Nonasbestos mixed fiber enhanced rubber base sealing composite materials and method for making same

A composite material and fiber-reinforced technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of poor aging performance, stress relaxation resistance, high manufacturing cost, etc., and achieve the effect of low sealing performance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

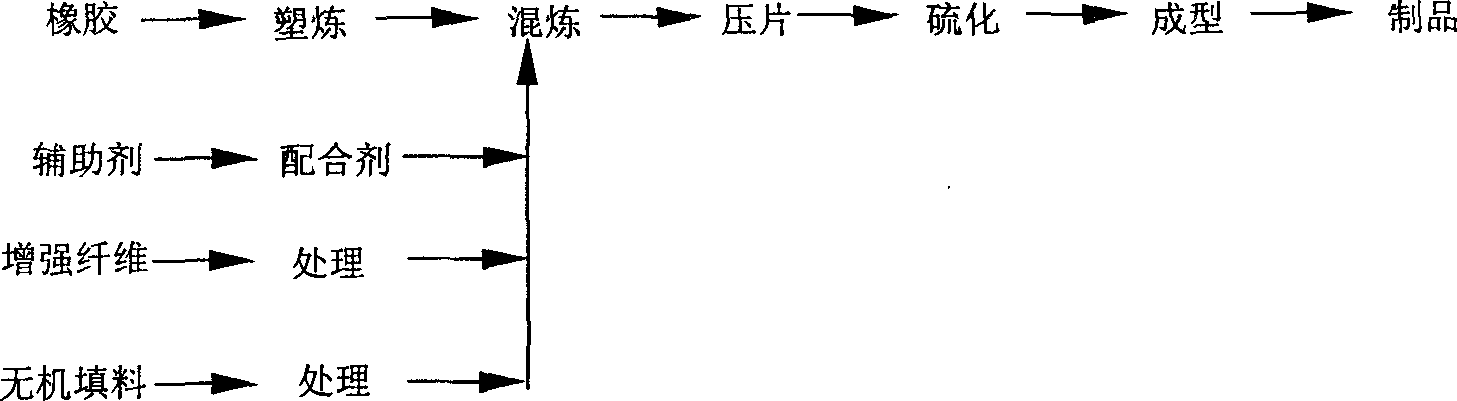

Method used

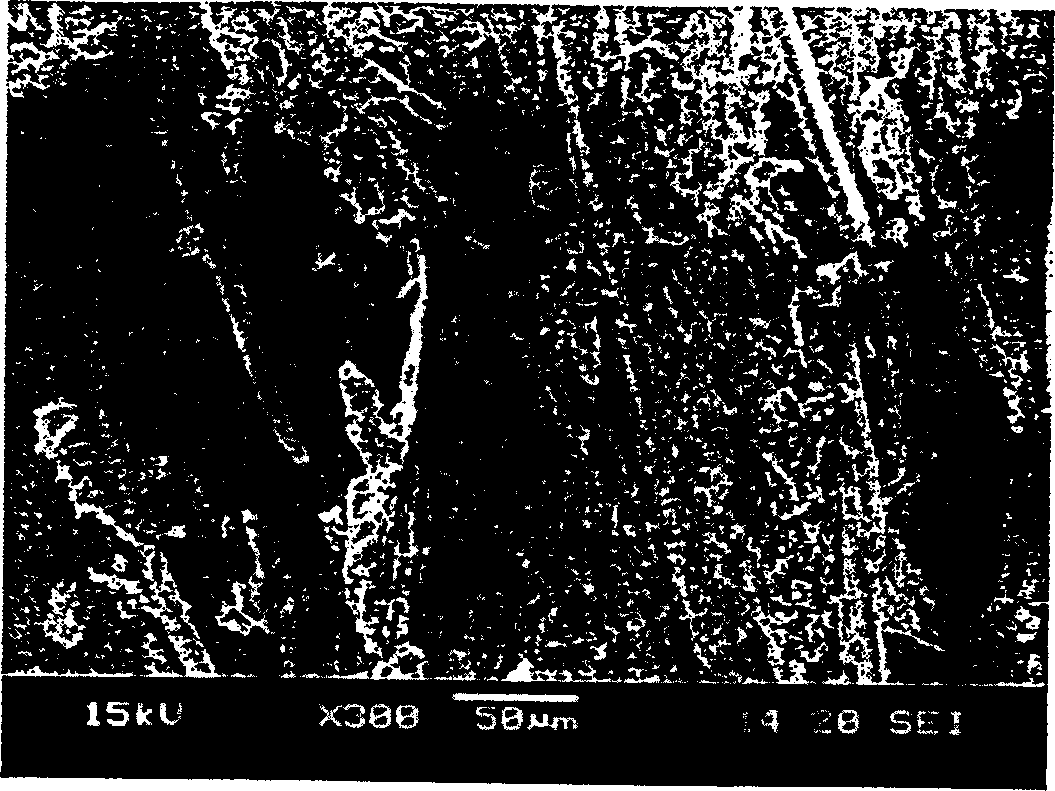

Image

Examples

Embodiment 1

[0162] NAFC material composition ratio 1 (as shown in the table below):

[0163] Composition ratio of NAFC1

[0164] Composition by weight (%) Composition by weight (%)

[0165] NBR-26 9.75 calcium carbonate

[0166] 8.2

[0167] NR 5.25 filled with kaolin

[0168] 2.5

[0169] Aramid 1313 fiber 6.0 Material Talc powder

[0170] 1.8

[0171] Pre-Oxidized Silk Fiber 9.0 White Carbon Black

[0172] 3.5

[0173] Sepiolite fiber 58.42

[0174] Antiaging agent 0.38

[0175] Vulcanizing agent 0.34

[0177] Accelerator TT 0.07

[0178] Stearic acid 0.5

[0179] Accelerator DM 0.12

[0180] Main process parameters: ...

Embodiment 2

[0189] NAFC material composition ratio 2 (see table below):

[0190] Composition ratio of NAFC 2

[0191] Composition by weight (%) Composition by weight (%)

[0192] NBR-26 6.825 Calcium Carbonate 7.0

[0193] NR 3.675 Filled Kaolin 3.0

[0194] Aramid 1313 fiber 8.55 material Talc powder 2.0

[0195] Pre-oxidized silk fiber 6.05 White carbon black 3.0

[0196] Sepiolite fiber 58.42 Anti-aging agent 0.26

[0197] Vulcanizing agent 0.27 Zinc oxide 0.53

[0198] Accelerator 0.1 Stearic acid 0.32

[0199] Main process parameters:

[0200] Plasticizing time: 15min

[0201] Mixing time: 20min

[0202] Vulcanization time: 10min

[0203] Vulcanization temperature: 145±5℃

[0204] Vulcanization pressure: 16±2MPa

[0205] NAFC material transverse tensile strength test results:

[0206] project

Embodiment 3

[0208] NAFC material composition ratio 3 (as shown in the table below):

[0209] Composition ratio of NAFC3

[0210] Composition by weight (%) Composition by weight (%)

[0211] NBR-26 9.0 Calcium Carbonate 4.8

[0212] NR 6.0 Filled with Kaolin 2.2

[0213] Aramid 1313 fiber 11.0 Material Talc powder 1.8

[0214] Pre-oxidized silk fiber 8.0 Silica 2.2

[0215] Sepiolite fiber 53 Antiaging agent 0.375

[0216] Vulcanizing agent 0.39 Zinc oxide 0.75

[0217] Accelerator 0.15 Stearic acid 0.45

[0218] Main process parameters:

[0219] Plasticizing time: 15min

[0220] Mixing time: 20min

[0221] Vulcanization time: 15min

[0222] Vulcanization temperature: 145±5℃

[0223] Vulcanization pressure: 16±2MPa

[0224] NAFC material transverse tensile strength test results:

[0225] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com