Phase change energy storage porous material and preparation method thereof

A technology of porous materials and phase change energy storage, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem of weak binding force between microcapsules and porous material pore walls, uneven dispersion of microcapsules, and phase change of core materials. Material leakage and other problems, to shorten the production cycle, mature the preparation process, and improve the binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) The polyvinyl alcohol is soaked in water at room temperature to swell, heated and dissolved to make a polyvinyl alcohol aqueous solution with a concentration of 4% by mass; the molecular weight of the polyvinyl alcohol is 25000-135000, and the degree of alcoholysis is 86%-99.9%;

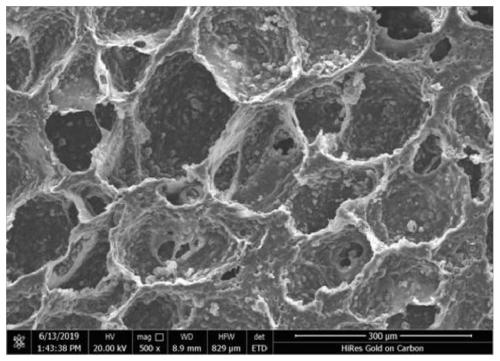

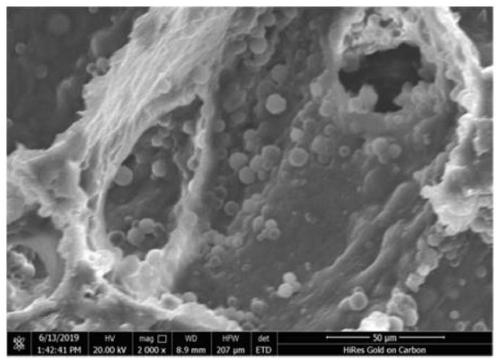

[0032] 2) adding the phase-change microcapsule emulsion into the aqueous solution of polyvinyl alcohol to obtain a blend; the mass ratio of the phase-change microcapsules and polyvinyl alcohol in the blend is 1:1, and the diameter of the phase-change microcapsules is 5 -6μm, the core material of the phase change microcapsule is hexadecane, and the wall material of the phase change microcapsule is polyurea / polyurethane composite shell resin formed by the reaction of polyisocyanate, polyol compound and polyamine compound;

[0033] 3) stirring and foaming the phase change material microcapsules and polyvinyl alcohol blend at a speed of 1500 r / min for 10 minutes at a high speed to prepare a foam...

Embodiment 2

[0036] 1) The polyvinyl alcohol is soaked in water at room temperature to swell, heated and dissolved to make a polyvinyl alcohol aqueous solution with a concentration of 6% by mass; the molecular weight of the polyvinyl alcohol is 25000-135000, and the degree of alcoholysis is 86%-99.9%;

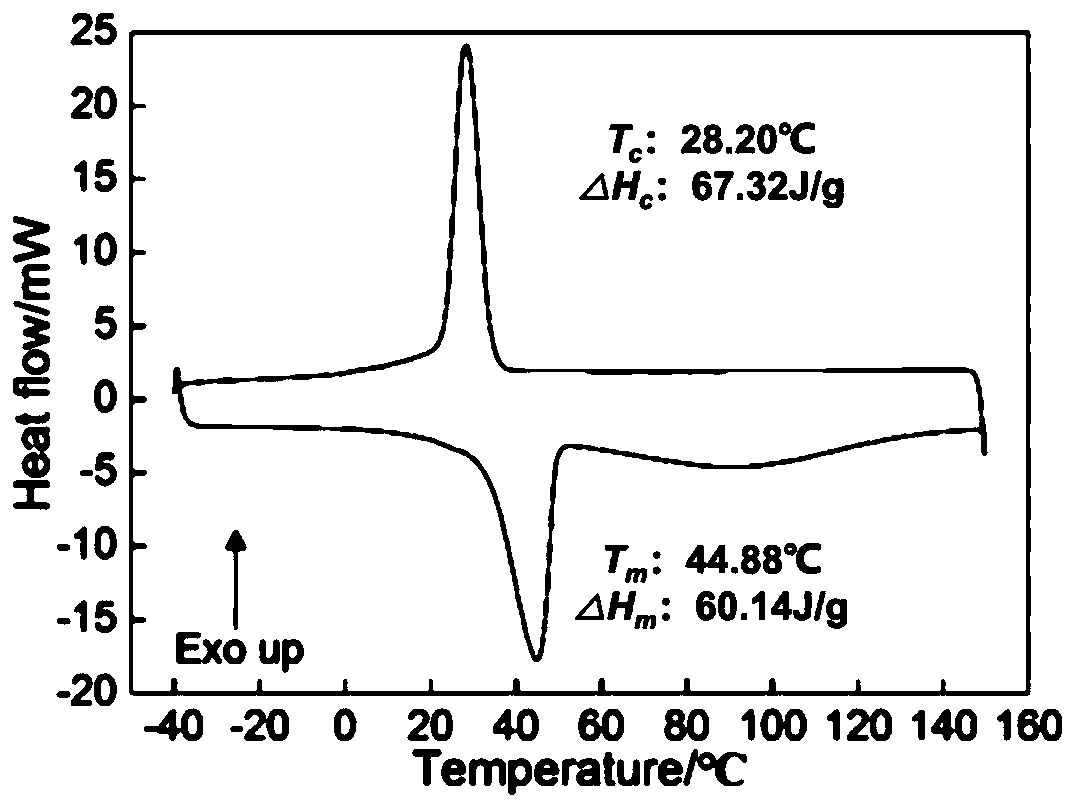

[0037] 2) The phase-change microcapsule emulsion is added in the aqueous solution of polyvinyl alcohol to obtain a blend; the mass ratio of the phase-change microcapsules and polyvinyl alcohol in the blend is 2.5:1, and the diameter of the phase-change microcapsules is 6 -8μm, the core material of the phase change microcapsule is octadecane, and the wall material of the phase change microcapsule is polyurea / polyurethane composite shell resin formed by the reaction of polyisocyanate, polyol compound and polyamine compound;

[0038] 3) Stirring and foaming the phase change material microcapsules and polyvinyl alcohol blend solution at a high speed of 1000r / min for 10 minutes to prepare a foam ...

Embodiment 3

[0041] 1) The polyvinyl alcohol is soaked in water at room temperature to swell, heated and dissolved to make a polyvinyl alcohol aqueous solution with a concentration of 6% by mass; the molecular weight of the polyvinyl alcohol is 25000-135000, and the degree of alcoholysis is 86%-99.9%;

[0042] 2) adding the phase-change microcapsule emulsion into the polyvinyl alcohol aqueous solution to obtain a blend; the mass ratio of the phase-change microcapsules and polyvinyl alcohol in the blend is 3:1, and the diameter of the phase-change microcapsules is 8 -10μm, the core material of the phase change microcapsule is methyl myristate, and the wall material of the phase change microcapsule is polyurea / polyurethane composite shell resin formed by the reaction of polyisocyanate, polyol compound and polyamine compound;

[0043] 3) stirring and foaming the phase change material microcapsules and polyvinyl alcohol blend at a speed of 1500 r / min for 10 minutes at a high speed to prepare a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com