A method for repairing tire inner liner

An airtight layer and tire technology, applied in the surface pretreatment bonding method, adhesive heating bonding method, bonding method, etc., can solve the problems of tire micro-leakage, etc., and achieve the improvement of mechanical properties and shape Increased fixation rate and shape recovery rate to improve the effect of repairing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of modified trans-polyisoprene:

[0040] Take TPI at 120°C and 60rpm / min, heat and melt it completely, then add N-BOC-4-methylene-L-proline methyl ester and mix for 3 minutes, then add initiator to melt and graft for 8 minutes; then the reaction The product was wrapped with tweezers burned by an alcohol lamp, used a Soxhlet extractor, added acetone and refluxed for 48 hours at 80°C, and then dried in a vacuum oven at 65°C to obtain the modified trans-polyisoprene Diene. The amount of each raw material added includes, in parts by weight, 100 parts of TPI, 7 parts of N-BOC-4-methylene-L-proline methyl ester, 2 parts of initiator DCP; modified trans polyisoprene The grafting rate of alkenes is 68.7%.

[0041] Preparation of Acrylate Composite Resin:

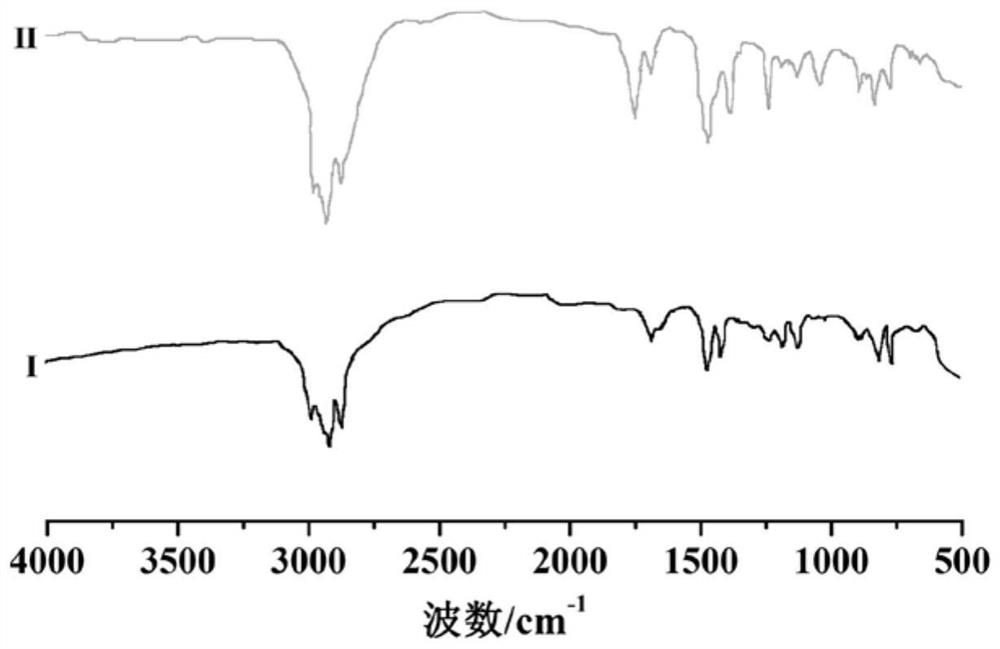

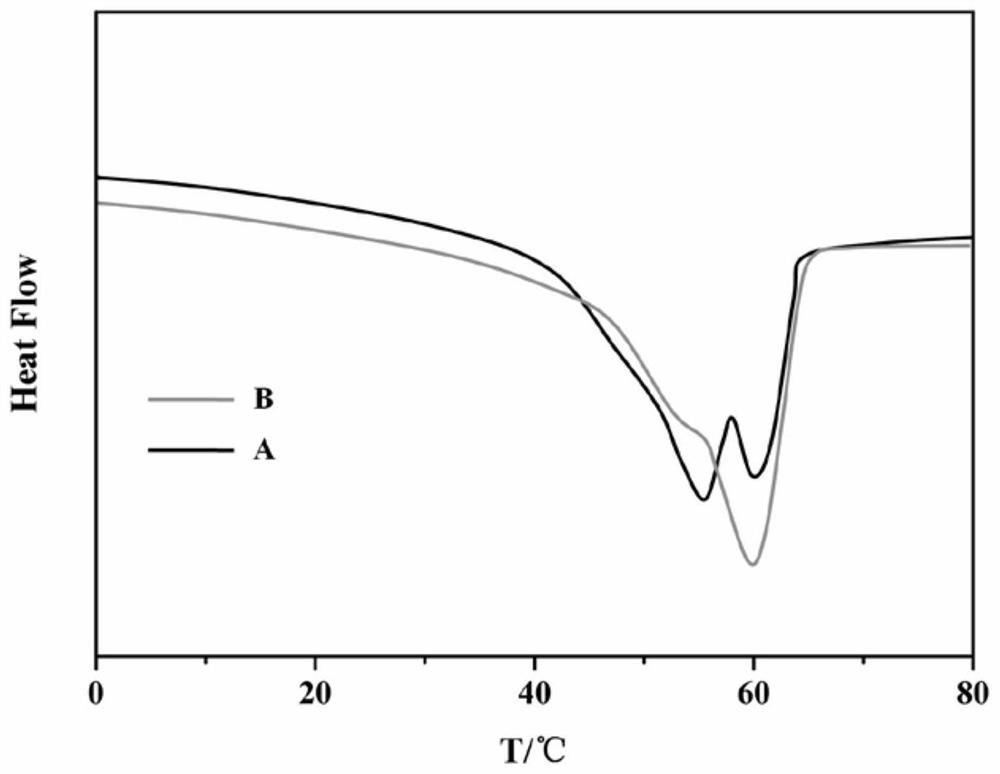

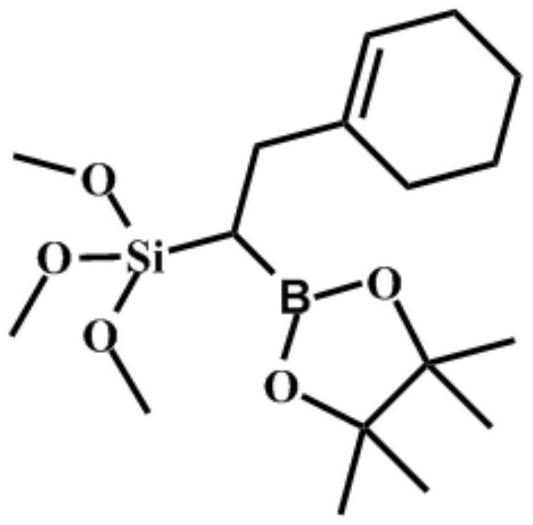

[0042] (1) Mix absolute ethanol and deionized water at a volume ratio of 1:1, adjust the pH to 3.5, add hollow spherical manganese dioxide, and after ultrasonic dispersion is uniform, add a silane coupling agen...

Embodiment 2

[0048] The difference between the preparation of modified trans polyisoprene and Example 1 is:

[0049] The amount of each raw material added includes, in parts by weight, 98 parts of TPI, 8 parts of N-BOC-4-methylene-L-proline methyl ester, 2.5 parts of initiator DCP; modified trans polyisoprene The grafting rate is 71.3%.

[0050] The preparation of the acrylate composite resin was the same as in Example 1.

[0051] A kind of polymer memory glue material raw material includes, by weight, 43 parts of modified trans polyisoprene prepared in this embodiment, 24 parts of acrylate composite resin, 9 parts of hydrogenated rosin glyceride, 7 parts of nano Grade chitin whiskers, 4 parts propylene glycol dicaprylate, 5 parts catalyst, 3 parts dibutyl phthalate, 1.5 parts antioxidant. Among them, the catalyst is N,N-dimethylethylaminoethylene glycol; the antioxidant includes antioxidant 1010 and antioxidant 168, and the weight ratio of the two is 6:4.

[0052] The preparation of th...

Embodiment 3

[0054] The difference between the preparation of modified trans polyisoprene and Example 1 is:

[0055] The amount of each raw material added includes, in parts by weight, 103 parts of TPI, 9 parts of N-BOC-4-methylene-L-proline methyl ester, 3 parts of initiator DCP; modified trans polyisoprene The grafting rate is 72.2%.

[0056] The preparation of the acrylate composite resin was the same as in Example 1.

[0057] A kind of polymer memory glue material raw material includes, by weight, 33 parts of modified trans polyisoprene prepared in this embodiment, 30 parts of acrylate composite resin, 12 parts of hydrogenated rosin glyceride, 9 parts of nano Grade chitin whiskers, 6 parts of propylene glycol dicaprylate, 4 parts of catalyst, 2 parts of dibutyl phthalate, 0.8 parts of antioxidant. Among them, the catalyst is N,N-dimethylethylaminoethylene glycol; the antioxidant includes antioxidant 1010 and antioxidant 168, and the weight ratio of the two is 6:3.5.

[0058] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com