Method for quick processing iron based shape memory alloy under large current impulse

A technology of memory alloy and fast pulse, which is applied in the field of shape memory alloy to achieve the effect of improving the effect, simplifying the processing technology and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

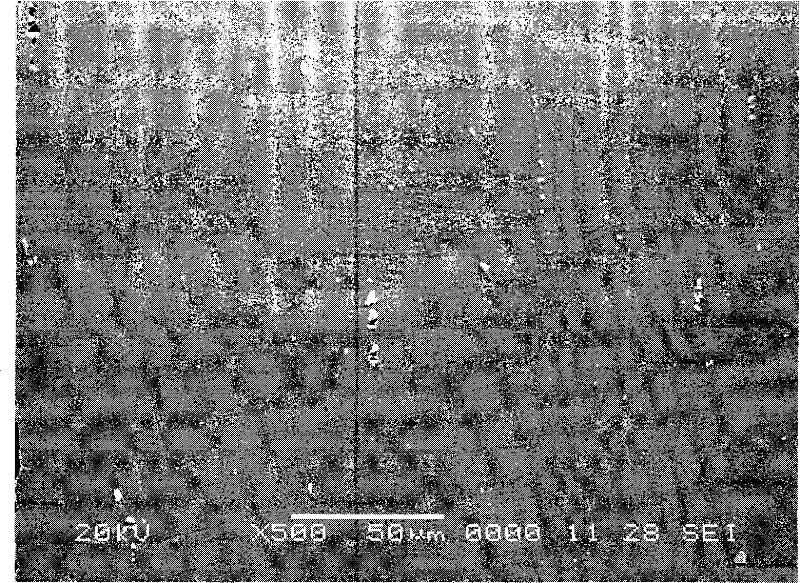

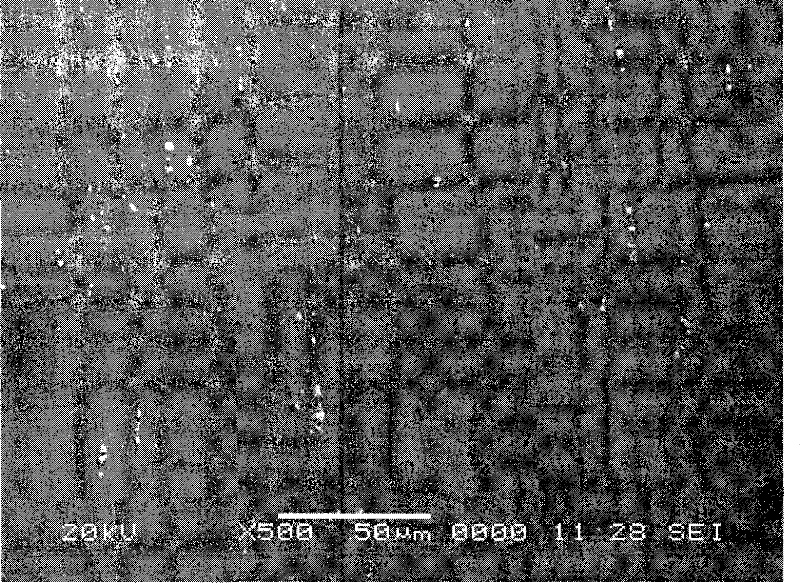

Image

Examples

Embodiment 1

[0020] According to the designed composition formula Mn30%, Si3%, Cr7%, Ni4%, C0.2%, Nb2% (the balance is iron, both are mass percentages), using industrial pure iron, metal manganese, metal silicon, metal chromium, Electrolytic nickel, graphite, and ferroniobium are used as raw materials, melted in an induction furnace, and then cast to obtain an ingot. The ingot size is φ78×160mm and weighs 5.5Kg. In order to eliminate the compositional inhomogeneity of the ingot, the ingot is homogenized and annealed at ~1100°C for 15 hours. After the surface scale is removed, it is hot-forged into a Φ15mm round bar at the initial forging temperature of 1100°C. Still at the initial forging temperature of 1100°C, the wire material of Φ3.5mm is formed by three rotary hammers. The Φ3.5mm wire is drawn into Φ1.5mm wire through 8 cold drawing (intermediate annealing process is 1273K×10min). Cut 20 wires with a length of 140 mm, put them in a straight pipe and keep them warm for 30 minutes at 11...

Embodiment 2

[0022] According to the designed ingredient formula, Mn is 14%, Si is 5%, Cr is 12%, Ni is 6%, C is 0.01%, and Nb is 0.1% (the balance is iron, which are all mass percentages). Pure iron, metal manganese, metal silicon, metal chromium, electrolytic nickel, and graphite are used as raw materials, melted in an induction furnace, and then poured to obtain an ingot. The ingot size is φ78×155mm and weighs 5.4Kg. In order to eliminate the compositional inhomogeneity of the ingot, the ingot is homogenized and annealed at ~1100°C for 15 hours. After the surface scale is removed, it is hot-forged into a Φ15mm round bar at the initial forging temperature of 1100°C. Still at the initial forging temperature of 1100°C, the wire material of Φ3.5mm is formed by three rotary hammers. The Φ3.5mm wire is drawn into Φ1.5mm wire through 8 cold drawing (intermediate annealing process is 1273K×10min). Cut 20 wires with a length of 140 mm, put them in a straight pipe and keep them warm for 30 minut...

Embodiment 3

[0024] According to the designed ingredient formula, Mn is 17%, Si is 7%, Cr is 8%, Ni is 5%, C is 0.1%, and Nb is 1% (the balance is iron, which are all mass percentages). Pure iron, metal manganese, metal silicon, metal chromium, electrolytic nickel, graphite, and ferroniobium are used as raw materials, melted in an induction furnace, and then poured to obtain an ingot. The ingot size is φ78×165mm and weighs 5.6Kg. In order to eliminate the compositional inhomogeneity of the ingot, the ingot is homogenized and annealed at ~1100°C for 15 hours. After the surface scale is removed, it is hot-forged into a Φ15mm round bar at the initial forging temperature of 1100°C. Still at the initial forging temperature of 1100°C, the wire material of Φ3.5mm is formed by three rotary hammers. The Φ3.5mm wire is drawn into Φ1.5mm wire through 8 cold drawing (intermediate annealing process is 1273K×10min). Cut 20 wires with a length of 140 mm, put them in a straight pipe and keep them warm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com