Lightweight compression-resistant warp-knitted elastic imitation leather fabric and preparation process thereof

An anti-compression and warp knitting technology, applied in the field of warp-knitted leather-like fabrics and its production, can solve the problems such as the large difference in the degree of shrinkage between the surface layer and the base layer, and the wrinkle of the fabric, so as to improve the wrinkle phenomenon, enhance the compression resilience, and Simple and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

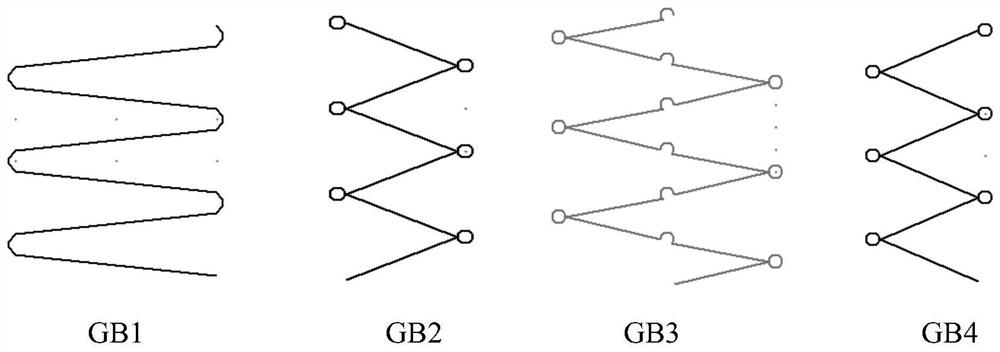

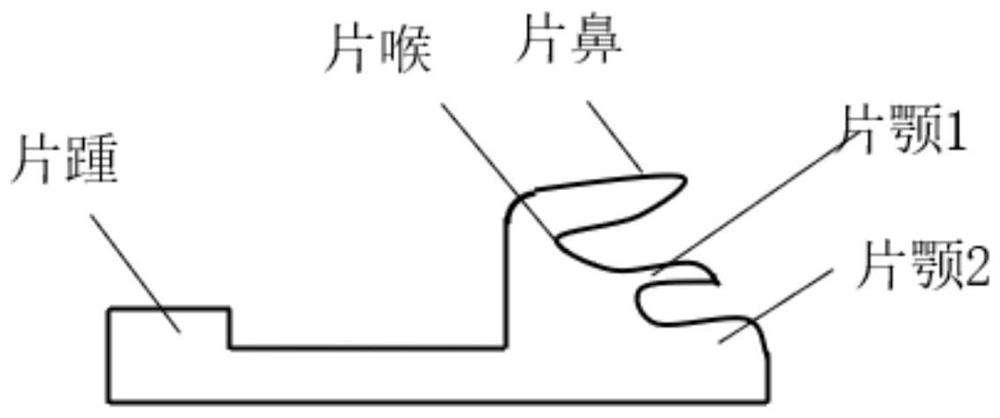

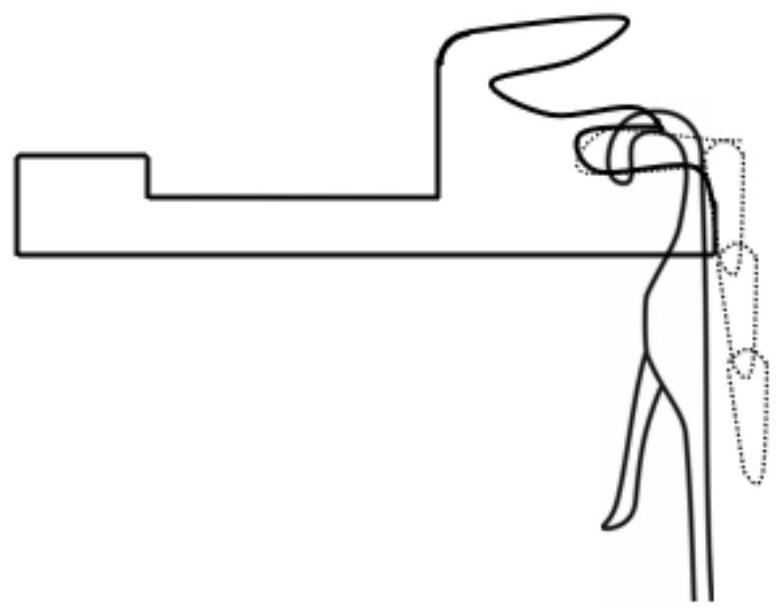

Method used

Image

Examples

Embodiment 1

[0049] A light-weight anti-compression warp-knitted elastic imitation leather fabric is obtained by compounding a warp-knitted sandwich structure fabric and elastic polyurethane coating, wherein the warp-knitted sandwich structure fabric is composed of the following mass percentage components: 100D PBT / PET composite yarn 32s cotton yarn is 37.1%, 30D monofilament polyester is 19.7%, 100D semi-gloss polyester DTY is 22.6%;

[0050] Concrete preparation process is as follows:

[0051] 1. Preparation process

[0052] Choose 100D PBT / PET composite yarn, 30D polyester monofilament, 32s cotton yarn, 75D36F semi-gloss polyester DTY, 100D semi-gloss polyester DTY.

[0053] 2. Warping process

[0054] Temperature and humidity at the warping site: temperature 25±2°C, relative humidity 65±3%, high and stable temperature and humidity are conducive to the generation of cotton yarn fly, polyester fiber surface is soft, less static electricity, avoid polyester fiber warping at high speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com