Thermosetting shape memory bismaleimide resin and preparation method thereof

A bismaleimide and maleimide sealing technology, which is applied in the field of thermosetting shape memory bismaleimide resin and its preparation, can solve the problem of reducing the shape recovery rate and the shape fixation rate, and it is difficult to have both excellent Heat resistance, high mechanical properties, shape memory properties and good manufacturability, etc., to achieve the effects of high shape recovery rate and shape fixation rate, thermal performance optimization, and toughness improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

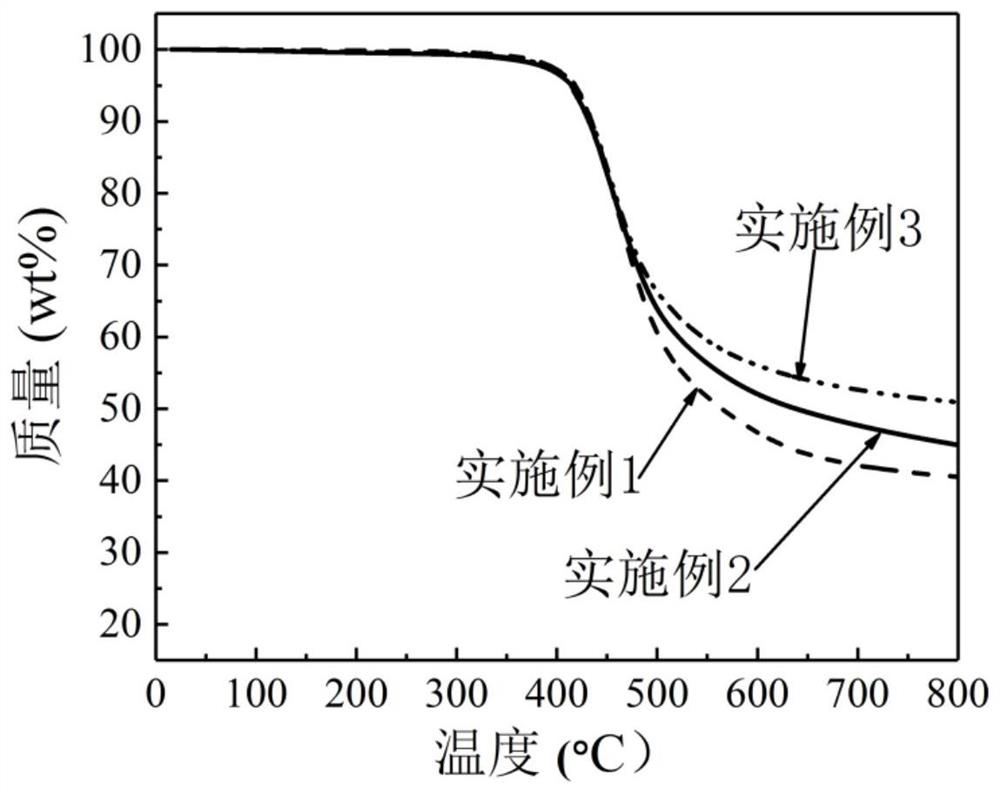

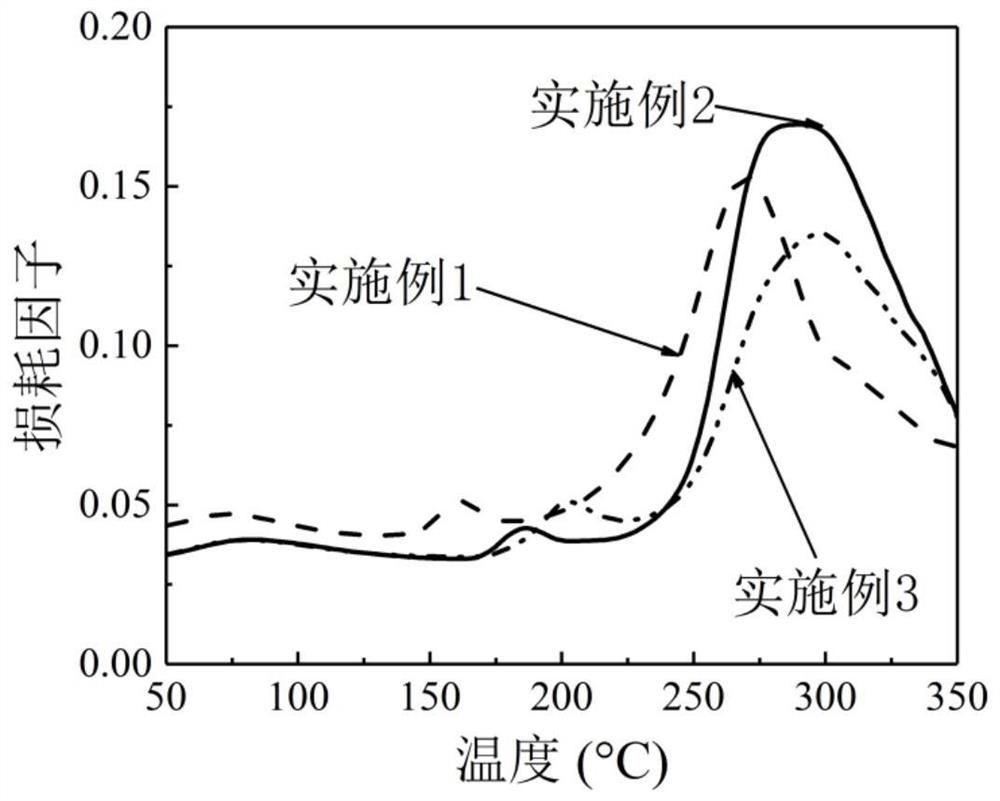

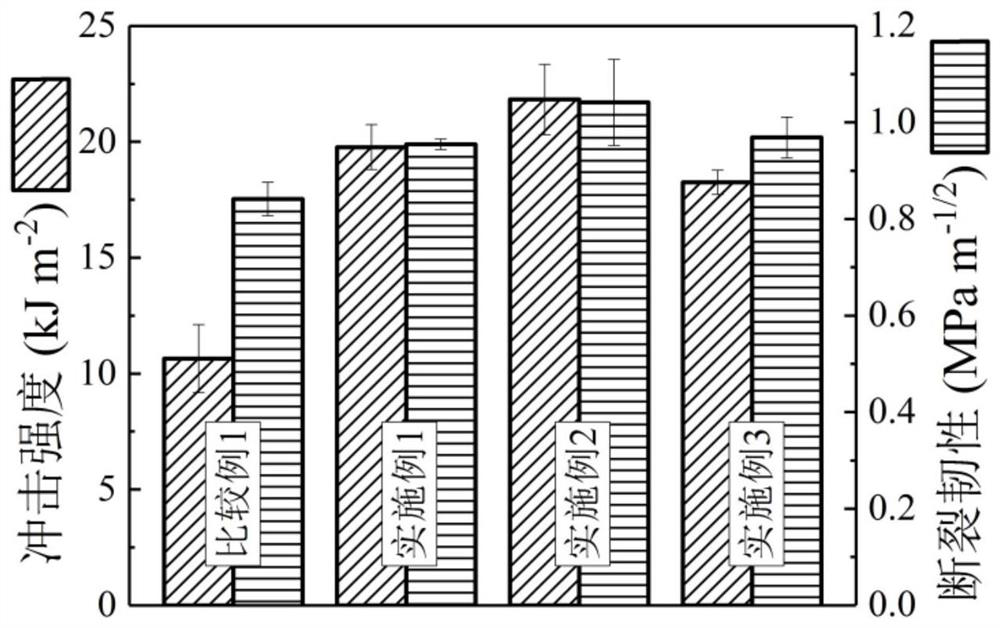

[0041] Mix 119.9g of O,O´-diallyl bisphenol A and 10.6g of phenolphthalein polyaryl ether ketone (purchased from Xuzhou Engineering Plastics, the same below), and stir vigorously at 130°C for 20min to obtain a clear and transparent solution. Then, add 100.0g N,N-(4,4-methylenediphenyl)bismaleimide and 10.6g maleimide-terminated hyperbranched polysiloxane to the transparent solution, and Continue to vigorously stir at 130° C. for 30 minutes to obtain a clear and transparent prepolymer. Pour the prepolymer into a preheated mold, put the mold into a vacuum oven at 130° C., and degas it to obtain a precursor for a thermosetting shape memory bismaleimide resin.

[0042] Then, the mold is put into a blast drying oven. The thermosetting shape memory bismaleimide resin precursor was cured according to the curing program of 150°C / 2h+180°C / 2h+200°C / 6h+220°C / 2h, and then post-cured at 240°C for 4h, followed by The oven is naturally cooled to obtain a thermosetting shape-memory bismalei...

Embodiment 2

[0044] 119.9g of O,O´-diallyl bisphenol A and 10.6g of phenolphthalein polyaryl ether ketone were vigorously stirred at 130°C for 20min to obtain a clear and transparent solution, then, 100.0g of N was added to the transparent solution, N-(4,4-methylenediphenyl)bismaleimide and 21.2g hyperbranched polysiloxane, and continue to stir vigorously at 130°C for 30min to obtain a clear and transparent prepolymer, and then The prepolymer is poured into a preheated mold and degassed in a vacuum oven at 130°C. Then, put the mold into the blast drying oven, cure according to the curing program of 150°C / 2h+180°C / 2h+200°C / 6h+220°C / 2h, and then post-cure at 240°C for 4 hours, and let it dry naturally with the oven. After cooling, a thermosetting shape-memory bismaleimide resin is obtained, denoted as BDPH10. Its initial decomposition temperature, glass transition temperature, toughness, flexural strength, rigidity, shape memory process and shape memory performance refer to the attached fi...

Embodiment 3

[0046] 119.9g of O,O´-diallyl bisphenol A and 10.6g of phenolphthalein polyaryl ether ketone were vigorously stirred at 130°C for 20min to obtain a clear and transparent solution, then, 100.0g of N was added to the transparent solution, N-(4,4-methylenediphenyl) bismaleimide and 31.8g hyperbranched polysiloxane, and continue to stir vigorously at 130°C for 30min to obtain a clear and transparent prepolymer, and then The prepolymer is poured into a preheated mold and degassed in a vacuum oven at 130°C. Then, put the mold into the blast drying oven, cure according to the curing program of 150°C / 2h+180°C / 2h+200°C / 6h+220°C / 2h, and then post-cure at 240°C for 4 hours, and let it dry naturally with the oven. After cooling, a thermosetting shape-memory bismaleimide resin is obtained, which is denoted as BDPH15. Its initial decomposition temperature, glass transition temperature, toughness, flexural strength, rigidity and shape memory properties refer to the attached figure 1 , 2 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com