Production method of silk cotton wadding material

A manufacturing method and floc technology, which are applied in non-woven fabrics, textiles, papermaking, adhesives, etc., can solve the problems of poor lasting resilience, low strength of floc products, attenuation of warmth and comfort functions, and improve compression resilience, Efficient warmth retention and lightweight properties, enhanced flock strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

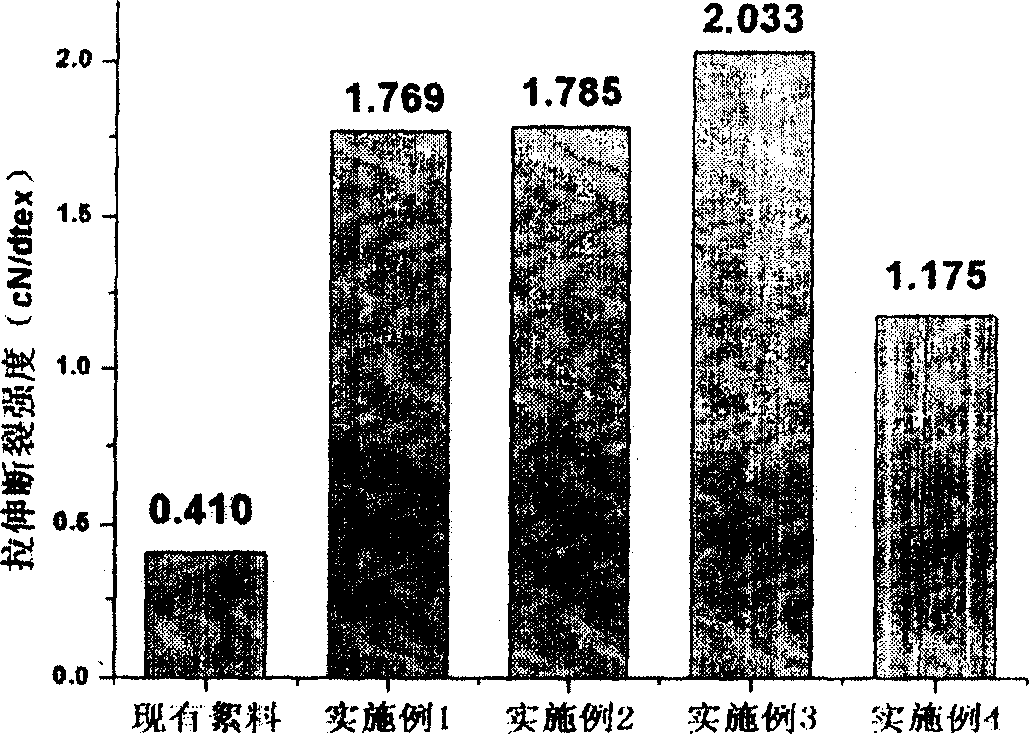

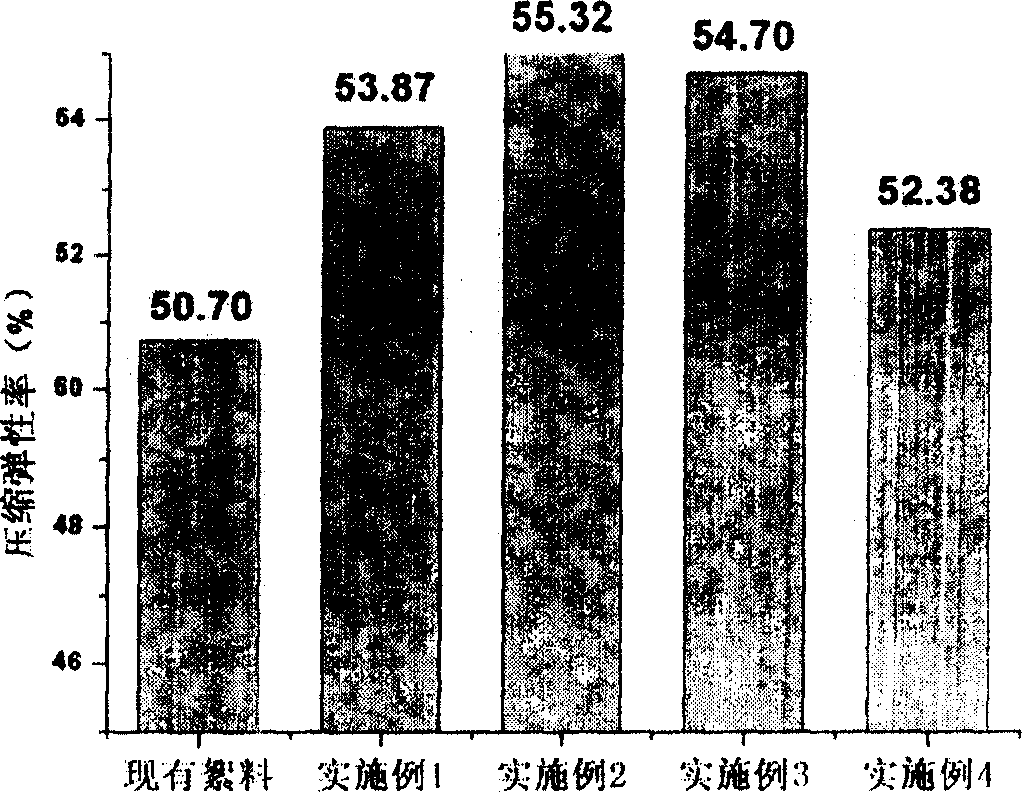

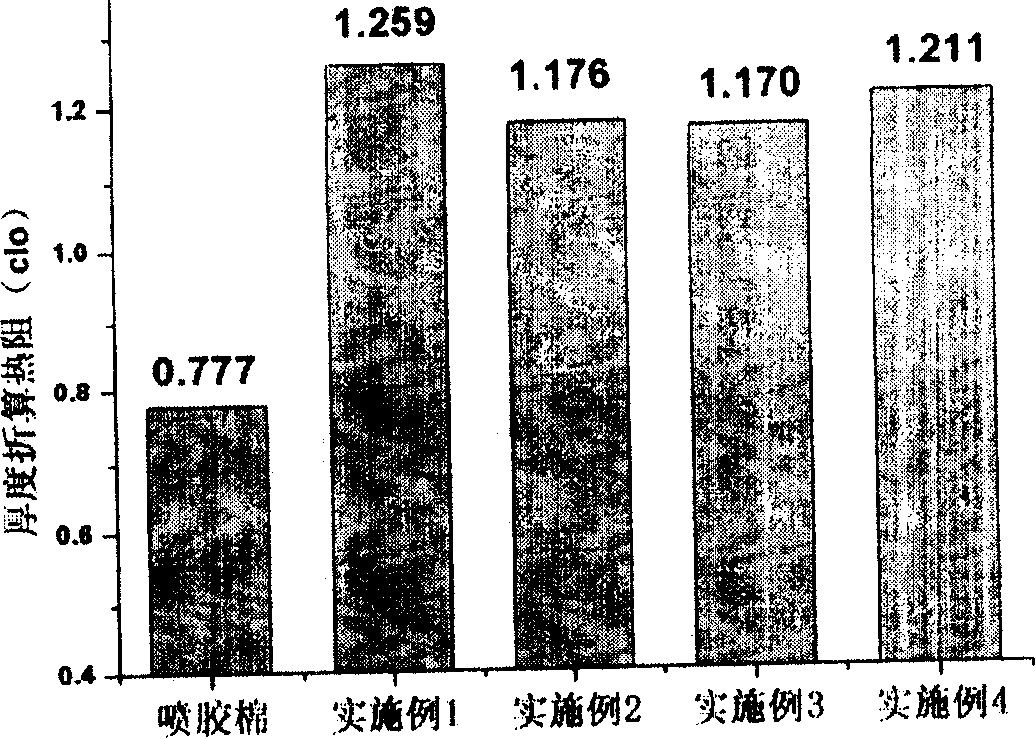

Embodiment 1

[0028] 80% kapok fiber, 20% polypropylene / polyethylene sheath-core composite (ES) fiber mixed and opened → air-laid → hot melt bonding;

Embodiment 2

[0030] 50% kapok fiber, 30% four-hole three-dimensional crimped hollow polyester, 20% polypropylene / polyethylene sheath-core composite (ES) fiber mixed and opened → air-laid → hot melt bonding;

Embodiment 3

[0032] 50% kapok fiber, 30% seven-hole three-dimensional crimped hollow polyester, 20% polypropylene / polyethylene sheath-core composite (ES) fiber mixed and opened → air-laid → hot melt bonding;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com