Seals and Compression Packers

A technology of seals and seals, which is applied in the direction of sealing/seal, engine seals, engine components, etc., can solve the problems of seals that cannot be sealed, and achieve the effects of preventing insufficient deformation, increasing deformation capacity, and improving compression resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

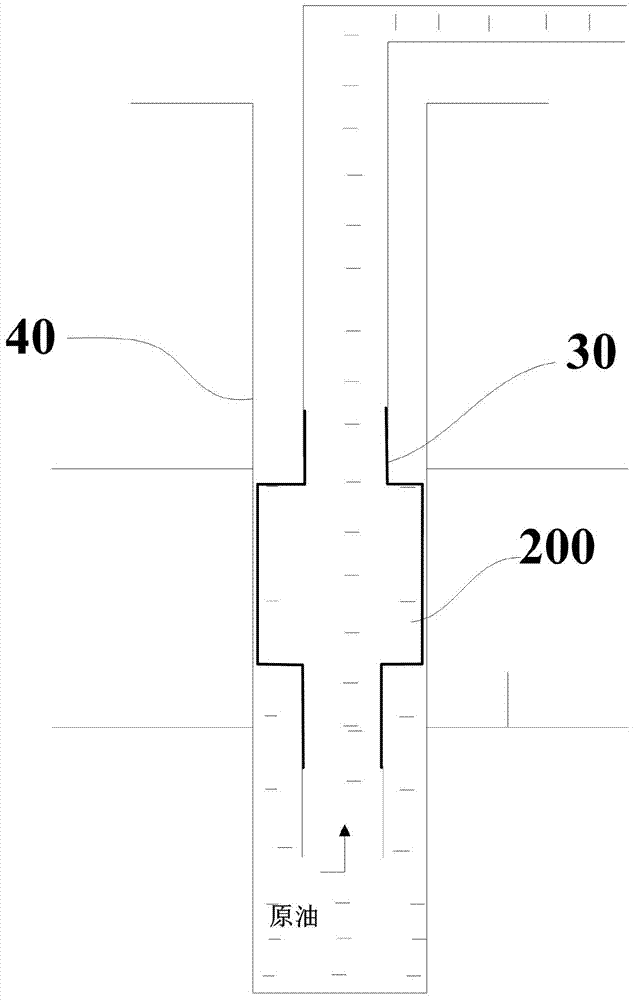

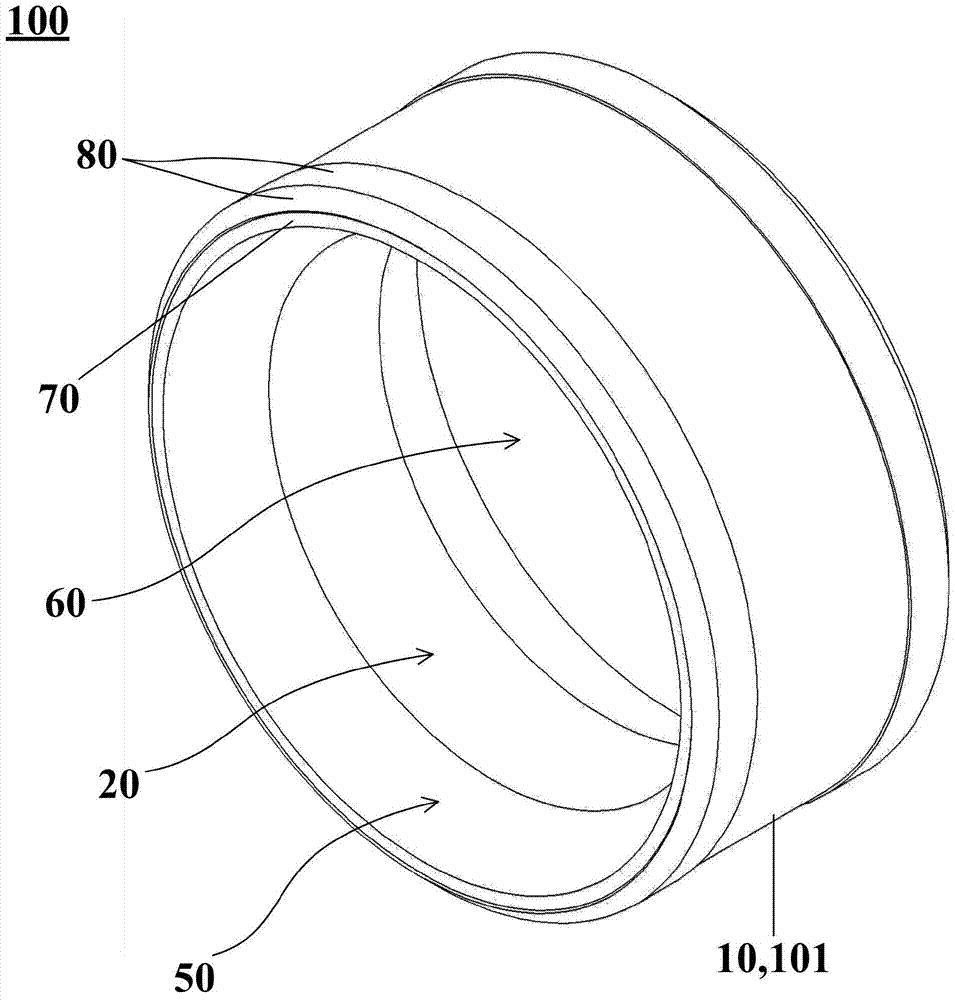

[0051] Such as figure 2 As shown, the present invention provides a seal 100, the seal 100 basically includes a ring-shaped elastic seal body 20, the seal body 20 includes a through hole 60, a sealing surface 101, an inner force-bearing surface 50, a shaft To the force surface 70.

[0052] Wherein, the through hole 60 runs through the sealing body 20 . The through hole 60 can be slidably connected with a through shaft, that is, the through shaft is sleeved in the through hole 60 to limit the overall movement direction of the sealing body 20 to the axial direction.

[0053] Wherein, the sealing surface 101 is formed on the axially extending outer surface 10 of the sealing body 20 .

[0054] Wherein, the inner force-bearing surface 50 is formed on the inner surface extending axially of the sealing body 20 and is close to the end of the sealing body 20, the inner force-bearing surface 50 is arranged around the through hole 60, so The inner force-receiving surface 50 shrinks gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com