Shape self-repairing wave-absorbing material and preparation method thereof

A wave-absorbing material and self-repairing technology, which is applied in the field of wave-absorbing material preparation, can solve problems such as short service life, decline in wave-absorbing performance, and low durability, and achieve improved service life, good shape recovery rate, and high toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

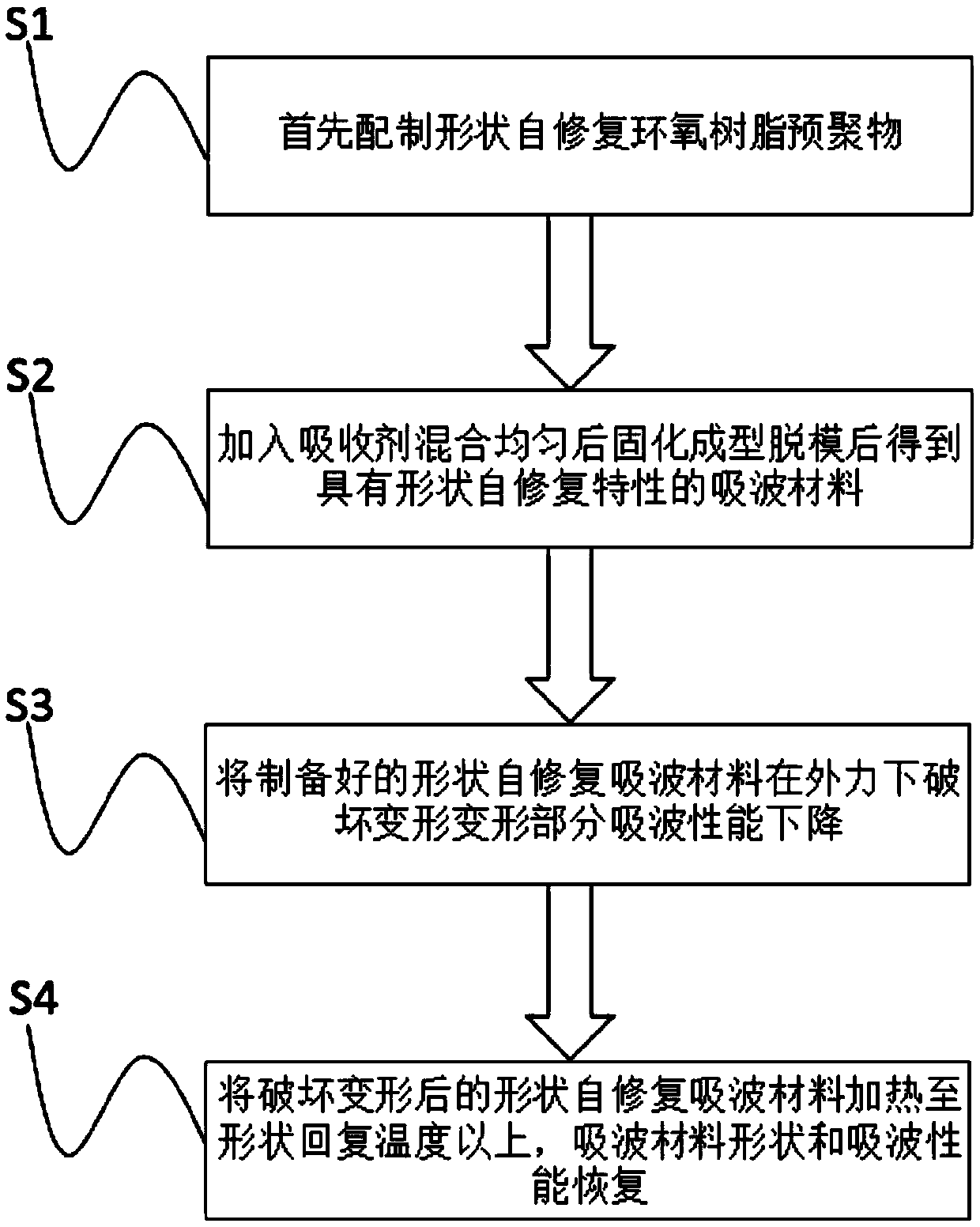

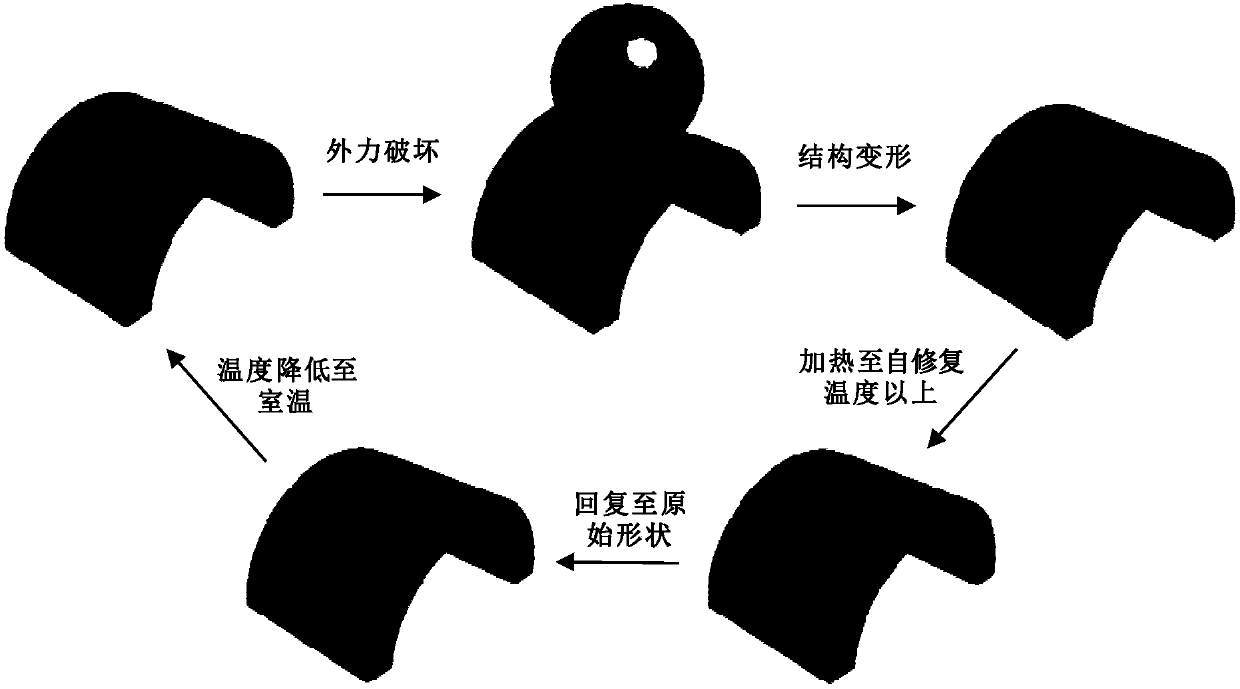

[0028] In the present invention, the preparation method of the shape self-repairing absorbing material includes the following steps:

[0029] (1) Set the mass ratio to 1: (0.02~0.33): (0.01~0.017) (for example, 1:0.02:0.01, 1:0.02:0.011, 1:0.02:0.012, 1:0.02:0.013, 1:0.02: 0.014, 1:0.02:0.015, 1:0.02:0.016, 1:0.02:0.017, 1:0.05:0.01, 1:0.05:0.011, 1:0.05:0.012, 1:0.05:0.013, 1:0.05:0.014, 1:0.05:0.015, 1:0.05:0.016, 1:0.05:0.017, 1:0.1:0.01, 1:0.1:0.011, 1:0.1:0.012, 1:0.1:0.013, 1:0.1:0.014, 1: 0.1:0.015, 1:0.1:0.016, 1:0.1:0.017, 1:0.2:0.01, 1:0.2:0.011, 1:0.2:0.012, 1:0.2:0.013, 1:0.2:0.014, 1:0.2: 0.015, 1:0.2:0.016, 1:0.2:0.017, 1:0.33:0.01, 1:0.33:0.011, 1:0.33:0.012, 1:0.33:0.013, 1:0.33:0.014, 1:0.33:0.015, 1:0.33:0.016 or 1:0.33:0.017) resin matrix, toughening agent (such as monoamine toughening agent) and curing agent (such as diamine curing agent) are mixed uniformly to obtain a resin prepolymer, the The resin matrix is selected from the group consisting of epo...

Embodiment 1

[0055] ① Weigh the corresponding mass of epoxy resin (E-51) and n-octylamine according to the mass ratio of 1:0.31, put them into an oven and heat to 80°C, and keep at constant temperature for 20min.

[0056] ②Then mix the epoxy resin with n-octylamine, stir evenly, add m-xylylenediamine, the mass ratio of m-xylylenediamine to epoxy resin is 0.017:1, stir again evenly, and obtain the resin prepolymer.

[0057] ③ Next, add the carbonyl iron powder absorbent into the resin prepolymer in four times and stir evenly. The amount of carbonyl iron powder added is 50% of the mass of the epoxy resin to obtain a shape self-repairing wave-absorbing resin.

[0058] ④Then put the shape self-repairing wave-absorbing resin into the vacuum oven for 10 minutes to remove the air bubbles in the system, and then inject it into the metal mold that has been preheated and coated with a release agent, and then evacuate again 10min, and heat curing, the specific curing system is: 60 ℃ / 1h + 100 ℃ / 2h...

Embodiment 2

[0062] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0063] In ①, according to the mass ratio of 1:0.33, weigh the corresponding mass of epoxy resin (E-51) and n-octylamine respectively, put them into an oven and heat to 80°C, and keep at constant temperature for 20min.

[0064] In ②, then mix the epoxy resin with n-octylamine, stir evenly and add m-xylylenediamine, the mass ratio of m-xylylenediamine to epoxy resin is 0.01:1, stir again evenly to obtain resin prepolymerization thing.

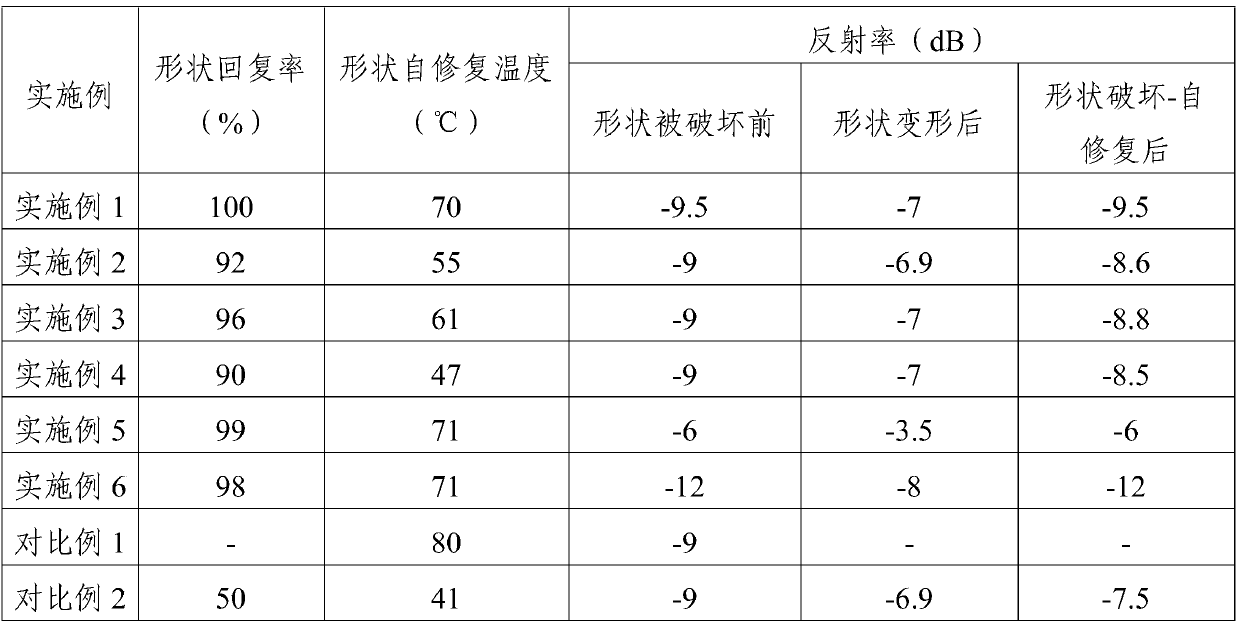

[0065] Using the same method as in Example 1, the shape self-repairing performance of the shape self-repairing absorbing material prepared in this example is tested, and the results are shown in Table 1. The shape self-repairing absorbing material prepared in this example is Before the shape is destroyed, the reflectivity value at 3GHz is -9dB. After the shape is compressed and deformed, the reflectivity value at 3GHz increases to -6.9dB. After the shape self-repair,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com