chloride unplasticized) tube with shape memory function and production method and application thereof

ActiveCN108373569AGood deformation memory functionRealize the repair effectPlasticizerPolyvinyl chloride

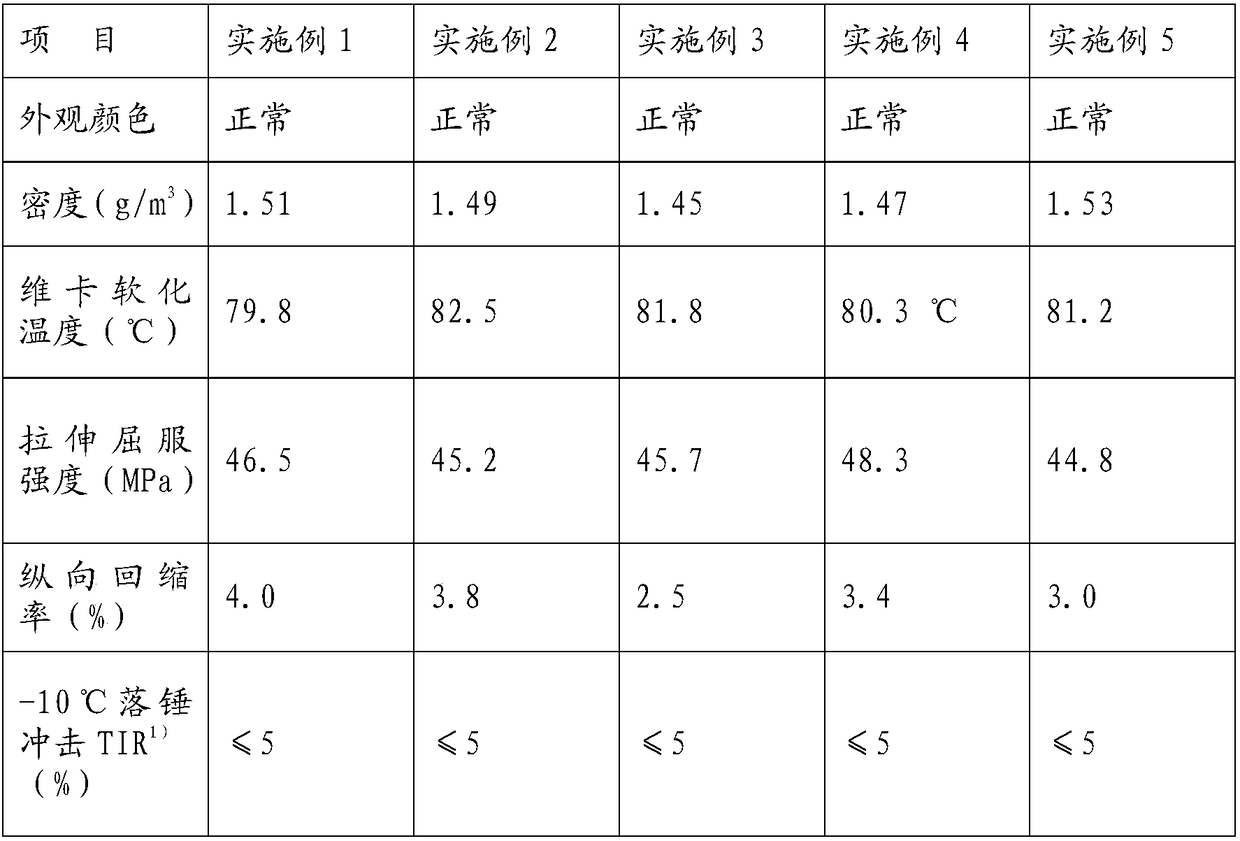

The invention provides a PVC-U (polyvinyl chloride unplasticized) tube with a shape memory function and a production method and application thereof. The PVC-U tube with the shape memory function is made from, by weight, 100 parts of polyvinyl chloride resin, 1.5-8.0 parts of a thermal stabilizer, 0.1-60 parts of a lubricant, 0-8 parts of a plasticizer, 0.5-8 parts of a processing modifier, 1-10 parts of a toughener, 0.02-5 parts of a crosslinker, 0-6 parts of an acid absorbent, and 0-30 parts of a filler. The PVC-U tube has the good shape memory function and is particularly suitable for the repair of a damaged conduit under micro-excavation or zero excavation. In addition, the production method of the PVC-U tube is simple and low in cost.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +2

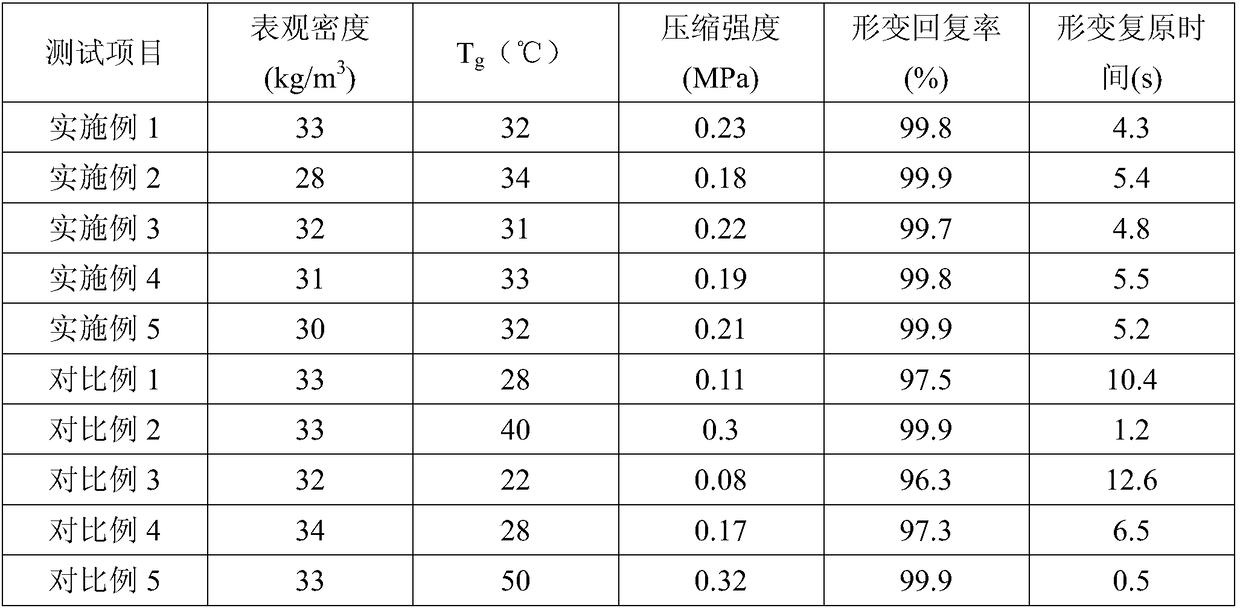

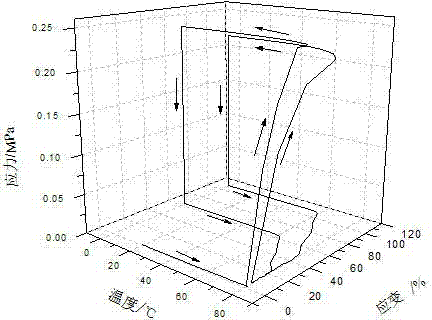

Polyurethane memory foam material for mattress as well as preparation method of material

The invention provides a polyurethane memory foam material for a mattress as well as a preparation method of the material. The polyurethane memory foam material comprises the following raw material components in parts by mass: 40 to 60 parts of diisocyanate, 90 to 110 parts of poly-polyol, 10 to 15 parts of a chain extender, 5 to 10 parts of carbon fiber, 1.5 to 3 parts of a foaming agent, 1 to 2parts of a foam stabilizer, 0.5 to 1 part of a pore opening agent and 0.3 to 1 part of a catalyst, wherein the poly-polyol comprises low-molecular-weight poly-polyol with the number-average molecularweight of 800 to 1500, medium-molecular-weight poly-polyol with the number-average molecular weight of 3000 to 5000 and high-molecular-weight poly-polyol with the number-average molecular weight of 8000 to 12000. The polyurethane memory foam material is prepared by a method for performing polymerization foaming at one step and finally curing. The polyurethane memory foam material provided by the invention has high strength, has glass transition temperature close to the human body temperature, has high shape recovery ratio and is particularly suitable for a mattress material.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

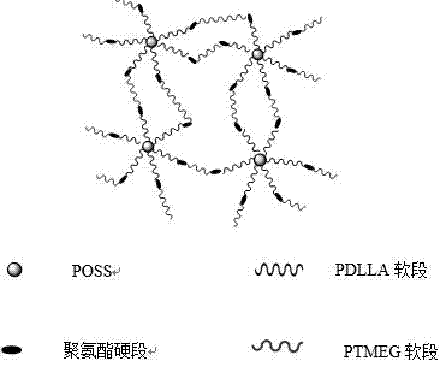

Method for preparing star-shaped biodegradable shape-memory-polymer nano composite material

The invention relates to a method for preparing a star-shaped biodegradable shape-memory-polymer nano composite material. According to the shape-memory composite material, POSS and isocyanate chain segments are taken as a hard phase, and poly-D,L-lactide and polytetramethylene ether glycol are taken as a soft phase. The method for preparing the shape-memory composite material comprises the steps of firstly preparing polyhedral silsesquioxane, of which eight vertexes are provided with hydroxyl groups, initiating the ring-opening polymerization of D,L-lactide with polyhedral silsesquioxane so as to prepare star-shaped POSS-PLA of a certain molecular weight, and then, coupling to polytetramethylene ether glycol through diisocyanate, thereby forming a three-dimensional reticulated copolymer. The shape-memory composite material prepared by the method has the characteristics of strong deformation holding ability, high shape recovery rate, good shape memory performance and repeatability, biodegradation and the like; furthermore, due to the adding of inorganic nanoparticle POSS, the recovery stress of a shape memory polymer is increased.

Owner:TONGJI UNIV

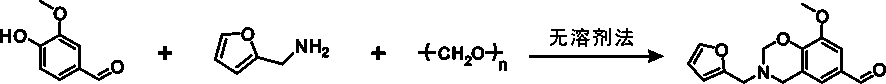

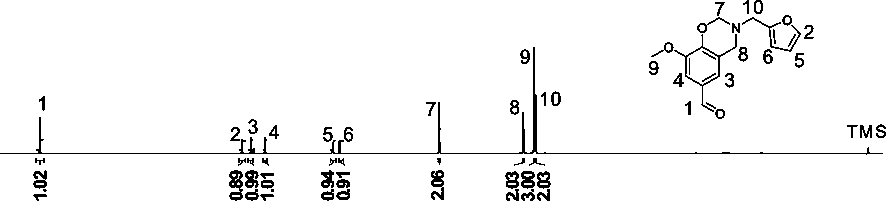

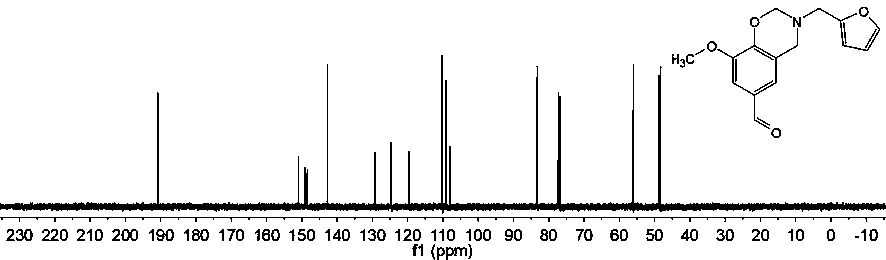

Shape memory resin based on biomass benzoxazine as well as preparation method and application of shape memory resin

ActiveCN111423580AOutstanding heat resistanceHigh tensile modulusOrganic chemistryPolymer scienceFurfurylamine

The invention discloses shape memory resin based on biomass benzoxazine as well as a preparation method and application of the shape memory resin. The preparation method comprises the following steps:taking biomass furfuryl amine, vanillic aldehyde and paraformaldehyde as raw materials, and carrying out a heating reaction to obtain an aldehyde group-containing biomass benzoxazine monomer; mixingan aldehyde group-containing biomass benzoxazine monomer with polyether amine, and carrying out a coupling reaction to obtain a Schiff base biomass benzoxazine monomer; and curing the Schiff base biomass benzoxazine monomer to obtain the biomass benzoxazine resin with the shape memory function. Compared with the prior art, the benzoxazine shape memory resin disclosed by the invention has excellentthermal performance, high tensile modulus and high strength. According to the benzoxazine resin obtained by the method disclosed by the invention, the original shape can be permanently changed according to needs, the defect that a traditional cross-linked polymer cannot be reprocessed after being formed is overcome, the recovery function under the condition of heating stimulation is achieved, andthe application range of the shape memory polymer is greatly widened due to the excellent thermal performance and mechanical performance.

Owner:SUZHOU UNIV

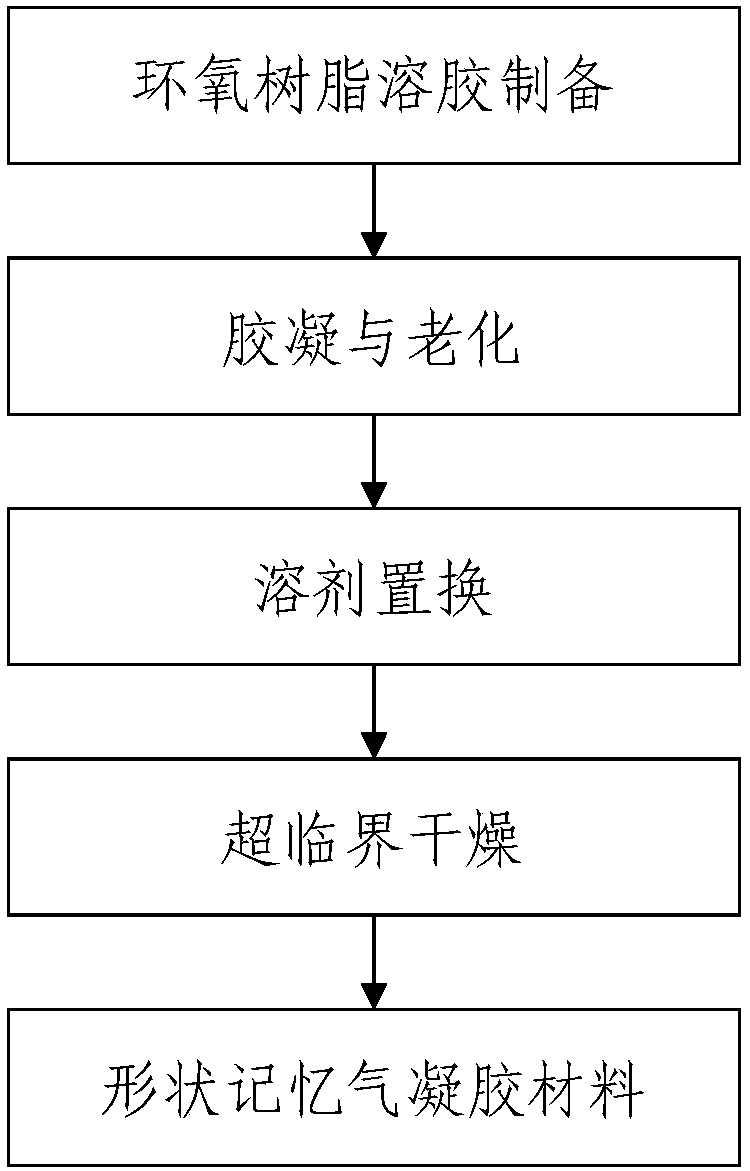

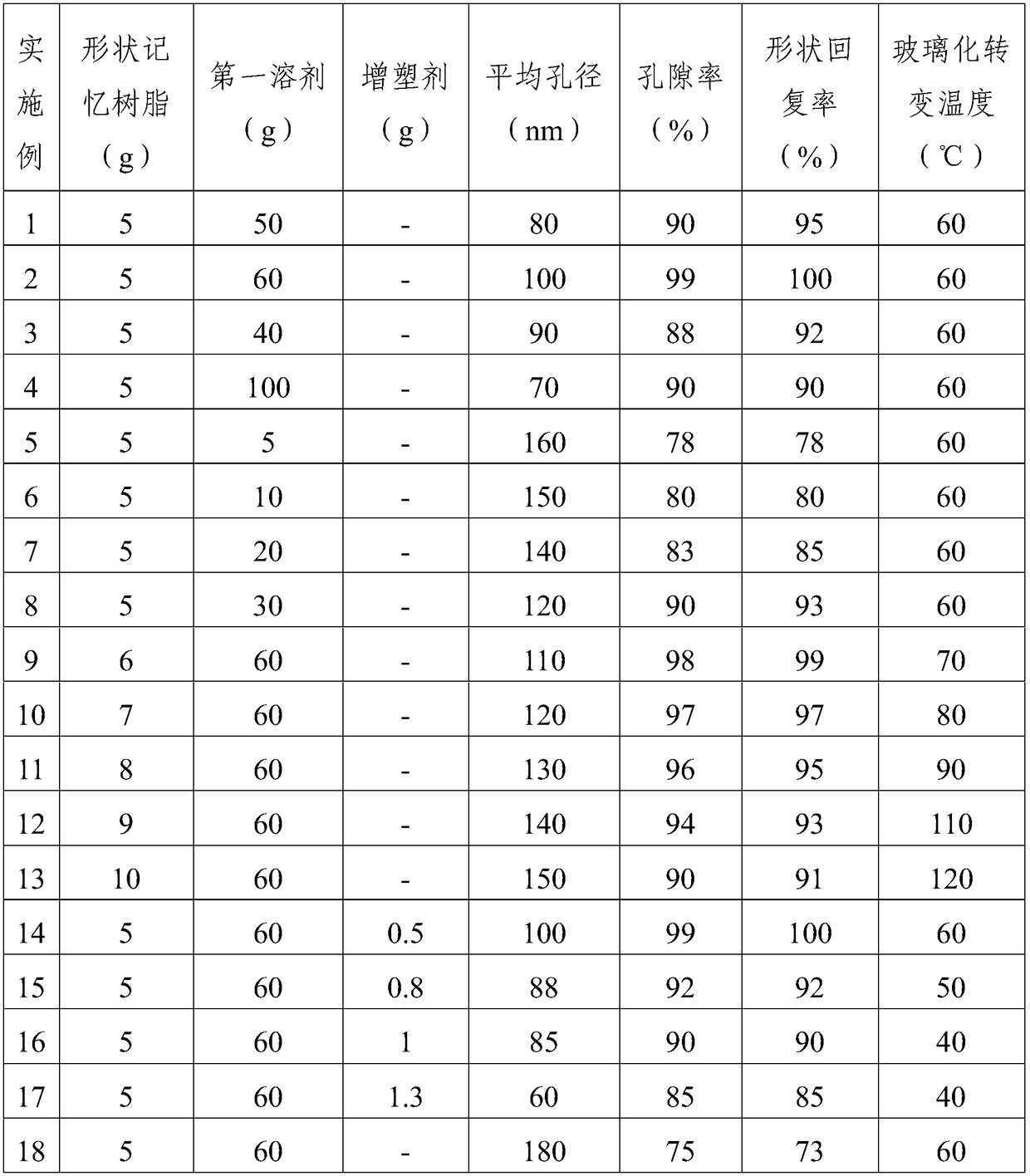

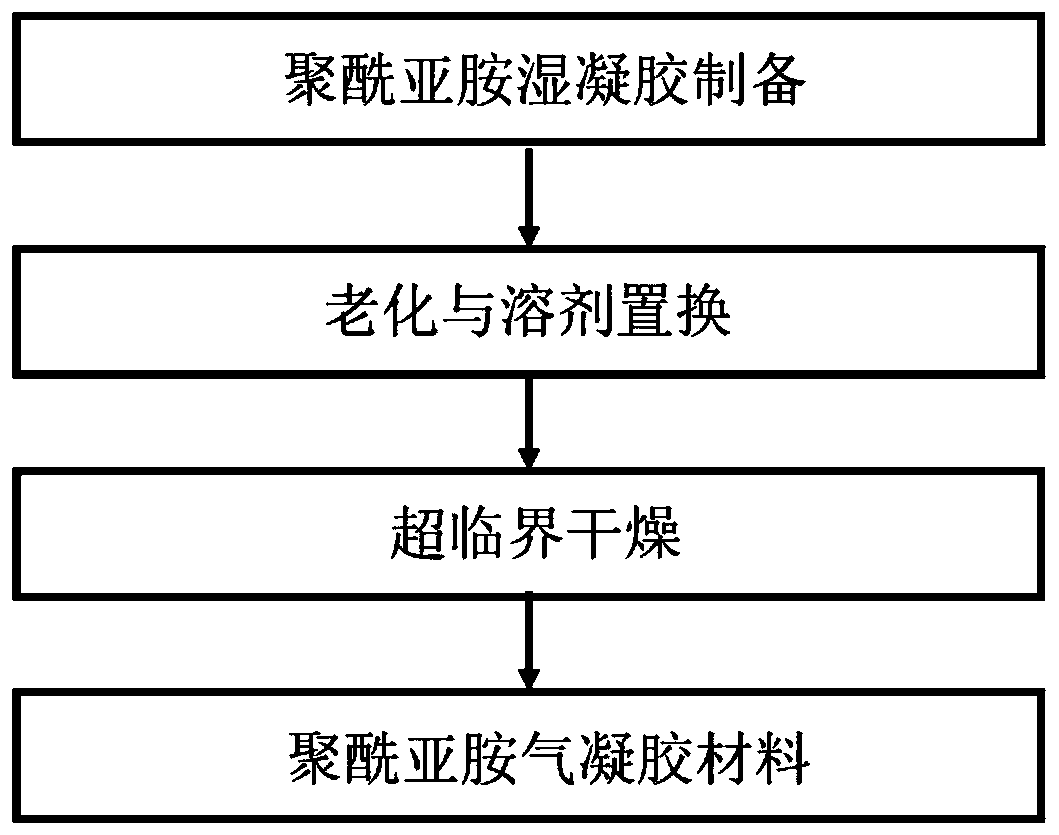

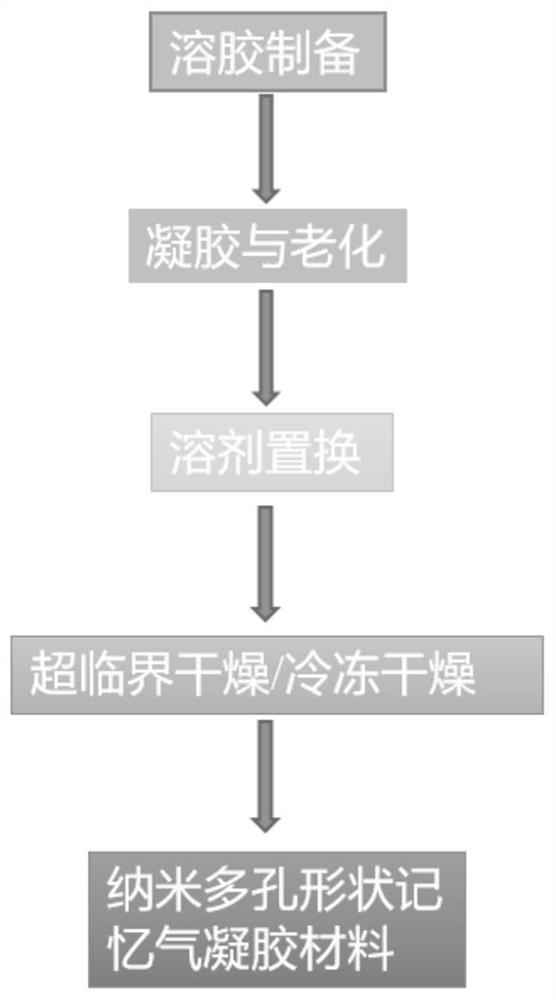

Shape memory aerogel material and preparation method thereof

ActiveCN108212032AEasy to makeLow costAerogel preparationColloidal chemistry detailsVitrificationPorosity

The invention relates to a shape memory aerogel material and a preparation method thereof. The preparation method comprises following steps: (1) dissolving shape memory resin in a first solvent to obtain sol; (2) adding a curing agent into the sol, and stirring the sol until the sol reaches a gel state to obtain wet gel; and (3) subjecting the wet gel to steps of gelling, aging, and solvent displacement to obtain elastic gel, and finally drying the elastic gel to obtain the shape memory aerogel material. A soil-gel method is adopted to combine a shape memory material and an aerogel structure to prepare the shape memory aerogel material. The preparation process is simple, and the cost is low. The prepared shape memory aerogel material has the advantages of high porosity (88-99%), high shaperecovery rate (90-100%), and adjustable deformation and recovery temperatures (glass-transition temperature: 40-120 DEG C).

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method of novel rapid-responded shape memorizing polyurethane

The invention discloses a preparation method of novel rapid-responded shape memorizing polyurethane. The novel rapid-responded shape memorizing polyurethane is prepared by pre-polymerizing diisocyanate and polyester polyol, and then polymerizing with bi-selenium glycol block. The novel rapid-responded shape memorizing polyurethane comprises the following components in parts by mass: 50-100 parts of polyester polyol, 25-50 parts of diisocyanate, 12-15 parts of bi-selenium glycol, 100-200 parts of an organic solvent, and 0.05-0.1 part of a catalyst. The method specifically comprises the following steps: 1, distilling polyester polyol for 3-5h in a vacuum condition in order to remove water; and controlling the vacuum degree to be not greater than 0.08MPa; 2, sequentially mixing polyester polyol, diisocyanate, the organic solvent and the catalyst; heating in a nitrogen atmosphere until the temperature is 60-75 DEG C; and stirring for 3-6h; and 3, adding bi-selenium glycol; maintaining thereaction temperature at 60-75 DEG C; and continuously stirring and reacting for 3-6h under nitrogen protection. The shape memorizing polyurethane prepared by the method is high in shape recovery rate,and has a good memorizing effect.

Owner:镇江利德尔复合材料有限公司

Shape memory polymer alloy for fused deposition based 3D printing and preparation method of shape memory polymer alloy

ActiveCN110079010AGood effectLow water absorptionAdditive manufacturing apparatusPolymer alloyPolyolefin

The invention discloses a shape memory polymer alloy for fused deposition based 3D printing and a preparation method of the shape memory polymer alloy. The polymer alloy is prepared from raw materialsin percentage by weight as follows: 30%-50% of polyolefin plastics, 10%-40% of nylon resin, 20%-40% of thermoplastic elastomer graft, 0.1%-1% of a peroxide crosslinking agent, 0-5% of an assistant crosslinking agent and 1%-5% of a nanofiller. The raw materials mixed by a high-speed mixer are subjected to melt extrusion molding, and the polymer alloy suitable for fused deposition based 3D printingcan be obtained. The prepared polymer alloy has excellent 3D printing performance, so that a printed product has the characteristics of being low in warping degree, high in dimensional stability, better in mechanical property and heat resistance and the like and has a smooth surface without defects and an excellent thermally induced shape memory function, and the printed product are higher in shape fixed rate and shape recovery rate, and the application requirement of a shape memory product can be met.

Owner:SOUTH CHINA UNIV OF TECH

Deformable aerogel material and preparation method thereof

ActiveCN110305360ARealize the function of deformationAchieving shape memory functionSupercritical dryingGas phase

The invention relates to a deformable aerogel material and a preparation method thereof. The method comprises the steps of carrying out a polycondensation reaction using a diamine and a dianhydride asmonomers, and then adding 1,1,1-tri[4-(aminophenoxyl)phenyl]ethane as a curing agent to obtain a polyamic acid solution, and adding fumed silica nanoparticles to obtain that polyamic acid solution doped with fumed silica nanoparticles, and then treating the polyamic acid solution in a vacuum oven and subjecting to thermal imidization at different temperature stages heating procedures to obtain apolyimide wet gel; subjecting the polyimide wet gel to ageing, solvent replacement and supercritical drying to obtain the deformable aerogel material. The aerogel material of the invention can be deformed and fixed under the heating condition, and the shape is restored under the next thermal response, and the temperature resistance of the material is good. The aerogel material of the invention hasthe advantages of high porosity (88-99%), high shape recovery rate (90-100%), adjustable deformation and recovery temperature and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

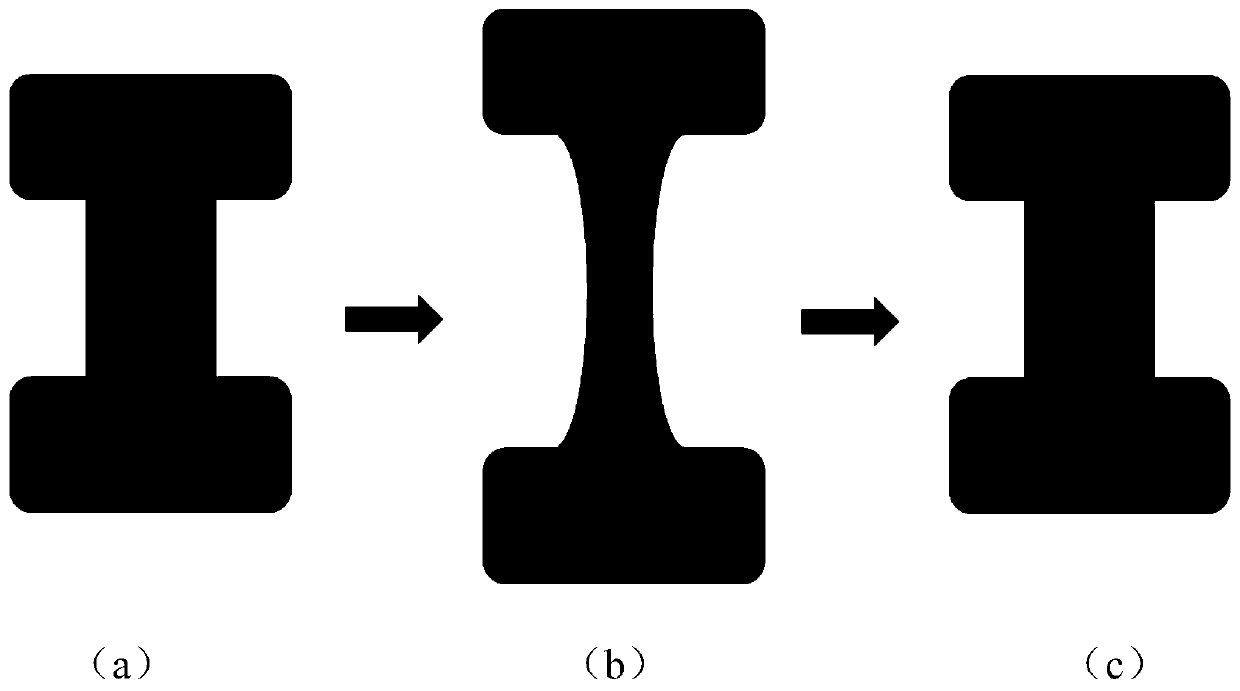

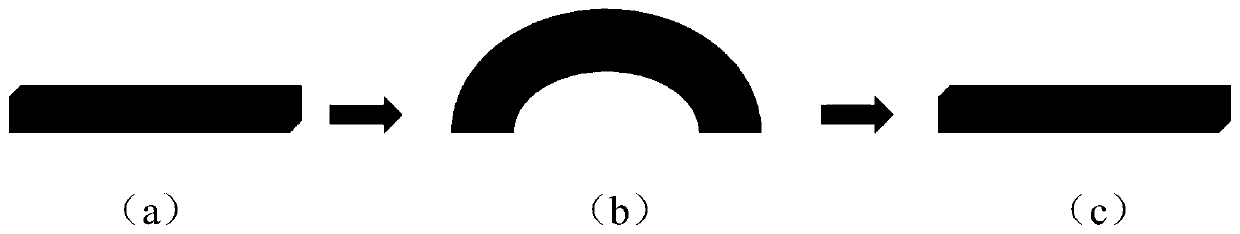

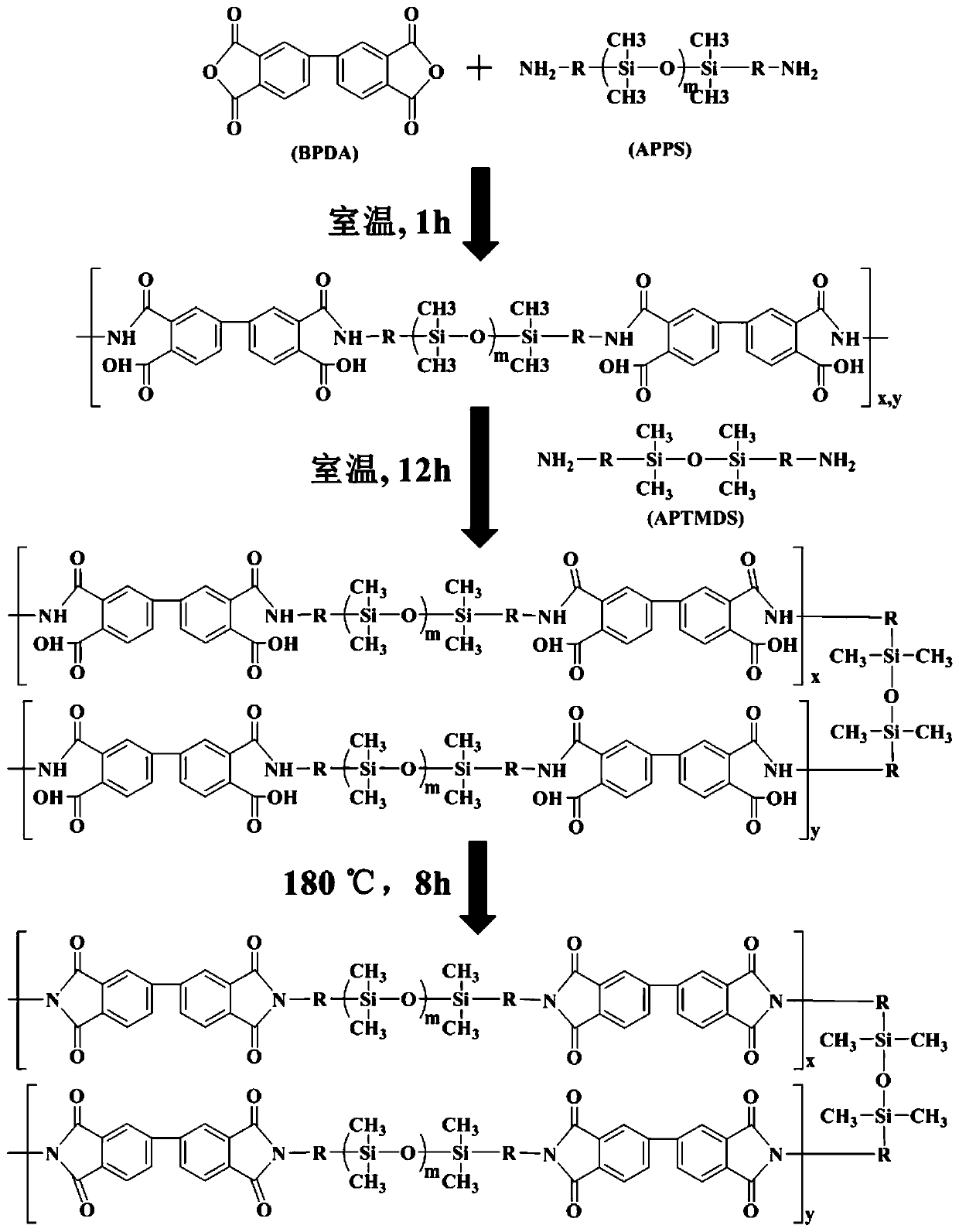

Multifunctional polysiloxane thermoplastic elastomer as well as preparation method and application thereof

The invention discloses a multifunctional polysiloxane thermoplastic elastomer as well as a preparation method and application thereof. The elastomer is prepared by the following method: taking 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane and octamethylcyclotetrasiloxane as raw materials, and carrying out a reaction under the action of a catalyst tetramethylammonium hydroxide pentahydrate,so as to obtain double amino-terminated polysiloxane; with double amino-terminated polysiloxane, 3,3',4,4'-biphenyl tetracarboxylic dianhydride and 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane as raw materials, and carrying out a reaction to obtain a polysiloxane-polyamic acid segmented copolymer; and finally, under the action of high temperature, obtaining the polysiloxane-polyimide block polymer with high mechanical properties, a shape memory function and a self-healing function.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing magneto type biodegradable shape-memory-polymer nano composite material

InactiveCN104744922AStrong deformation retentionHigh shape recovery ratePolymer sciencePoly dl lactide

The invention relates to a method for preparing a magneto type biodegradable shape-memory composite material. According to the shape-memory composite material, isocyanate chain segments are taken as a hard phase, and poly-D,L-lactide and polytetramethylene ether glycol are taken as a soft phase. The method for preparing the shape-memory composite material comprises the steps: initiating the ring-opening polymerization of D,L-lactide with micromolecular glycol, so as to prepare poly-D,L-lactide of a certain molecular weight, of which the two terminals are provided with hydroxyl groups, and then, coupling to polytetramethylene ether glycol through diisocyanate, so as to form a straight-chain block copolymer; then, mixing with surface modified Fe3O4 nanoparticles, thereby preparing the magneto type biodegradable shape-memory composite material. The shape-memory composite material prepared by the method has the characteristics of strong deformation holding ability, high shape recovery rate, good shape memory performance and repeatability, biodegradation and the like; furthermore, the function of initiating shape memory in a non-contact manner is realized, and the material can have a targeting property due to the presence of the Fe3O4 nanoparticles.

Owner:TONGJI UNIV

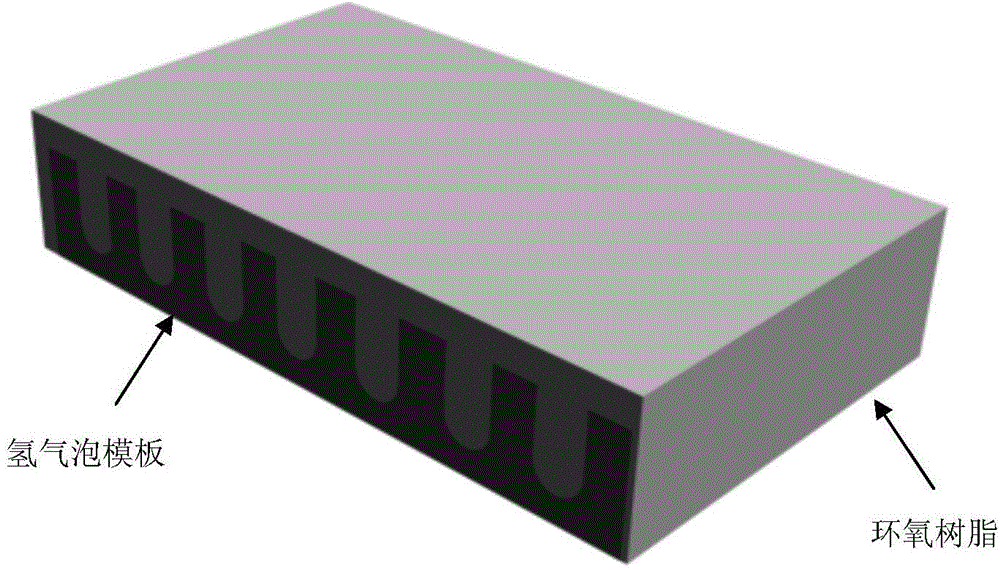

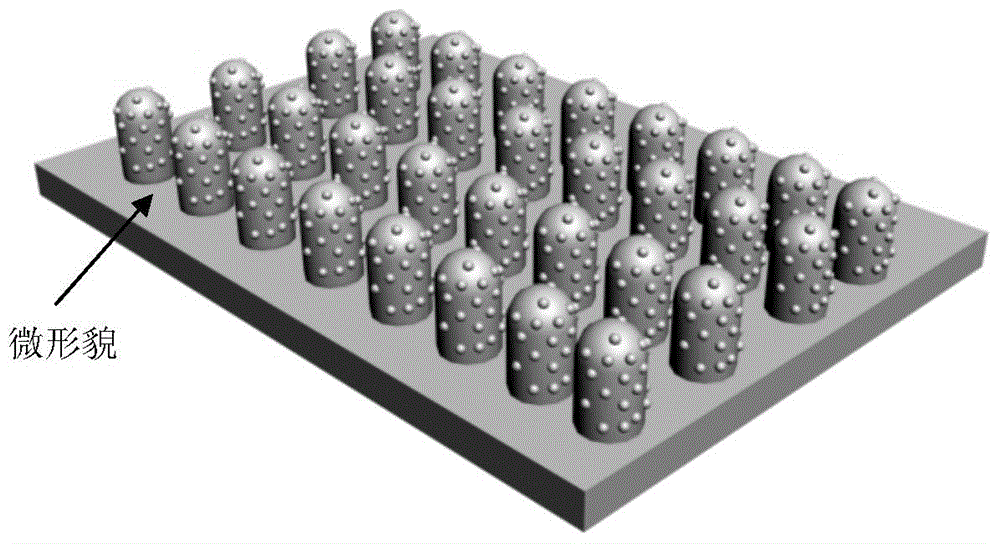

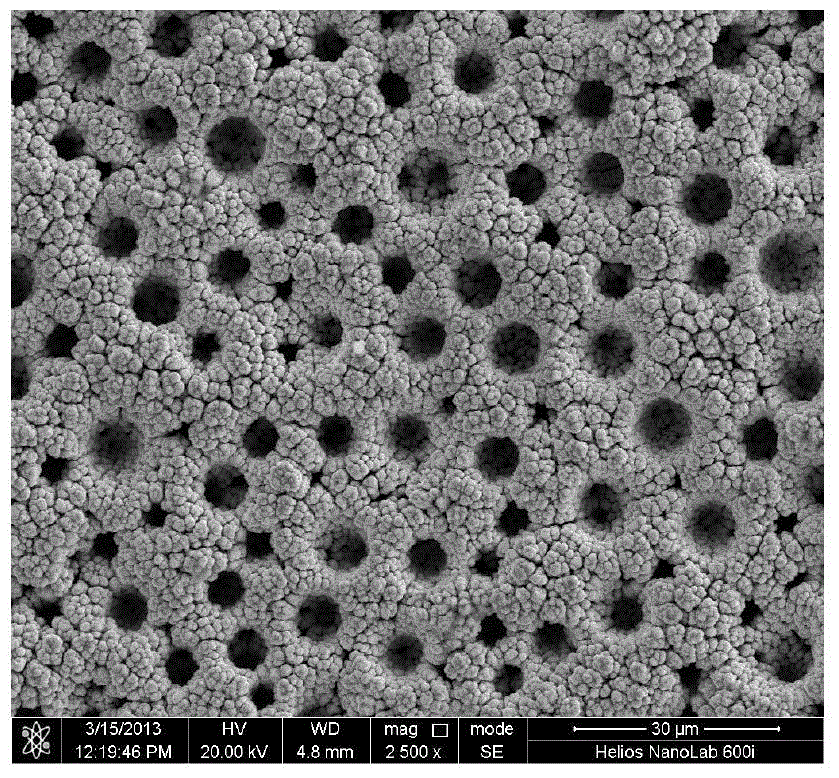

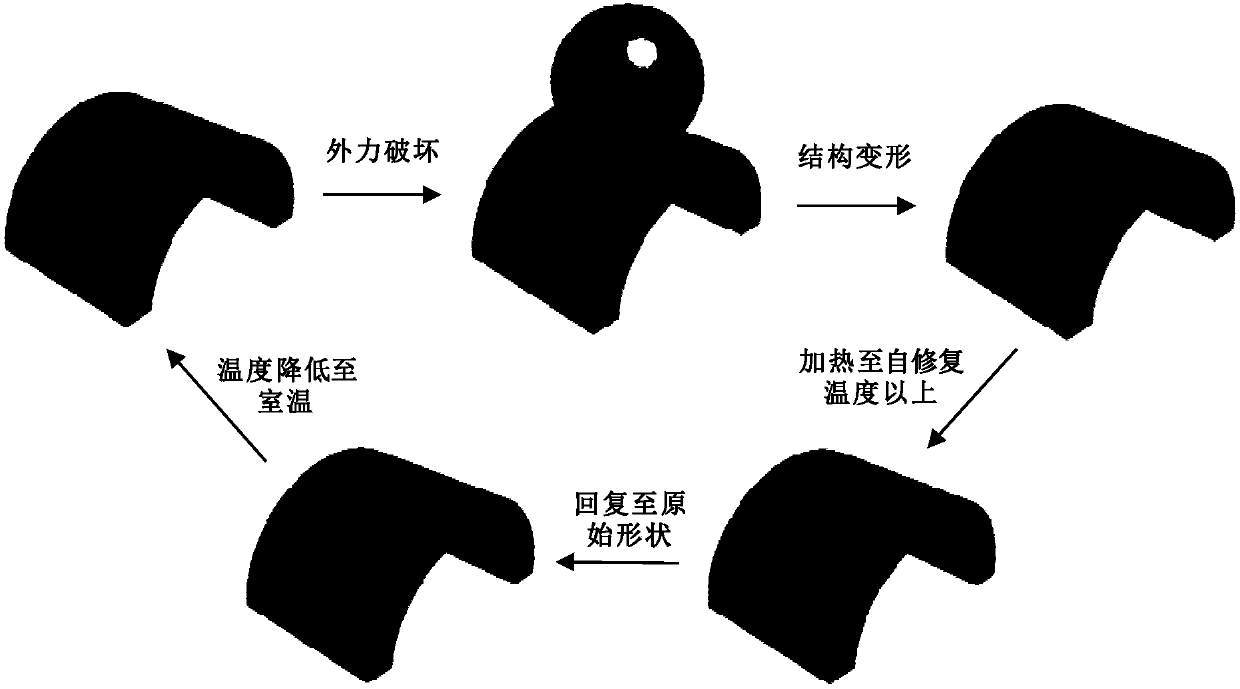

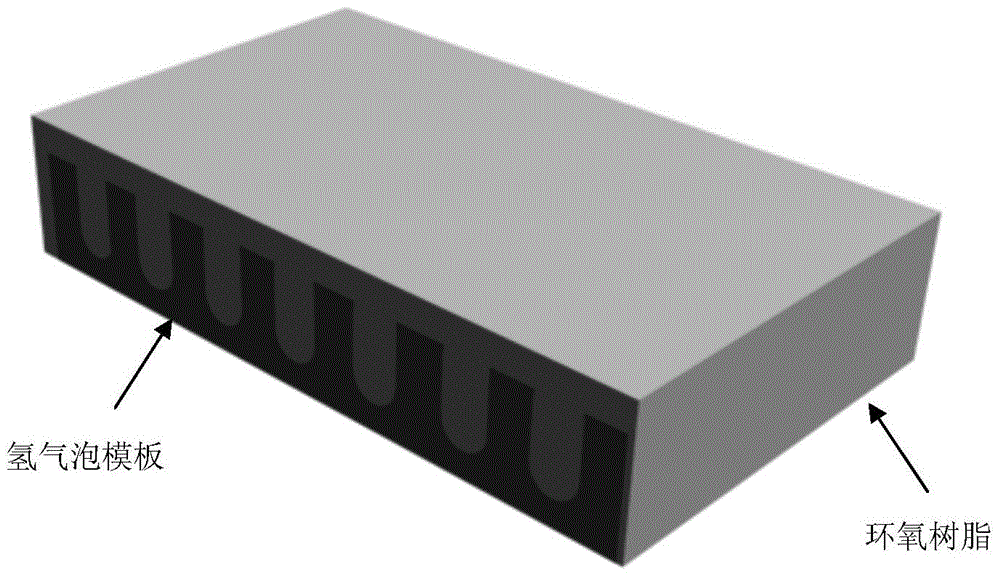

Preparation method of shape memory material capable of physically self-repairing superhydrophobic property

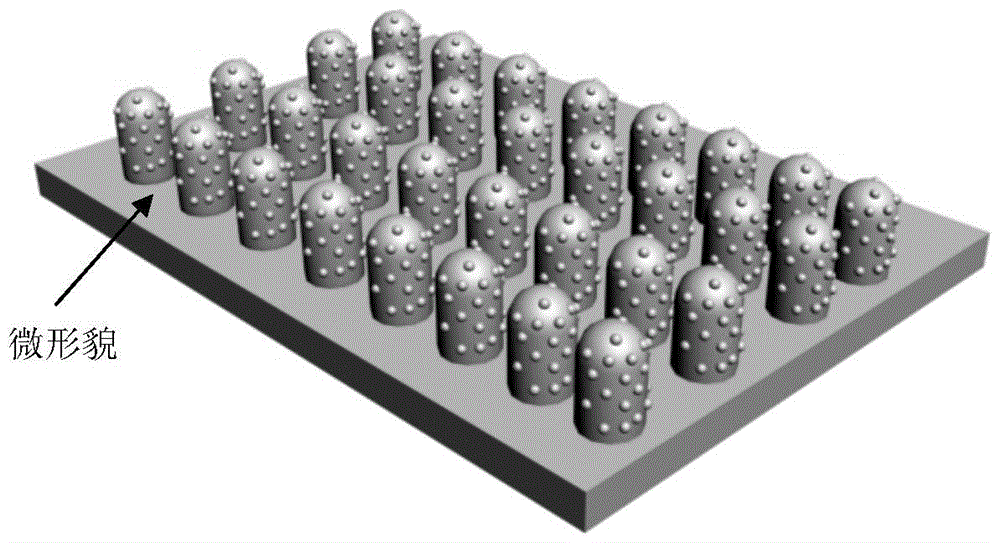

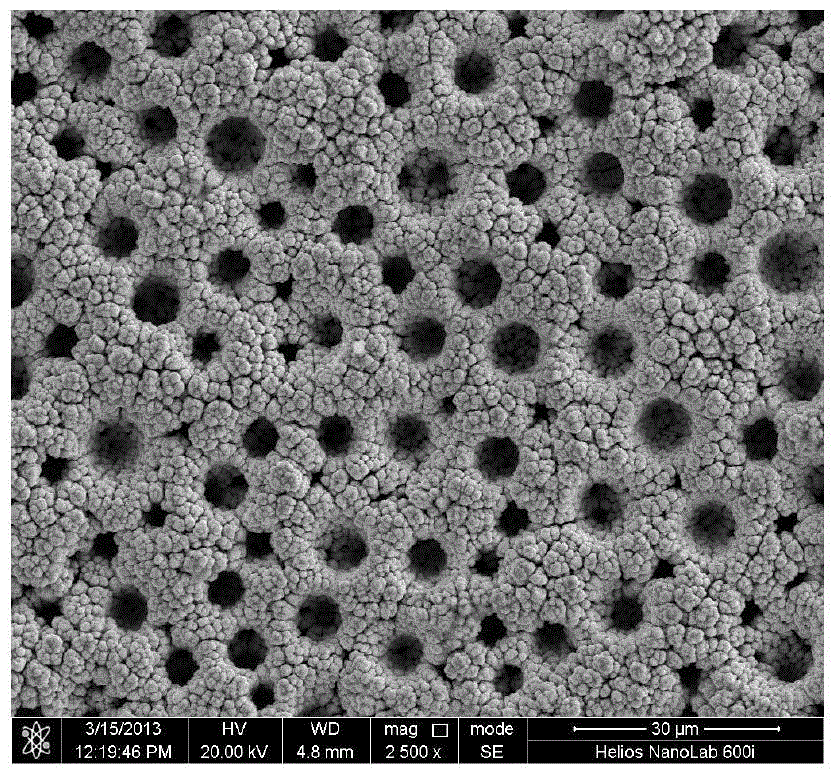

The present invention discloses a preparation method of a shape memory material capable of physically self-repairing superhydrophobic property. The preparation method comprises: 1, preparing a template, wherein a layer of a porous metal is electroplated on the surface of a metal sheet as a material micro-morphology template; and 2, preparing an epoxy resin material having microtopography, wherein an epoxy resin curing system is prepared, a toughening agent is added to the system, the prepared epoxy resin system and the template are placed into a metal mold to cure, and the hydrogen bubble template is removed after curing so as to obtain the epoxy resin material having micro-morphology. According to the present invention, the material prepared by using the preparation method can repair the disappeared superhydrophobic property caused by material micro-morphology deformation due to physical damage, and the method is simple and is easy to perform, and can be provided for substantially increasing the service life of the superhydrophobic material and enhance the durability of the material.

Owner:HARBIN INST OF TECH

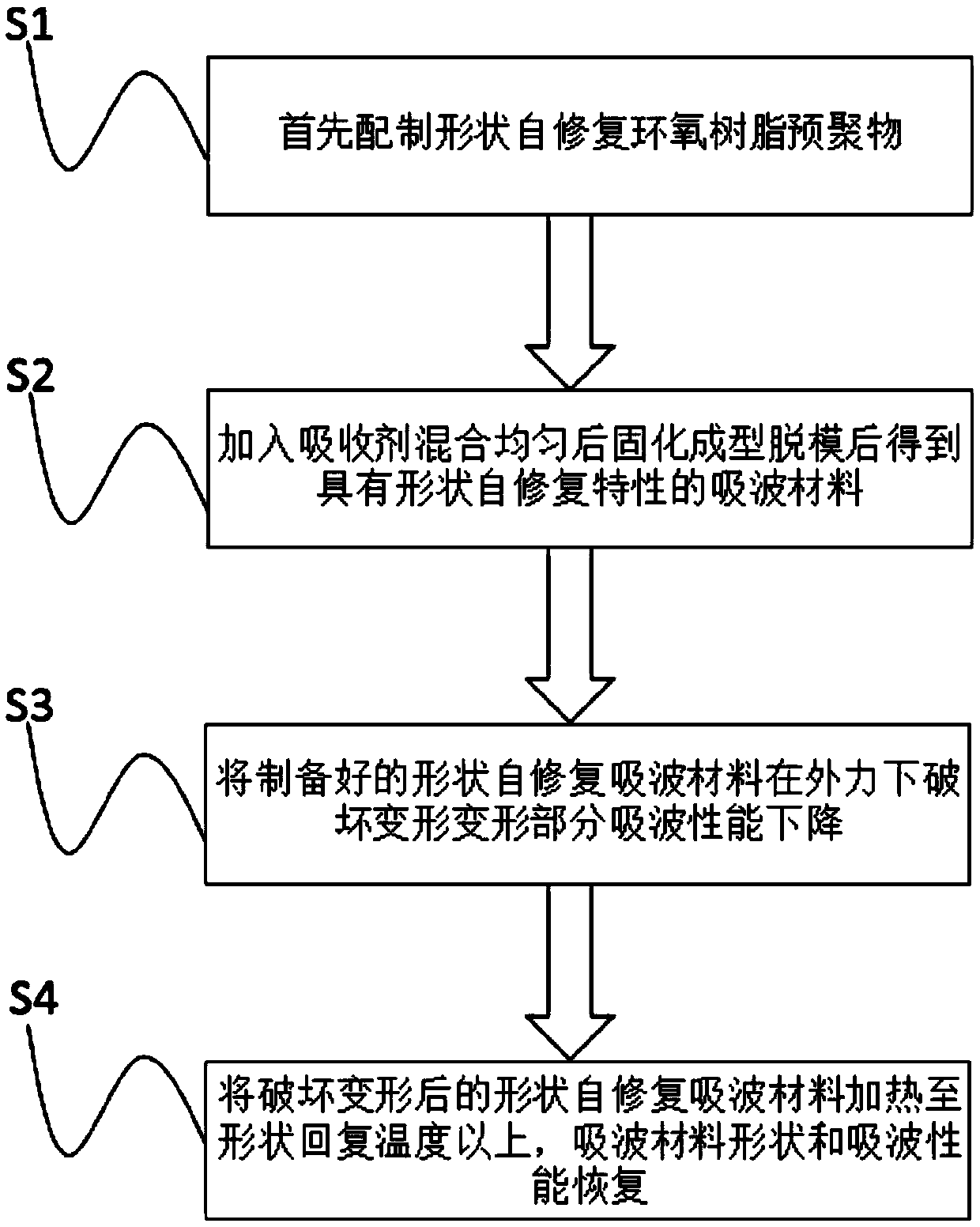

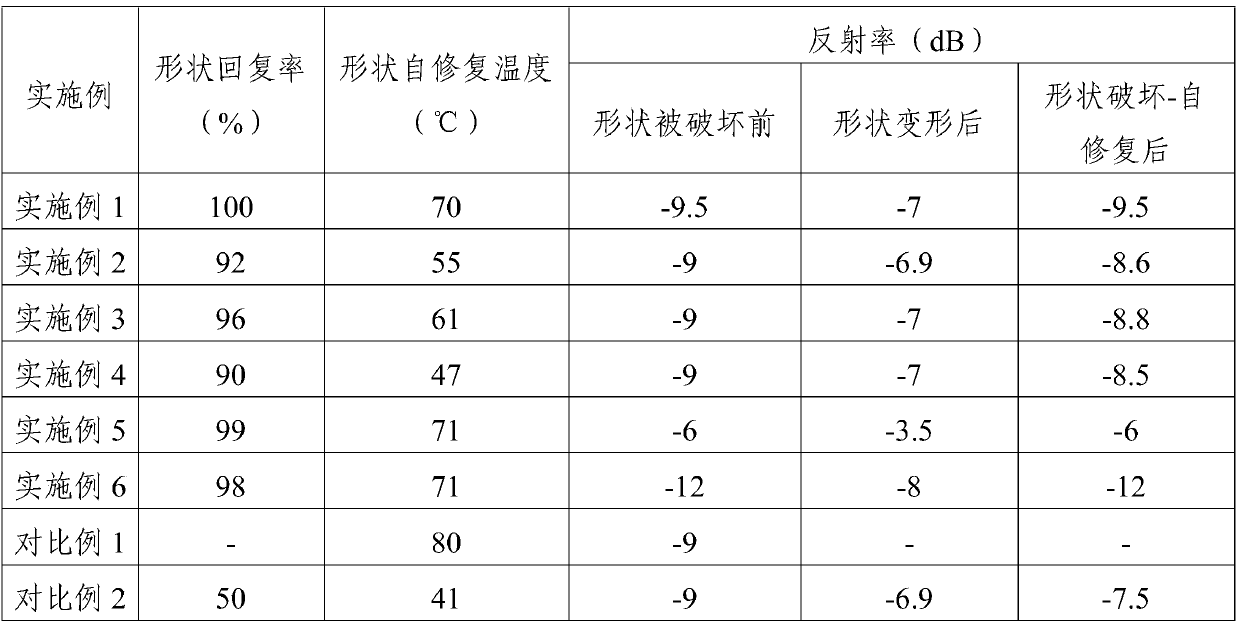

Shape self-repairing wave-absorbing material and preparation method thereof

ActiveCN109666262AShape self-healing performance optimizationExcellent shape self-healing performanceEpoxyCarbon fibers

The invention relates to a shape self-repairing wave-absorbing material and a preparation method thereof. The method comprises the following steps: (1) uniformly mixing a resin matrix, a toughening agent and a curing agent of which a mass ratio is 1:(0.02-0.33):(0.01-0.017), to obtain a resin prepolymer, wherein the resin matrix is selected from a group formed by epoxy resin, polyurethane resin, polystyrene resin and polynorbornene resin; (2) adding an absorbent selected from a group formed by ferrite powder, carbonyl iron powder, conducive carbon black, carbon fibers, silico carbide fibers, carbon nano tubes and graphene to the obtained resin prepolymer, and uniformly stirring, to obtain shape self-repairing wave-absorbing resin; and (3) curing the shape self-repairing wave-absorbing resin in more than two different temperature stages, preparing the shape self-repairing wave-absorbing material. The wave-absorbing material is endowed with shape self-repairing performance through the method, and a requirement of wave-absorbing performance recovery can be satisfied after the wave-absorbing material is damaged to be deformed by an external force.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

EVA (Ethylene-Vinyl Acetate) modified PU (Polyurethane) shape memory vehicle bumper and preparation method thereof

The invention belongs to the technical field of automobile materials, and provides an EVA (Ethylene-Vinyl Acetate) modified PU (Polyurethane) shape memory vehicle bumper and a preparation method thereof. The preparation method is characterized in that when polyether polyol and isocyanate are used as raw materials for carrying out chemical polymerization to prepare PU, the polyether polyol and isocyanate together with EPDM (Ethylene Propylene Diene Monomer) rubber and EVA are subjected to hot mixing and are commonly injected into a mold for placing a metal framework, and carrying out irradiation crosslinking during a curing process after taking out a product, thus obtaining the EVA modified PU shape memory vehicle bumper. Compared with a traditional method, the EVA modified PU shape memoryvehicle bumper prepared through the preparation method disclosed by the invention has the advantages that a shape memory function is given to a vehicle bumper through modification of EVA resin, the shape recovery rate is high, the shape memory property is excellent, excellent impact resistance, good elasticity and good safety are obtained, external impact force can be effectively absorbed and buffered, a vehicle body can be protected, and the vehicle driving safety can be remarkably increased.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

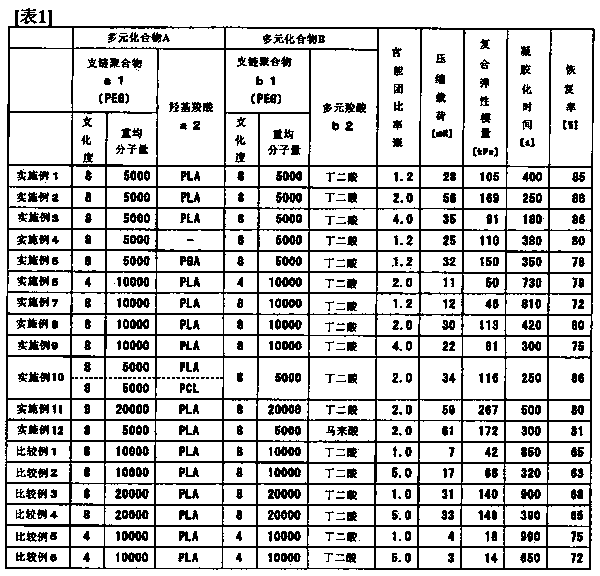

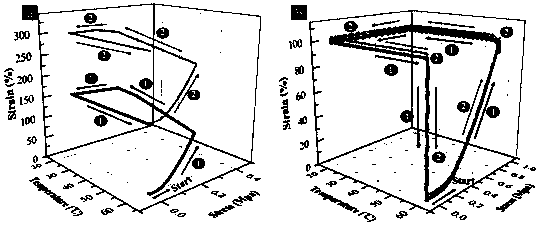

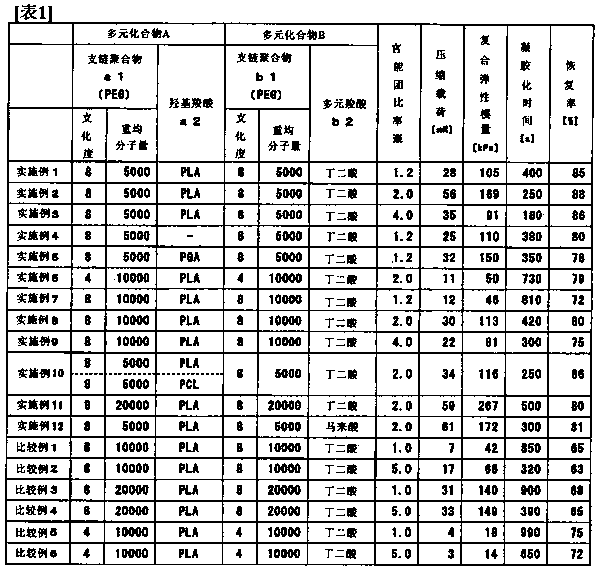

Biodegradable material and method for producing biodegradable material

InactiveCN104185480AGood flexibilityHigh shape recovery rateSuture equipmentsSurgical adhesivesComposite materialChemical compound

The objective of the present invention is to provide a biodegradable material that has improved flexibility and increased percentage of shape recovery after the material has been deformed. The present invention provides a biodegradable material resulting from a polyvalent compound (A) having at least three functional groups (X) such as hydroxyl groups and a polyvalent compound (B) having at least three functional groups (Y) such as carboxyl groups being chemically crosslinked by means of a condensation reaction, and when the number of functional groups (X) that are not condensed to functional groups (Y) is x, the number of functional groups (Y) that are not condensed to functional groups (X) is y, the number of chemical crosslinks is z, the weight average molecular weight of polyvalent compound (A) is MA, and the weight average molecular weight of polyvalent compound (B) is MB, when MA >= MB, the value of (y+z) / (x+z) is 1.2-4.0, and when MA < MB, the value of (x+z) / (y+z) is 1.2-4.0.

Owner:TORAY IND INC

Preparation method of a shape memory material with physical self-healing superhydrophobic properties

ActiveCN103951936BThe preparation process is easy to prepareOptimizing Control ParametersEpoxyMetal sheet

The present invention discloses a preparation method of a shape memory material capable of physically self-repairing superhydrophobic property. The preparation method comprises: 1, preparing a template, wherein a layer of a porous metal is electroplated on the surface of a metal sheet as a material micro-morphology template; and 2, preparing an epoxy resin material having microtopography, wherein an epoxy resin curing system is prepared, a toughening agent is added to the system, the prepared epoxy resin system and the template are placed into a metal mold to cure, and the hydrogen bubble template is removed after curing so as to obtain the epoxy resin material having micro-morphology. According to the present invention, the material prepared by using the preparation method can repair the disappeared superhydrophobic property caused by material micro-morphology deformation due to physical damage, and the method is simple and is easy to perform, and can be provided for substantially increasing the service life of the superhydrophobic material and enhance the durability of the material.

Owner:HARBIN INST OF TECH

Thermoplastic composition and preparing method thereof

The invention discloses a thermoplastic composition and a preparing method thereof.The thermoplastic composition comprises, by weight, 60-90 parts of epoxidation polyethylene-vinyl acetate, 10-40 parts of thermoplastic polymers and 0.1-20 parts of cross-linking agent.The preparing method of the thermoplastic composition can be achieved on a traditional high-polymer-material processing device, cost is low, the environment is friendly, and industrial production is easy to achieve.The thermoplastic composition obtained with the provided preparing method has the advantages of being high in shape recovery rate and strength, large in elongation at break, excellent in thermoplastic performance and the like, and can be directly used for extrusion molding, compression molding and the like to be used for preparing various thermoplastic and rubber products.

Owner:JIANGNAN UNIV

Shape memory polymer alloy based on fused deposition 3D printing and its preparation method

ActiveCN110079010BLow water absorptionImprove mechanical propertiesAdditive manufacturing apparatusElastomerPolymer alloy

The invention discloses a shape memory polymer alloy for fused deposition based 3D printing and a preparation method of the shape memory polymer alloy. The polymer alloy is prepared from raw materialsin percentage by weight as follows: 30%-50% of polyolefin plastics, 10%-40% of nylon resin, 20%-40% of thermoplastic elastomer graft, 0.1%-1% of a peroxide crosslinking agent, 0-5% of an assistant crosslinking agent and 1%-5% of a nanofiller. The raw materials mixed by a high-speed mixer are subjected to melt extrusion molding, and the polymer alloy suitable for fused deposition based 3D printingcan be obtained. The prepared polymer alloy has excellent 3D printing performance, so that a printed product has the characteristics of being low in warping degree, high in dimensional stability, better in mechanical property and heat resistance and the like and has a smooth surface without defects and an excellent thermally induced shape memory function, and the printed product are higher in shape fixed rate and shape recovery rate, and the application requirement of a shape memory product can be met.

Owner:SOUTH CHINA UNIV OF TECH

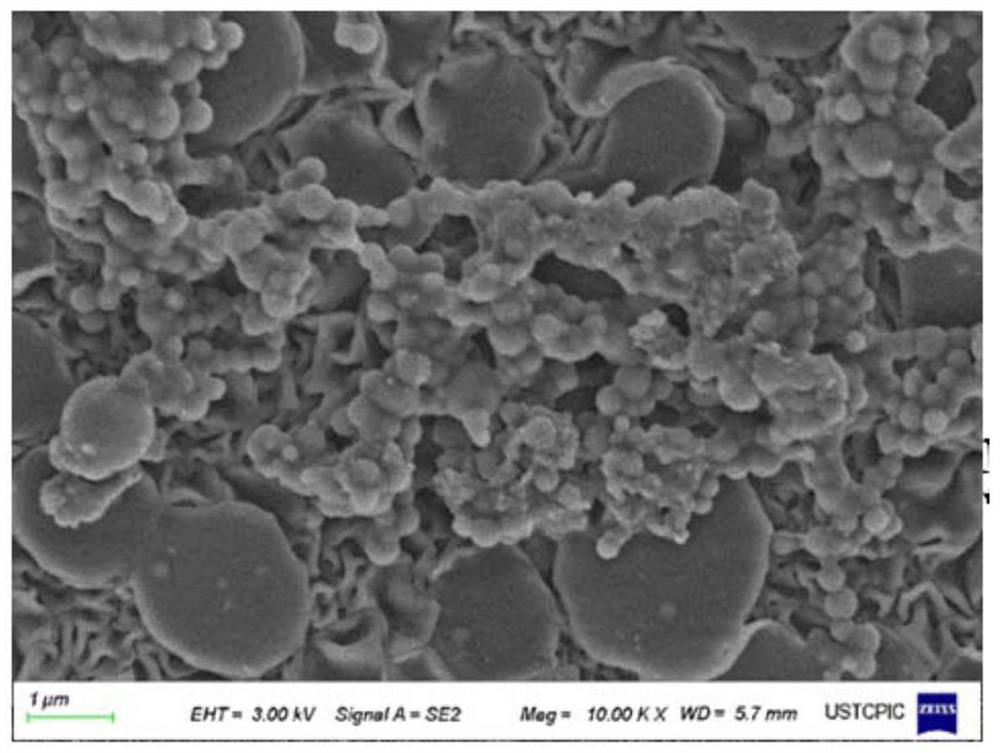

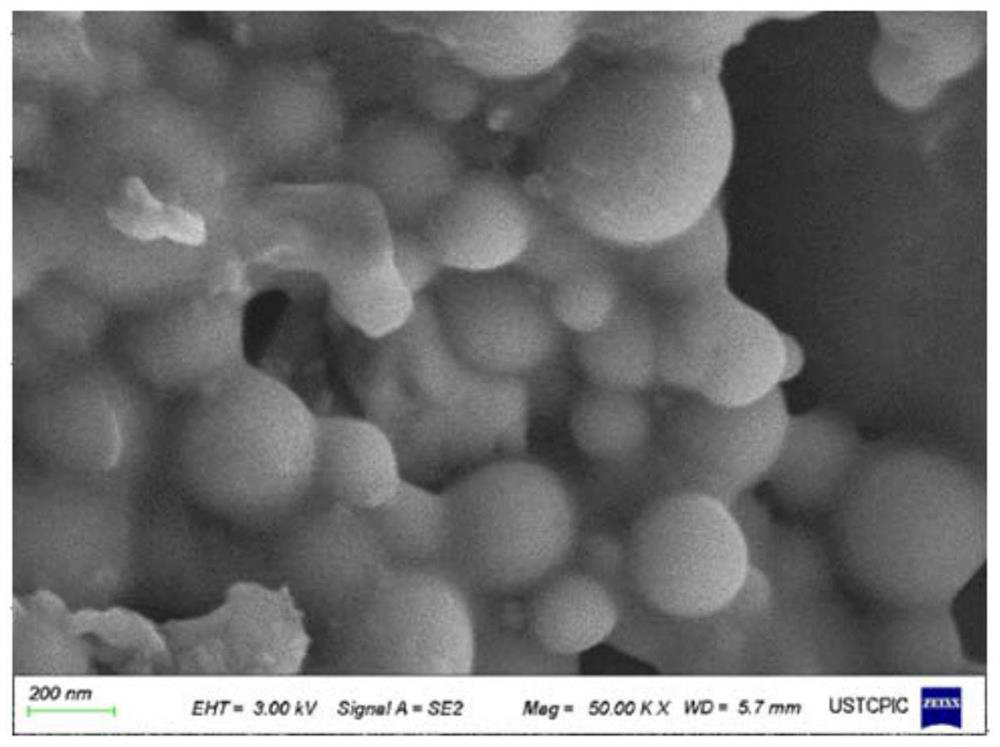

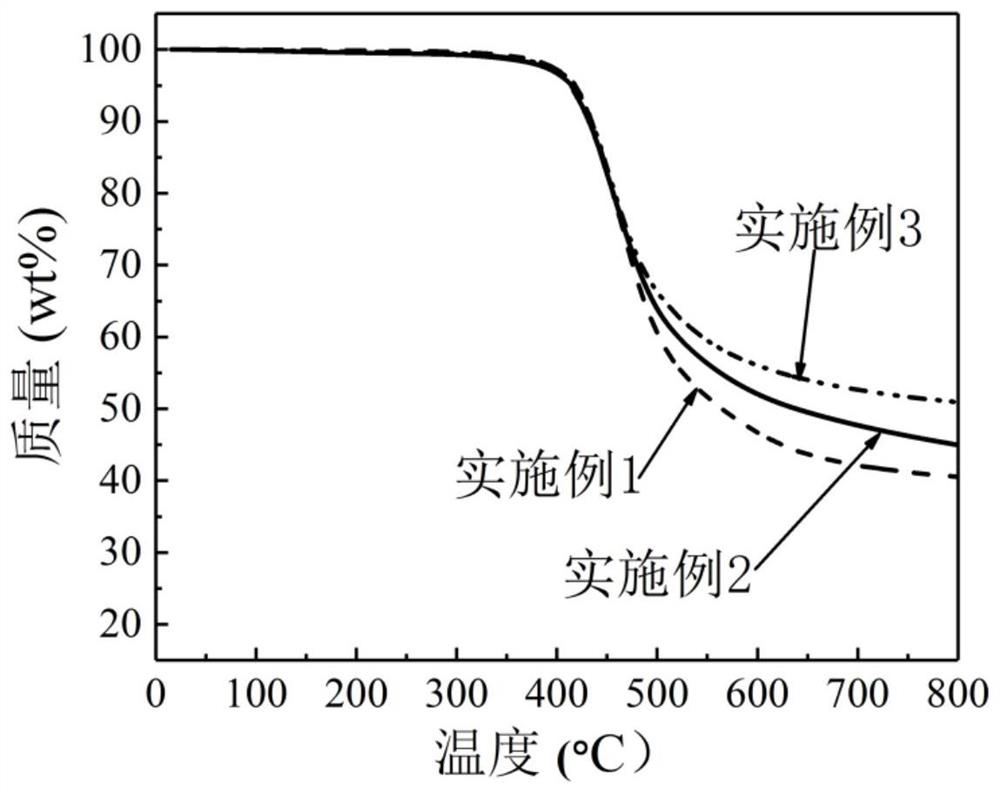

Shape memory aerogel and preparation method thereof

ActiveCN113651992ALight weightImprove heat insulationAerogel preparationColloidal chemistry detailsSupercritical dryingPtru catalyst

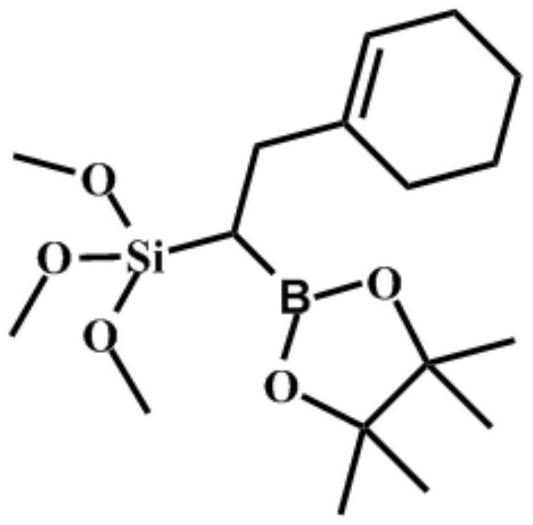

The invention provides a preparation method of shape memory aerogel, which comprises the following steps: step a) in a non-alcohol organic solvent, under anaerobic and stirring conditions, carrying out a first reaction on a sulfydryl reagent and an olefin reagent under the action of a benzoyl polymerization catalyst; step b), carrying out a second reaction on the reaction mixture obtained in the step a) under the action of aromatic tertiary amine under oxygen-free and stirring conditions; c) carrying out a third reaction on the reaction mixture obtained in the step b) under the action of water and a phase transfer catalyst, and carrying out aging and solvent replacement on the obtained reaction mixture to obtain gel; and d) carrying out carbon dioxide supercritical drying on the gel obtained in the step c). The method provided by the invention is simple in process, high in controllable degree, high in accuracy and simple and convenient to operate, and the obtained shape memory aerogel has the characteristics of high porosity, low density, high shape recovery rate, glass-transition temperature range of-60 to 180 DEG C and the like.

Owner:UNIV OF SCI & TECH OF CHINA

A kind of polyurethane memory foam material for mattress and preparation method thereof

The invention provides a polyurethane memory foam material for a mattress as well as a preparation method of the material. The polyurethane memory foam material comprises the following raw material components in parts by mass: 40 to 60 parts of diisocyanate, 90 to 110 parts of poly-polyol, 10 to 15 parts of a chain extender, 5 to 10 parts of carbon fiber, 1.5 to 3 parts of a foaming agent, 1 to 2parts of a foam stabilizer, 0.5 to 1 part of a pore opening agent and 0.3 to 1 part of a catalyst, wherein the poly-polyol comprises low-molecular-weight poly-polyol with the number-average molecularweight of 800 to 1500, medium-molecular-weight poly-polyol with the number-average molecular weight of 3000 to 5000 and high-molecular-weight poly-polyol with the number-average molecular weight of 8000 to 12000. The polyurethane memory foam material is prepared by a method for performing polymerization foaming at one step and finally curing. The polyurethane memory foam material provided by the invention has high strength, has glass transition temperature close to the human body temperature, has high shape recovery ratio and is particularly suitable for a mattress material.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Thermosetting shape memory resin based on bismaleimide and preparation method thereof

The invention relates to a bismaleimide-based thermosetting shape memory resin with high deformation and a preparation method thereof. Comprise the following steps, bismaleimide and 1,6-hexanedithiol are added in m-cresol to form a solution; triethylamine is added dropwise in the solution, and N 2 Under protection and stirring conditions, react at room temperature to obtain linear oligomers; by mass, mix bismaleimide, linear oligomers and O, O´‑diallyl bisphenol A at a temperature of 130 ~ React at 150°C for 25-45 minutes to obtain a prepolymer; vacuum defoam the prepolymer at a temperature of 130-150°C, and then undergo curing and post-treatment to obtain a thermosetting shape memory resin based on bismaleimide. Compared with the prior art, the resin of the present invention has a large deformability, and its elongation at break at the programmed temperature is greater than 30%. In addition, the cured resin combines high glass transition temperature (>131°C) and initial decomposition temperature (>370°C), high toughness and outstanding shape memory properties.

Owner:SUZHOU UNIV

A method for repairing tire inner liner

ActiveCN113603814BImprove mechanical propertiesImprove adsorption removal effectNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentPolymer scienceSilicone oil

Owner:WUXI I REACH TECH

Elastic shape memory polyurethane

InactiveCN102391460BHigh tensile strengthHigh shape recovery rateFibre treatmentSodium methoxideTrimethoprim

The invention discloses elastic shape memory polyurethane, which is prepared through the following steps of: adjusting pH of 50g / L titanium dioxide nanosuspension to be 4.5 by using acetic acid and then ultrasonically dispersing for 30 minutes; adding 10g / L KH550 and heating to 80 DEG C to react for 3 hours; and finally, filtering a reaction product, washing with de-ionized water and then drying, and then crushing into fine grains to obtain modified titanium dioxide catalyst; and b, mixing the obtained modified titanium dioxide catalyst and DMAC (Dimethyl Acetylamide) and then dispersing under the action of ultrasonic wave to obtain catalyst suspension; adding ethyl acetate and MDI (Diphenyl-Methane-Diisocyanate) into a reaction kettle filled with nitrogen gas, heating to 40-50 DEG C, and adding a small amount of sodium methoxide and the catalyst suspension obtained by the step b after full dissolution; then slowly adding TMP (Trimethoprim); reacting at the temperature of 75 DEG C for 3-4 hours; and adding a small amount of phosphoric acid. The elastic shape memory polyurethane has high tensile strength and shape recovery rate.

Owner:上海馨源新材料科技有限公司

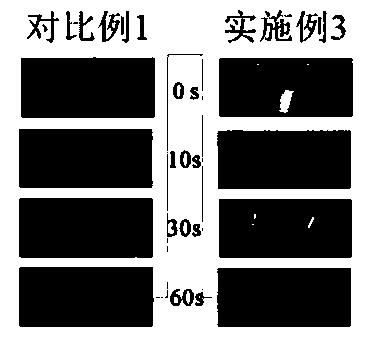

Method for quick processing iron based shape memory alloy under large current impulse

This invention discloses a method for rapidly treating iron-based shape memory alloy via high-current pulse generated by a remote-control (RC) charge / discharge apparatus. The method comprises: pre-defoaming the iron-based shape memory alloy, and treating by high-current pulse. By the method, a large amount of the second phase of the iron-based shape memory alloy can be rapidly precipitated within60 s. In the method, the current density, the width, the frequency and the time of the pulse can be controlled by regulating the capacitance (10-10000 mu.F), the voltage (50-600 V) and the pulse frequency (0.5-500 Hz) of the RC charge / discharge apparatus. The treated iron-based shape memory alloy has a shape recovery rate above 80% (when bending deformation amount is 5%) and a recoverable deformation amount above 4.0%. The RC charge / discharge apparatus used in the method has simple structure and convenient maintenance. The method has such advantages as short treatment period and high efficiency.

Owner:SICHUAN UNIV

Polylactic acid-based biodegradable shape memory material excited by body heat and its preparation method and application

The invention discloses a body-heat-excited polylactic-acid-base biodegradable shape memory material, and a preparation method and application thereof. The material is composed of the main components polylactic acid and thermoplastic elastomer in a mass ratio of (70-90):(30-10), and also composed of 10-40 phr of plasticizer. The preparation method comprises the following steps: mechanically mixing the main components into a premix, adding into an extruder, and carrying out melt blending to obtain the shape memory material. The shape memory material is used for manufacturing fixers for medical treatment. The shape recovery temperature of the polylactic-acid-base biodegradable shape memory material can be adjusted to near body temperature, thereby implementing the body-heat-excited effect. The shape memory material can be better applied to biological medical materials to greatly enhance the market competitiveness of the product.

Owner:SOUTH CHINA UNIV OF TECH

Thermoplastic composition and method for its preparation

The invention discloses a thermoplastic composition and a preparing method thereof.The thermoplastic composition comprises, by weight, 60-90 parts of epoxidation polyethylene-vinyl acetate, 10-40 parts of thermoplastic polymers and 0.1-20 parts of cross-linking agent.The preparing method of the thermoplastic composition can be achieved on a traditional high-polymer-material processing device, cost is low, the environment is friendly, and industrial production is easy to achieve.The thermoplastic composition obtained with the provided preparing method has the advantages of being high in shape recovery rate and strength, large in elongation at break, excellent in thermoplastic performance and the like, and can be directly used for extrusion molding, compression molding and the like to be used for preparing various thermoplastic and rubber products.

Owner:JIANGNAN UNIV

Biodegradable material and method for producing biodegradable material

InactiveCN104185480BGood flexibilityHigh shape recovery rateSuture equipmentsSurgical adhesivesCompound aPolymer science

An object of the present invention is to provide a biodegradable material with improved shape recovery rate after material deformation and improved flexibility. The present invention provides a biodegradable material in which a polyvalent compound A having a functional group X such as three or more hydroxyl groups and a polyvalent compound B having a functional group Y such as three or more carboxyl groups are chemically cross-linked through a condensation reaction between the functional group X and the functional group Y. When the number of functional groups X not condensed with functional group Y is denoted as x, the number of functional groups Y not condensed with functional group X is denoted as y, the number of chemical crosslinks is denoted as z, and the number of polyvalent compounds A is When the weight average molecular weight is written as MA and the weight average molecular weight of the polyvalent compound B is written as MB, when MA≥MB, the value of (y+z) / (x+z) is 1.2 to 4.0, and when MA<MB, the The value of (x+z) / (y+z) is 1.2 to 4.0.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com