PVC-U (polyvinyl chloride unplasticized) tube with shape memory function and production method and application thereof

A PVC-U and pipe technology, which is applied to the PVC-U pipe with shape memory function and its preparation field, can solve the problems of limiting the application of PVC-U shape memory pipe and complicated processing technology, and achieves good memory deformation function, comprehensive The effect of good performance and high deformation recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

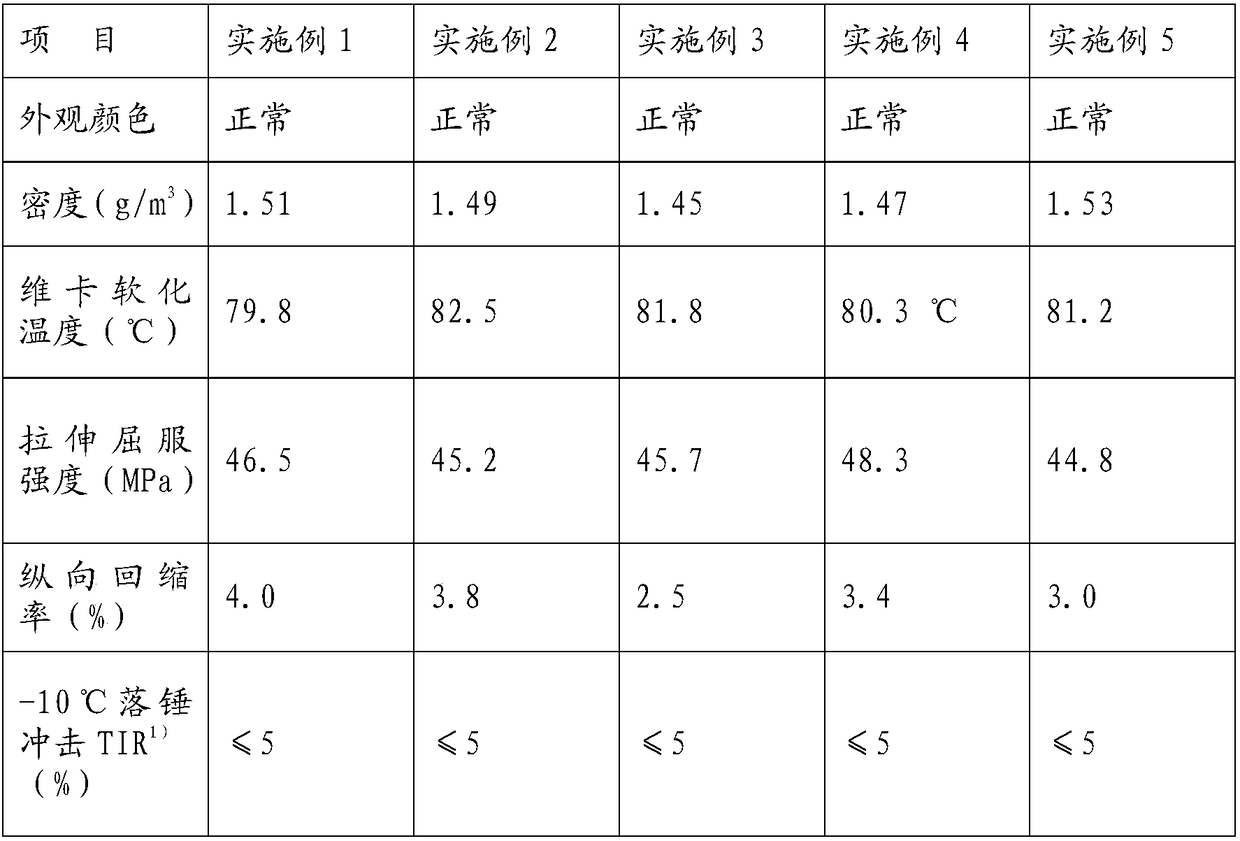

Embodiment 1

[0053] Prepare the PVC-U pipe material with shape memory function, its formula comprises each component of following mass parts:

[0054] Polyvinyl chloride resin SG-5: 100 parts; calcium zinc heat stabilizer CZ-8601E-2: 3.5 parts; lubricant polyethylene oxide wax: 0.5 parts; processing modifier copolymer of methacrylate and ethyl acrylate : 1.5 parts; ethylene-vinyl acetate-carbonyl copolymer (toughening agent): 6 parts; 0.58 parts of crosslinking agent (wherein, dicumyl peroxide (DCP): 0.08 parts; phthalic acid diene Propyl ester (DAP): 0.5 parts); acid absorbent magnesium oxide: 3.0 parts; filler calcium carbonate: 20 parts; pigment titanium dioxide 2.0 parts.

[0055] The method for preparing a PVC-U pipe with shape memory function specifically includes the following steps:

[0056] (1) Put the polyvinyl chloride resin, heat stabilizer, processing modifier, toughening agent, and plasticizer (0 parts of plasticizer in this embodiment) into the high-speed mixing unit (Zhang...

Embodiment 2

[0060] Prepare the PVC-U pipe material with shape memory function, its formula comprises each component of following mass parts:

[0061] Polyvinyl chloride resin SG-5: 100 parts; thiol octyl tin T-890: 2.0 parts; lubricant fatty alcohol: 0.5 parts; lubricant monoglyceride monooleate: 0.2 parts; plasticizer epoxy soybean oil (ESO ): 2 parts; processing modifier methyl methacrylate-ethyl methacrylate-ethyl acrylate copolymer: 0.8 parts; toughening agent ethylene-butyl acrylate-carbonyl copolymer (E / nBA / CO): 5 parts; crosslinking agent dithiotetramethylthiuram (TMTD): 2.5 parts; acid absorbent (magnesium oxide: 3.0 parts; zinc oxide: 2.0 parts); filler calcium carbonate: 15 parts, pigment titanium dioxide 2.0 parts share.

[0062] The specific steps of the method for preparing a PVC-U pipe with shape memory function in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0064] Prepare the PVC-U pipe material with shape memory function, its formula comprises each component of following mass parts:

[0065] Polyvinyl chloride resin SG-5: 80 parts; PVC resin SG-3: 20 parts; calcium zinc heat stabilizer CZ-8601E-2: 3.8 parts; lubricant OP wax: 0.8 parts; lubricant homopolyethylene Wax 0.1 part; plasticizer epoxy butyl stearate (EBST): 0.5 part; processing modifier methyl methacrylate-styrene-butyl acrylate copolymer: 1.2 part; toughening agent ethylene-vinyl acetate Ester-carbonyl copolymer (E / VA / CO): 4 parts; crosslinking agent 1.6 parts (DCP: 0.1 part; triallyl isocyanurate (TAIC): 1.5 parts); acid absorbent zinc oxide: 2 parts; filler talcum powder: 8 parts, pigment titanium dioxide 2.0 parts.

[0066] The specific steps of the method for preparing a PVC-U pipe with shape memory function in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com