Floating mechanism of reactor

A reactor and floating bucket technology, applied in the field of floating mechanisms, can solve problems such as troublesome operation, and achieve the effects of convenient adjustment, improved binding capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

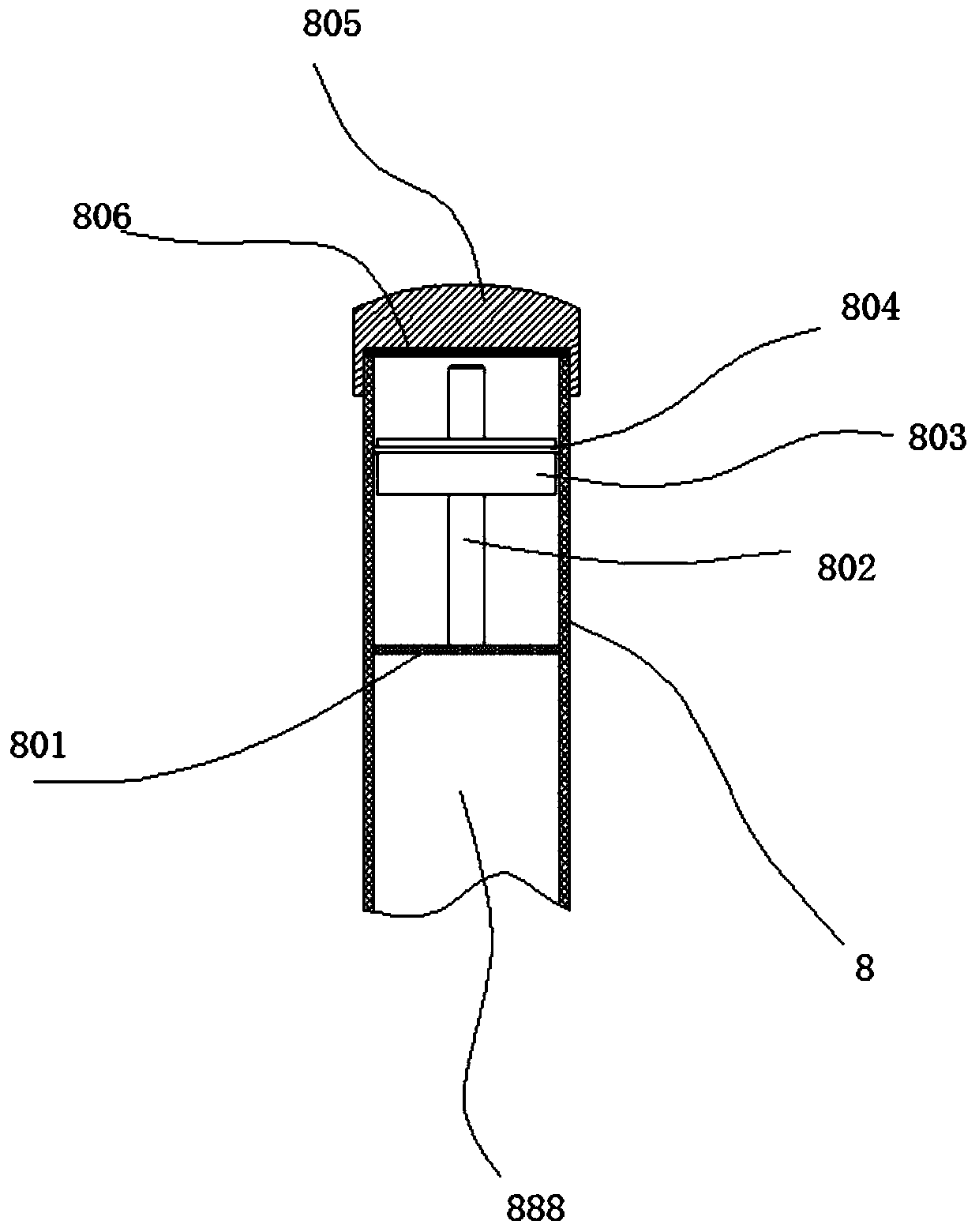

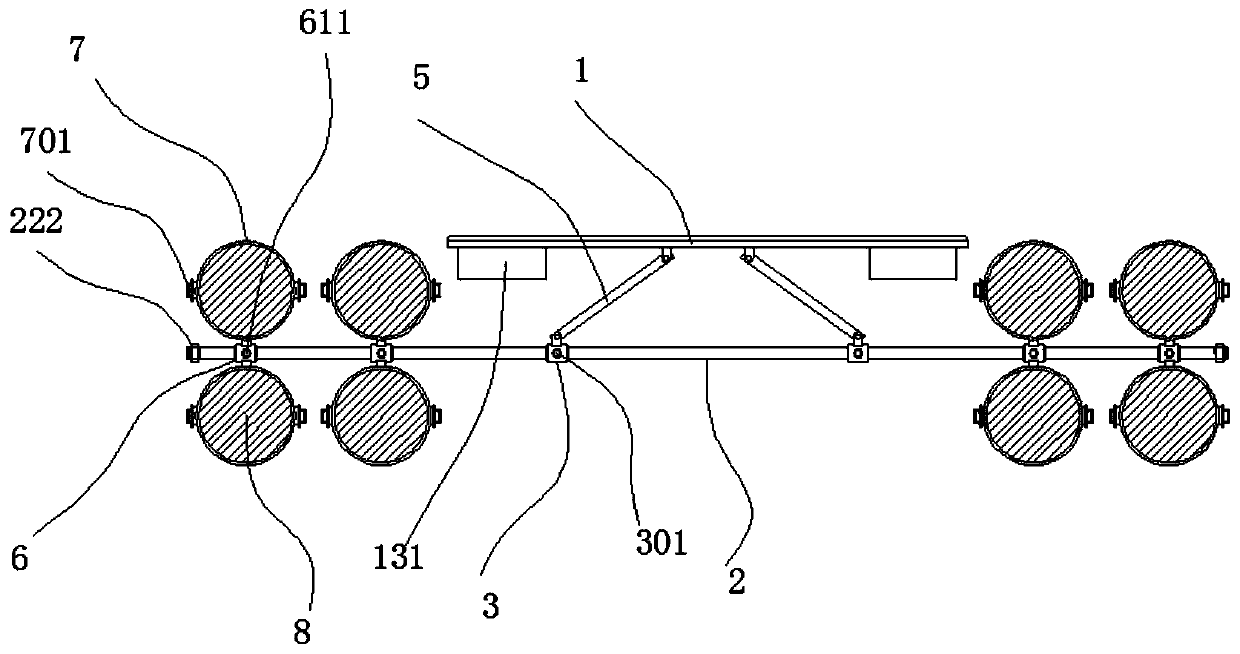

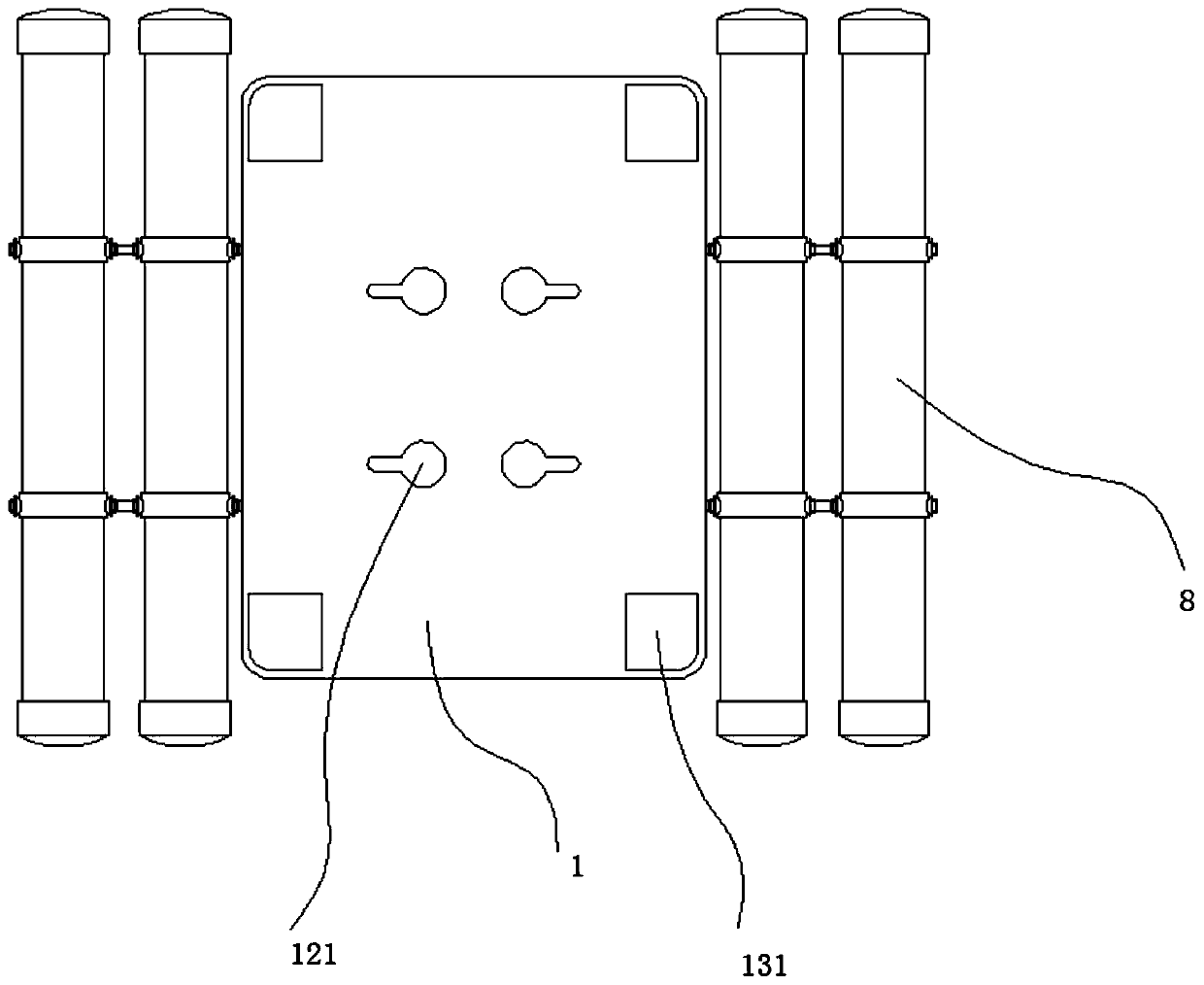

[0056] Such as figure 1 , figure 2 , image 3 with Figure 4 The floating mechanism of a reactor shown includes a frame plate 1, two horizontal rods 2 are arranged below the frame plate 1, and the two horizontal rods 2 are arranged in front and rear in parallel. Two sliding sleeves 3 are provided on each of the cross bars 2, a connecting rod 4 is welded between the front and rear sliding sleeves 3, and a screw 301 is fitted between the sliding sleeve 3 and the cross bar 2. A first connecting rod 5 is hinged between the frame plate 1 and the sliding sleeve 3, and a first sliding sleeve 6 is mounted on the cross bar 2. The upper and lower ends of the first sliding sleeve 6 are A ring body 7 for fixing is welded, a floating bucket 8 is installed between the ring bodies 7 on the front and rear sides, and a first screw 701 is installed between the ring body 7 and the floating bucket 8. A second screw 611 is installed between a sliding sleeve 6 and the cross bar 2, and a hole 121 fo...

Embodiment 2

[0063] Such as figure 1 , figure 2 , image 3 with Figure 4 The floating mechanism of a reactor shown includes a frame plate 1, two horizontal rods 2 are arranged below the frame plate 1, and the two horizontal rods 2 are arranged in front and rear in parallel. Two sliding sleeves 3 are provided on each of the cross bars 2, a connecting rod 4 is welded between the front and rear sliding sleeves 3, and a screw 301 is fitted between the sliding sleeve 3 and the cross bar 2. A first connecting rod 5 is hinged between the frame plate 1 and the sliding sleeve 3, and a first sliding sleeve 6 is mounted on the cross bar 2. The upper and lower ends of the first sliding sleeve 6 are A ring body 7 for fixing is welded, a floating bucket 8 is installed between the ring bodies 7 on the front and rear sides, and a first screw 701 is installed between the ring body 7 and the floating bucket 8. A second screw 611 is installed between a sliding sleeve 6 and the cross bar 2, and a hole 121 fo...

Embodiment 3

[0076] Such as figure 1 , figure 2 , image 3 with Figure 4 The floating mechanism of a reactor shown includes a frame plate 1, two horizontal rods 2 are arranged below the frame plate 1, and the two horizontal rods 2 are arranged in front and rear in parallel. Two sliding sleeves 3 are provided on each of the cross bars 2, a connecting rod 4 is welded between the front and rear sliding sleeves 3, and a screw 301 is fitted between the sliding sleeve 3 and the cross bar 2. A first connecting rod 5 is hinged between the frame plate 1 and the sliding sleeve 3, and a first sliding sleeve 6 is mounted on the cross bar 2. The upper and lower ends of the first sliding sleeve 6 are A ring body 7 for fixing is welded, a floating bucket 8 is installed between the ring bodies 7 on the front and rear sides, and a first screw 701 is installed between the ring body 7 and the floating bucket 8. A second screw 611 is installed between a sliding sleeve 6 and the cross bar 2, and a hole 121 fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com