Bio-based wood-plastic composite material and preparation method

A wood-plastic composite material, bio-based technology, used in plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of reducing water-absorbing groups, increasing water-absorbing performance, and reducing mechanical strength, and improving uniform mixing, The effect of improving the binding force and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

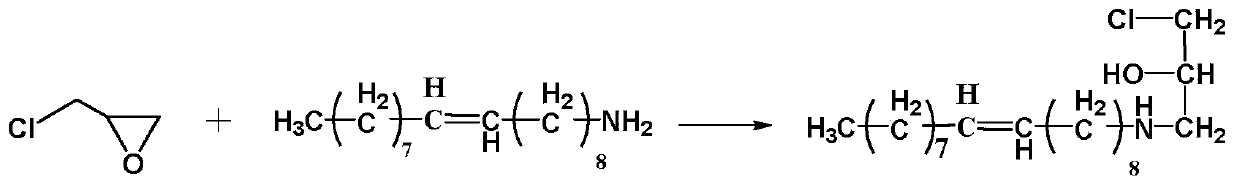

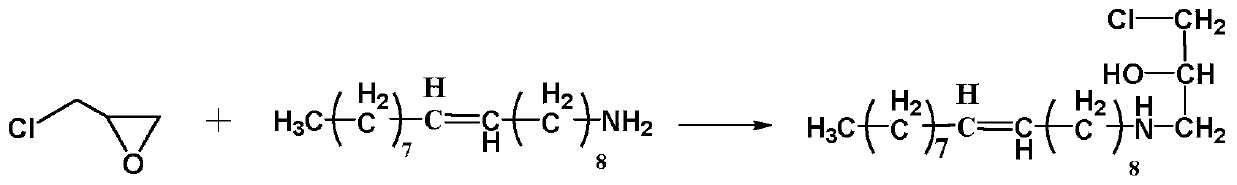

Method used

Image

Examples

Embodiment 1

[0024] The specific preparation process of hydroxylated polyethylene resin is as follows: Add 1kg of low-density polyethylene resin into 10L of chlorobenzene solvent, raise the temperature to 90-100°C and stir until the resin is completely dissolved, then continue to blow nitrogen into the reaction vessel for 20-30min, then Add 0.41kg of initiator to the reaction vessel under the protection of nitrogen, stir and mix evenly, then add 1.23kg of allyl alcohol drop by drop, after the drop is complete, raise the temperature to 120°C for constant temperature reaction for 5-6h, and then filter to remove the solvent , washed and then dried to obtain a hydroxylated polyethylene resin.

[0025] The specific preparation process of polymer modified bio-based wood fiber is as follows:

[0026] Step 1: Clean the wood powder, rice husk and straw, dry and crush them, then add 1 kg of the crushed biomass raw material into 20L of 55% sodium hydroxide solution, stir at room temperature for 60-65...

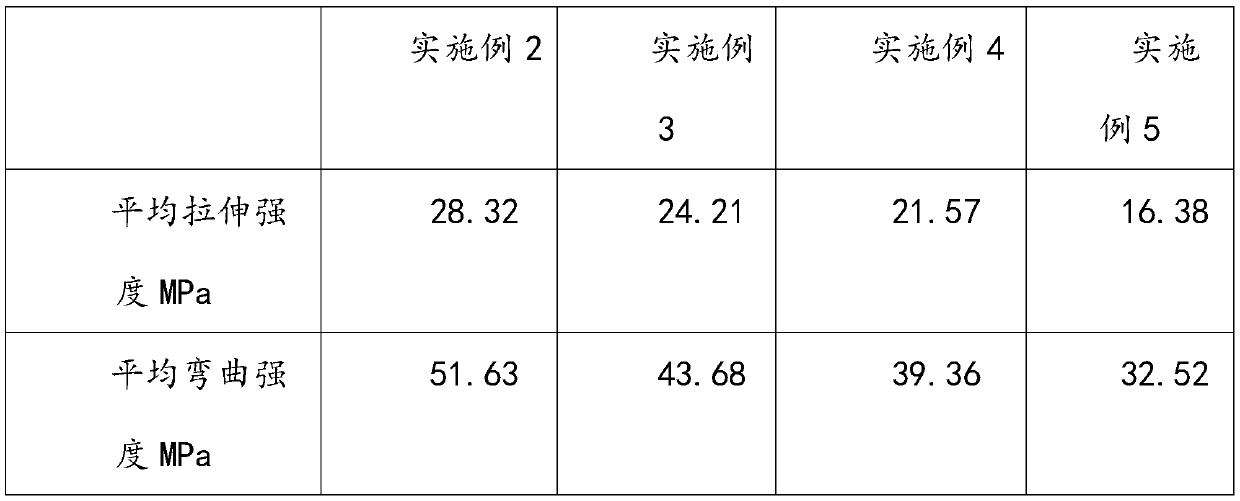

Embodiment 2

[0030] A preparation method of a bio-based wood-plastic composite material, the specific preparation process is as follows:

[0031] The first step, the hydroxylated polyethylene resin prepared in 2.3kg embodiment 1, the polymer modified bio-based wood fiber prepared in 5kg embodiment 1 are added in the high-speed mixer of 100-110 ℃ at 1200-1300r / min Mix for 5-10min at a certain speed, then add 0.5kg talcum powder and 0.3kg active calcium carbonate to it, keep the speed and temperature constant, and stir and mix for 10-15min;

[0032] In the second step, put the material mixed in the high-speed mixer in the first step into the plastic mixer, and add 1.3kg of isophorone diisocyanate to it at the same time, refine at 120-130°C for 20-30min, and then heat up Refining at 150-160°C for 5-10min, then passing the refined material through a twin-screw extruder at 160-180°C, and forming a profile with a certain cross-section through a mold with a specific end face, which is a bio-based...

Embodiment 3

[0034] A preparation method of a bio-based wood-plastic composite material, the specific preparation process is as follows:

[0035] In the first step, 2.3kg of polyethylene resin and 5kg of the polymer modified bio-based wood fiber prepared in Example 1 were added to a high-speed mixer at 100-110°C and mixed for 5-10min at a speed of 1200-1300r / min. Then add 0.5kg talcum powder and 0.3kg active calcium carbonate therein, control the rotating speed and temperature constant, stir and mix for 10-15min;

[0036] In the second step, add the materials that have been completely mixed in the high-speed mixer in the first step to the plastic mixer, and add 1.3kg of toluene diisocyanate to it at the same time, refine at 120-130°C for 20-30min, and then heat up to 150- Refining at 160°C for 5-10 minutes, and then passing the refined material through a twin-screw extruder at 160-180°C, and molding it into a profile with a certain cross-section through a mold with a specific end face, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com