Manufacturing method of graphene foam

A technology of graphene foam and a manufacturing method is applied in the field of foam materials to achieve the effects of large compressive modulus, simple and feasible method, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of manufacture method of graphene foam, it is characterized in that, this manufacture method comprises the following steps:

[0030] 1) The aqueous dispersion of graphene oxide is reduced by a hydrothermal method, so that the graphene sheet self-assembles to obtain a graphene wet gel block. Pour the water dispersion liquid into the sealed inner cup of the hydrothermal reaction kettle, add ammonia water to adjust the pH value to form a mixed solution with a pH value of 10, raise the temperature to 200°C and keep it warm, and finally the graphene oxide in the mixed solution is reduced and reunited into graphite olefin wet gel block;

[0031] 2) The graphene wet gel block obtained in step 1) is frozen on a metal tray, and the metal tray has a preset freezing temperature of -20° C. After 1 h of freezing, the graphene wet gel block is completely crystallized into gel crystalline solid;

[0032] 3) The gel crystalline solid obtained in step 2) is subjected to vacuum ...

Embodiment 2

[0035] The manufacturing method of the graphene foam is the same as that of Example 1 except that the preset freezing temperature is -196° C. (liquid nitrogen temperature).

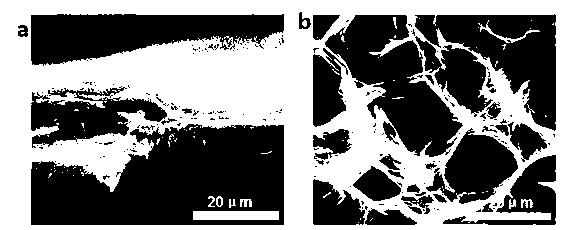

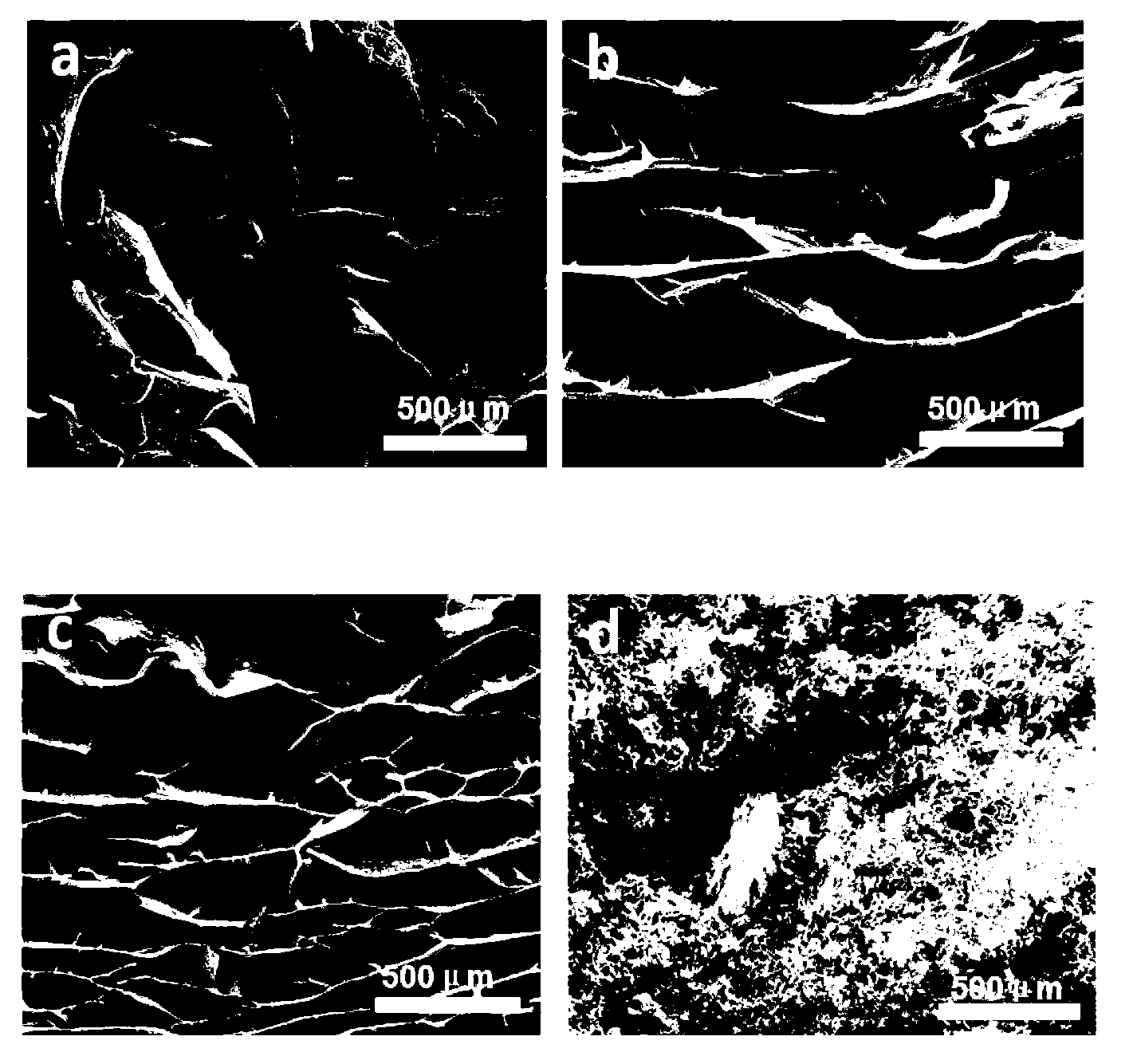

[0036] Effect: The obtained graphene foam has an isotropic diffuse cell pore structure, the interlayer spacing is about 15 microns, and the sheet thickness is less than 50 nanometers. figure 1 d with attached figure 2 as shown in b.

Embodiment 3

[0038] Except that the preset freezing temperature is-10°C in the manufacture method of the graphene foam, all the other are the same as in Example 1.

[0039] Effect: as attached figure 1As shown in a, the obtained graphene foam has a lamellar structure parallel to the freezing direction, and the central axis of the cylinder is wrapped in a cabbage structure (that is, a layered cabbage wrapped structure), but the lamellar arrangement has no obvious directionality. Example 1 is more confusing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com