A kind of dialdehyde nanocellulose three-dimensional flexible material and its preparation method and application

A nanocellulose, three-dimensional technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., to achieve the effect of rich aldehyde group content, good compressibility and high stress retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

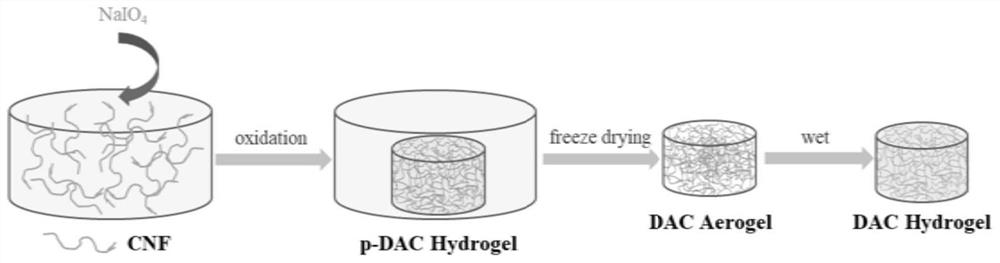

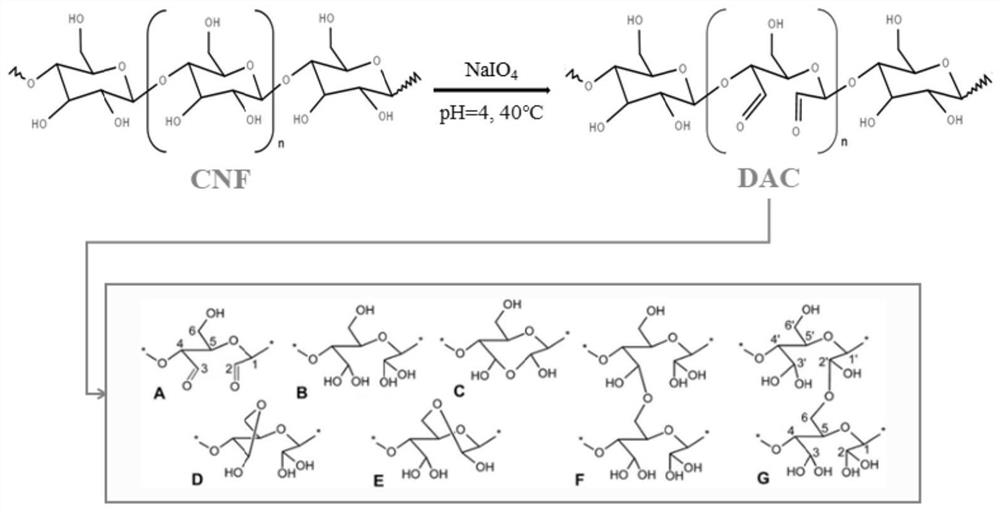

[0053] (1) A cellulose nanofiber (CNF, Beijing North Tianchen Technology Co., Ltd., model: TC-UCN-001) aqueous dispersion with a concentration of 0.6 wt% was prepared. In the beaker, add sodium periodate (NaIO) with a mass of 1.5 g 4 ) and 50 mL of CNF aqueous dispersion, adjust the pH to 4 with 1% hydrochloric acid, stir for 10 minutes and mix well, and then ultrasonically disperse for 20 minutes. Then, the sol was placed in a water bath shaker in the dark, the reaction temperature was 40°C, and the reaction time was 5 hours. After the reaction, the initial hydrogel was repeatedly soaked in deionized water, and finally treated with liquid nitrogen, and dried in a freeze dryer for 48 hours to obtain an aerogel product.

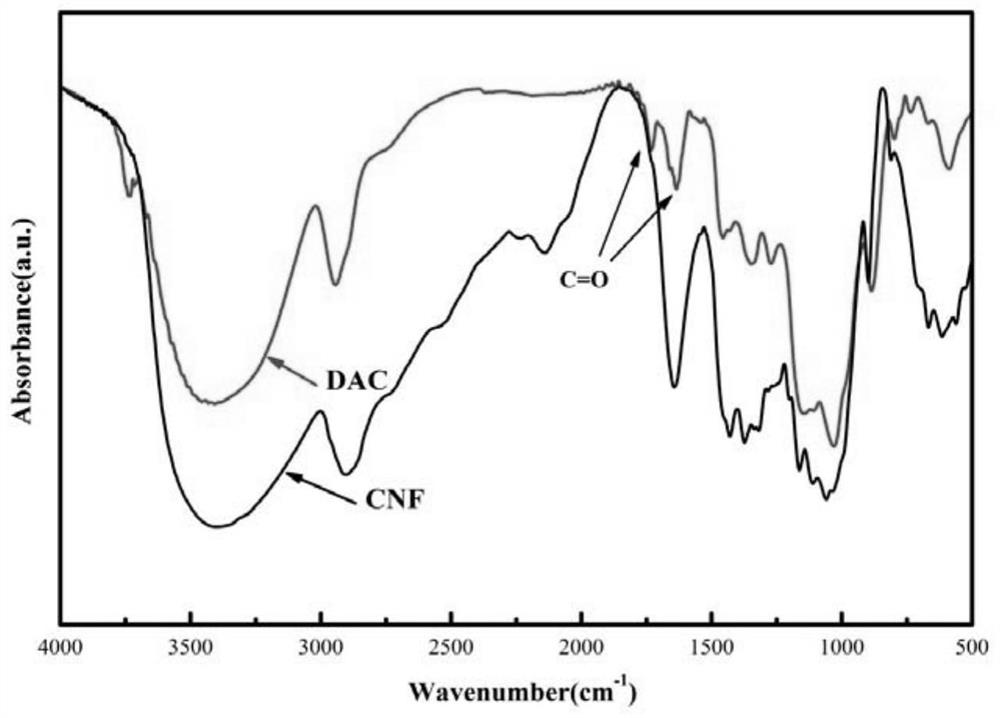

[0054] (2) The obtained aerogel product was soaked in deionized water, repeatedly squeezed and washed with water to remove the reaction by-products remaining in the interior to obtain a dialdehyde nanocellulose hydrogel. The infrared spectrum is shown in im...

Embodiment 2

[0058] (1) The aqueous dispersion of cellulose nanofibers (CNF, Beijing North Tianchen Technology Co., Ltd., model: TC-UCN-001) with a concentration of 0.6 wt% was prepared, and sodium periodate (1.0 g) was added to the beaker. NaIO 4 ) and 50 mL of CNF aqueous dispersion, adjust the pH to 4 with 1% hydrochloric acid, stir for 10 minutes and mix well, and then ultrasonically disperse for 20 minutes. Then, the sol was placed in a water bath shaker in the dark, the reaction temperature was 40°C, and the reaction time was 10 hours. After the reaction, the initial hydrogel was repeatedly soaked in deionized water, and finally treated with liquid nitrogen, and dried in a freeze dryer for 48 hours to obtain an aerogel product.

[0059] (2) The obtained aerogel product is soaked in deionized water, squeezed and washed repeatedly, and the reaction by-products remaining in the interior are removed to obtain a dialdehyde nanocellulose hydrogel.

[0060] (3) The dialdehyde nanocellulos...

Embodiment 3

[0063] (1) A cellulose nanofiber (CNF, Beijing North Tianchen Technology Co., Ltd., model: TC-UCN-001) aqueous dispersion with a concentration of 1.0 wt% was prepared, and sodium periodate (3.0 g) was added to the beaker. NaIO 4 ) and 50 mL of CNF aqueous dispersion, adjust the pH to 4 with 1% hydrochloric acid, stir for 10 minutes and mix well, and then ultrasonically disperse for 20 minutes. Then, the sol was placed in a water bath shaker in the dark, the reaction temperature was 40°C, and the reaction time was 24 hours. After the reaction, the initial hydrogel was repeatedly soaked in deionized water, and finally treated with liquid nitrogen, and dried in a freeze dryer for 24 hours to obtain an aerogel product.

[0064] (2) The obtained aerogel product is immersed in deionized water, and repeatedly squeezed and washed to remove the reaction by-products remaining in the interior to obtain the desired hydrogel product.

[0065] (3) The dialdehyde nanocellulose hydrogel has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com