Shape memory polymer alloy for fused deposition based 3D printing and preparation method of shape memory polymer alloy

A memory polymer, 3D printing technology, applied in additive processing and other directions, can solve the problems of lack of functionality such as shape memory, lack of reversible phase and stationary phase, single type of components, etc., to alleviate uneven volume shrinkage, improve Mechanical properties, the effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

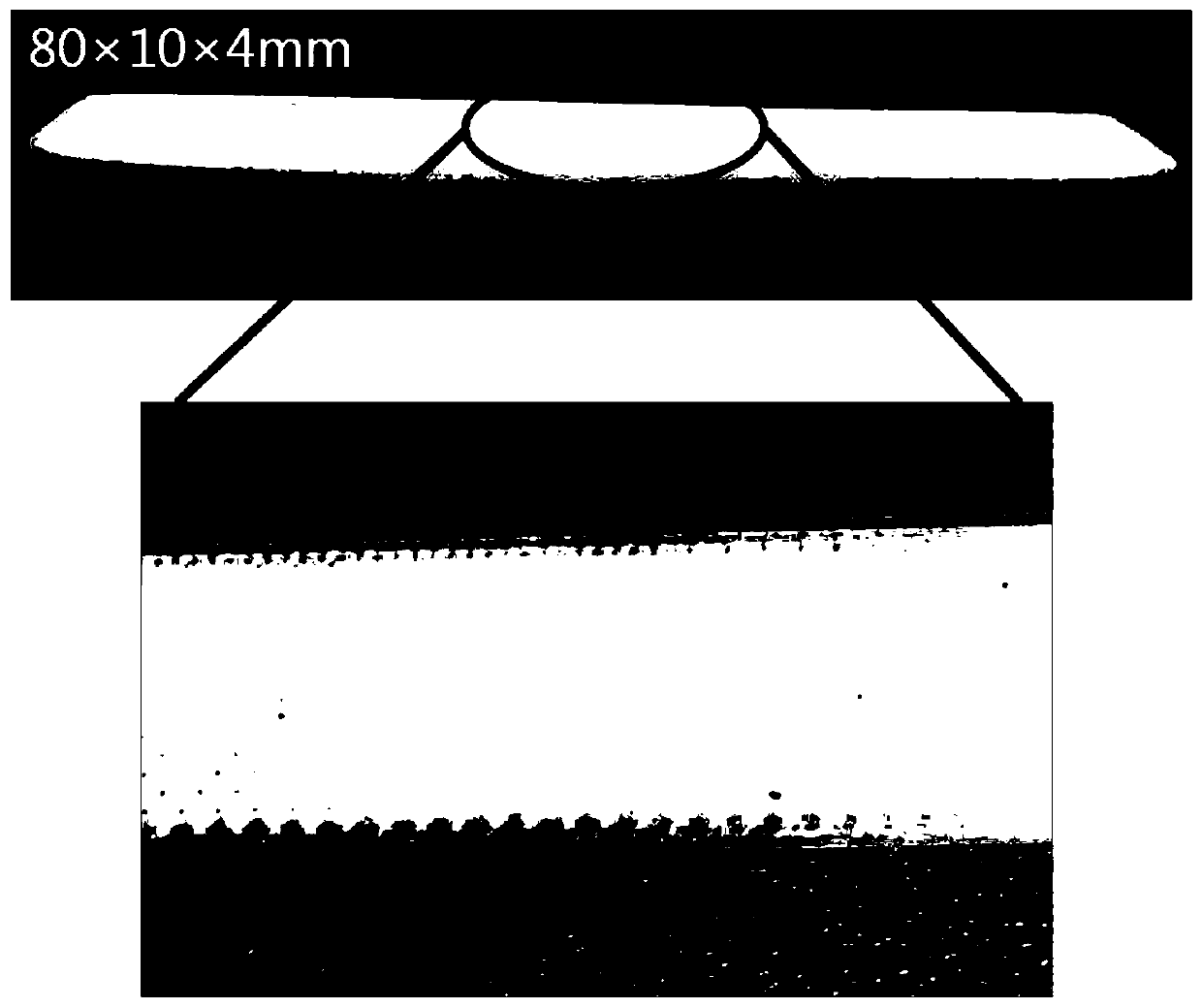

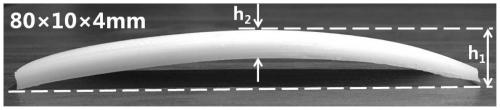

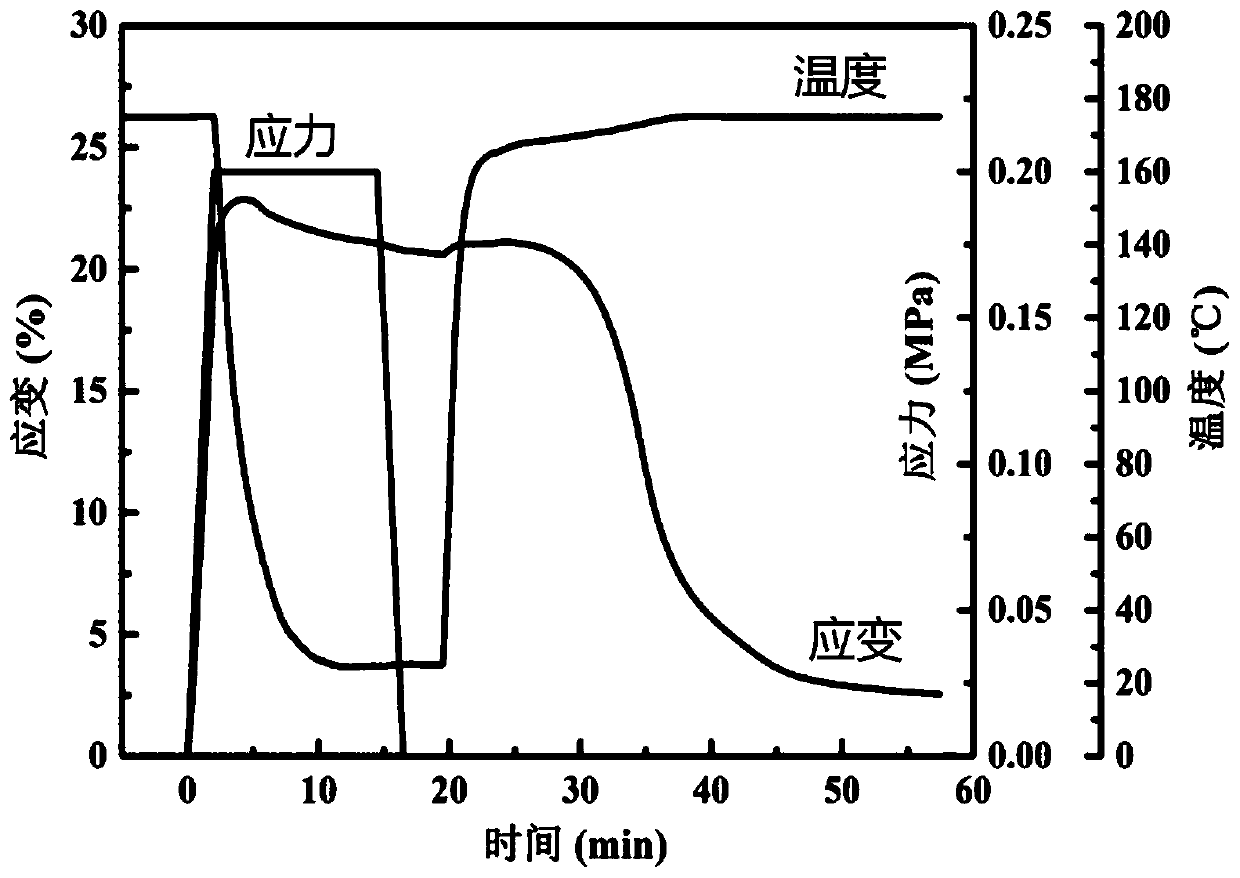

[0041] The preparation method of the shape memory polymer alloy based on fused deposition 3D printing comprises the following steps: according to the weight percentage of raw materials, 44wt% polypropylene plastic, 30wt% nylon 66, 22wt% POE-g-MAH, 1wt% Nano-silica was dried at 60°C for 5 hours, and then the above materials were mixed with 0.2wt% dicumyl peroxide DCP and 2.8wt% turpentine in a high-speed mixer at a mixing temperature of 50°C and a mixing time of 20 minutes; the mixed raw materials are put into a twin-screw extruder to melt and extrude and pelletize, wherein the extrusion temperature is 250°C, and the screw speed is 80r / min; after drying the obtained pellets at 60°C for 6 hours, Through melt extrusion in a twin-screw extruder, a polymer alloy wire rod with a diameter of 1.75±0.1 mm that can be used for fused deposition 3D printing is obtained, wherein the extrusion temperature is 255° C., and the screw speed is 40 r / min.

[0042] Send the prepared wire into the ...

Embodiment 2

[0052] 35wt% high-density polyethylene, 30wt% nylon 6 and 32wt% EPDM-g-MAH, 2.5wt% nano calcium carbonate were dried at 80°C for 4 hours, and then the above materials were mixed with 0.5wt% diisoperoxide Propylbenzene and DCP are put together in a high-speed mixer for mixing, the mixing temperature is 60°C, and the mixing time is 15 minutes; the mixed raw materials are put into a twin-screw extruder to melt and extrude and pelletize, and the extrusion temperature is 235°C. The screw speed is 70r / min; the obtained pellets are dried at 80°C for 5 hours, and then melted and extruded through a twin-screw extruder to obtain a polymer alloy with a diameter of 1.75±0.1mm that can be used for fused deposition 3D printing Wire rod, wherein the extrusion temperature is 235° C., and the screw speed is 50 r / min.

[0053] The test sample was prepared by fused deposition 3D printing, where the printing arrangement was ±45°, the printing filling rate was 100%, the nozzle temperature of the p...

Embodiment 3

[0055] 38wt% polypropylene, 30wt% nylon 1010 and 28wt% SEBS-g-MAH, 3wt% nano silicon dioxide were dried at 70°C for 5 hours, and then the above materials were mixed with 0.3wt% dicumyl peroxide DCP and 0.7wt% styrene are put together in a high-speed mixer for mixing, the mixing temperature is 40°C, and the mixing time is 30 minutes; the mixed raw materials are put into a twin-screw extruder to melt and extrude and granulate, wherein the extrusion temperature The temperature is 230°C, and the screw speed is 60r / min; after drying the obtained pellets at 80°C for 4 hours, they are melted and extruded through a twin-screw extruder to obtain fused deposition 3D printing with a diameter of 1.75±0.1mm A polymer alloy wire rod, wherein the extrusion temperature is 210° C., and the screw speed is 60 r / min. The test sample was prepared by fused deposition 3D printing, where the printing arrangement was ±45°, the printing filling rate was 80%, the nozzle temperature of the printing equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com