Shape memory aerogel material and preparation method thereof

An aerogel, memory technology, applied in aerogel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of high chemical activity of memory resin, unsuitable for use environment, etc., achieve low density, low cost, porosity, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

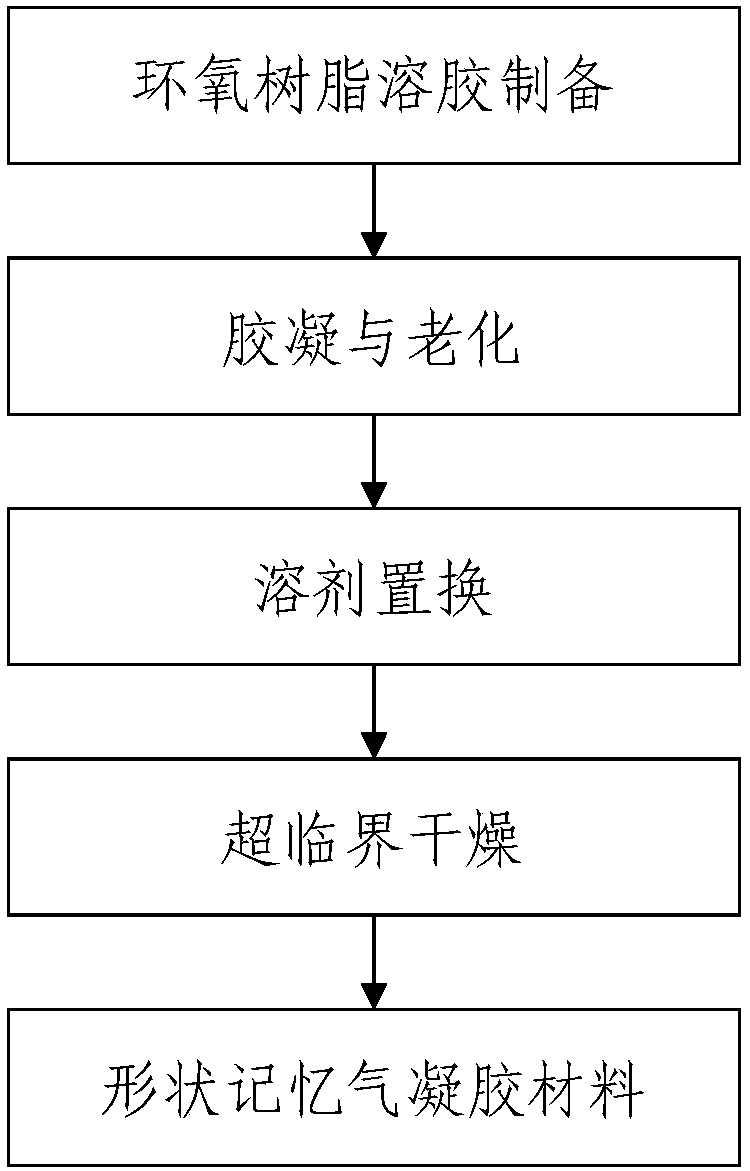

[0029] The present invention provides a kind of preparation method of shape memory airgel material in the first aspect, described method comprises the following steps:

[0030] (1) dissolving the shape memory resin in the first solvent to obtain a sol;

[0031] (2) adding a curing agent to the sol obtained in step (1) and stirring to a gel state to obtain a wet gel; and

[0032] (3) The wet gel obtained in step (2) is sequentially subjected to gelation, aging and solvent replacement steps to obtain an elastic gel, and then the elastic gel is dried to obtain a shape memory airgel material.

[0033] According to some preferred embodiments, the shape memory resin is a thermotropic shape memory resin, and the thermotropic shape memory resin is preferably bisphenol A epoxy resin (also known as bisphenol A diglycidyl ether); The first solvent is selected from the group consisting of N,N-dimethylformamide, acetone and ethanol; preferably, the first solvent is N,N-dimethylformamide; ...

Embodiment 1

[0050] ① Preparation of epoxy resin wet gel

[0051] Bisphenol A type epoxy resin (the trade mark is E-51) 5g is dissolved in the N of 50g, N-dimethylformamide (DMF) solvent, magnetic force stirs 10 minutes under room temperature, obtains sol; Slowly pour 0.88 g of curing agent triethylenetetramine (purity 69%) into the sol, stir slowly for 10 minutes, and dissolve in a transparent gel state to obtain a wet gel. Remove the ice bath and seal with a plastic wrap.

[0052] ②Gelation, aging and solvent replacement of wet gel

[0053] Place the wet gel prepared in ① not wrapped in plastic wrap in an oven at 60°C for 24 hours at a constant temperature, then take it out and let it stand at room temperature for 72 hours; add N,N-dimethylformamide every 24 hours (5mL) to prevent the gel from drying and cracking; separate the gel from the container boundary, take out the gel, and perform solvent replacement on the aged gel, first remove the excess solvent in the gel, add 10 times the v...

Embodiment 18

[0058] Embodiment 18 is basically the same as Embodiment 2, except that the curing agent is not added dropwise under the condition of ice bath.

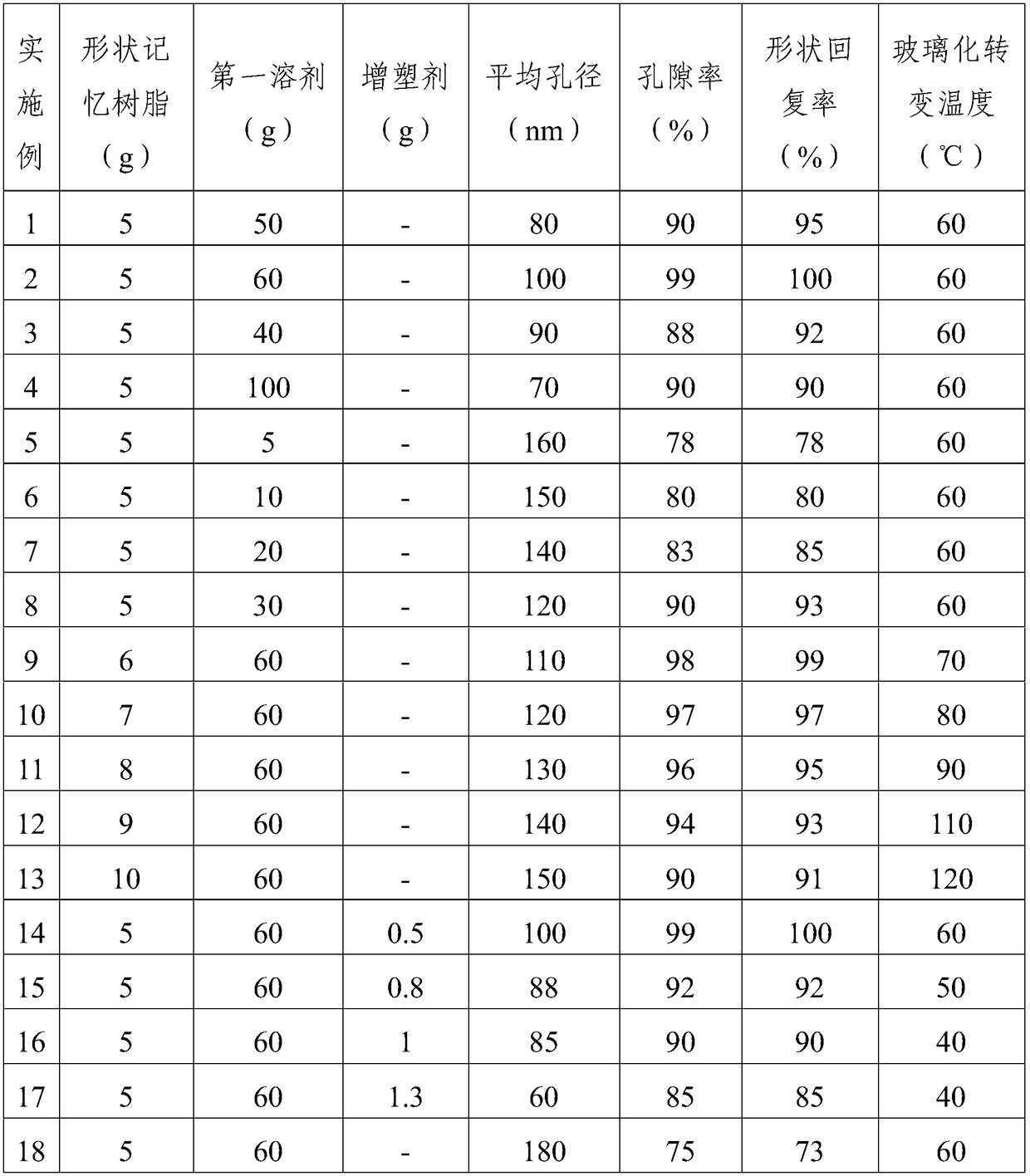

[0059] Table 1: Raw material ratios of Examples 1-18 and performance indexes of the prepared shape-memory airgel materials.

[0060]

[0061] In particular, the symbol - indicates that there is no such component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com