Graphene conductive elastomer and its preparation method and sensor

A graphene and elastomer technology, applied in the field of sensors, can solve the problems of poor induction of small deformation, limited detection range, low sensitivity, etc., and achieve the effect of increasing elasticity, improving detection range and good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The embodiment of the present invention also provides a preparation method of the graphene conductive elastomer of the above embodiment, comprising:

[0049] S100, providing an elastic matrix 100, the elastic matrix 100 has at least partially interconnected holes 102 therein;

[0050] S200, immersing the elastic matrix 100 in a mold equipped with a graphene aqueous dispersion for freeze molding to obtain a graphene frozen ice-like composite structure of the elastic matrix 100; and

[0051] S300, freeze-drying the graphene frozen ice-like composite structure of the elastic matrix 100 at -200°C to -40°C to form graphene gas condensation in the graphene frozen ice-like structure in the interconnected holes 102 Glue the 3D network structure.

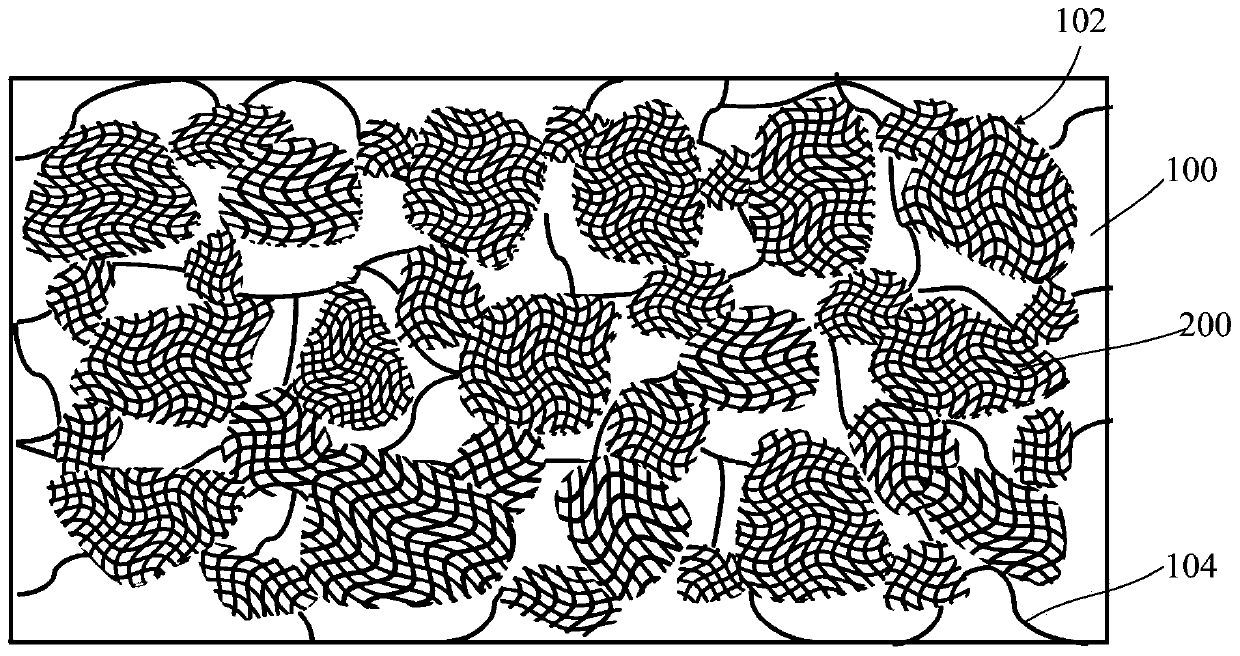

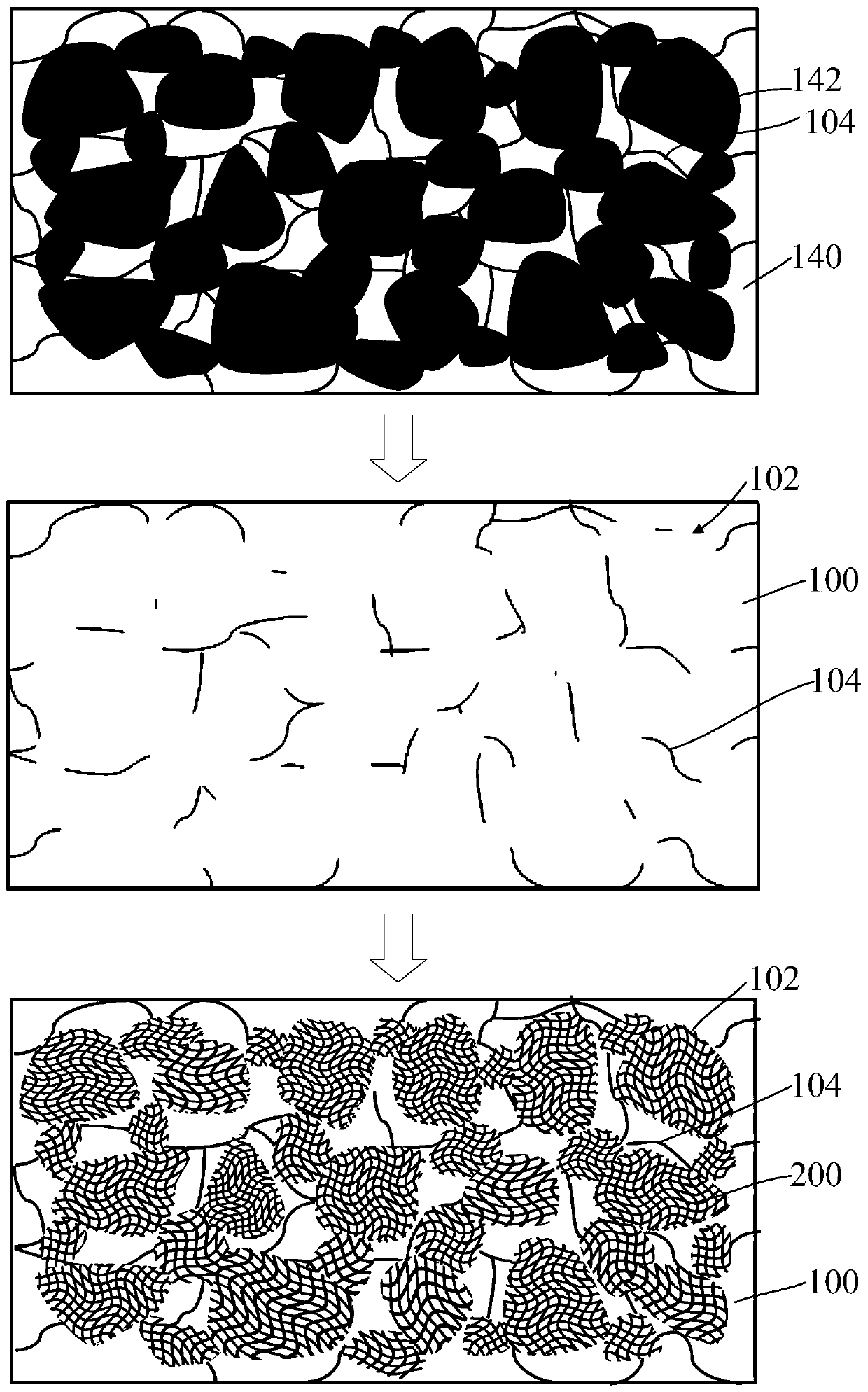

[0052] In a specific embodiment, the preparation process of graphene conductive elastomer can refer to figure 2 shown.

[0053] In step S100, the preparation method of the elastic matrix 100 having a multi-interconnected structure...

Embodiment 1

[0072] (1) 10g of two-component polydimethylsiloxane, 0.3g of graphene, 5g of ethyl acetate, and 50g of sodium chloride were mixed and stirred evenly, and after centrifugal defoaming using a centrifuge, they were packed into a plastic mold and placed in a plastic mold. Curing at a constant temperature in an oven at 50° C. for 24 hours to obtain an elastic matrix preform 140 .

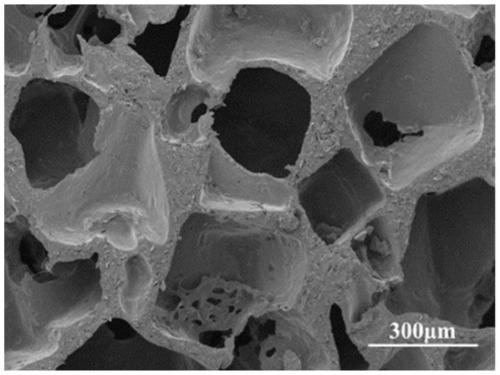

[0073] (2) Place the cured elastic matrix preform 140 in water, wash at 80° C. for 24 hours, and remove the sodium chloride particles in the elastic matrix preform 140 . Then place it in an organic solvent (ethanol) and wash at 30° C. for 1 hour to remove other impurities in the material. Dry the material after the organic solvent treatment overnight to obtain a spongy elastic matrix 100 with a spongy-like structure. For the microstructure, please refer to Figure 3A and Figure 3B shown.

[0074] (3) Add 0.2 g of graphene oxide and 0.4 g of ascorbic acid into 100 mL of water to form a graphene aqueo...

Embodiment 2

[0078] (1) Mix and stir 10g of silicone rubber, 0.3g of copper nanowires, 5g of polythiophene, and 70g of sodium chloride evenly, use a centrifuge to defoam, put it into a plastic mold, and cure at a constant temperature in an oven at 50°C for 24h An elastic matrix preform 140 is obtained.

[0079] (2) Place the cured elastic matrix preform 140 in water, wash at 80° C. for 24 hours, and remove the sodium chloride particles in the elastic matrix preform 140 . Then place it in an organic solvent (ethanol) and wash at 30° C. for 1 hour to remove other impurities in the material. The material treated with the organic solvent was dried overnight to obtain the elastic matrix 100 with a sponge-like structure.

[0080] (3) Add 1 g of graphene oxide and 1 g of hydrazine hydrate into 100 mL of water to form a graphene aqueous dispersion. The spongy elastic matrix 100 is immersed into the mold containing the graphene aqueous dispersion, so that the graphene aqueous dispersion is fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com