Thermoplastic composition and method for its preparation

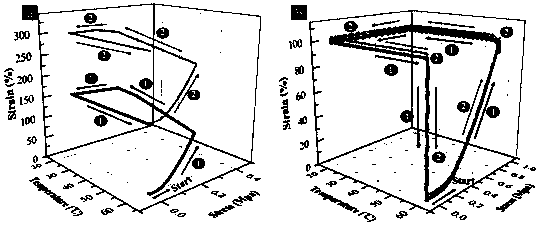

A thermoplastic composition and thermoplastic polymer technology, applied in the field of polymer materials, can solve the problems of no longer having secondary melt processing performance, failure to re-melt and plasticize, and reduced elongation at break, achieving low cost and shape recovery The effect of high rate and large elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, epoxidized polyethylene-vinyl acetate (vinyl acetate content is 60%, and the mass percent composition of epoxy group is 0.5%) 70g and polylactic acid 30g are mixed uniformly by internal mixer at 175 ℃ (totally The mixing time was 5 minutes, the rotor speed was 50 rpm), and then 6.3 g of methyl hexahydrophthalic anhydride was added and the melt blending was continued for 10 minutes to obtain a thermoplastic composition. The thermoplastic composition was hot-pressed by a flat vulcanizer to obtain a sheet with a thickness of 1 mm, which was cut into a standard sample according to national standards for mechanical performance testing. The test results are listed in Table 1.

Embodiment 2

[0030] First, epoxidized polyethylene-vinyl acetate (vinyl acetate content is 60%, and the mass percent composition of epoxy group is 0.5%) 70g and polylactic acid 30g are mixed uniformly by internal mixer at 175 ℃ (totally The mixing time is 5 minutes, the rotor speed is 50 rpm), and then 1.0 g of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane is added and melt-blended for 10 minutes to obtain a thermoplastic composition. The thermoplastic composition was hot-pressed by a flat vulcanizer to obtain a sheet with a thickness of 1 mm, which was cut into a standard sample according to national standards for mechanical performance testing. The test results are listed in Table 1.

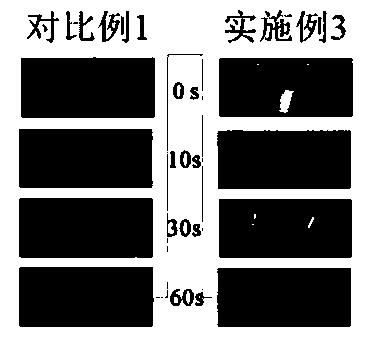

Embodiment 3

[0032] First epoxidized polyethylene-vinyl acetate (vinyl acetate content is 60%, the mass percentage composition of epoxy group is 0.5%) 65g and polylactic acid 35g are mixed 5 minutes with internal mixer (blending condition: The temperature is 170°C, the rotor speed is 50 rpm), and then 6.3 g of methyl hexahydrophthalic anhydride is added to continue melt blending for 10 minutes (blending conditions: the temperature is 170 °C, the rotor speed is 80 rpm) to obtain a thermoplastic composition . The thermoplastic composition was hot-pressed by a flat vulcanizer to obtain a sheet with a thickness of 1 mm, which was cut into a standard sample according to national standards for mechanical performance testing. The test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com