Screwing type steel wire throat hoop

A technology of steel wire and hose clamps, which is applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., which can solve the problems of long connection time and insufficient strength, and achieve short connection time , Improve the binding force and binding effect, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

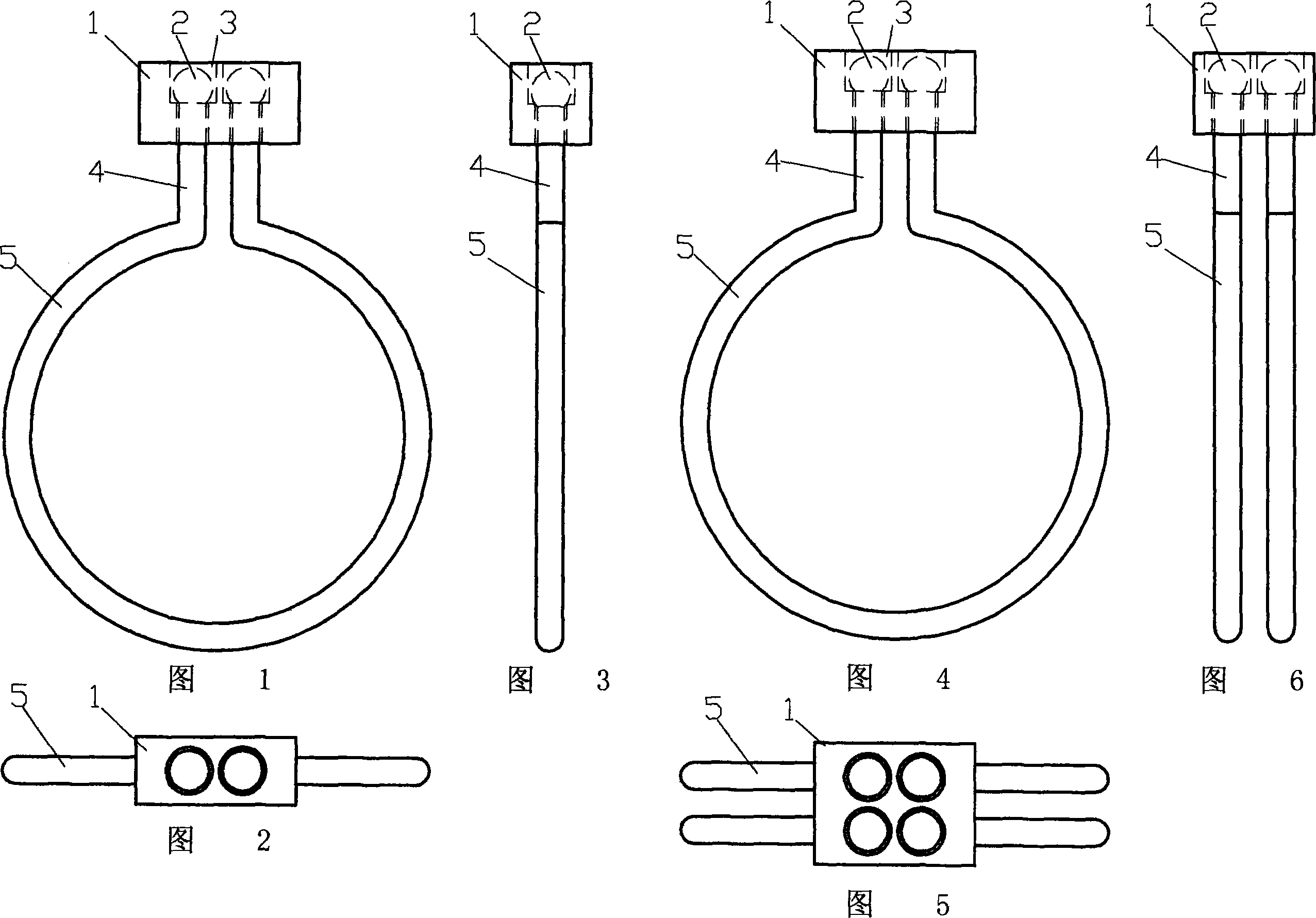

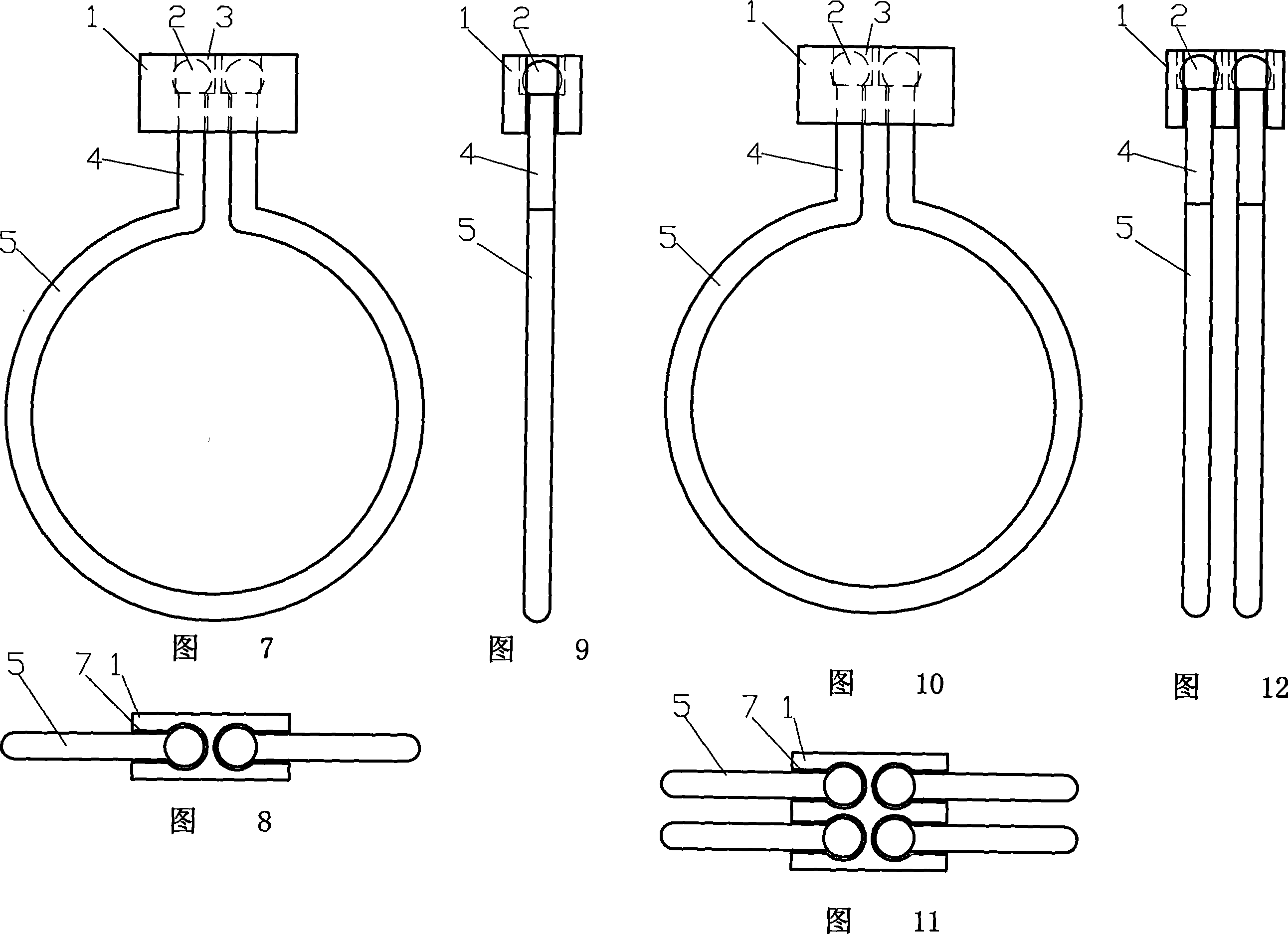

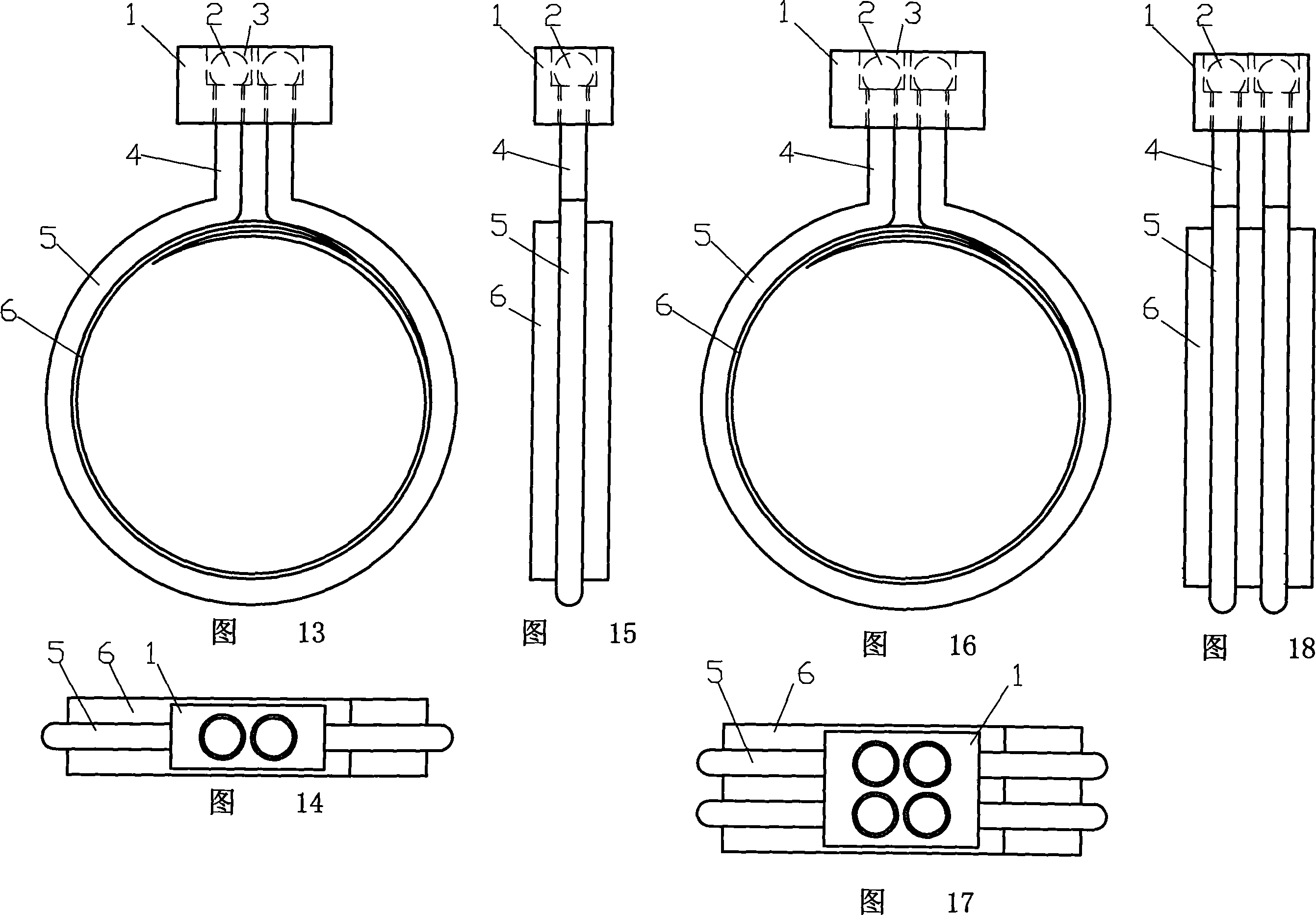

[0036] The present invention includes a screw block 1 and a fixed steel wire, and a pair of through holes 3 are arranged on the screw block 1, as shown in Figs. There are two pairs of through holes 3 on the screw block 1, as shown in Figures 4, 5, 6, 10, 11, 12, 16, 17, 18, 22, 23, and 24. The middle part of the fastening steel wire is an arc segment 5, and the closed two ends are neck straight sections 4, and the fastening steel wire forms a flask shape. The neck straight section 4 of the fixed steel wire passes through the through hole 3 on the screw block, the end of the neck straight section 4 is a spherical head 2, and the size of the spherical head 2 is larger than the size of the through hole.

[0037] The through hole 3 of the screw block 1 has an opening groove 7 on the side wall parallel to the axis, so that the fastening steel wire can be fastened to the screw block 1, as shown in Figures 2, 8, 11, 20, and 23 .

[0038] The through hole 3 of the screw block 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com