A kind of polyurethane memory foam material for mattress and preparation method thereof

A technology of memory foam and polyurethane, which is applied in the field of polyurethane memory foam materials for mattresses and its preparation, to achieve the effect of high strength and high shape recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

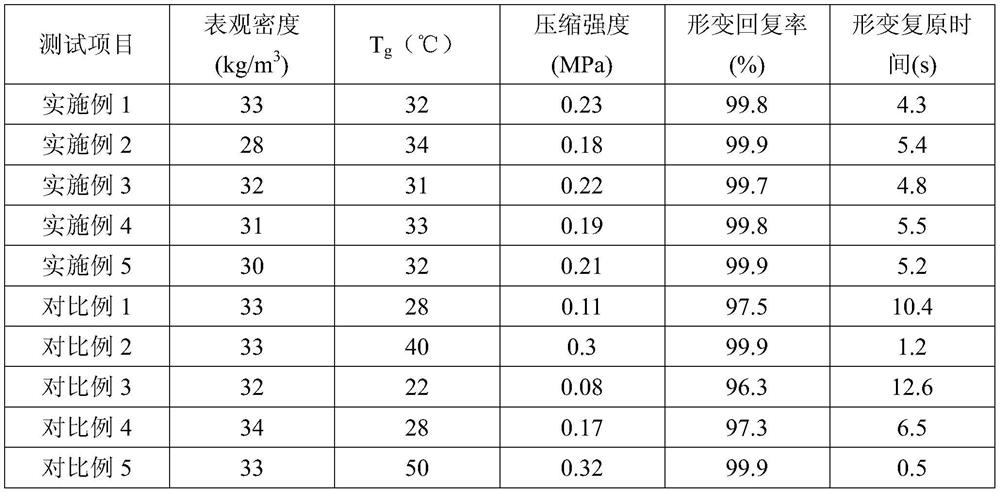

Examples

Embodiment 1

[0045] A polyurethane memory foam material for mattresses, comprising the following raw material components in parts by mass:

[0046] 40 parts of diisocyanate (carbodiimide modified MDI), 110 parts of polyol, 10 parts of chain extender (ethylene glycol), 30 parts of carbon fiber, 1.5 parts of foaming agent (water), 2 parts of foam stabilizer ( polyether modified organosiloxane), 0.5 parts of cell opener (Y-1030) and 1 part of catalyst (N,N-dimethylcyclohexylamine);

[0047] Among them, the polypolyol is composed of 20 wt% polyoxypropylene polyol with a number average molecular weight of 800, 60 wt% polycaprolactone polyol with a number average molecular weight of 3000, 20 wt% polyoxyethylene polyol with a number average molecular weight of 8000 Alcohol composition.

[0048] The preparation method of above-mentioned polyurethane memory foam material is as follows:

[0049] (1) Mix polypolyol, carbon fiber, chain extender, foaming agent, foam stabilizer, cell opener and catal...

Embodiment 2

[0053] A polyurethane memory foam material for mattresses, comprising the following raw material components in parts by mass:

[0054] 60 parts of diisocyanate (TDI), 90 parts of polyol, 15 parts of chain extender (1,3-propylene glycol), 20 parts of carbon fiber, 3 parts of foaming agent (water), 1 part of foam stabilizer (polyether modified organosiloxane), 1 part cell opener (Y-1030) and 0.3 part catalyst (bis(2-dimethylaminoethyl) ether);

[0055] Wherein, the polypolyol is the polyoxypropylene polyol that the number average molecular weight of 30wt% is 1500, the polycaprolactone polyol that the number average molecular weight of 40wt% is 5000 and the polyoxyethylene polyol that the number average molecular weight of 30wt% is 12000 composition.

[0056] The preparation method of above-mentioned polyurethane memory foam material is as follows:

[0057] (1) Mix polypolyol, carbon fiber, chain extender, foaming agent, foam stabilizer, cell opener and catalyst at a stirring r...

Embodiment 3

[0061] A polyurethane memory foam material for mattresses, comprising the following raw material components in parts by mass:

[0062] 45 parts of diisocyanate (MDI), 105 parts of polyol, 12 parts of chain extender (1,4-butanediol), 28 parts of carbon fiber, 1.8 parts of foaming agent (water), 1.6 parts of foam stabilizer (polyether modified organosiloxane), 0.8 parts of cell opener (Y-1030) and 0.5 parts of catalyst (tetramethylalkylene diamine);

[0063] Wherein, the polypolyol is the polyoxypropylene polyol that the number average molecular weight of 25wt% is 1200, the polycaprolactone polyol that the number average molecular weight of 50wt% is 4000 and the polyoxyethylene polyol that the number average molecular weight of 25wt% is 10000 composition.

[0064] The preparation method of above-mentioned polyurethane memory foam material is as follows:

[0065] (1) Mix polypolyol, carbon fiber, chain extender, foaming agent, foam stabilizer, cell opener and catalyst at a stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com