Graphene reinforced rubber sealing material and preparation method thereof

A sealing material and graphene technology, applied in the field of mechanical materials, can solve the problems of reducing the production efficiency of enterprises, harming people and the environment, and accelerating the aging speed, so as to improve the anti-aging and thermal-oxidative performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

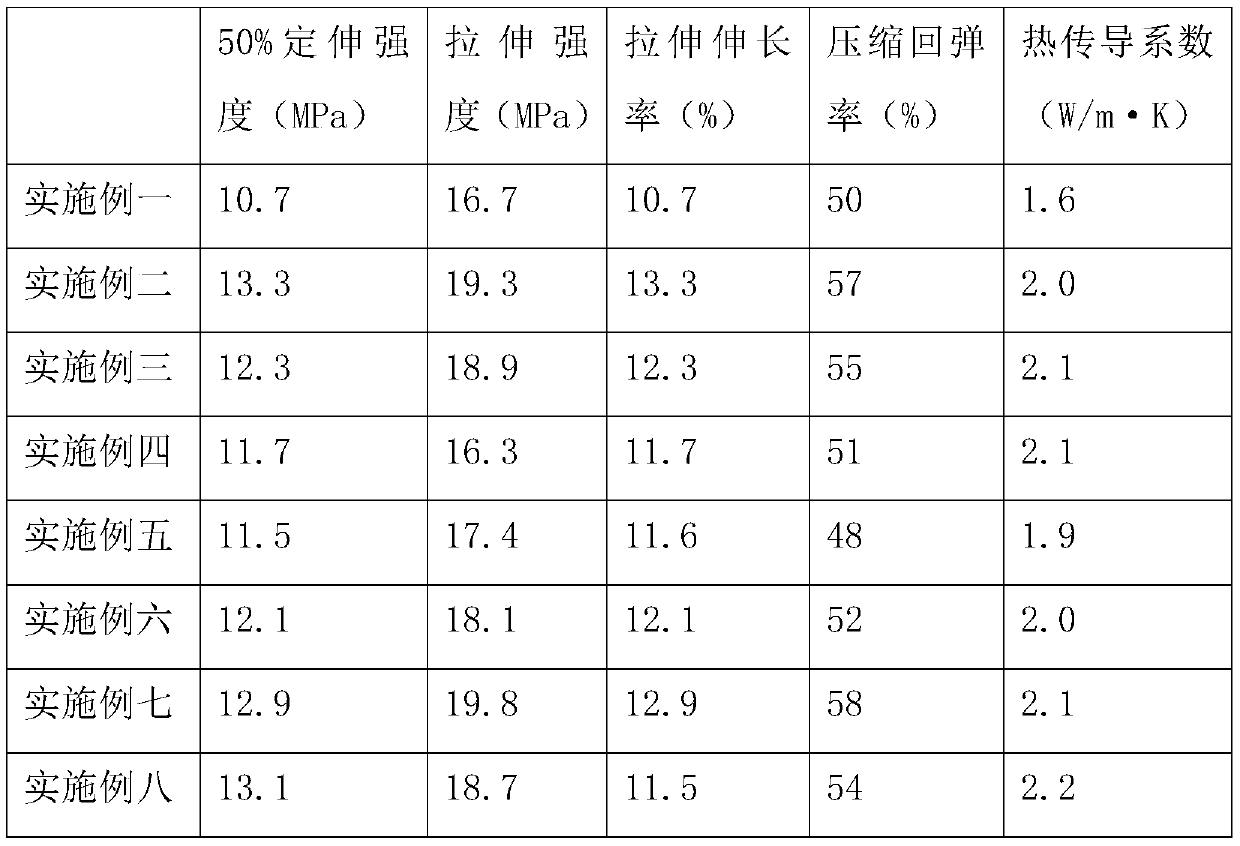

Examples

Embodiment 1

[0020] A rubber sealing material, which is composed of the following components in parts by mass: 100 parts of nitrile rubber, 5 parts of aramid fiber, 3 parts of graphene, 3 parts of zinc oxide, 2 parts of calcium oxide, 0.6 parts of zinc stearate 1 part, accelerator CZ 1 part, accelerator TT 2 parts, antioxidant RD 1 part, antioxidant 4010NA 2 parts, vinyl silicone resin 2 parts, sulfur 2 parts.

[0021] The preparation method of described rubber sealing material, comprises the following steps:

[0022] (1) Mastication: put the nitrile rubber on the open mill for thin pass plastication treatment, and knead at 50-80°C for 3-5 minutes;

[0023] (2) Mixing: the plasticized rubber of step (1) is mixed with zinc oxide, calcium oxide, zinc stearate, accelerator CZ, accelerator TT, anti-aging agent RD, anti-aging agent 4010NA, vinyl silicone resin, Add sulfur to the mixer one by one, and knead at 50-80°C for 6-8 minutes;

[0024] (3) Adding micro-scale fibers: adding aramid fiber...

Embodiment 2

[0028] A rubber sealing material, which is composed of the following components in parts by mass: 100 parts of nitrile rubber, 5 parts of aramid fiber, 5 parts of graphene, 3 parts of zinc oxide, 3 parts of calcium oxide, 0.7 parts of zinc stearate 2 parts, accelerator CZ 2 parts, accelerator TT 2 parts, antioxidant RD 2 parts, antioxidant 4010NA 2 parts, vinyl silicone resin 5 parts, sulfur 2.5 parts.

[0029] The preparation method of described rubber sealing material, comprises the following steps:

[0030] (1) Mastication: put the nitrile rubber on the open mill for thin pass plastication treatment, and knead at 50-80°C for 3-5 minutes;

[0031] (2) Mixing: the plasticized rubber of step (1) is mixed with zinc oxide, calcium oxide, zinc stearate, accelerator CZ, accelerator TT, anti-aging agent RD, anti-aging agent 4010NA, vinyl silicone resin, Add sulfur to the mixer one by one, and knead at 50-80°C for 6-8 minutes;

[0032] (3) Adding micro-scale fibers: adding aramid ...

Embodiment 3

[0036] A rubber sealing material, which is composed of the following components in parts by mass: 100 parts of nitrile rubber, 5 parts of aramid fiber, 7 parts of graphene, 5 parts of zinc oxide, 5 parts of calcium oxide, 0.7 parts of zinc stearate 3 parts, accelerator CZ 3 parts, accelerator TT 3 parts, antioxidant RD 3 parts, antioxidant 4010NA 3 parts, vinyl silicone resin 6 parts, sulfur 4 parts.

[0037] The preparation method of described rubber sealing material, comprises the following steps:

[0038] (1) Mastication: put the nitrile rubber on the open mill for thin pass plastication treatment, and knead at 50-80°C for 3-5 minutes;

[0039] (2) Mixing: the plasticized rubber of step (1) is mixed with zinc oxide, calcium oxide, zinc stearate, accelerator CZ, accelerator TT, anti-aging agent RD, anti-aging agent 4010NA, vinyl silicone resin, Add sulfur to the mixer one by one, and knead at 50-80°C for 6-8 minutes;

[0040] (3) Adding micro-scale fibers: adding aramid fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com