Environment-friendly type polyimide-based high temperature-resistant adhesive and preparation method thereof

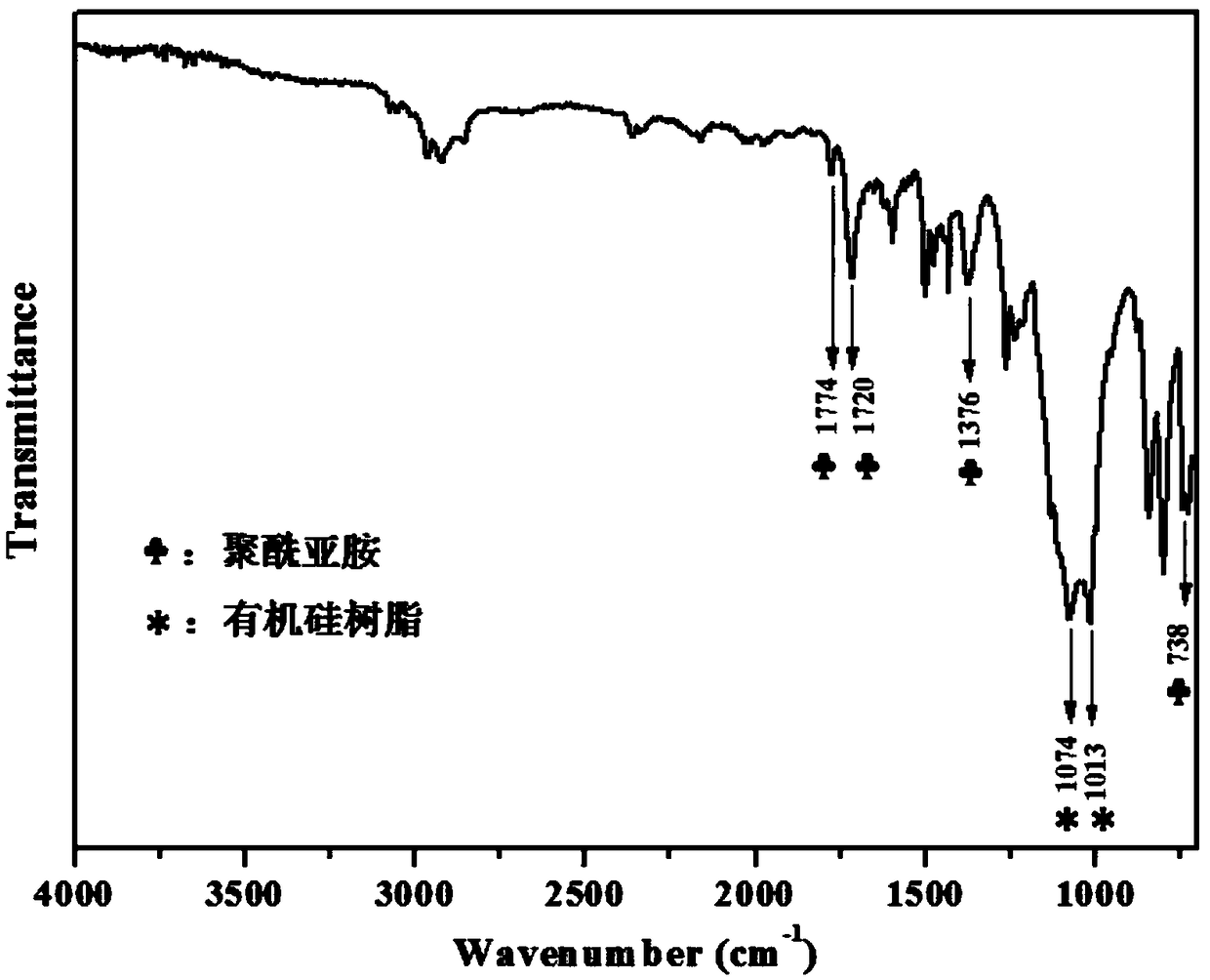

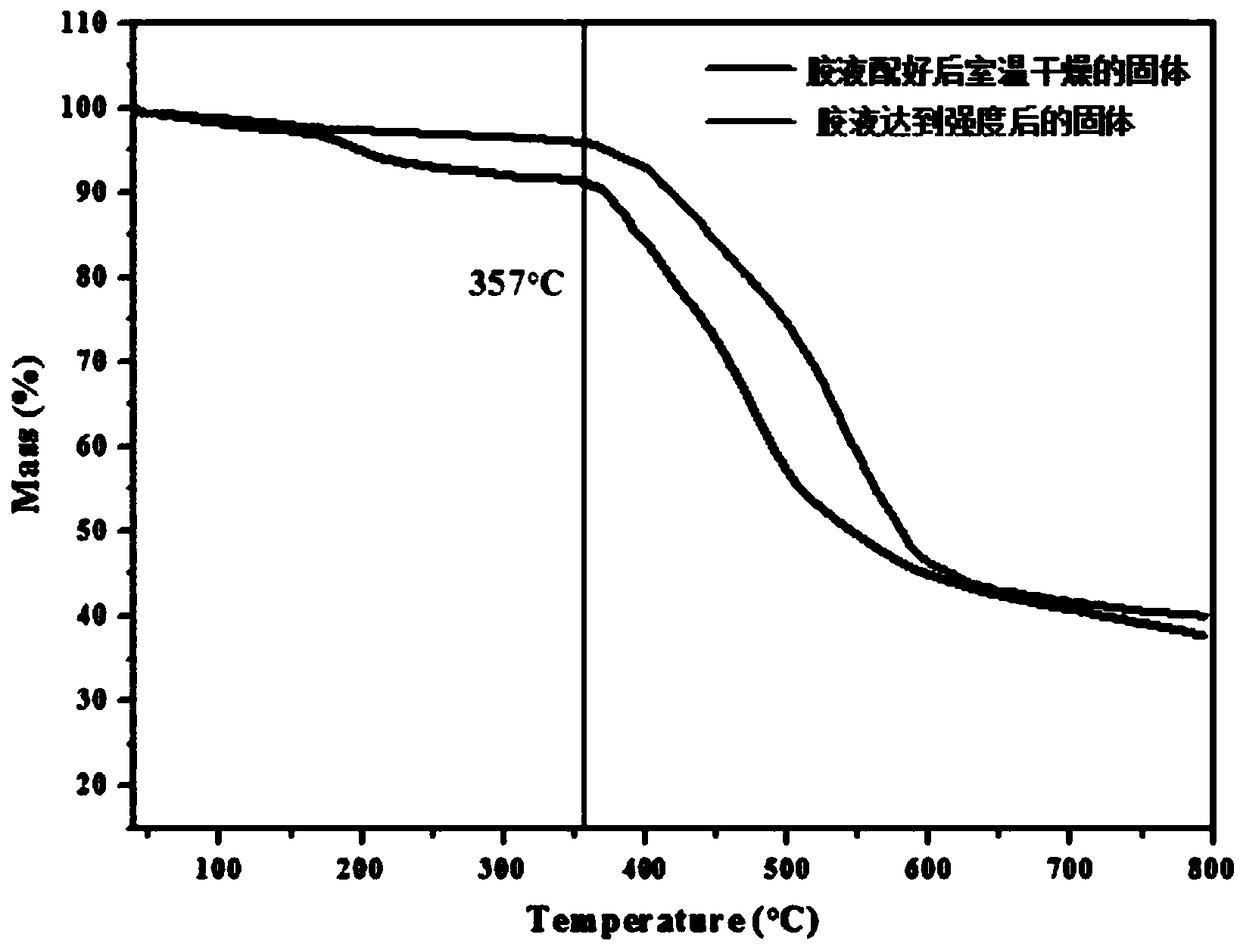

A high-temperature-resistant adhesive and polyimide-based technology, applied in the direction of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems of volatile rigidity and brittleness, achieve low volatility, improve resistance Effects of improving thermal performance and shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

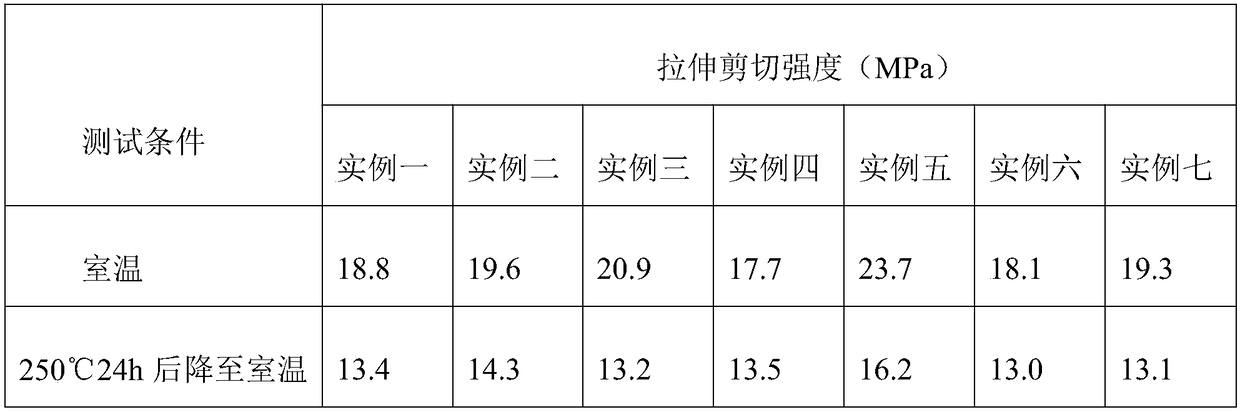

Examples

Embodiment 1

[0028] Add 10 g (0.05 mol) of 4,4'-diaminodiphenyl ether and 104.4 g of dimethylacetamide into the three-necked flask, start mechanical stirring and fill with nitrogen protection, place the three-necked flask in an ice-water bath, and wait for 4,4' -After the diaminodiphenyl ether is completely dissolved, slowly add 16.1g (0.05mol) of 3,3',4,4'-benzophenone tetracarboxylic dianhydride into the three-necked flask in small amounts several times, and keep the ice-water bath for 12 hours to obtain Viscous homogeneous solution, then add 15.15g (0.15mol) triethylamine, stir at room temperature for 2h; then slowly pour into 700ml acetone with a rotation speed of 1000rpm, filter and collect the precipitate, vacuum dry at room temperature for 2h; take 20g of dried powder Add 80g of water, stir at 3000rpm for 1h to form a transparent viscous aqueous solution, continue to add 20g of methylphenyl silicone aqueous dispersion with a solid content of 50wt%, stir at 10000rpm for 2h, and finall...

Embodiment 2

[0030] Compared with Example 1, except that the diamine was replaced by 9.4 g (0.05 mol) of 2,5-diaminobenzenesulfonic acid, other processes remained unchanged.

Embodiment 3

[0032] Compared with Example 1, except that the dianhydride was replaced by 16.2 g (0.05 mol) of 3,3',4,4'-diphenylmethanol tetraacid dianhydride, other processes remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com