Method for preparing star-shaped biodegradable shape-memory-polymer nano composite material

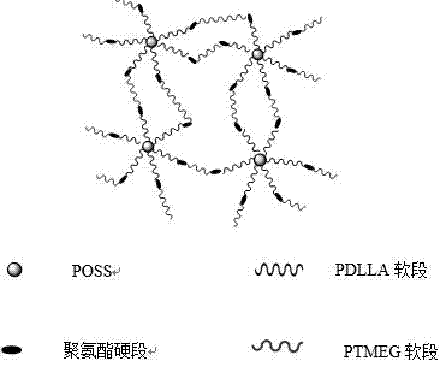

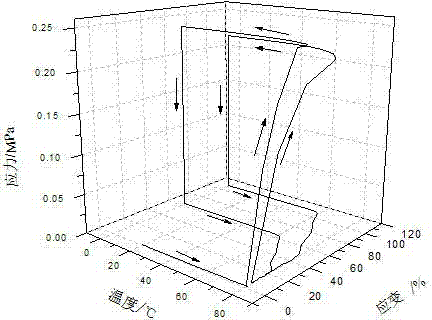

A technology of nanocomposite materials and memory polymers, which is applied in the field of preparation of star-shaped biodegradable shape memory polymer nanocomposites, can solve the problems of unsatisfactory repeated memory effect, insufficient mechanical strength, and small shape recovery force. Achieve the effects of repeatable biodegradability, strong deformation retention and high shape recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put 1.8L methanol, 79.5g (3-chloropropyl) trimethoxysilane, 90ml hydrochloric acid in a 2.5L beaker, stir at room temperature for 5 weeks, filter to obtain white powder, wash with deionized water and dry to obtain POSS -(Cl) 8 . Add 4.71g AgNO to a 100ml round bottom flask 3 , add 30ml deionized water to dissolve it. An aqueous solution containing 1.11 g of NaOH was added to the above solution under vigorous stirring. Brown Ag 2 O was precipitated, filtered with suction, and washed three times with deionized water. Add 3g POSS-(Cl) in 250ml round bottom flask 8 , 75ml ethanol, 75ml tetrahydrofuran, the above Ag 2 O was added to the solution together with 3ml of deionized water, and the system was vigorously stirred for 48 hours in a dark environment, and refluxed at 74°C. Filtrate twice, take the clear liquid and then spin evaporate to obtain a white solid, namely POSS-(OH) 8

[0025] Add 7.258g (0.0504 mol) of D,L-lactide after three times of recrystallization...

Embodiment 2

[0028] POSS-(OH) 8 The preparation method is as embodiment 1.

[0029]Add 8.064g (0.056mol) of D,L-lactide after three times of recrystallization from vinyl acetate into a 50ml dry round bottom flask, add 0.0414g (4.93×10 -5 mol) POSS-(OH) 8 , 15μl stannous octoate (0.001mol / L). Polymerize for 24 hours at 130°C under nitrogen protection. After the reaction was completed, dichloromethane was added to dissolve, and then the product was precipitated and purified by adding iced n-hexane, and vacuum-dried to obtain a white flocculent polymer. The molecular weight is 128,000. Dissolve 1.396g of the obtained white flocculent polymer in 14ml of anhydrous dichloromethane, add 0.0875g of polytetramethylene ether glycol, and add 0.0166g of 1,6-hexamethylene diisocyanate after it is completely dissolved and 0.01 wt% chain extension catalyst stannous octoate. Stir at room temperature for 4h, pour into a polytetrafluoroethylene mold, room temperature, N 2 The solvent was volatilized ...

Embodiment 3

[0031] POSS-(OH) 8 The preparation method is as embodiment 1.

[0032] Add 7.98g (0.055mol) of dried D,L-lactide after three times of recrystallization from vinyl acetate into a 50ml dry round bottom flask, add 0.0258g (3.08×10 -5 mol) POSS-(OH) 8 , 15μl stannous octoate (0.001mol / L). Polymerize for 24 hours at 130°C under nitrogen protection. After the reaction was completed, dichloromethane was added to dissolve, and then the product was precipitated and purified by adding iced n-hexane, and vacuum-dried to obtain a white flocculent polymer. The molecular weight is 244,000. Dissolve 1.44g of the obtained white flocculent polymer in 14ml of anhydrous dichloromethane, add 0.0472g of polytetramethylene ether glycol, and add 0.0089g of 1,6-hexamethylene diisocyanate after it is completely dissolved and 0.01 wt% chain extension catalyst stannous octoate. Stir at room temperature for 4h, pour into a polytetrafluoroethylene mold, room temperature, N 2 The solvent was volatil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com