Method for preparing magneto type biodegradable shape-memory-polymer nano composite material

A composite material and memory technology is applied in the field of preparation of magnetotropic biodegradable shape memory polymer nanocomposite materials, which can solve the problems of low mechanical strength and small shape recovery stress, and achieve high shape recovery rate and deformation retention ability. Strong, shape memory performance with good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

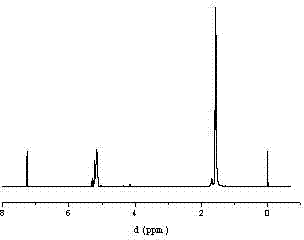

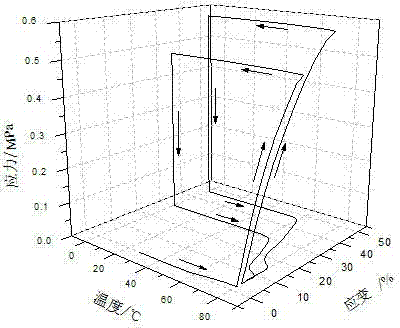

Image

Examples

Embodiment 1

[0027] Put 500ml of ethanol and deionized water solution (volume ratio 1:1) in a 1L round bottom flask, 10g Fe 3 o 4 Nanoparticles were dispersed in it, and 5ml (3-(2,3-propylene oxide)propyltrimethylsilane was added, and stirred at 40°C for 4h under the protection of nitrogen. After washing with water and ethanol three times, put them into a vacuum drying oven to dry.

[0028] Put 7.5ml of anhydrous toluene in the sample bottle, and 0.03g of surface-modified Fe 3 o 4 Nanoparticles are dispersed therein. Ultrasonic dispersion 30 ~ 45min. spare.

[0029] Add 8.064g (0.056 mol) of D,L-lactide after three times of recrystallization from vinyl acetate to a 50ml dry round bottom flask, add 0.0126g (1.4×10 -4 mol) butanediol, 15μl stannous octoate (0.001mol / L). Polymerize for 24 hours at 130°C under nitrogen protection. After the reaction was completed, dichloromethane was added to dissolve, and then the product was dropped into iced n-hexane to precipitate and purify the pr...

Embodiment 2

[0033] Fe 3 o 4 The nanoparticle surface modification method is as in Example 1.

[0034] Put 15ml of anhydrous toluene in the sample bottle, and 0.06g of surface-modified Fe 3 o 4 Nanoparticles are dispersed therein. Ultrasonic dispersion 30 ~ 45min. spare.

[0035] Add 8.064g (0.056 mol) of D,L-lactide after three times of recrystallization from vinyl acetate to a 50ml dry round bottom flask, add 0.0126g (1.4×10 -4 mol) butanediol, 15μl stannous octoate (0.001mol / L). Polymerize for 24 hours at 130°C under nitrogen protection. After the reaction was completed, dichloromethane was added to dissolve, and then the product was dropped into iced n-hexane to precipitate and purify the product, and vacuum-dried to obtain a white flocculent polymer. The molecular weight is 50,000. Dissolve 1.28 g of the obtained white flocculent polymer in 2 ml of anhydrous toluene, and stir at 65° C. for 30 min. Add 0.024 g of 1,6-hexamethylene diisocyanate and 20 μl of chain extension cat...

Embodiment 3

[0037] Fe 3 o 4 The nanoparticle surface modification method is as in Example 1.

[0038] Put 22.5ml of anhydrous toluene in the sample bottle, and 0.09g of surface-modified Fe 3 o 4 Nanoparticles are dispersed therein. Ultrasonic dispersion 30 ~ 45min. spare.

[0039] Add 8.064g (0.056 mol) of D,L-lactide after three times of recrystallization from vinyl acetate to a 50ml dry round bottom flask, add 0.0126g (1.4×10 -4 mol) butanediol, 15μl stannous octoate (0.001mol / L). Polymerize for 24 hours at 130°C under nitrogen protection. After the reaction was completed, dichloromethane was added to dissolve, and then the product was dropped into iced n-hexane to precipitate and purify the product, and vacuum-dried to obtain a white flocculent polymer. The molecular weight is 50,000. Dissolve 1.28 g of the obtained white flocculent polymer in 2 ml of anhydrous toluene, and stir at 65° C. for 30 min. Add 0.024 g of 1,6-hexamethylene diisocyanate and 20 μl of chain extension c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com